-

Posts

4,591 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

The best thing about using a two-part catalyzed putty, is that there's virtually no shrinkage. That's preferable, especially in larger areas, like custom bodywork. For general filling of sink marks, etc., most standard fillers will work just fine!

-

If I don't find what I went to the hobby shop for, specifically, I always buy some building materials. Especially when I see the K&S Special Shapes rack. I snag up the 1/32" and 3/64" brass tubing, anytime I see it! Last time I was there, they had K&S square aluminum tube in 3/32" and 1/8", neither of which I'd seen, before. Anyhoo...you can never go wrong investing in materials (or tools!).😃

- 35,976 replies

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

I love them. I think you did a great job, capturing the motion and energy! Nice work!

-

Here in the Denver area, there used to be what was probably the greatest model railroad store in the country--Caboose Hobbies. My friend, Don and I spent hours, in that place looking at different castings and machined parts. He started using the handrail stanchions, and told me about them. I have used them, since. There is no telling how much money I spent, in that place on materials and supplies, alone! Alas, while the name still exists (I think), it's not really even a shadow of its former greatness. I agree--whatever works, I'll use it! If I don't have it, thankfully, I mostly have the ability to make it with round stock, and PCB bits in the lathe. I always have my eyes open for building materials, no matter the source. I've made steering axles from brass and plastic, both--it depends on what the rest of the project requires. If I'm going for quick and easy, I'll generally use plastic. My Nostalgia Top Fuel dragster has brass components, up front. The attached are a Monogram Model A Coupe, I'm working on--well, was--and will be again, at some point.

-

1/16th Scale Top Fuel Dragster Eddie Hill 4:99

Straightliner59 replied to Ian McLaren's topic in WIP: Drag Racing Models

That will truly be a joy, to watch!- 78 replies

-

- scratch built

- super shops

-

(and 2 more)

Tagged with:

-

Very nice, Dennis! Dig the Minnesota plate, too!

-

For tie rod ends and heim joints, I almost exclusively use HO scale handrail stanchions. When I built the steering for my Nostalgia Top Fuel dragster, I milled them, for the first time. That can easily be accomplished with a file, as well. I use 3/64" brass tube for the tie rods. For the longer shafts/rods on the NTF car, I used .040" aluminum armature wire that I bored on the lathe, to accept the stanchions.

-

Clearing over decals?????

Straightliner59 replied to WillyBilly's topic in Tips, Tricks, and Tutorials

I would add that, if accuracy is important, to you, study the subject you're doing. Vinyl stripes won't be as shiny as the paint, on a real car. On race cars, all the little contingency decals are applied after everything is painted, so they shouldn't get clear-coated. That said, often, earlier period race cars had some of their contingency markings actually painted on, as were car names, local sponsor names/logos, driver names, etc. Research is paramount! And, it's fun! You just have to be careful not to fall down any rabbit holes (which are also fun!).🙂 -

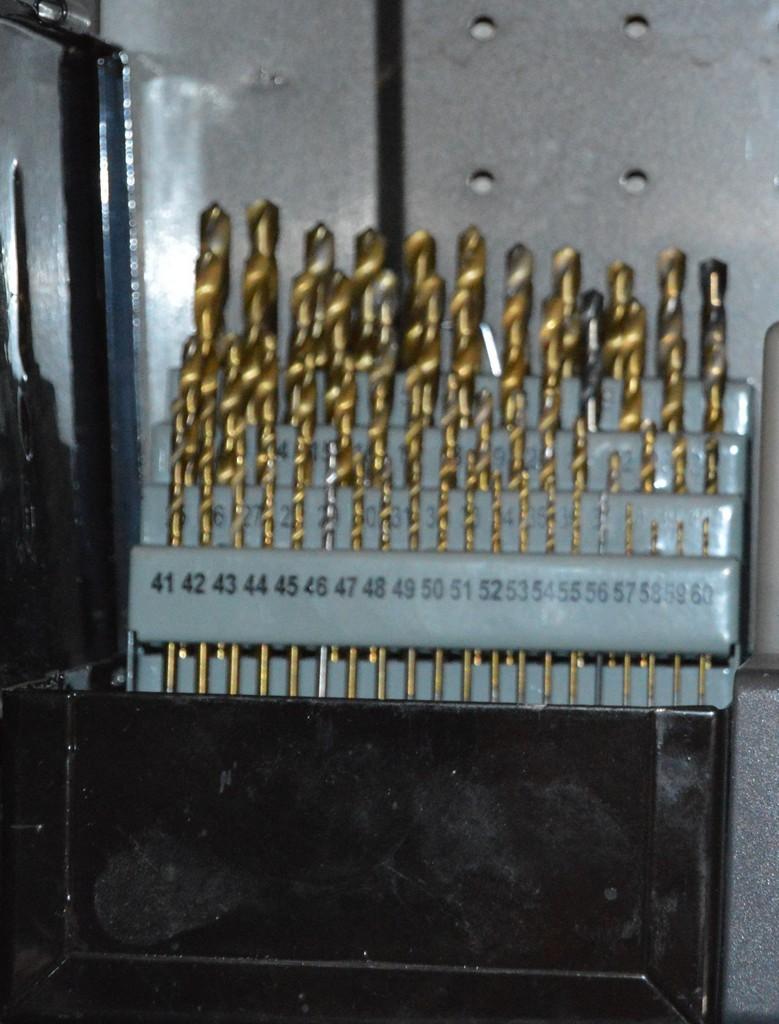

Tired of switching chucks in my pin vise

Straightliner59 replied to Camaro lover's topic in Tips, Tricks, and Tutorials

That sounds like a nice piece of decor! -

Who doesn't love a mock-up? Let's see yours!

Straightliner59 replied to Belairconvertable's topic in WIP: Model Cars

I've been playing around, with this thing. Was supposed to be quick and easy. Apparently, I have to work on that.😃 -

67 Camaro B&R Performance C/SM

Straightliner59 replied to Nitro330's topic in WIP: Drag Racing Models

This is really coming along, beautifully, Terry. The stance is perfect! It could not look more like a Stocker! -

This is very cool, Dennis! I wish I had your knack for bodywork. Now, these shocks--this illustrates the biggest reason I scratchbuild so much stuff. It's often easier than cleaning up molded kit pieces, it's a helluva lot more interesting and fun than cleaning up those mold lines, and, they always look way better than the kit parts! Beautiful work, sir, as always!

-

Always happy to share! We aren't guarding any State Secrets, or anything!🙂

- 50 replies

-

- scratchbuilt

- brass

-

(and 1 more)

Tagged with:

-

@tim boyd I think I misunderstood what you asked me about the inserts. The confusion was on my end, not in any way your fault. Once I had primed the panels, I shot them with a mixture of Humbrol Brass and Humbrol Gold from their standard line, cut with lacquer thinner. I overshot that with Tamiya clear orange lacquer. I then masked off the panel areas with Parafilm M, and sprayed them with cheap Walmart Color Place gloss black, straight from the can. Once I'd removed the masks, I dabbed the orange panels with Black Sign Painter's One-Shot, thinned a little with mineral spirits, applied with a torn off bit of natural sponge. Finally, I applied the red borders with One-Shot.

- 50 replies

-

- scratchbuilt

- brass

-

(and 1 more)

Tagged with:

-

My next project will be fixing up my side cutters! I really enjoy advanced stuff, like drawing wire, etc.

-

Thanks, Tim. They really are cool-looking dragsters! I sincerely appreciate your kind words, regarding my project. By "inserts" are you referring to where the panels overlap? If so, it took me a while to figure out how to accomplish that, satisfactorily. I ended up doing it like this: I cut brass strip to my desired "profile", smoothed it, and superglued it to the jaws of a sheet metal hand brake. I then aligned and taped the sheet into position, and laid the tool on my biggest anvil and gave it a rap with the ballpeen hammer. It worked out very well!

- 50 replies

-

- scratchbuilt

- brass

-

(and 1 more)

Tagged with:

-

Acceptance of 3D printed models?

Straightliner59 replied to jdhog's topic in Model Building Questions and Answers

Absolutely! If you're not enjoying it, there's no point to any of this (unless it's your profession). I have known several people who seemed to build mostly for competition. At least half of them don't build, anymore, claiming burnout. I can't even comprehend that.