-

Posts

5,816 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Straightliner59

-

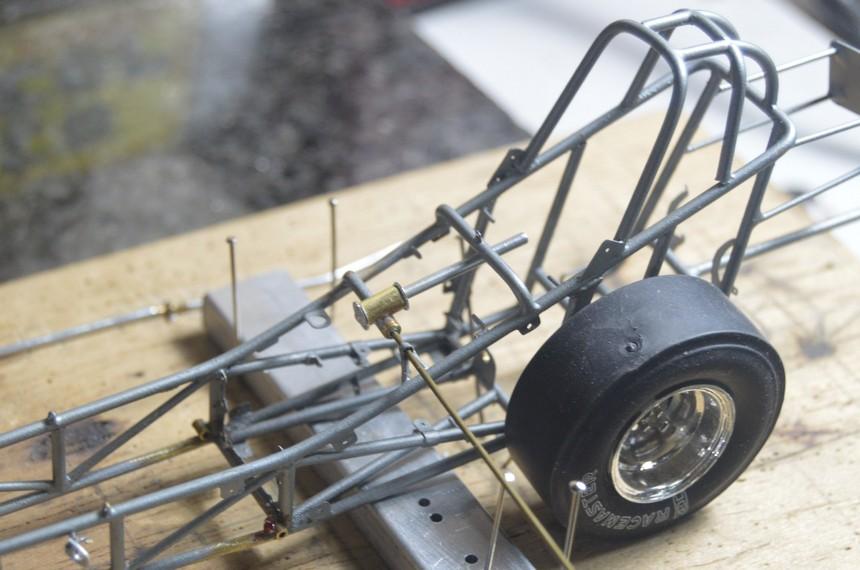

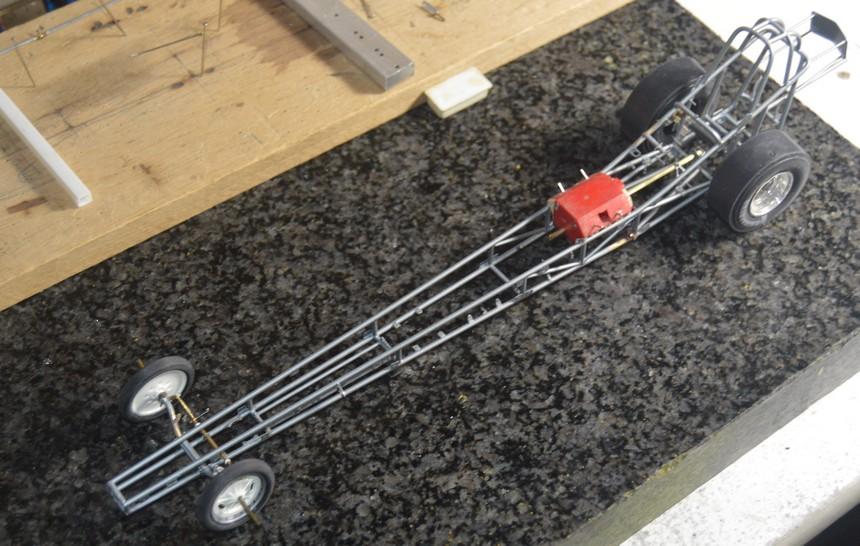

I would recommend it. I wouldn't recommend waiting for that, to start, though! Like I said--I built this entire chassis using a cheap Weller pencil-type iron. I still use it, frequently, as well. New resistance units can be very expensive. Generally, to piece a unit together, the most expensive proposition is the handset. There are instructions to build them, on the interwebs, but, if you can get a tweezers set for under a hundred bucks, you're not doing too bad. I had to make new ends for my tweezer cords, to adapt them to my unit. Anyway, if you decide to pursue it, let me know, and I'll help out as much as I can! To the subject at hand. Near as I can figure, I first began work on this project in late 1997, or early 1998. This morning is the first time, since its inception, that this dragster has stood on its own legs! What a fantastic feeling! I'm hoping to have a set of my new front wheels cast, soon. Heck, if I can find the components, I may just build a mate for the first one, and use it.. I did change up the mounting of the third-member brackets (inside from outside). I don't have the pumpkin in the car, at the moment, but, I have, so I know it fits. Once I have that installed, I will work on the brakes, and finalizing installation of the rear wheels. I have a couple of spots to clean up, as well, before I can respray the repaired areas. I may add some discoloration to the welds. That's ambitious. I'll have to give it thought. I'm very happy with the progress I've made with this heap! Please comment in whatever manner you'd like. Thanks for looking!

-

I've been making new mounting brackets for the third-member, from aluminum. I want to get the rear axle set up, so I can put this thing on the wheels! Many of you know this, some may not: This assembly is critical, where dragsters, FCs and fuel altereds are concerned (any vehicle that's sans u-joints). It's best to rigidly mount a solid rod that represents the c/l of the drivetrain, and keeps everything aligned, horizontally(This applies to things like old Fords, with a rigid torque tube driveline, as well). I'm finding this to be a lot of work. Some of it's quite challenging. I'm having a frigging blast! Your comments, critiques and questions are always welcome. Thanks for looking!

-

That's some fine brass work, Ian. Nicely done!

- 352 replies

-

- brass

- tube chassis

-

(and 2 more)

Tagged with:

-

Exactly!

-

Marcos, thanks for your kind words. Once you get used to working with brass--and other metals, you really begin to appreciate their versatility. If something's built properly, it's not coming apart! Unless you cut something too short, errors can usually be pretty readily fixed. It's a little more difficult to work with, because of its hardness, but, its advantages are multitude. For most of the time I've used it, I did all my soldering with a cheap Weller iron. I cobbled together my resistance soldering outfit on Ebay, for right at $100, about five years ago. I just kept searching for the equipment, until I found stuff I could afford, except for the foot switch. I think that cost me $10. Later, I found a better power unit for a great price! I really like the resistance rig!

-

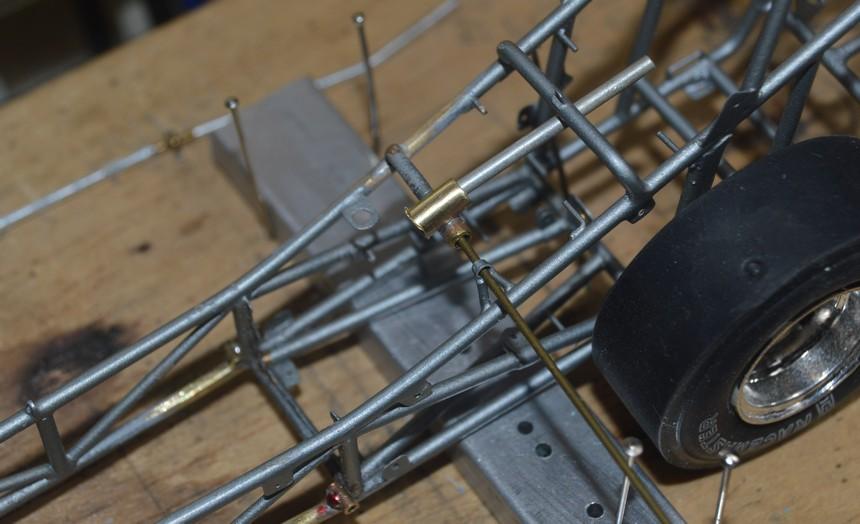

Inspired by Francis and Tim, I did some work between the lathe and the mill, to make the ends for the steering box. I've figured out how I'm going to mount the pittman arm, so that it will work as flawlessly as the tie rods do. I am very happy with the way this is going--so far--knock on wood! As always, questions, critiques and comments are always welcome. Thanks for looking!

-

I've started work on the steering box. Now, it's brass. It's still the same size as the plastic one I had, before. This will work much better! I'm in the process of making aluminum end caps, for it...I poured a new mold for the front wheel. It's curing, but, it's taking its sweet time! Not sure what the deal is, with this batch. It's supposed to be 8-12 hours. It's getting toward 24.

-

Those did clean up, nicely!

-

’72 Dodge Demon Drag Racer 1/25 scale

Straightliner59 replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Like you mentioned, Ian, replica building isn't for the faint of heart! Most of the time, even if you can find plenty of period photos for reference, most cars never remained the same from race to race. Back when I built my replica of The Bug, I had very little reference. I had the two-page spread, in the January '73 Hot Rod and two or three small black-and-white photos. At some point, a friend of mine went to Florida, and took pictures of the restored version, there. Of course, that was different than anything I had to that point! I showed the barest of bones of the project to Garlits at a World Of Wheels show in what must have been 1987 or '88. The line was held up, while he started telling me some of the technical aspects of the car--brakes, differential, trans, stuff like that. Long story shorter--the model is in Garlits' museum, as it has been, since 1992! My Cook and Bedwell may not be the right color of blue. I was convinced it was right, based on the color photo from the 1957(?) issue of Hot Rod's cover that featured the car. I'm now wondering if it's not a couple of shades too dark. C'est la vie! There's always that one more little bit of info that will have you shaking your head, and, often, your fist!? All that said, I like to have some leeway in what I'm building--collecting cool ideas from several sources, and combining them in one project. For me, it's important to keep the technical aspects of them correct, not simply limited to chassis and rollcage configuration, suspension setup, and other mechanical aspects of the car, but including graphics/paint that looks like it belongs, proper-era contingency decals, consultation of a rule book, in the case of race cars. Everything else is fair game! I'm looking forward to following this, my friend! -

Bravo!

-

Very nicely done replica. I don't recall anyone ever doing this car, before. I don't think even Barry Price did this one, and he did just about every dragster you could think of! Excellent work, Phil!

-

This looks very cool, Marcos. I like that the nose isn't a mile high, too!

-

Shirley Shahan’s Hornet Pro Stock

Straightliner59 replied to dragcarz's topic in WIP: Drag Racing Models

This is coming along, very nicely, Roger! I've been watching to get a promo, of one of these. I can't see the motor mounts in the photo, but, yours don't look really out of scale. -

Thanks again, Marcos. Balsa is the only thing I ever build on. I draw my guidelines--chassis centerline, axle centers, overall width and length, and, with dragsters, I usually draw the outline of the bottom of the chassis and the crossmembers, for use in layout. Simple lines work, I just use a single line to denote the centerlines of things added to the chassis. I can pin tubing or strips of other stock, to determine ride height. It's worked great, for almost 40 years! I solder on it, too. Never even set off a smoke detector. Give it a shot. I think you'll like it! Oh, and get yourself a bunch of straight pins, too. I'm no pro at moldmaking, either. Since I only make parts for myself, or maybe a friend, I just go for the most basic, quickest way to get it done! ? After I gave up on the rubber curing and dug out the part and cleaned it up, I got home from work, tonight, and all the wads of destroyed mold had cured. I don't have 48 hours to wait for rubber to cure. I'll mix the next batch hotter. I ordered this rubber, because the Oomoo I got about three months ago had set. I'm aware of its shelf life, but I have never had it go bad, that quickly!

-

Fan-freaking-tastic, sir! I use that hex stock, all the time. Congratulations, Andy. A beautiful piece of work.

-

Thank you, Marcos. Yes, it's my fancy balsa wood alignment thingie!? I just tweaked the steering components, a bit, to get everything aligned and give it a tidier look. I shortened the outer shafts of the tie rod, because I had some toe-in, before. I'm very happy with it, now! I "sleeved" these wheels, so they'd fit the spindles, and I would have a better visual on the alignment, etc. I'm about to put the sheering shafts back together, and devising a way to connect the joints. I think I am nearing a method, to that end. I expect to get that at least mostly done, on Saturday. I have been trying to make a working worm-and-sector steering box for quite a few years, and have made inroads, but, am not sure if I'm quite there, yet. I have the gears, it's just making a box that's small enough, to house them. We'll see... I had a setback, when I poured the mold for my front wheel. The rubber didn't cure properly. I'm not sure why. I didn't do anything differently than I normally do. Anyway, it took a while to clean that glop off the master. I'm going to mix a test batch of rubber, and just leave it in the cup I mix it in, to see if I did something wrong, or if it's a bad batch of rubber. Comments, questions, etc., are always welcomed. Thanks for looking!

-

Source for Number 11 Blades

Straightliner59 replied to Tom Geiger's topic in Model Building Questions and Answers

I did that, a while back. I think, for $10, I got 100 blades and a handle! -

It's looking great, so far. Seat is very cool!

- 352 replies

-

- brass

- tube chassis

-

(and 2 more)

Tagged with:

.jpg.19cef0bd83f73b4fdabfd81fc275e0ae.jpg)

.jpg.092e55e80cf22d425e0a514c588b0d7f.jpg)

.jpg.7c29971a6120606021747ff5597ba8ab.jpg)