-

Posts

2,983 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by 10thumbs

-

-

UPDATE:

Today the upper level ratlines and shrouds were started. Same procedure as below, just a little bit lesser involved. This level allowed the sailors to get up higher to handle the upper sails.

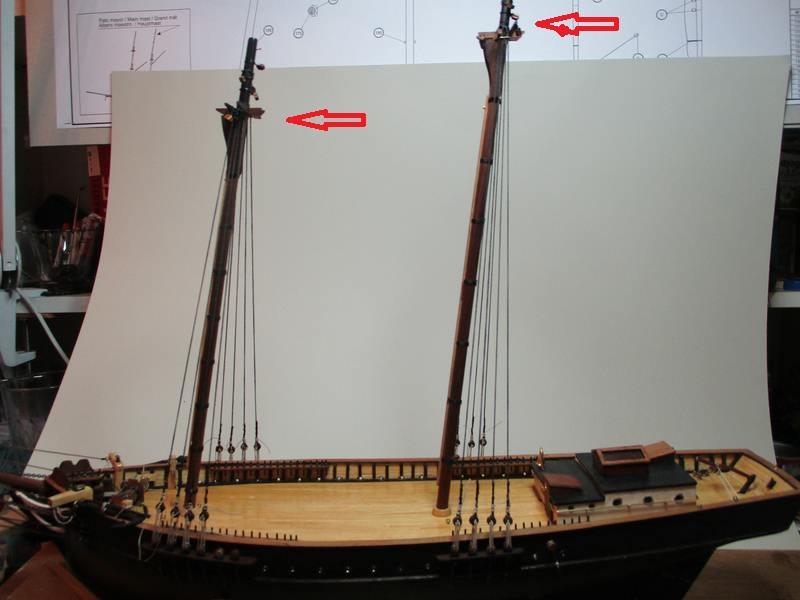

Here the area shown with red arrows;

The dead-eyes were made up with brass wire. and attached to the top of the lower shrouds;

I think the ends should be crimped tighter around the bracing;

Also, no way was this done with shiny metal wire. I'm thinking maybe a little gray-looking metalizer paint might help out.

-

A good day indeed.

Happy Birthday Carl!

-

Hi Greg,

Great choice with the solder wire headers. I have some experience with solder rod.

Important: Here in Europe we still have lead solder, and in the size you'll use for scale headers, the flux is built in. Meaning, the rosin is filled into about 5 channels through the soldering rod. This rosin will have to be removed as good as possible! Otherwise with time, and if the material gets sunlight and/or warmth, the flux will run out the ends. A real mess will incur.

Either, you take care in drilling out the ends as far as possible (2mm maybe?) and seal them off with CA, or you cut the lengths to about the size you'll need, and with tweezers, dunk them in boiling water to melt the flux out. As an extra kicker, the solder rod gets a nice color from hot water.

Sorry if you already knew this info.

Good idea too, to drill out the exhaust ports to make a nice connection. I like to drill the ports out a lot, so the solder can be really stuck into the block. This way it's a lot easier to make the remaining bends needed.

Another tip, if you don't mind. Cut a length about twice the size you need, and work both ends. Here a little, there a little. You can easily snip off either end when it starts getting close.

Again, great choice with solder headers.

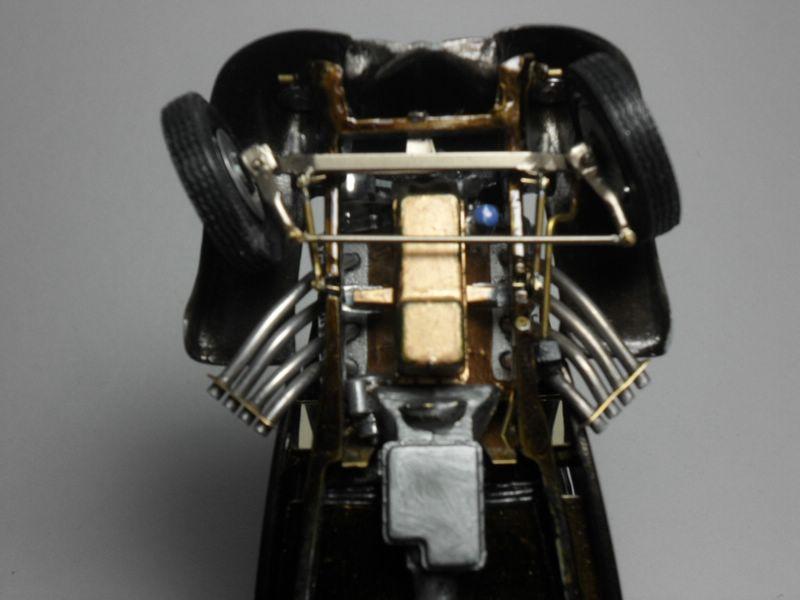

This was a couple of years ago, 2.5mm makes to a scale 2 1/2 ". Perfect. The AMT '33 Willys;

Good luck and let us see some pics.

Michael

-

Shade tree mechanics in my area. A home that's mobile, and 5 cars that aren't!

"That thing must have a cam in it"....

-

I'm with Gerald, back in '63 the Willys.

On another note....that darned Revell "Orange Crate". Never finished it as it kicked my butt good. I broke so many parts trying to get them off the trees, I gave up. What a cool old model.

....maybe, just maybe, one of these days

-

Thanks Bill for the great info.

I'm thinking right now one of those 66 Fords just might be my next model project. All metal with a resin body.

I like 'em.

With a magneto too.

-

I always thought his evening robe deal was really funky and kind of creepy.

Lots of photo presentations too with a pipe. Smoking a pipe.

Hey....smoking a pipe means something else in several other languages.

With all of those ladies....never mind.

Fumare la pipa...si.

-

1st snow in Germany already.

First time this fall, I wish I had long-johns on. Gray and foggy, zero sun, the gray shield is over middle Europe. Sunshine probably again in January.

No problem, going to Italy soon.

-

When I hear 'cam' I think often about a buddy from my youth days. A Chevy guy.

He had an obsession with cams, and was able to disassemble a motor and rebuild as well. Just his motors were weak, and never ran well. Probably built in cams that were not supported from the rest of the motor. Heads and such.

"Three quarter cam". lol.

"Here my new Isky 505"....I'll never forget those times.

Ha!....another favorite is 'diy head porting'.

-

Great touch Tom with the real wood and staining, nothing better than real wood or metal on our models.

A great looking set, very realistic.

-

I like it Brian!

Man, great detailing, the motor exhausts can't get much better.

Also, you've set the rig in scene very well, compliments. Nicely photographed.

I really like the drive wheels, would love to have these types for a future project.

-

Super clean build Thomas.

Guys....what is the extremely extended front bumper for?

Geez, I rented an apartment that had a smaller balcony.

-

Guys, this is an old topic, about 6 years.

Soooo, I'm gonna do a slight hijack now.

@Spike, do you have any more pics to offer from these insane boats? Love them! SoCalBoats....your site?

Sorry for the interruption.

-

New pics today;

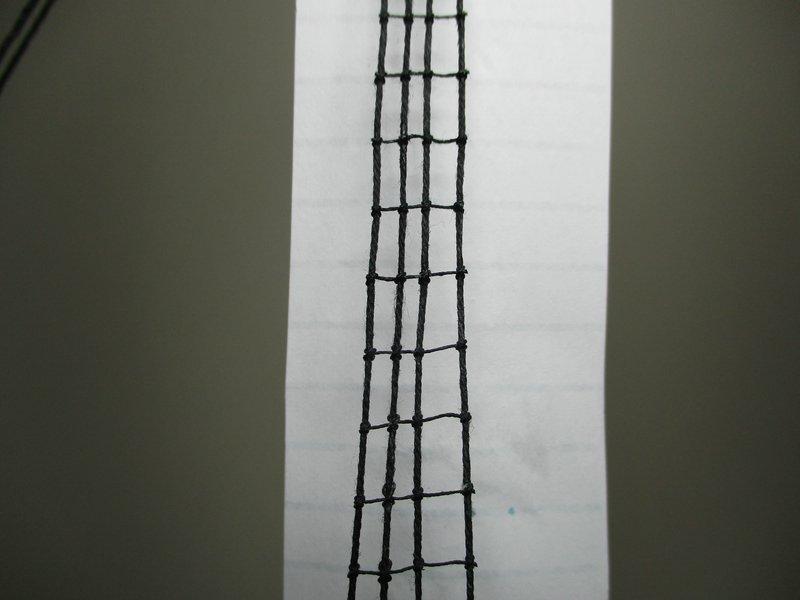

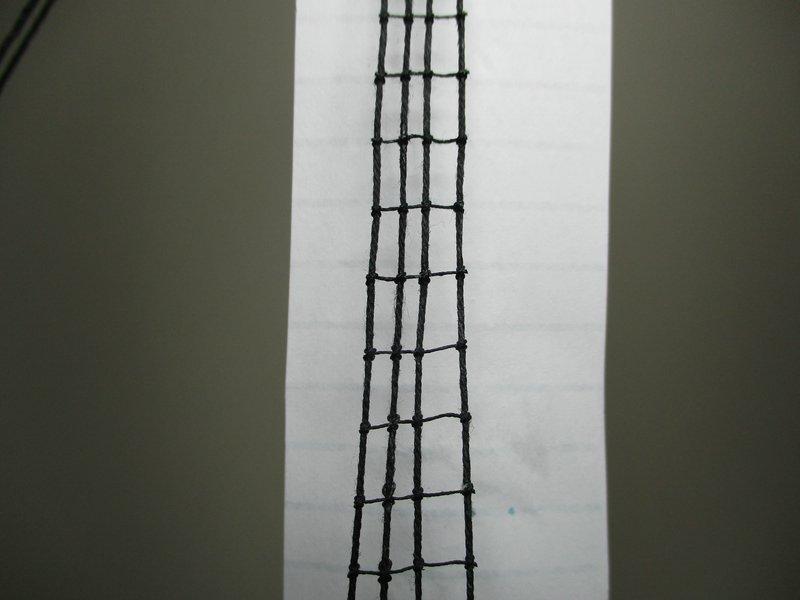

Finally the ratlines for the lower mast segments are finished. In the beginning, the 1st try left lots to be desired. Lousy knots, and from tying so many, 132 knots per segment, the main shroud lines had started to run crooked. Not good, here the 1st segment, this is the left side;

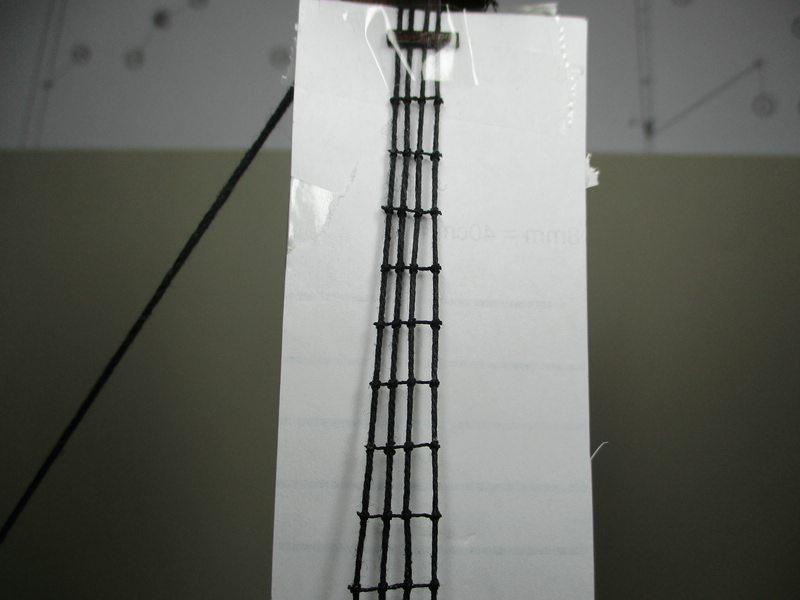

Then it hit me. I'd forgotten to add cross-bracing. Just like on real ships, these kept the vertical spacing correct right on up to the top. This bracing allowed me to give each knot a good tug to get them good, tight and small;

Now they look a lot better. I'm happy this part is finished, I took my time, one of them took me 3 days to do, another was done in one day. I like them now;

All four lower segments done, time to finish up and mount all of the deck furniture;

Starting to look like a ship now. In real life the vessel would already be afloat. Next up is mounting the upper mast extensions....and more ratlines. Ugh. They'll be smaller though and not quite as intense, I don't mind at all.

Thanks for looking.

-

Hi guys. Several browsers have been tried out in the meantime. Right now it's Chromium, again. I reinstalled and it works so far without glitches, although I do have warnings about some possible issues, but don't have a clue to fix it. Anyways, the thing works nicely.

I like too the layout, nice and clean and extensions are easy to get.

I appreciate the input from Steve and Doug others who know about these things, many thanks.

-

Hello Tom, good to see a great truck modeler drop in, thanks a lot.

The 2nd and 3rd ratlines are finished now, they look a lot better than the 1st shown above. In a day or so I can post new pics of the lower 4 shrouds finished.

Tedious stuff, some days don't go well, I'll not force it.

-

I'm here with Sea Monkey now, this is working well.

Chromium was installed but kept crashing, I just can't get it to work.

Chrome has been deleted.

-

Ha! OK, I'll get rid of Chrome, and find Chromium.

Also, I installed Sea Monkey....I like! Reminds me of a years ago Firefox, and it does seem to be quick.

This is fun.

I tried again with Firefox....didn't work.

-

1st ratline finished..

The 2nd part went a little better. Several issues came up and I'll attend these with further progress.

Here the top half of the main mast shrouds, with ratlines;

Looking better;

The direct result from the previous mistakes, the long shroud lines are starting to sway, the vertical run has been pinched, causing the line to have a curve. Not good;

The knots have gotten better though. The last ship I made was in '09. No big, well lit magnifying piece back then, no digi camera either. I had a look at the old tub from back then and have to write that things haven't changed much, and the ship looks good on the shelf. I'll press on as is.

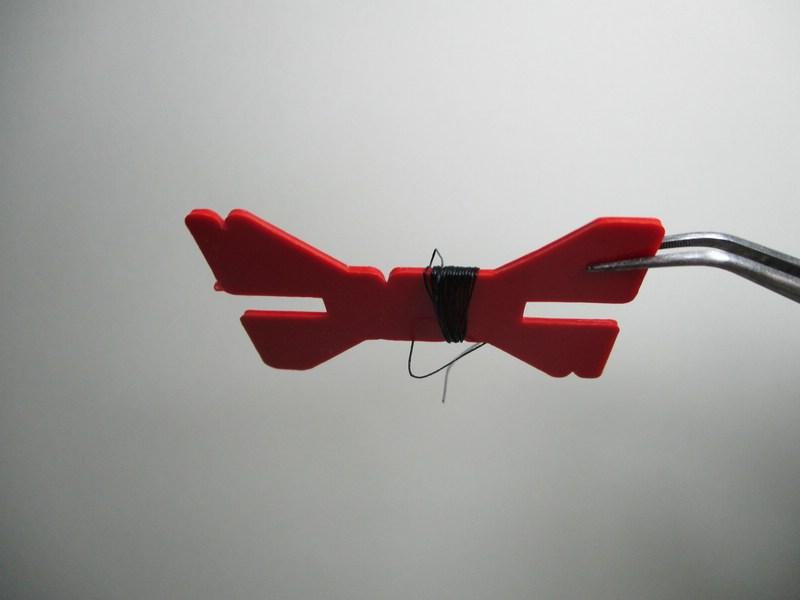

Here a problem I've discovered. This is the crummy way some ship kits spool the thread needed;

Result is, a really kinky piece of thread that is just about impossible to easily correct. I refuse to iron a thread that's about 2" long;

This a better way to have thread from a spool, no kinks;

This is just a small update and now I'll move to the other side, main mast. Probably things will go better, although not quicker. Read, this is a pita.

Thanks for your interest.

-

Great infos guys, many thanks.

Until the Firefox 56 updates I never had a problem, I liked FF as it seemd to be easy to set up and to use the addons.

As stated above, Google and their rep is not something I'm happy with. So far, with Chrome I can update my topic and post otherwise too, like right here. FF just now crashed again, strangely though, only here on this forum. Still, it aggravates.

@Snake above...lol. I've even thought about installing Win98SE just for the interent. (Don't know if it would work though).

-

That's nice of you JC, I appreicate it.

-

Now with Chrome, so far so good.

-

OK, thanks guys, enough for me, bye bye Firefox.

Moving to Chrome now, hope I can get acquainted quickly.

-

Still no pics here?

Baltimore Clipper 1825...lower ratlines done

in WIP: All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Posted

No way JC these guys had height problems, you're right.

Not only the height, but the ship was pitching and rolling, the masts were whipping around, wind and rain, cold, maybe awful humid heat and stink everywhere. Dead weight to handle, nothing is lightweight on a sailing ship, it's all rugged and heavy duty. These old souls were tough as nails.

One hand for the ship, one for your life.

Thanks for looking.