-

Posts

25 -

Joined

-

Last visited

Previous Fields

-

Scale I Build

1/25

Contact Methods

-

Yahoo

jdfoxz2000@yahoo.com

Profile Information

-

Full Name

Joseph F. Dobrowolski

Recent Profile Visitors

Joeys Models's Achievements

MCM Regular (3/6)

-

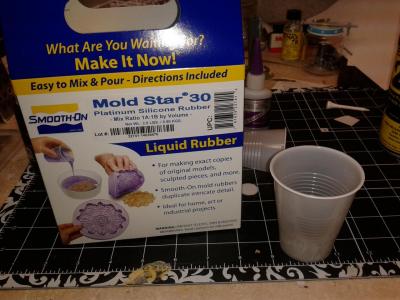

Shucky I agree with you !00%. People always trying to find cheep ways to build molds. This is fine if you are just casting for yourself. But I see guys trying to sell their stuff. Missing parts of the mold, full of pin holes. Just plain BLAH_BLAH_BLAH_BLAH because the want to cut corners. I believe if they want to step up there quality. They need to step up on their casting methods. Use quality supply's and better mold quality. People stop trying to reinvent the wheel. YouTube is full of videos that show what professional casters do.All I have ever used is a good quality RTV, several different mold releases, and quality resin like Smooth On. Been doing this for 35 years. Never a problem with my castings.

-

Freeman Supplies carry's everything you need. I uses 202 pattern release for two part molds to keep the second pour of rubber from sticking to the first pour. Or you can use Vaseline. And they carry paintable silicon release for the mold. Best to use this for molding as it will not leave silicon behind that you cant wash off but lubs the mold.They also carry Sulfur less Plastisine clay which will work with silicon molds. Will not react to the silicone.

-

Freeman Pattern Supply carries 202 Pattern release and Paintable silicone spray release . I use them for my casting. 202 is basically a Vaseline in a spray can. Used to keep two part molds from sticking together when you pour the second half. Paintable spray release is just that. You can paint the part after you cast them.

-

Do you have masters ready to cast?

Joeys Models replied to GaryR's topic in Car Aftermarket / Resin / 3D Printed

Its is very cast able. But you would have to have the noes piece as a separate piece. Can not pull that body out of a mold with that nose as part of the body. Belly pan would have to be a separate piece too. -

Modelhaus going, going Gone !!!!!!

Joeys Models replied to WoodyRDC's topic in Car Aftermarket / Resin / 3D Printed

Greg Wann can you give me a contact number for Don? I would be interested in his masters and any molds he wants to sell. Email me a jdfoxz2000@yahoo.com -

Should not be a problem. The silicon rubber has a shrink factor to it. Usually .001 to .003 . Worse if it's cheap rubber like Alluminlit. Check their website for spec. on there resin. With painted parts and plated. In my experience will not effect the casting. I usualy prime all my parts before I mold them.

-

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

That's true. But Model Chrome is not telling you that on their Facebook .I was just bring up that you have to provide them with a perfect part. They will not do the work for you. I know if you send me a bad part. I will send it back unfinished. -

Refreshing Old Kit Chrome

Joeys Models replied to StevenGuthmiller's topic in Model Building Questions and Answers

Vacuume platting is usually so thin that any rubbing on it will remove it. -

Casting small parts - help

Joeys Models replied to mopargreg's topic in Model Building Questions and Answers

If your only going to do just a few castings. Go to Hobby Lobby and get and Aluminlite casting kit. And use the 40% off coupon to save some money. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

Rack is only $10. but reusable. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

12 X 8 flat rate box is $12. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

Depends on the platter. Me I would use an airbrush. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

To avoid paying tax's on the business their running. Pay Pal will do the same to you if your doing to many money transfers. They will ask you to do an business account to report to the IRS. -

NEW PLACE TO GET PARTS CHROME PLATED!

Joeys Models replied to Ben's topic in Car Aftermarket / Resin / 3D Printed

This is really not a new process. It’s the same process they use to silver plate mirrors. Centuries old. I just bought a kit. And will soon start doing platting. This is a chemical process not real chrome platting. Thickness depends on how much you apply. About the same thickness as vacuum platting. But what they don’t tell you is that your parts have to be perfectly smooth. Any flaws in the surface will show up. They like me will not finish the parts for you. So I would recommend that you paint a black or very dark blue base coat on your parts. This way you will see the surface shine that you will get back. If it is shinny and no marks. The silver will coat it and shine like chrome. The clear coat is sprayed on it to protect it. An automotive clear urethane is UV protected. It will not turn yellow in time. I don’t know about Model Chrome. But they will tell you that they are not responsible for under surface finish. What you see is what you get. -

Casting resin and air bubbles

Joeys Models replied to Hawk312's topic in Car Aftermarket / Resin / 3D Printed

I never have problems with bubbles. I always pressure cast. I mostly do two part molds. Some cheaper resins have a tendency to naturally produce bubbles. Careful, Some resins will foam up when you vacuum. I use Smooth-On products for all my casting needs.