-

Posts

5,815 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

Testors Aluminum plate.

Straightliner59 replied to Mike 1017's topic in Model Building Questions and Answers

I'd recommend Parafilm, as a masking agent. It conforms better than tape. It sticks and masks, and it doesn't lift the paint. I've had very good luck, with it. -

There are still a few, there. I bought a couple of boxes of assorted sizes from a place in MN, that no longer seems to be there--I bought a couple of boxes of 50, of assorted sizes for $25 each, and free shipping! Sadly, they seem to be, no more. Most of those I find, now are boxes of single-sized bits (which is fine, like you say, if it's a size that's frequently used) at $25, but with added shipping. $.50/bit is pretty dang reasonable, though!

-

I only started using the carbide bits, a couple of years ago. While I still use my regular bits, as well, wherever possible, I prefer using the carbide bits, because they're made not to "walk", when they're started. That makes them an excellent choice for boring rod and hex, in the lathe. Yes, they're brittle, and I go through them, but, I've countered that, by having a few hundred on hand!?I seem to have a thing for drill bits. And pinvises--I probably have a dozen of those, too. I may need an intervention!

-

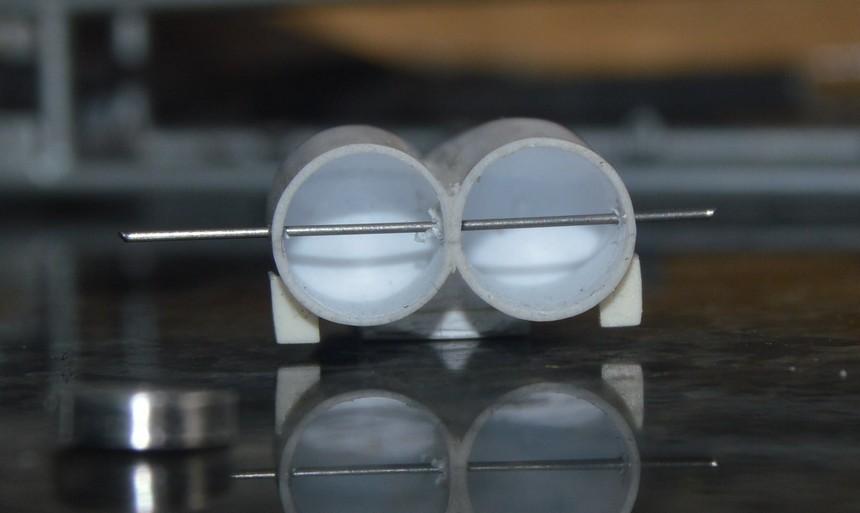

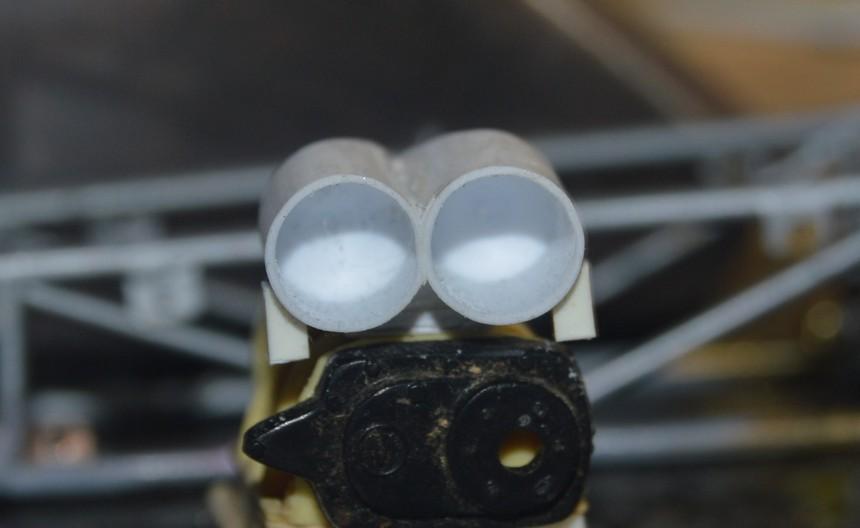

I got some more work done on the hat. Here are the butterflies and the cross shaft, inserted into the hat. I didn't push the butterflies into the injector, because I'm not sure I could get them back out! I probably could, but, why risk damaging the injector, right? I am having to cut a small piece of angle stock, to offset the barrel valve, as it doesn't clear the blower. It's a minor deal. I am thinking about painting the hat yellow, as a Surfers tribute. I've also added a couple of shots of the data recorder I built when I was originally working on the car. I just was going through an old issue of Car Craft's Drag Racing magazine from the late '80s that has a nice article about RacePak data recording systems. It will help some, with sensor locations, etc. I think it's cool, the way the paint has chipped off the metal case. I won't be touching that up! Mike Ditchen--I have also attached a few pics (Mark Brown hated "pics". It's the main reason I so rarely use it.) of the bucks I made, to form the nose and tail sections. As you can see, I also soldered them on the bucks. As always, questions, comments and critiques are welcomed. Thanks for looking!

-

That, my friend, is killer! Beautiful work, Ian.

- 352 replies

-

- 3

-

-

- brass

- tube chassis

-

(and 2 more)

Tagged with:

-

Thanks, Ian. I think that's exactly what I'll do--leave it alone, except for refining the shape, and polishing the plastic. I punched a couple of discs for the blades, and they're a few thousandths too big. Rather than try to sand them to fit, and keep them round, I ended up turning some aluminum rod to fit the openings. I figured it wouldn't matter, since I'm not making them operable. Mike, the tail section and the nose are hammered and soldered tin sheet. For the tail, I formed the top and sides over a buck, then used the same buck to shape the bottom. After that, I just soldered the parts together, and took a file, and emery cloth to them! Happy New Year, to you, as well, my friend! I am very appreciative of your comments, Francis. To receive a compliment from an accomplished modeler likely means more, to me than contest success. Thank you, very much. I will continue to share the things I figure out, until someone tells me to shut up! ?

-

Maybe they should just make it a two-headed snake, one head for the marketplace stuff, like Amazon (I buy a lot of my tools and supplies, there, so I appreciate having that option), and one for collectibles. Or just make it easy for a seller to differentiate what they're selling, between the two. This kind of junk is why I don't run a company--I would be sadly incapable!

-

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Those are awesome, Francis! There are some applications in which plastic isn't the best option--most of the time, it's fine--as you continue to illustrate. Generally, it's due to a lack of strength. Again, sir, beautiful work, as always! -

I got started on the injector. I have envisioned this car with a Hilborn shotgun injector, since its inception. Ian's comments have only strengthened my resolve, that way! I only recall ever seeing one in (I think) an AMT Challenger kit. That one looked too short, to me. I haven't found a ton of info on them, either, and maybe 20 photos. I have found, though, that the openings are 5.25" in diameter, so, I can reasonably extrapolate from that. Here, the mounting bosses for the barrel valves are too long. They'll be sanded down. I used two short lengths of Plastruct 1/4" rod to create the main body of the unit. I would have used .100" triangle stock to flatten the bottom of the scoop, but don't have any. Fortunately, I have a package of .100" quarter round stock. That did the trick. I think the shape is pretty good, but, the unit might be about .040" too long (I'll probably just keep it, since shortening it would require moving the aforementioned bosses. It'll get cross-drilled for the blade shaft, and aluminum throttle blades will be punched. I'll go with an Enderle barrel valve, and a single pump. Questions, comments and critiques are always welcomed. Thanks for looking!

-

P 51 Mustang kits

Straightliner59 replied to cobraman's topic in Model Building Questions and Answers

MPC is the same as Airfix. -

Thank you, Joe! I really appreciate that! Thank you for your kind words, Bob. I'll try to keep stuff coming! Thanks, Ray!

-

Excellent work with the welting, Joe! That's a good idea, too!

-

69 pro mod chevelle, chassis started mock ups

Straightliner59 replied to mr68gts's topic in WIP: Drag Racing Models

Hell to the yeah! Your insanity is amazing! Excellent work, Paul. -

Thank you, Gordon. Thanks, Doyle. Thanks, Carl. It was a productive year--for me!