-

Posts

409 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Old Sprinter

-

-

Very well done race car. There isn't much better than an F-1 car; love them

-

-

-

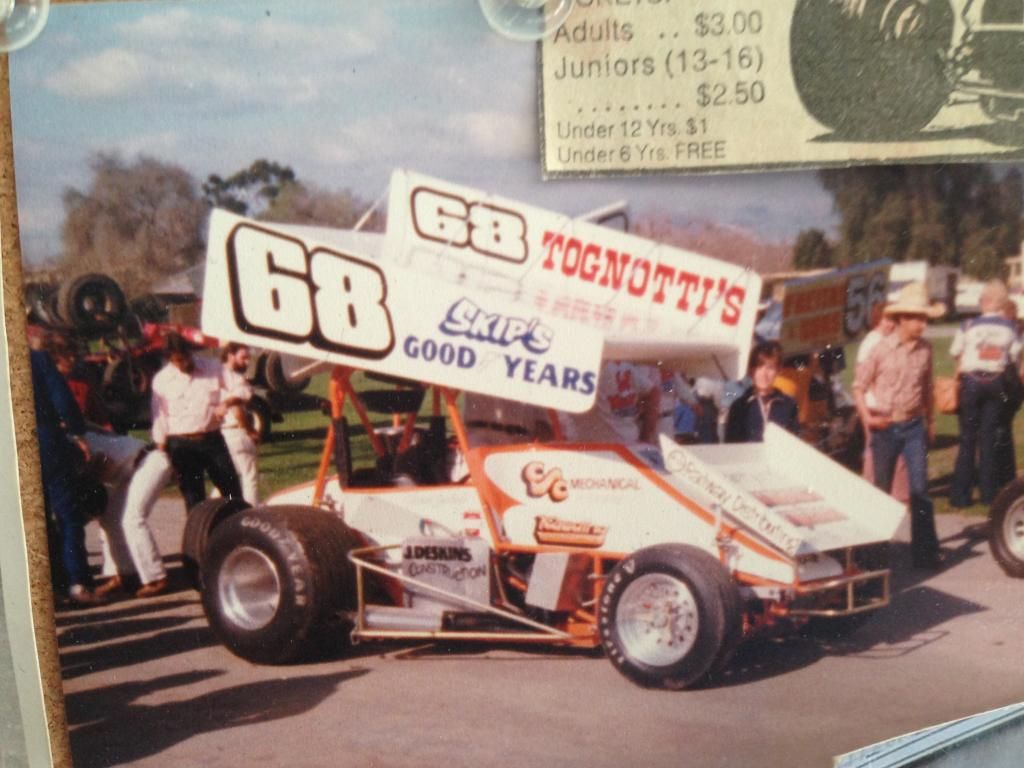

This car is actually 69 which was driven by Brent Kaeding. The pictured car at the top is the 68 of Howard Kaeding, Brent's dad. They both had identical cars except for the number and that is the picture I built from. Both those guys were multi time champions in supermodifieds and sprint cars and now Brent's two sons Tim and Bud are also multi time champions in sprint cars. They have a speed shop in San Jose. Quite the family.

-

-

I have built a 1/12 scale model for the first time. All scratch built with styrene, aluminum and fiberglass just like the 1/8th scale guys I always do, this is just smaller.

I have built a 1/12 scale model for the first time. All scratch built with styrene, aluminum and fiberglass just like the 1/8th scale guys I always do, this is just smaller.Here is the real car. Built and now raced by Mike Sargent on the West Coast. A new vintage car with old style body and frame and modern running gear, motor and safety equipment.

-

Thank you guys. Ray, I have built stuff my whole life and I am 68. I have been at his model building stuff for 5 years now, every day, practically. I spend a lot more hours than most people do building.

-

-

-

-

I build race car replicas for people all over the country. Mainly sprint cars and supermodifieds but some stock cars. I build all my cars out of styrene tube or rod. Of it is a space frame it will not sag with tube because of all the different pieces used in a frame like that. If it is a single tube frame then use styrene rod because it's solid. My cars end up weighing around 4 lbs when complete and the frames, and axles are all styrene. I even build slot cars, that really take a beating, out of styrene. When I first started this 5 years ago I did use brass tubing because that's what I was told that would hold up best. Well it does hold up but why go to all that trouble and just make a good frame, with good connections out of styrene. Another tip is to use a tooth pick and spread the CA glue around the connection like a weld. I sometimes use JB weld on parts with a lot of strain.

-

-

-

I am replica of the most famous race car in Arizona, the Twister. It was built by Hank Arnold back in the early 60s and he won a bunch of races with it until he was killed in 67'. The car was found by a friend of his and restored and the guy live a few miles from me. It has a Chevy 283 with a blower and Hilborn injection.

-

-

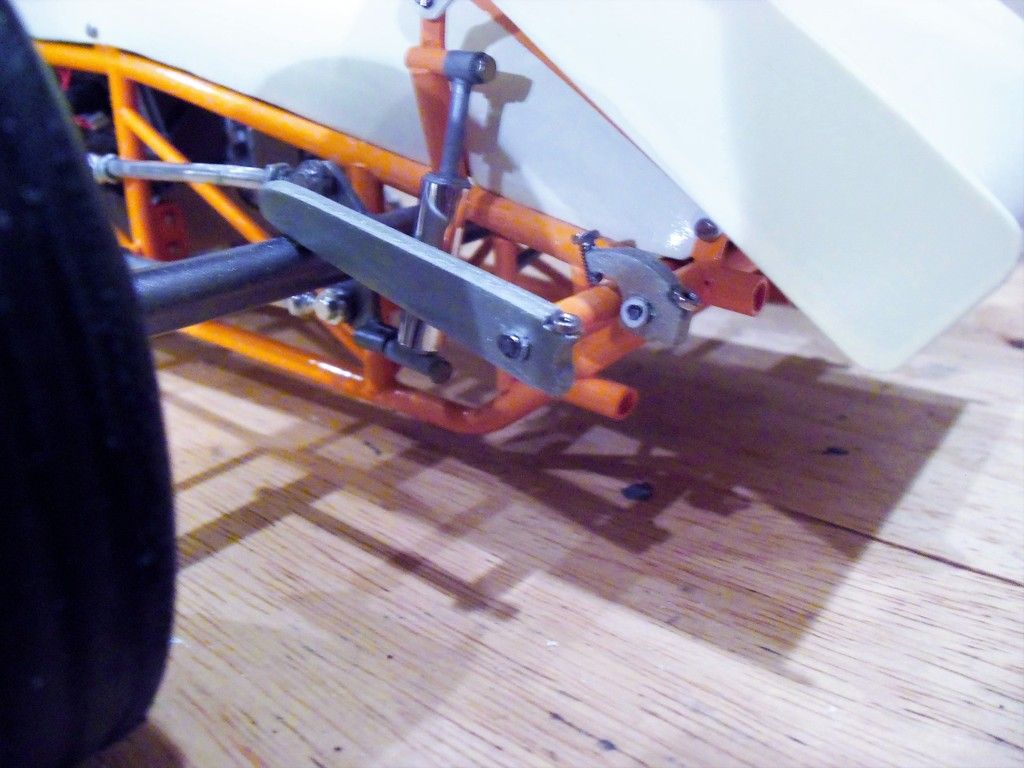

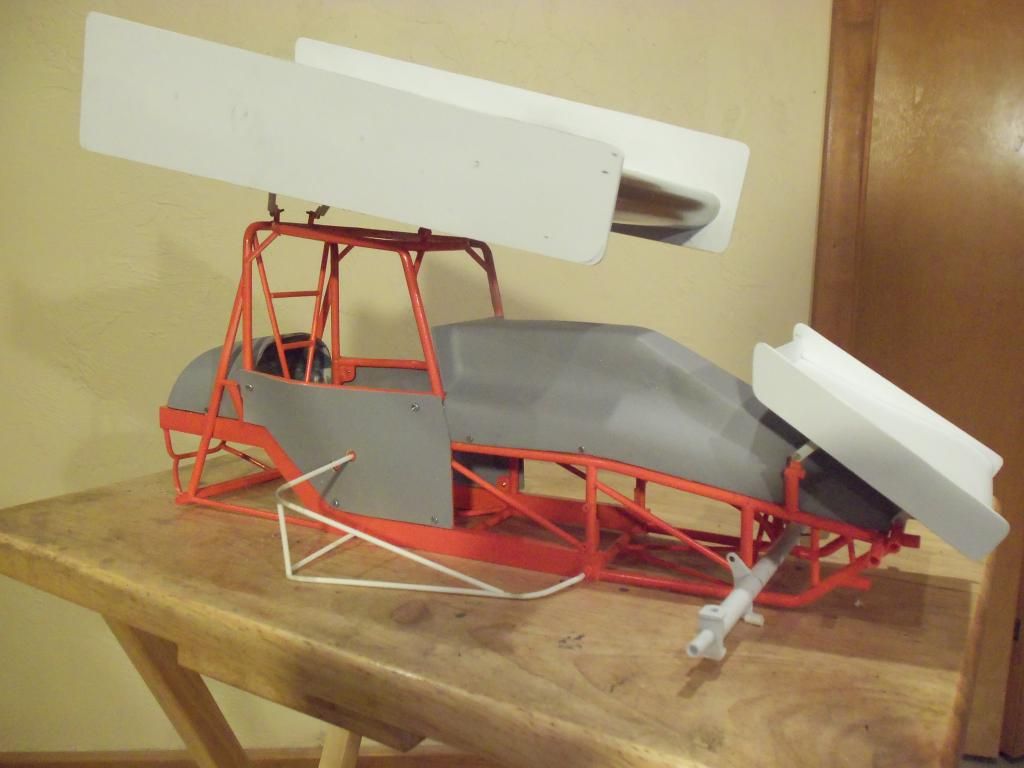

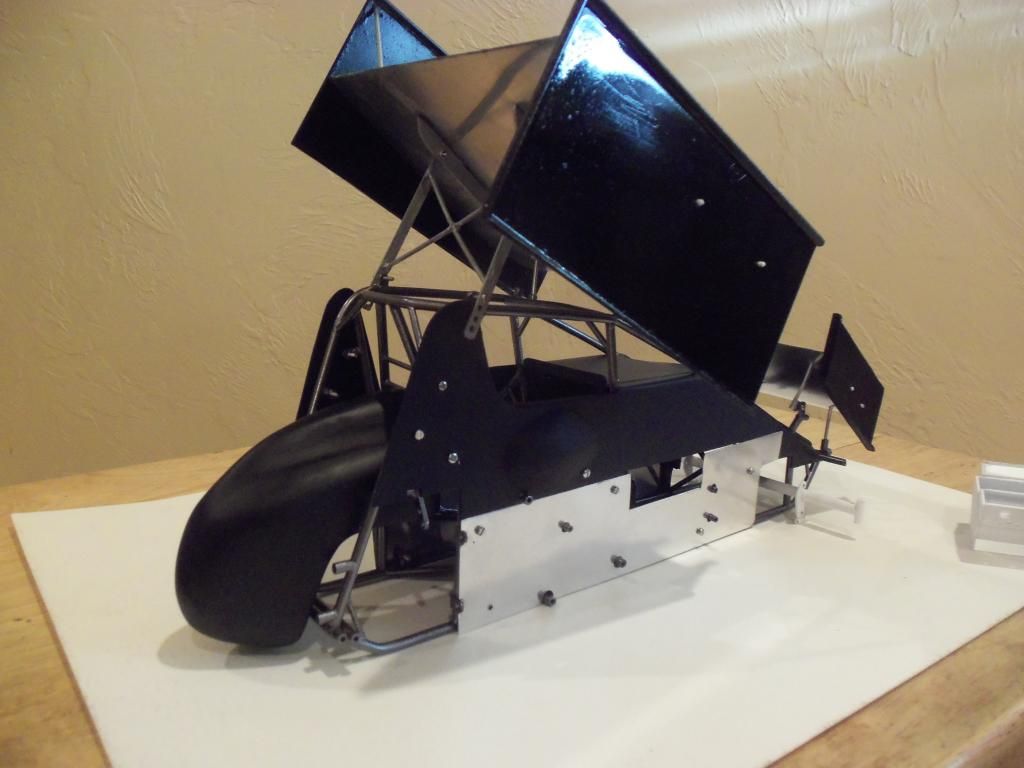

In the late 70s the pavement track in San Jose closed down. It had been around forever. The fair grounds opened a 1/3 mile dirt track that drew all the guys who raced the pavement plus some. They first ran their asphalt cars then built new dirt supermodifieds. Also at this time wings grew bigger and bigger. It really help get the car into the corner but they also caused wrecks from touching wings not wheels. I am building a 1/8 scale replica of Brent Kaedings dirt supermodified from 80. Crazy giant wings and all.

In the late 70s the pavement track in San Jose closed down. It had been around forever. The fair grounds opened a 1/3 mile dirt track that drew all the guys who raced the pavement plus some. They first ran their asphalt cars then built new dirt supermodifieds. Also at this time wings grew bigger and bigger. It really help get the car into the corner but they also caused wrecks from touching wings not wheels. I am building a 1/8 scale replica of Brent Kaedings dirt supermodified from 80. Crazy giant wings and all. -

You're right Chris, that would be fun. I have wanted to do that since I started building models 4 years ago. Because I build these for customers, I usually never have more than one completed car. As soon as they are finished they are shipped of. Still I would like to bring what I have then and check out all the cool builds from all the talented people who also enjoy building model cars.

-

For the last 4 years, since I started building models, I have made everything in 1/8 scale. It's easier to see and make parts for. The problem is what do you do with something that big to display. I decided to try a smaller scale. I drew plans and started building a 1/12 scale modern sprint car. I doubt I will ever go smaller but this is a nice size. The 1/8 cars are 18" long and this one is 12" long so about 1/3 smaller.

-

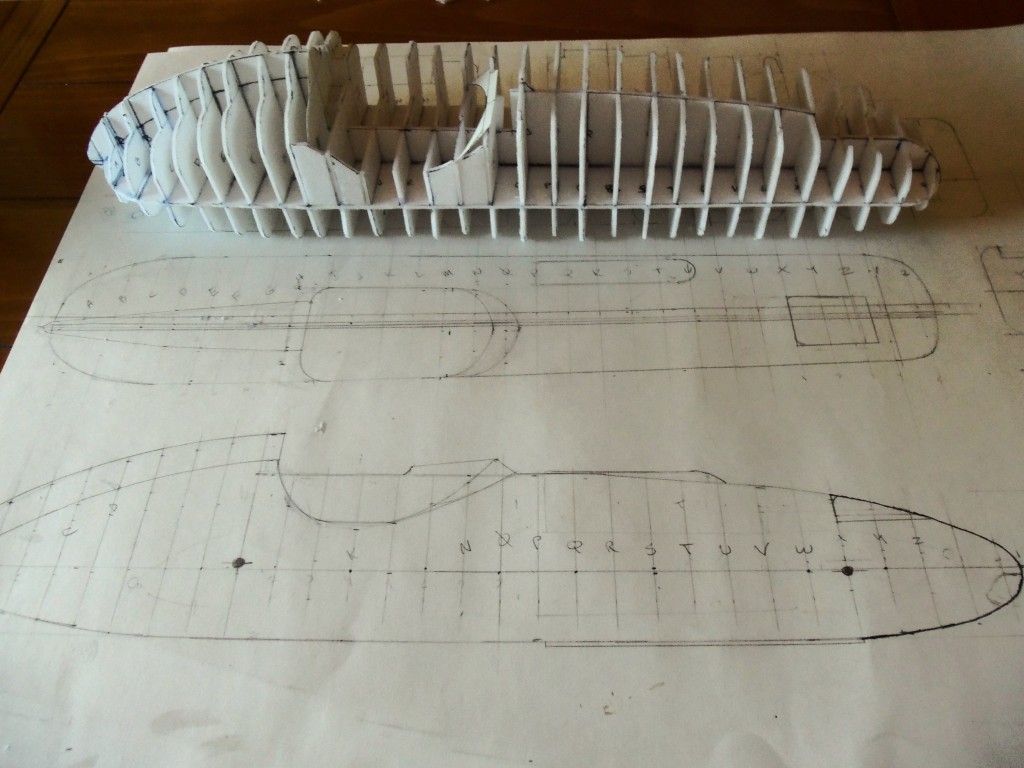

Thank you. I make what I call a buck. Sort of like building a balsa wood model plane. I have sections or solid ribs every 1/2" to 1" apart glued to a center section cut to the profile I want. Then I glue poster board or heavy paper to the ribs which gives it the shape. I paint that with some kind of paint that's left over and smear petroleum jelly lightly all over the surface. Then I lay medium fiberglass cloth and spread resin over that. When dry, usually the next day, I sand it to get any big bumps out and put on another layer of glass and resin. Again sand it a little bit smoother this time and put a third layer of glass and resin on it. Again waiting until it is dry I apply one more coat of resin to the whole thing. I leave it on the buck and sand it smooth and fill in any low or nasty looking spots with Bondo. Then I strip the buck out and wash of the jelly residue and cut it to fit wherever I need to on the frame.May i know how you facricate the body shell,.. its amaze me how well you make it

Here's a picture of a buck, before it gets covered with paper. This is an Indy roadster and it is so big I used 1/8" foam for ribs, which is easier to strip out later but I like the styrene better. It's kind of a mess at first but it works great. I am building another one of these sprint cars right now and if you want I will take pictures of the process. Once you can do this the sky is the limit. You can build anything.

Here's a picture of a buck, before it gets covered with paper. This is an Indy roadster and it is so big I used 1/8" foam for ribs, which is easier to strip out later but I like the styrene better. It's kind of a mess at first but it works great. I am building another one of these sprint cars right now and if you want I will take pictures of the process. Once you can do this the sky is the limit. You can build anything.

-

I will. It's still dangerous but not as bad as a weekly sprint car show. You have to be over 40 to even drive one of these. That's the rule and they are considering making it 50. So as fast as I think I use to be, I also realize the importance of not driving over my head or making moves that might startle the other guy.Ken, have fun with your new hobby," VINTAGE RACE CARS". Be safe and have FUN !!!!!

CHEERZZZZZZZZZZZ!!!!!!!!!!!!!!!!!! MADD FABRICATOR

-

-

I built this mock up of a car I designed and am going to build starting next month. I will race this in vintage shows in the west. The cars have to look like supers from the 70s and have a buggy spring front with a beam axle, and a roof. It will be a 410. They can't have more than 6" of offset so I moved the motor over 3" and the axles over another 3" then tilted the engine 30 degrees for left side weight bias.

I built this mock up of a car I designed and am going to build starting next month. I will race this in vintage shows in the west. The cars have to look like supers from the 70s and have a buggy spring front with a beam axle, and a roof. It will be a 410. They can't have more than 6" of offset so I moved the motor over 3" and the axles over another 3" then tilted the engine 30 degrees for left side weight bias. -

-

I'm locked out of my thread about the Beck Pavement Sprinter. I didn't cuss, call anyone names, post lewd pictures and do anything I haven't done for the last two years here. What is the problem? I'm sure this will get deleted fast so hopefully someone will see it and fix the situation.

1/12 Scratch Built 70s Supermodified

in Other Racing: Road Racing, Salt Flat Racers

Posted

That's cool and thanks. If you ever want to know how to build something, let me know. I am always glad to share what I have learned in scratch building race cars. I don't know a thing about kits though.