Doctordarryl

Members-

Posts

160 -

Joined

-

Last visited

About Doctordarryl

- Birthday 03/14/1948

Previous Fields

-

Scale I Build

1/24-1/25

Profile Information

-

Full Name

Darryl W. Peters

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Doctordarryl's Achievements

MCM Friend (4/6)

-

Moon Tank Decal Emblem

Doctordarryl replied to JPolli's topic in Car Aftermarket / Resin / 3D Printed

John, That URL is not up and running yet as I mentioned. Please send me an e-mail as noted three posts above yours. I hope to have the on-line store running by NNL East which is in two months. I hope that helps. Darryl -

Moon Tank Decal Emblem

Doctordarryl replied to JPolli's topic in Car Aftermarket / Resin / 3D Printed

By the way. The tank decals will be labeled "Fuel Tank Labels" with no reference to that object that circles the Earth! Last comment. I print silver so the decals will be silver on black on a white, opaque base. They will be available through Scale Auto Details. I hope to have my website and on-line store up and running before NNL East 2015. The URL will be www.scaleautodetails.com . -

Moon Tank Decal Emblem

Doctordarryl replied to JPolli's topic in Car Aftermarket / Resin / 3D Printed

I am doing decals for Moon tanks. They should be out in a few weeks. I may not list them on eBay since I had a bad experience with Moon Eyes USA who bullied eBay into removing my listing for the Moon Eyes Dragster decals (now referred to as Dean Moon's Dragster in my price list). Feel free to email me at doctordwp@gmail.com for an updated price list and order form. I have not yet finalized the tank decal but the sheet will likely have 4 tank decals. Pricing to come shortly. I am still selling the decal set seen in the January Issue of Model Cars Magazine for Dean Moon's Dragster - you know the yellow iconic dragster from the 60s that I kitbashed in the article. This eBay experience is a classic example of having too many lawyers. Why hassle hobbyists? I doubt that I will ever again buy any products from Moon Eyes USA. -

Just to let all know I am still selling the Moon Eyes dragster decals seen in the January Issue of Model Cars Magazine. Feel free to drop me a note at doctordwp@gmail.com and I will send you an updated price list and an order form. I had them listed on eBay but eBay removed my listing. It seems I was targeted by Moon Eyes USA and they bullied eBay into removing my listing. Do a simple search on eBay for Moon Eyes decals and you get about 145 listings. Why was my listing singled out by Moon Eyes USA??? Why did they choose to harass hobbyists? This was not doing them any harm and was some free advertising for them. I was not competing with them nor was I using their name in a derogatory manner. Dean Moon's dragster (which is how the decals will be labeled from this point forward with no mention of Moon Eyes) is an iconic dragster from the 60s and hobbyists deserve to have decent, high quality decals available to build a replica if they want to. I hopefully will have my website and on-line store up and running soon (www.scaleautodetails.com) and I will have these and other decals for sale on-line. Until then, feel free to email me for Dean Moon's dragster decals. I can send you an invoice through PayPal. I also can accept credit cards through PayPal Now.

-

Here is the finished model with the figure (sort of my trademark). I found a biki-clad woman from S.E. Ltd.

-

Yet another one. This is the V8 Pontiac dragster that Mickey Thompson had at the '61 NHRA Nationals along with his Tempest 4-cylinder dragster. Kit: Revell Attempt 1 Record Car, #7119, and Blueprinter Engine Parts Pack, 1/25th scale Builder: Darryl W. Peters Body: The body panels were cleaned up of very light mold lines. The kit tach mounting hole in the cowl panel was filled with Evergreen Styrene rod. The body was wet sanded with a 4000-grit polishing cloth, washed, and dried in a dehydrator at 110° F overnight. The body panels were sprayed with two wet coats of Tamiya White Fine Surface Primer and dried in a dehydrator overnight. The inside of the body panels were sprayed with Tamiya AS-12 Bare Metal and dried in a dehydrator for 24 hours. The inside of the body panels were masked with 3M Blue Painter’s Tape and the body was then airbrushed with two wet coats of Tamiya TS-19 Metallic Blue, cut 1:1 with Dupli-Color lacquer thinner, using an Aztek A470 airbrush at 35psi with a 1mm (yellow) nozzle. The body panels were dried in a dehydrator for 24 hours. Dzus button fasteners on the body sides and cowl panel were simulated with photoetched large screw heads from Model Car Garage. The custom decals from Scale Auto Details were cut out and placed into warm water before applying them to the body panels. They were positioned and blotted with a piece of clean dry chamois and the body panels were then placed back into the dehydrator for 24 hours. The body panels were gently washed with warm water and dish soap to remove any decal glue. They were rinsed with warm water and placed back into the dehydrator for several hours to dry. They were then airbrushed with two wet coats of Testor’s Wet Look Gloss Clear, cut 1:1 with Dupli-Color lacquer thinner. Before the second clear coat flashed off, the paint jar was filled with straight Dupli-Color lacquer thinner and a wet coat of thinner was airbrushed over the body panels. They were placed back into the dehydrator and allowed to dry for 48 hours. The body panels were lightly wet sanded with an 8000-grit polishing cloth followed by rubbing out with Novus Plastic Polish #2. The panels were polished with Turtle Wax Clear Coat and given a final clean with Novus Plastic Polish # 1. The body panels were assembled to the chassis using super glue. The fire wall was drilled for a hydraulic throttle line and tachometer cable, sprayed with Tamiya AS-12 Bare Metal, and glued to the chassis. Frame: The front axel, radius rod, tie rod, and steering link were stripped of chrome using Purple Power cleaner, rinsed, and dried. The front axel parts were assembled using IPS Weld-On #4 and redone by airbrushing Alclad II Chrome over Testor’s Gloss Black. The rear axel was assembled with Weld On #4 and squeezed to fill the join. Once dry, the rear end seams were sanded smooth and the rear end was sprayed with Tamiya TS-17 Gloss Aluminum followed by Testor’s Dull Coat. The rear end cover was sprayed with Model Master Stainless Steel Metalizer. The frame was assembled using IPS Weld On #4 while mounted on a Micro Mark steel plate with magnets holding the chassis sides to square up the chassis. Because different slicks and wheels were used, the rear axel had to be extended 1/8th inch on each side so the slicks would extend far enough from the body. After the frame was assembled and dried, it was sprayed with two wet coats of Tamiya White Fine Surface Primer and then dried in a dehydrator for 24 hours. It was then airbrushed with two wet coats of Tamiya TS-19 Metallic Blue and placed back into the dehydrator overnight. The kit’s front torsion bars were replaced with fine, uninsulated wire. The throttle pedal and brake handle were sprayed with Tamiya TS-30 Silver Leaf. A gauge face was added to the gauge pod on the cockpit cross member. A 60s style tach from Detail Master was added under the rear of the cowl panel with a mount made from printer’s aluminum sheet. The seat was airbrushed with Tamiya AS-12 Bare Metal. After drying, the back was masked with 3M Blue Painter’s tape and the seat cushion was sprayed with Tamiya TS-63 NATO Black. Seat belt decals from Colorado decals were added to the seat with Simpson logos from Scale Auto Details. The steering wheel was airbrushed with Alclad II Chrome over Testor’s Gloss Black and the rim was painted with Tamiya NATO Black. The kit’s front wheels were stripped of chrome. The 5-window rear Halibrand wheels were from an AMT parts pack. They were stripped of chrome and all wheel stud holes were drilled out. Each rear wheel consists of 13 individual pieces. The wheels were sprayed with Model Master Magnesium Metalizer followed by Testor’s Dull Coat. Valve stems were made from fine black insulated wire. Wheel studs were made from 0.020 inch Evergreen Styrene rod. Lug nuts were made from drilled 0.040 inch hexagonal Plastruct Styrene rod. The studs and lug nuts were assembled with IPS Weld-On #4 and painted with Model Master Steel Metalizer. The axel stub was simulated with Tamiya Flat Black. The slicks and front tires were from AMT parts packs. A machined aluminum Moon Tank from Detail Master was drilled for fuel lines and mounted to the chassis using their photoetched hold downs. The remote oil filter was plumbed to the engine with black insulated wire. Fittings on the oil and fuel lines were made using drilled Plastruct 0.040 inch hexagonal rod. Engine: The Blueprinter Pontiac V8 was assembled using IPS Weld-On #4. The block and Attempt One kit heads were sprayed with two wet coats of Tamiya White Fine Surface Primer. After drying for 24 hours, the block and heads were sprayed with Tamiya TS-23 Light Blue. The oil pan and timing cover were sprayed with Tamiya TS-30 Silver Leaf. The freeze plugs were painted with Model Master Brass Metalizer. All chrome engine parts were stripped of kit chrome using Purple Power cleaner. The GMC blower, injector, and scoop from a Revell 41 Willys kit were used. The blower was assembled and the snout was shortened and drilled to accept a pulley from an AMT Hemisphere kit. The idler and crank pulleys were also from a Hemisphere kit. The blower and scoop were sprayed with Tamiya TS-19 Gloss Aluminum followed by Testor’s Dull Cote. Machined aluminum breather caps from Detail Master were added to the valve covers. The blower belt was from a Hemisphere kit and part number decals were from Scale Auto Details. The water filler neck on the heads was scratch built from Detail Master hard line with a cap cut from 0.060 inch Evergreen styrene rod. The Scale Auto Details Hilborn fuel pump was sprayed with Tamiya TS-29 Semi-Gloss Black and drilled to accept fuel lines. The fuel injector was sprayed with Model Master Aluminum Plate and drilled to accept fuel lines. The fuel block at the front of the injector was also drilled for fuel lines. The exhaust header flanges were thinned, the header tubes were shortened, and their ends drilled out. The valve covers and assembled exhaust headers were airbrushed with Alclad II Chrome over Model Master Classic Black. The magneto was scratch built from telescoping pieces of K&S aluminum tubing which were assembled with super glue and polished with a piece of 8000-grit polishing cloth. A black magneto cap from Morgan Automotive Details was added with a magneto top decal from Scale Auto Details. The bellhousing and transmission were sprayed with Model Master Stainless Steel Metallizer. A hydraulic throttle actuator was scratch built from thin wall 1mm stainless steel tubing, drilled 0.040 inch hexagonal Plastruct Styrene rod, and a strip of thin metal with black insulated wire as the hydraulic line. A photoetched throttle linkage from MAS was attached to the injector rod and linked to the hydraulic throttle with thin wire. The shop rag stuffed into the injector scoop was made from a piece of cotton Tee shirt painted with Tamiya Flat Red. Figure: The figure was a modified Tamiya Rally mechanic that was painted with various Testor’s and Model Master colors followed by Testor’s Dull Cote.

-

Here's another one. This was also on my build list for quite some time. it: Revell Attempt 1 Record Car, #7119, 1/25th scale Builder: Darryl W. Peters Body: The body panels were cleaned up of very light mold lines. The kit tach mounting hole in the cowl panel was filled with Evergreen Styrene rod. The body was wet sanded with a 4000-grit polishing cloth, washed, and dried in a dehydrator at 110° F overnight. The body panels were sprayed with two wet coats of Tamiya White Fine Surface Primer and dried in a dehydrator overnight. The inside of the body panels were sprayed with Tamiya AS-12 Bare Metal and dried in a dehydrator for 24 hours. The inside of the body panels were masked with 3M Blue Painter’s Tape and the body was then airbrushed with two wet coats of Tamiya TS-19 Metallic Blue, cut 1:1 with Dupli-Color lacquer thinner, using an Aztek A470 airbrush at 35psi with a 1mm (yellow) nozzle. The body panels were dried in a dehydrator for 24 hours. Dzus button fasteners on the body sides and cowl panel were simulated with photoetched large screw heads from Model Car Garage. The custom decals from Scale Auto Details were cut out and placed into warm water before applying them to the body panels. They were positioned and blotted with a piece of clean dry chamois and the body panels were then placed back into the dehydrator for 24 hours. The body panels were gently washed with warm water and dish soap to remove any decal glue. They were rinsed with warm water and placed back into the dehydrator for several hours to dry. They were then airbrushed with two wet coats of Testor’s Wet Look Gloss Clear, cut 1:1 with Dupli-Color lacquer thinner. Before the second clear coat flashed off, the paint jar was filled with straight Dupli-Color lacquer thinner and a wet coat of thinner was airbrushed over the body panels. They were placed back into the dehydrator and allowed to dry for 48 hours. The body panels were lightly wet sanded with an 8000-grit polishing cloth followed by rubbing out with Novus Plastic Polish #2. The panels were polished with Turtle Wax Clear Coat and given a final clean with Novus Plastic Polish # 1. The body panels were assembled to the chassis using super glue. The 60s style tach was a machined aluminum item from Detail Master. The tach mount was made from printer’s aluminum sheet and detailed with a tach hold down strap, a hex nut made from drilled 0.040 inch hexagonal Plastruct Styrene rod, and screw heads from Model Car Garage. The fire wall was drilled for a hydraulic throttle line and sprayed with Tamiya AS-12 Bare Metal and glued to the chassis. Frame: The front axel, radius rod, tie rod, and steering link were stripped of chrome using Purple Power cleaner, rinsed, and dried. The front axel parts were assembled using IPS Weld-On #4 and redone by airbrushing Alclad II Chrome over Testor’s Gloss Black. The rear axel was assembled with Weld On #4 and squeezed to fill the join. Once dry, the rear end seams were sanded smooth and the rear end was sprayed with Tamiya TS-17 Gloss Aluminum followed by Testor’s Dull Coat. The rear end cover was sprayed with Model Master Stainless Steel Metallizer. The frame was assembled using IPS Weld On #4 while mounted on a Micro Mark steel plate with magnets holding the chassis sides to square up the chassis. Because different slicks and wheels were used, the rear axel had to be extended 1/8th inch on each side so the slicks would extend far enough from the body. After the frame was assembled and dried, it was sprayed with two wet coats of Tamiya White Fine Surface Primer and then dried in a dehydrator for 24 hours. It was then airbrushed with two wet coats of Tamiya TS-19 Metallic Blue and placed back into the dehydrator overnight. The kit’s front torsion bars were replaced with fine, uninsulated wire. The throttle pedal and brake handle were sprayed with Tamiya TS-30 Silver Leaf. A gauge face was added to the gauge pod on the cockpit cross member. The seat was airbrushed with Tamiya TS-19 Metallic Blue. After drying, the back was masked with 3M Blue Painter’s tape and the seat cushion was sprayed with Tamiya TS-63 NATO Black. The seat belt adjusters and buckles were painted with Tamiya Chrome. The steering wheel was airbrushed with Alclad II Chrome over Testor’s Gloss Black and the rim was painted with Tamiya NATO Black. The kit’s front wheels were stripped of chrome. The 5-window rear Halibrand wheels were from a Polar Lights funny car kit. They were stripped of chrome and all wheel lug holes were drilled out. Each rear wheel consists of 13 individual pieces. The wheels were sprayed with Model Master Magnesium Metallizer followed by Testor’s Dull Coat. Valve stems were made from fine black insulated wire. Wheel studs were made from 0.020 inch Evergreen Styrene rod. Lug nuts were made from drilled 0.040 inch hexagonal Plastruct Styrene rod. The studs and lug nuts were assembled with IPS Weld-On #4 and painted with Model Master Steel Metallizer. The axel stub was simulated with Tamiya Flat Black. The white wall slicks were from an AMT parts pack (AMT-PP001). A machined aluminum Moon Tank from Arrowhead Accessories was drilled for fuel lines and mounted to the chassis using their resin tank hold downs that were sprayed with Tamiya TS-17 Gloss Aluminum. A photoetched chassis loom from Arrowhead Accessories was used to route the intake and return fuel lines from the Moon tank to the engine. Machined aluminum fittings from Detail Master were used on the main fuel lines. Engine: The kit’s slant 4 Pontiac engine (1/2 of a 326 V-8) was assembled using IPS Weld-On #4. The assembled block and head were sprayed with two wet coats of Tamiya White Fine Surface Primer. After drying for 24 hours, the block and head were sprayed with Tamiya TS-23 Light Blue. The oil pan was sprayed with Tamiya TS-30 Silver Leaf. The freeze plugs were painted with Model Master Brass Metallizer. All chrome engine parts were stripped of kit chrome using Purple Power cleaner. The 4-71 GMC blower was assembled and the snout was shortened and drilled to accept a machined aluminum pulley from MAS. The timing chain cover was drilled to accept MAS blower drive and idler pulleys. The blower, timing chain cover, valley cover, valve cover, breathers, and lower block cover were airbrushed with Alclad II Chrome over Testor’s Gloss Black. A machined aluminum breather from Detail Master was added to the valve cover as a filler cap and painted with Tamiya Flat Black with a thin strip of yellow decal film to represent a label. The blower belt was from MAS and part number decals were from SAD. The water filler neck on the head was scratch built from Evergreen Styrene tubing with a turned aluminum cap and photoetched flange from Detail Master with bolt heads made from 0.030 inch hexagonal Plastruct rod. The fuel pump was sprayed with Model Master Stainless Steel Metallizer and drilled to accept fuel lines. The fuel injector was sprayed with Model Master Aluminum Plate and drilled to accept fuel lines. The fuel block at the rear of the injector was also drilled for fuel lines. The exhaust header flange was thinned and the header pipes were shortened and their ends drilled out. The assembled exhaust header was sprayed with Tamiya TS-30 Silver Leaf. The magneto was scratch built from telescoping pieces of K&S aluminum tubing which were assembled with super glue and polished with a piece of 8000-grit polishing cloth. A tan colored cap from a Morgan Automotive Details magneto had 4 wires removed and a 4-cylinder magneto top decal from SAD. The magneto body was drilled for a tach drive cable. The bellhousing and transmission were sprayed with Model Master Stainless Steel Metallizer. A hydraulic throttle actuator was scratch built from thin wall 1mm stainless steel tubing, drilled 0.040 inch hexagonal Plastruct Styrene rod, and a strip of thin metal with black insulated wire as the hydraulic line. A photoetched throttle linkage from MAS was attached to the injector rod and linked to the hydraulic throttle with thin wire. The shop rag stuffed into the scoop was made from a piece of cotton Tee shirt painted with Tamiya Flat Red. Figure: The Mickey Thompson figure was from the Revell Challenger One kit. The base was removed, the feet drilled for wire pins, and it was sprayed with Testor’s Dull Coat.

-

Don Garlits' Record Setting Swamp Rat VIb

Doctordarryl replied to Doctordarryl's topic in Model Cars

Here is another build I wanted to do for some time. This is the historic AA/FD that Mr. Garlits drove to a world record of 203.1mph on 8/1/64 at Island Dragway in Great Meadows, NJ. Kit: AMT Hemisphere Dragster, kit# 38483, 1/25th scale Builder: Darryl W. Peters Decals: Scale Auto Details SAD0111 Incentive for Building: This is the car that Mr. Garlits drove to an official speed of 201.34mph at Island Dragway in Great Meadows, NJ on August 1, 1964 Body: The body panels were cleaned up of very light mold lines. The molded on windshield was removed with an abrasive wheel in a Dremel tool. Panel lines were scribed with a dental pick. A slot was cut into the right side of the cowl panel for the throttle linkage. Holes were drilled for the front hairpins and the steering linkage. The body was wet sanded with a 4000-grit polishing cloth, washed, and dried in a dehydrator at 110° F overnight. The body panels were sprayed with two wet coats of Tamiya White Fine Surface Primer and dried in a dehydrator overnight. The body panels were airbrushed with two wet coats of Tamiya TS-14 Black, cut 1:1 with Dupli-Color lacquer thinner, using an Aztek A470 airbrush at 35psi with a 1mm (yellow) nozzle. They were dried in a dehydrator for 24 hours. The decals from Scale Auto Details were cut out and placed into warm water before applying them to the body panels. They were positioned and blotted with a piece of clean dry chamois and the body panels were placed back into the dehydrator for 24 hours. The body panels were gently washed with warm water and dish soap to remove any decal glue. They were rinsed with warm water and placed back into the dehydrator for several hours to dry. They were then airbrushed with two wet coats of Testor’s Wet Look Gloss Clear, cut 1:1 with Dupli-Color lacquer thinner. Before the second clear coat flashed off, the paint jar was filled with straight Dupli-Color lacquer thinner and a wet coat of thinner was airbrushed over the body panels. They were placed back into the dehydrator and allowed to dry for 48 hours. The body panels were lightly wet sanded with an 8000-grit polishing cloth followed by rubbing out with Novus Plastic Polish #2. The panels were polished with Turtle Wax Clear Coat and given a final clean with Novus Plastic Polish # 1. Dzus button fasteners on the body sides and cowl panel were simulated with photoetched large screw heads from Model Car Garage attached with Pledge. A cut down windscreen from a Revell Kurtis Kraft midget was dipped in Pledge and attached to the cowl using Elmer’s White Glue. Small photoetched screw heads from Model Car Garage were attached to the cowl with Pledge simulating screws that attached the windscreen to the body. The body panels were assembled to the chassis using super glue. The plastic rod portions of the steering arm were replaced with 1mm OD stainless steel tubing. The throttle linkage was made from strips of Printer’s aluminum sheet and fine wire with nuts made from drilled Plastruct 0.03 inch hexagonal styrene rod. A rip cord was added to the parachute along with a “Remove Before Flight” warning pendant from an old IPMS Nationals decal sheet. Frame: The front axel, hairpins, tie rod, and steering linkage were stripped of kit chrome using Purple Power cleaner, rinsed, and dried. The front axel parts were assembled using IPS Weld-On #4 and airbrushed with Alclad II Chrome over Model Master Classic Black. The rear axel was assembled with Weld On #4 and sprayed with Tamiya TS-14 Black. The frame was assembled using IPS Weld On #4 while mounted on a Micro Mark steel plate with magnets holding the chassis sides to square up the chassis. After the frame was assembled and dried, it was sprayed with two wet coats of Tamiya White Fine Surface Primer and then dried in a dehydrator for 24 hours. It was then airbrushed with two wet coats of Tamiya TS-14 Black and placed back into the dehydrator overnight. The throttle pedal, fuel tank, and brake handle were sprayed with Tamiya TS-30 Silver Leaf. A photoetched butterfly steering wheel from a Model Car Garage set was added to the steering shaft. The seat cushion was sprayed with Tamiya TS-29 Semi-Gloss Black. Seat belt decals from Colorado Decals were added to the seat along with Simpson logo decals from Scale Auto Details. The kit rear wheels were stripped of chrome and all wheel lug holes were drilled out. Each rear wheel consists of 13 individual pieces. The wheels were sprayed with Model Master Magnesium Metalizer followed by Testor’s Dull Coat. Valve stems were made from fine black insulated wire. Wheel studs were made from 0.020 inch Evergreen styrene rod. Lug nuts were made from drilled 0.040 inch hexagonal Plastruct styrene rod. The studs and lug nuts were assembled with IPS Weld-On #4 and painted with Model Master Steel Metalizer. The axel stub was simulated with a disk punched from Printer’s aluminum sheet. The M&H pie crust slicks were from an AMT parts pack (AMT-PP001). The front wire wheels were photoetched items from Machined Aluminum Specialties. The front tires were from the parts box. The front “wing” was made from Printer’s aluminum sheet. Engine: The kit’s engine was assembled using IPS Weld-On #4. The block and heads were airbrushed with Tamiya TS-14 Black. The oil pan was sprayed with Tamiya TS-30 Silver Leaf. Water necks were made for the heads from Detail Master #3 hard line with caps made from 0.06 inch Evergreen styrene rod. The engine chrome parts were stripped and redone with Alclad II Chrome over Model Master Classic Black or Model Master Metalizers where appropriate. The blower was assembled with IPS Weld-On #4 and sprayed with Tamiya TS-17 Gloss Aluminum followed by a coat of Testor’s Dull Cote. The kit’s blower pulleys and belt were used with part number decals from Scale Auto details. The cap on the kit’s Schiefer magneto was removed and replaced with a resin cap from Replicas and Miniatures Company of Maryland with cap clips made from printer’s aluminum sheet. A photoetched hold down clamp from a Detail Master distributor set was added to the base of the magneto with a nut made from 0.030 inch hexagonal Plastruct styrene rod. Spark plug wires and boots were added. A fuel block was added to the Enderle Bug Catcher injector. A fuel line was run from the Enderle fuel pump to the fuel block. Fuel lines were also run from the fuel pump to the fuel tank. A gauge face decal was added to the gauge on the back of the Bug Catcher injector. The zoomie headers were modified items from a Monogram Slingster kit that were sprayed with Tamiya TS-30 Silver Leaf. -

Latest Build: Don Garlits' Swamp Rat 13 AA/FD in 1/25th Scale

Doctordarryl replied to Doctordarryl's topic in Model Cars

The book by Mr. Garlits (Big Daddy, A Career Pictorial, volume 1) has specs on all his front engined SR dragsters and SR12C as well as SR13 had 250 inch wheel bases which scales to 10 inches in 1/25th scale so the kit is actually a little short but we aren't tank or airplane guys who could nitpick the most trivial things with a kit or model. We don't whip out a ruler when looking at someone's model. The kit wheel base scales out to 215 inches but what's 35 inches among friends? Does it look right - Yea, that's what I strive for. I don't have wheel base data on the TV Tommy FE dragster but I am thinking of building that next (or SR12C). I can maybe get data from Mr. Ivo by contacting him through his website. -

Just finished my latest model build, Don Garlits' Swamp Rat 13, the dragster that nearly killed him at Lions Dragway in early 1970 (March?). This model has been on my build list for quite some time. The re-release of the MPC Young American got me started. Little did I know that AMT/R2 would re-release the MPC WYNNSCHARGER which is a better starting point for SR13. The MPC kit is of SR12C which is very easily converted into SR13. SR13 was built in early 1969 because SR12C failed to qualify at the Winternationals. SR13 was the last front engined dragster that Mr. Garlits drove in competition. SR15 was also a front engined dragster but was built as a back stop to SR14, which was a rear engined dragster. SR15 was the fall back if SR 14 failed to be competitive. History says otherwise. SR14 was wildly successful and SR15 was sold to Good Year for display. I remember seeing a montage of large format pictures on the front wall in the lobby at Crower (in Chula Vista, CA) of Mr. Garlits' accident at Lions in SR13. The pictures were graphic and chilling. It was a miracle that he survived. That was Feb. of 1971 and I met Mr. Garlits and sold him the paint used for the front body panels on SR14 that were installed just before he won the '71 Winternationals. That is a story in itself. Here is a brief write up of the build (I do this so I don't forget the little tricks I developed during the build - a lesson learned from building plastic models for 60 years). Don Garlits’ Swamp Rat 13 (1969) Kit: MPC Young American AA/Fuel Dragster, kit #MPC760, 1/25th scale Builder: Darryl W. Peters Decal Set: Scale Auto Details #SAD 0113 Body: I modified the body rear side panels by cutting off the bottom center sections. I made a new bottom panel from 0.015 inch thick styrene sheet. I extended the rear sections of the cowl panel with 0.015 inch thick styrene sheet to match up with the rear side panels. I cut a slot into the right front of the cowl panel for the throttle linkage. I made the forward side panels aside of the engine from 0.015 inch thick styrene sheet. I wet sanded all body panels with a 2000-grit polishing cloth before spraying them with two wet coats of Tamiya White Fine Surface Primer then dried in a dehydrator overnight. I airbrushed them with two wet coats of Tamiya TS-14 Black, cut 1:1 with Dupli-Color lacquer thinner, using an Aztek A470 airbrush. I placed the panels into a dehydrator to dry overnight. I carefully cut out the decals from Scale Auto Details and placed them into warm water before applying them. I positioned the decals and blotted them with a piece of clean chamois. After the decals dried overnight, I airbrushed the body panels with two wet coats of Tamiya TS-13 Clear followed by a wet coat of straight lacquer thinner before placing them back into a dehydrator. I wet sanded the painted body panels with an 8000-grit polishing cloth before rubbing them out with Meguiar’s Scratch X and waxing them with Turtle Wax Clear Coat. I made a wind deflector from a piece of 0.005 inch thick metal which I cut to size and bent to shape. I attached it to the cowl panel using Elmer’s White Glue. I applied photoetched screw heads from Model Car Garage to the body panels using Future as an adhesive. I glued all the body panels to the completed chassis using super glue. Chassis: I removed the mold lines on the frame rails by scraping them with a #11 Exacto blade. I added mounts for the fuel tank from strips of 0.01 inch thick styrene. I sprayed the frame with two wet coats of Tamiya White Fine Surface Primer before airbrushing it with two wet coats of Tamiya TS-14 Black. I applied the decals to the panels behind the seat. I drilled holes for an intake line on the bottom and a return line on the top in an Arrowhead Aluminum Accessories machined aluminum Moon tank. I assembled the tank and resin mounts with super glue. I sprayed the assembled tank with Tamiya TS-29 Semi Gloss Black. I used 0.025 inch fuel line and fittings from Pro-Tech for the return line. I used Detail Master #3 hard line for the fuel pump intake line, I glued the vinyl seat to the chassis using Elmer’s White Glue. I painted the snaps on the top of the seat with Tamiya Chrome acrylic. I added seat belt decals from Colorado Decals along with Simpson logos from Scale Auto Details. I made roll bar padding from black Electrician’s tape. I stripped the chrome from the front axel, radius rods, and tie rod using Purple Power cleaner. I assembled the front axel and then airbrushed it and the radius rods with Alclad II Chrome over Testor’s Classic Black. I made a ballast weight for the front axel from Evergreen styrene tube and disks of 0.02 inch thick styrene sheet and painted it with Model Master Steel Metalizer. I carved a master out of 0.04 inch thick styrene sheet for the hanger which suspends the ballast weight below the axel. I made resin copies of the hanger, painted them with Model Master Steel Metalizer, cut the end that mounts to the axel, attached the weight, and attached the hangers to the axel. I used photoetched and turned aluminum front wheels from Machined Aluminum Specialties with motorcycle tires from the parts box. I made the disk on the front wheel by punching it out of 0.005 inch thick metal foil and then punching out the center using different size cork borers. I attached it to the outside of the right wheel with Floquil Flat clear. I narrowed the front wing from an AMT Wynn’s Jammer kit and airbrushed it with Alclad II Aluminum. I applied the Wynn’s decal and airbrushed a wet coat of Tamiya TS-13 over the wing and connecting rod mounts. I replaced the plastic steering arm parts with polished sections of 1mm OD stainless steel tubing. I carved steering arm guides/mounts from 0.02 inch thick styrene sheet, painted them with Model Master Steel Metalizer, and mounted them to the top frame rail. The kit’s rear wheels were stripped of chrome and drilled for a valve stem and wheel lugs. I sprayed the rear wheels with Model Master Magnesium Metalizer followed by Testor’s Dull Coat. I made wheel lugs using 6mm lengths of Evergreen 0.02 inch styrene rod. I made lug nuts from 0.5mm thick slices of drilled 0.04 inch Plastruct hexagonal styrene rod. I assembled the lugs and nuts with IPS Weld-On #4 and painted them with Model Master Steel Metalizer. I punched disks from printer’s aluminum sheet to represent the rear axel ends. I used the kit slicks and sanded the contact area with a coarse sanding stick. I sprayed the assembled rear end with Tamiya TS-14 Black. I sprayed the fire wall, brake handle, clutch pedal, and gas pedal with Tamiya TS-30 Silver Leaf. I made a parachute release cable using fine un-insulated wire with a loop on the end by the seat to represent a hand pull. Engine: I assembled the kit’s engine block and heads with IPS Weld-On #4 and airbrushed them with Tamiya TS-14 Black. I drilled the rear of the heads for water necks and made them from solder with caps made from 1mm thick slices of 0.06 inch Evergreen styrene rod painted Testor’s Chrome Silver. I added plugs on the front of the heads which I made from small disks of printer’s aluminum sheet. I used valve covers from an AMT TV Tommy Ivo dragster kit with the Young American breather caps. I stripped the chrome, drilled them for spark plug wires, and airbrushed them with Alclad II Chrome over Testor’s Classic Black. I applied the Dodge decals to the valve covers. I scratch built a Vertex magneto from telescoping sections of K&S aluminum tubing. I used a black prewired cap from Morgan Automotive Detail with a applied the firing order decal. I added an oil filter mount to the timing cover to mount dual filters and sprayed the timing cover, bell housing, and oil pan with Tamiya TS-30 Silver Leaf. Two resin oil filters with Fram decals from Scale Auto Details were added to the timing cover. I used a blower from a Revell ’41 Willys kit with a Crower bug catcher injector from an AMT ’69 Cougar funny car kit. I stripped the chrome from the blower and injector. I sprayed the blower with Model Master Aluminum followed by Testor’s Dull Cote. I drilled the injector base for fuel lines. I airbrushed the injector scoop with Alclad Aluminum. I applied the Cragar decals to the sides of the bug catcher scoop. I made a fuel distribution block from square Evergreen styrene rod. I made a fuel bypass from square styrene rod. I plumbed the injector with black insulated wire and Pro-Tech 0.025 fuel line with fittings. I added a gauge and panel from Detail Master to the rear left side of the blower. I used Arrowhead Aluminum Accessories blower pulleys and blower belt with part number decals from Scale Auto Details. I modified the kit’s zoomie headers by drilling the ends, adding a support strap made from styrene strip, and a support rod made from styrene rod. I then sprayed them with Tamiya TS-9 Matt Black. Figure: I modified a Tamiya rally mechanic figure by using different arms and positioned the left arm so he was grabbing the roll bar. I assembled it using IPS Weld On #4. I removed mold lines by scraping them with a new #11 Exacto blade. I sprayed the figure with two wet coats of Tamiya White Fine Surface Primer. I made sponsor logo decals for the driver’s suit based on pictures from Mr. Garlits’ book “Big Daddy, A Career Pictorial”, Volume 1. I painted the figure with various Model Master and Testor’s paints. I applied the sponsor decals and after drying, I sprayed the figure with two wet coats of Tamiya TS-80 Clear Flat.

-

Great suggestion. I have not yet finished the display I do for all my models. I do have some figures of models in bathing suits. Looks like that's the way I'll go for this model.

-

Nice paint. I built the full detail version when it first came out and found some nice images (from the Oakland Museum) to put together a little display with a figure (as I always do). You are correct. You need white primer under the Boyd Aluma Coupe Yellow to get the correct hue. I tend to use Tamiya Fine White Surface Primer.

-

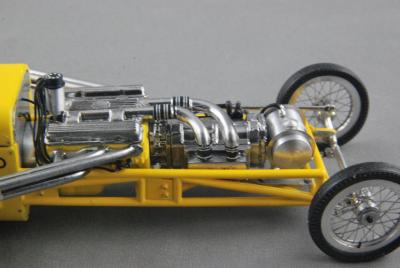

The model is finally finished. I have to work on the display but here are some pictures of the finished model. I used the chassis from the Revell Mickey Thompson Attempt One dragster (a nice Dragmaster chassis that requires some modification to give a semi-accurate Mooneyes model). The fire wall was covered with Bare Metal Foil Aluminum. The head rest was made by gluing scribed styrene sheet to printer's aluminum sheet and cutting/bending to shape. The set belts were from Colorado Decals with Scale Auto Details Simpson logos. Gussets were added to the roll bars. The side panels were modified by removing the upper parts that extended behind the slicks. All kit chrome was stripped with Purple Power cleaner and redone with Alclad II Chrome over Model Master Black. I used a Revell 283 Parts Pack engine. AMT Parts Pack slicks. The headers were from a Blueprinter 283 engine parts pack (just re-released by AMT). The Vertex magneto was scratch built from K&S aluminum tubing with a cap from Morgan Auto Details. The rear four window Halibrand wheels were from the AMT 33 Willys Coupe kit. The front wheels were from Machined Aluminum Specialties. Front tires were from the parts box. The Moon tank was from Detail Master (the old style shorter tank). I scratch built the marine hydraulic throttle with linkage from Machined Aluminum Specialties. Decals were from Scale Auto Details (SAD0115) and are selling on e-bay or through me. The decal set includes new art work with correct Mooneyes, hose and clamp decals, and a decal for the magneto cap. The paint is two wet coats of airbrushed Tamiya TS-16 Yellow. After applying the decals, I airbrushed two wet coats of Tamiya TS-13 Clear (glad it is back!!!!). No polishing or rub out needed. The screw heads were PE items from Model Car Garage (a set they no longer produce). I am working on an article covering this model build for a well known model car magazine. Enjoy.

-

Latest Model Build: Mickey Thompson's 1961 Pontiac V8 Dragster

Doctordarryl replied to Doctordarryl's topic in Model Cars

See Lou Hart's book "Slingshot Dragsters of the 1960s Photo Archive" for pictures of both dragsters at the 1961 NHRA Nationals. Mickey entered two dragsters; one with the Tempest slant-4 cylinder (and a double roll bar) and one with a blown Pontiac V8 (with a single roll bar hoop) on p. 10 and 11. The Attempt One was first a dragster and second a land speed record car. -

Here is my latest model build. I used the Revell Attempt One kit along with a Pontiac V8 from an AMT (Blueprinter) parts pack (which has just been re-released). One can still find the Attempt One kit on-line and even in some hobby stores (I just bought another one a week ago from a local hobby store). Great kit to have in your stash since it can be a basis for many 60s era dragsters using a Dragmaster chassis. I am in the middle of a build of the original Mooneyes dragster using this kit and a Revell 283 parts pack engine. The July 2012 issue of Hot Rod Deluxe has an article and photo spread on the original Mooneyes dragster, not the copy that currently resides in the Garlits' Drag Race Museum (there are subtle differences). I modified the kit's chassis to match pictures of the real car which had a single roll bar instead of the kit's double roll bar. I airbrushed the inner body panels with Tamiya AS-12 Bare Metal. I airbrushed the outer body panel surfaces and chassis with Tamiya TS-19 Metallic Blue. I custom made the decals. I used the heads and valve covers from the Attempt One kit along with a blower, injectors, and scoop from a Revell 41 Willys kit. The headers were modified items from the AMT parts pack. All chrome was redone with Alclad II Chrome over Model Master Classic Black. I used the rear wheels, slicks, and front tires from AMT parts packs. I added wheel studs and lug nuts to the rear wheels. The blower pulleys and belt were from an AMT Hemisphere kit. The Moon tank was from Detail Master. The Hilborn fuel pump was from Scale Auto Details. The engine was wired and plumbed. I scratch built the magneto from polished K&S aluminum tubing with a cap from Morgan Automotive Details and a decal from Scale Auto Details.