-

Posts

3,477 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Aaronw

-

My parents took me to the Harrah's collection when I was a kid, and it was building after building filled with cars. It was an all day event to see it all and my parents were not even car people, so that was at a pace of seen it move on, seen it move on. I do remember that he had a reconnaissance version of the P-38 that had been used for aerial survey after the war. At the time I saw it, it was one of only a handful of P-38s on display. Several more have been recovered and restored since then, but at the time it was a very rare plane to see in person. The current museum is impressive, and worth a visit but a considerably smaller collection. According to google, Harrah owned around 1500 vehicles, the current museum has 200-300. The Hayes truck collection was donated to the museum in the 2010s, but unfortunately they have not been able to raise the money to build a companion truck museum to display that collection.

-

Roadworthy Rescues Wrecker

Aaronw replied to Steamboat's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Nice job. I like the beacons, they look a lot like early Whelen strobes. -

First time resin casting question

Aaronw replied to Sledsel's topic in Model Building Questions and Answers

I have wondered about syringes, but thought they would be one use only, so never tried it. I can reuse the little plastic cups I mix the resin in, and since syringes seem to be made of a similar plastic, it makes sense that the resin doesn't stick well. Investing in a pressure pot makes sense for anybody casting in volume, but there are lots of little tricks to keep things simple for the just cast a part once in a while caster. -

First time resin casting question

Aaronw replied to Sledsel's topic in Model Building Questions and Answers

It will largely depend on how much of an under cut there is for the rim. If there isn't a deep undercut, maybe up to an 1/8" you will probably be fine, particularly if you are only going to make a few. Silicone is pretty stretchy, but the mold will tear more easily the greater the under cut. I'm assuming you are not pressure casting, so bubbles will be an issue but with some practice and "thinking like a bubble" you can eliminate a lot of them. Squeezing the mold and poking recesses with a tooth pick to help fill them with resin and allow bubbles to escape will help. -

Roadworthy Rescue Wrecker

Aaronw replied to Steamboat's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Nice to see you made all this. I initially expected it to be the wrecker bed from the Midnite cowboy kit with the weird mini "Peterbilt" cab. -

Acceptance of 3D printed models?

Aaronw replied to jdhog's topic in Model Building Questions and Answers

It is new so you are going to see push back from some. I wasn't around to see it, but I'm sure there were those who thought the sky was falling when plastic started replacing balsa wood. I think 3D printing is great and I'm looking forward to learning to use the new tools. -

Fire investigation unit

Aaronw replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

There is a feature within Word called Word Art that allows quite a few options, and a drop shadow is one of them. You can also use a font with a shadow which would be an easier but more limited option. I long ago switched to a more advanced drawing program (Corel Draw), so I'm a bit rusty with Word's options related to this stuff, but any word or drawing program, even the free ones can do a lot. With a little practice, printing basic decals is not much more complex than printing a document. GIMP is a free drawing program similar to Adobe Illustrator or Corel Draw that some use, but there is a learning curve to it. This is another example of decals I did with either Word or Microsoft Paint, this one with shadowed lettering. Again done 2005-07-ish so I'm fuzzy on the details. -

Fire investigation unit

Aaronw replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That is one of the joys of light colored (white, yellow etc) fire apparatus. Decal film and a regular printer work just fine for decals. These are a couple I did close to 20 years ago just using decal film, Microsoft Word and an ink jet printer. You can even get around the darker colors by using white decal film. I printed the text on white decal film and then cut the white film into strips for the striping and door logo. On darker colors sometimes you need to double up the white film to keep the color from bleeding through. -

2021 Pierce Ascendent Tower

Aaronw replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I did not know that, a neat piece of trivia. -

Yeah, I wasn't sure on the inkjet paper. I knew it is bad news in a laser since the heat of a laser printer can / will melt the coating on the inkjet paper. I long ago switched to using a laser printer so use the same paper for both the ALPS and my laser printer. Glad this thread popped up. I'm on io groups for several other groups but had not run across the ALPS io group, so was able to join it. I agree FB is really not a great format for collecting that kind of info long term.

-

2021 Pierce Ascendent Tower

Aaronw replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

The first one looks pretty amazing, but I'll trust you that it has flaws. 😆 I think a lot of us have boxes of projects that just didn't make the cut. Love the little details like including the eagle clutching arrows and an olive branch under the drivers side head lamp that Pierce places on their cabs. -

Fire investigation unit

Aaronw replied to Firebuilder's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Coming along nicely. I really enjoy watching people make things out of nothing, scratch building parts, resin casting, printing decals etc. -

If you want to know more about actually operating machine tools, these two youtubers have a lot of great videos. Mr Pete is a retired high school shop teacher who has been on youtube "forever" so he literally has hundreds of videos. Blondihacks is just a hobbyist and much more recent (so not as many videos), but she breaks things down in a way I find very easy to follow. She also has very good production quality so it is easy to see what she is talking about. There are a ton of good machining oriented youtubers, but I find these two to be the best for explaining basic operations. https://www.youtube.com/@mrpete222 https://www.youtube.com/@Blondihacks

-

I have an ALPS 5500 that I bought new around 2008. I did not know about the IO Groups ALPS group, but there is an ALPS group on Face Book as well. I have always used laser printer decal paper with mine, but not sure that the printer is that fussy since it uses a film, rather than ink or toner. You do want to use a good quality decal paper though, some of the cheaper paper may have grit which will damage (scratch) your ALPS print heads. I always used Tango Papa but I bought a large amount of paper the last time and have not done much printing in recent years, so still have a large stock on hand (somewhere). I have heard some complaints that Tango Papa has had issues with paper quality. I never did, but also haven't bought any new paper for probably 10 years, so don't know if I got lucky or their quality has declined. I used to use a vender out of New Zealand ALPS Supplies for my cartridges, but again haven't had to buy new supplies in some time. I see a lot of people now are using Elephant's Rocket a company in Japan that has taken over supplies and printer support for ALPS. They have created ALPS drivers compatible for Windows 10 which I really need to download and try out. Part of the reason I haven't done much printing lately was one I made a lot of decals for my popular subjects and haven't run out, but the other reason was the nuisance of having to use an ancient Windows 7 laptop with the printer.

-

These are not common in the US, and very expensive over here compared to other small lathes. Based on comments from a Unimat list I belong to the Proxxon PD250/E lathe is pretty good, but comments about the 150 were not nearly so complementary. In the USA the 250/E retails for around $1800 making it much more expensive than other options. Pricing in Europe may be better since it is a local product.

-

I also have a watchmakers lathe, made by the Waltham Watch Tool Co sometime between 1890 and 1914. It was kind of an impulse buy because it was only 10 minutes from home and a great deal. I got the working lathe with motor, a cool jewelers desk and a bunch of jewelers and watchmakers tools and tooling for the lathe for $500. Pros - They are small, light weight and assuming they have been properly cared for they are very accurate lathes. The classic "8mm W-W (Webster-Whitcomb) style watchmakers lathe" like the one pictured above are pretty universal, so parts and tooling exchanges between brands liberally for the most part. They cost more than first appearances, but there are bargains out there if you are patient and quick when one turns up. Because of the type of work they were made for owners tend to be very meticulous in their care and use. Cons - They are fairly delicate, so it is easy for a careless prior owner to ruin them. Prices can be deceptive, you will see watchmakers lathes sometimes for as little as $250 making them seem like a budget lathe. That will usually just get you a bare lathe maybe not even a motor. What you get may be useless without spending a lot more money. Not unusual to find well equipped watchmakers lathes in the $2000-3000 range, particularly for one from a well known maker, if Swiss or German made add another 10-20% to the price. Considering that there are only a handful of manufacturers that still make these lathes, and the starting new prices run $9000+, then $2000 for a used one is actually quite a bargain. They are made to be mounted to a solid base, so not really portable. The base lathe is intended for use with collets, so the maximum size of round stock is limited to 8mm / 5/16". Collets have a very narrow holding range of about 0.1mm / 1/64" so you need a pretty decent number of collets. Collets are not cheap, used you may find decent ones around $5-10 each, new $40+ so if you get the lathe without collets, you can easily spend as much as the lathe for a useful size set of collets. The basic lathe also just comes with a simple tool rest for hand working material like a wood working lathe, not a cross slide like most other metal lathes. You can get chucks, cross slides and other accessories, but they are very expensive and often cost more than the lathe itself. They have a very small working size, generally 50mm (2") swing and 4-8" between centers.

-

One thing the Unimats really have going for them is they are very small but still capable. The SL like yours is only about 1/2 the foot print of even the short Sherline lathe.

-

Funny you say that. I bought my Sherline to make model parts. I've made some parts, but really not a lot. What I've done a lot more of is make tools (some for modelling) and fix things around the house. Having a lathe is super handy. We had to replace a TV, and the new TV did not fit the old mount. 30 minutes at the lathe and I had cut down the spacers and bolts to fit the new TV. I had a co-worker who had a sentimental (but kind of cheap) key lanyard that failed. I took it home and was able to make a new fitting to repair it. These other uses are what led me to bigger machines. I've spent an inordinate amount of time fixing up vintage machines instead of building models... Like I said, it can be a rabbit hole, but it is fun and they are really nice tools to have available.

-

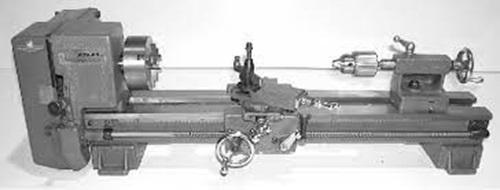

Yes, but be aware it can be a rabbit hole. It starts with a lathe, and then you want a vertical mill. Then you get tired of cutting your stock by hand so you find yourself looking at bandsaws and power hacksaws. Don't know where you are coming from, but some lathe basics. Lathes are "rated" by swing and distance between centers. Swing is the largest diameter (in the USA, some countries like the UK use the radius) that can be turned at the spindle. This is a theoretical maximum, about 1/2 this diameter is more realistic for most operations. Distance between centers is basically how long of a part the lathe can work. Again kind of theoretical as most people these days are going to use a chuck, not turn between centers. The chuck will eat up some of this available space, and any tooling used in the tail stock drill, taps etc will also take away length available. There are literally dozens if not hundreds of small lathes out there, but this is a list of the usual suspects: Emco Unimat DB200, SL1000 and Unimat 3, Austrian made from the 1950s to the late 80s. These are very small lathes 2.5-3" swing and 6-7" between centers that are popular with model railroaders and model makers. Need about 1x2 feet of working area and weigh 20-30lbs. These are often recommended as they are popular and used to be pretty inexpensive on the used market. Since they have been out of production for 30+ years they are starting to become collectable, driving the prices up and making them a lot less of a bargain. Used to be you could pick up a decent one for $200-300, but now much more common to see them asking $500-1000+ and they are all old, the last ones were sold about 1990, 34 years ago. A positive for these is they are combination machines so with the right parts you can use them as a lathe or a milling machine / drill press. Parts and accessories are getting expensive. Taig Micro Lathe II. Taig is made in USA (Arizona) and is one of the more affordable options. 4.5" swing and 9.5" between centers so a bit larger than the Unimats, but still weigh 30-40lbs. These have been around since the 1970s and are still in production. Taig also makes small milling machines and you have the option of manual or buying one set up for CNC (computer control). You can get a basic set up from Taig for around $500. Carter tools is a Taig dealer who has a much more user friendly website than the official Taig site. Taig Carter Tools Sherline offers several small lathes and milling machines. Also made in USA (Southern California) these are more expensive than Taig, but in my opinion also more refined. Sherline offers a ton of accessories for their machines. Looking at around $900 for a basic set up on the entry level 3.5" swing, 8" between centers Model 4000. Sherline offers some really good value package deals with additional accessories, but you can quickly find yourself spending $1200-1500. Like the others weight is 30-40lbs. Sherline uses a variable speed motor which allows speed changes by turning a dial. Taig and Unimat use belts and pullies so speed changes are a little more work. Like Taig you can buy manual or CNC versions up to full CNC set ups with the computer and software. Sherline is very popular with model makers, I'd guess a survey of members of this site who own lathes would find Sherline in front by a large margin. In my opinion the long bed Sherline Model 4400 with 17" between centers is one of the best options if you can make it fit your budget and space. You quickly run out of length on small lathes and that 17" between centers puts the Model 4400 way ahead of the others in this area. Sears sold these for a few years in the 1980s, so you will occasionally run across a used Sherline marked as Craftsman. These usually have a brass bed instead of steel, but parts from new ones will mostly fit the early ones. Sherline The other major contender is the Chinese mini-lathe which comes in sizes from 7x10 (really 7x8"), 7x12, 7x14 and 7x16. These can be good lathes, but quality control is spotty requiring many buyers to do a fair bit of work to get them running well. Prices are all over the place, there are sellers on Ebay selling as low as $450, and reputable vendors selling them for $800-1200+. Prices are not real clear cut, some are selling stripped down machines with almost no tooling, and some of the more expensive include popular upgrades and more tooling like a steady rest and follow rest. Like Sherline these are variable speed lathes. There are good features to these lathes, and many people do good work with them, but be prepared to tinker. These are also much heavier than the others weighing around 100lbs. Harbor Freight sells 7x10" and 7x12" versions Grizzly sells 7x12 and 7x14" Little Machine Shop sells a 7x14" and an upgraded 7x16" Lots of other sellers, Vevor, Eastwood, Northern Tool, King, Princess Auto. Almost all come from the same factory, but they are not identical with the different sellers choosing from a variety of options. Another older lathe that I see mentioned less frequently on model sites are the Atlas 6x18" lathes. These are a bit larger and heavier than the others (150lbs), but you can often find them for a good price and they are solid little lathes with more features and better low speed power than most of the others I've mentioned. Speed is controlled with belts and pullies. There are two primary versions, the older (1940s-1970s) Atlas 618 with Art Deco styling, and the later (1970s-early 80s) 3950 often called the Mk 2 with a more modern looking blocky shape. Thousands of these lathes were sold, many through Sears under the Craftsman brand. Not unusual to find one for $500-700, but the used market is highly variable by geographic location. If you do look for one of these though do be aware Sears sold another much lower quality lathe under the Craftsman and Dunlop brands in the 1940s, these have a model number starting with 109. The better Atlas made lathes sold as Craftsman had model numbers starting with 101. Like Unimat, the used market is your only option for these since production ended in the early 1980s. This is a huge can of worms, but this should give you a starting point.

-

What was the last actual AMT kit issued?

Aaronw replied to Monty's topic in General Automotive Talk (Trucks and Cars)

I think the question is too vague for a definitive answer. AMT as an independent company ended in the late 1970s. I'm not familiar enough with the organization of Round 2 to know if in its current form AMT is any less an entity than it was under Lesney (late 70s), Ertl (1980s) or RC2 (2000s). Maybe somebody familiar with the operation at Round 2 could chip in to explain if the AMT line has its own design organization, or if there is a general design team for Round 2 and the different brands are just used for marketing. -

What was the last actual AMT kit issued?

Aaronw replied to Monty's topic in General Automotive Talk (Trucks and Cars)

I didn't understand your question. As others have said, Round 2 is the parent company, AMT is just one of several brands under Round 2. Like many other businesses the model industry has gone through a lot of mergers and it can get confusing as to who owns what. -

What was the last actual AMT kit issued?

Aaronw replied to Monty's topic in General Automotive Talk (Trucks and Cars)

There are 2021 Dodge Charger and Ford Bronco kits. There was also the Garwood Garbage truck, based on the Ford C600 kit. Those are pretty recent. It has been the trend for AMT to do several re-issues, modified re-issues with each brand new kit pretty much since R2 took over.