-

Posts

1,350 -

Joined

-

Last visited

About my66s55

- Birthday 01/13/1945

Previous Fields

-

Are You Human?

yes

-

Scale I Build

1/24

Contact Methods

-

Website URL

https://www.facebook.com/3dprintsbyDoug/

-

Facebook

https://www.facebook.com/3dprintsbyDoug/

Profile Information

-

Full Name

Doug Craig

Recent Profile Visitors

15,042 profile views

my66s55's Achievements

MCM Ohana (6/6)

-

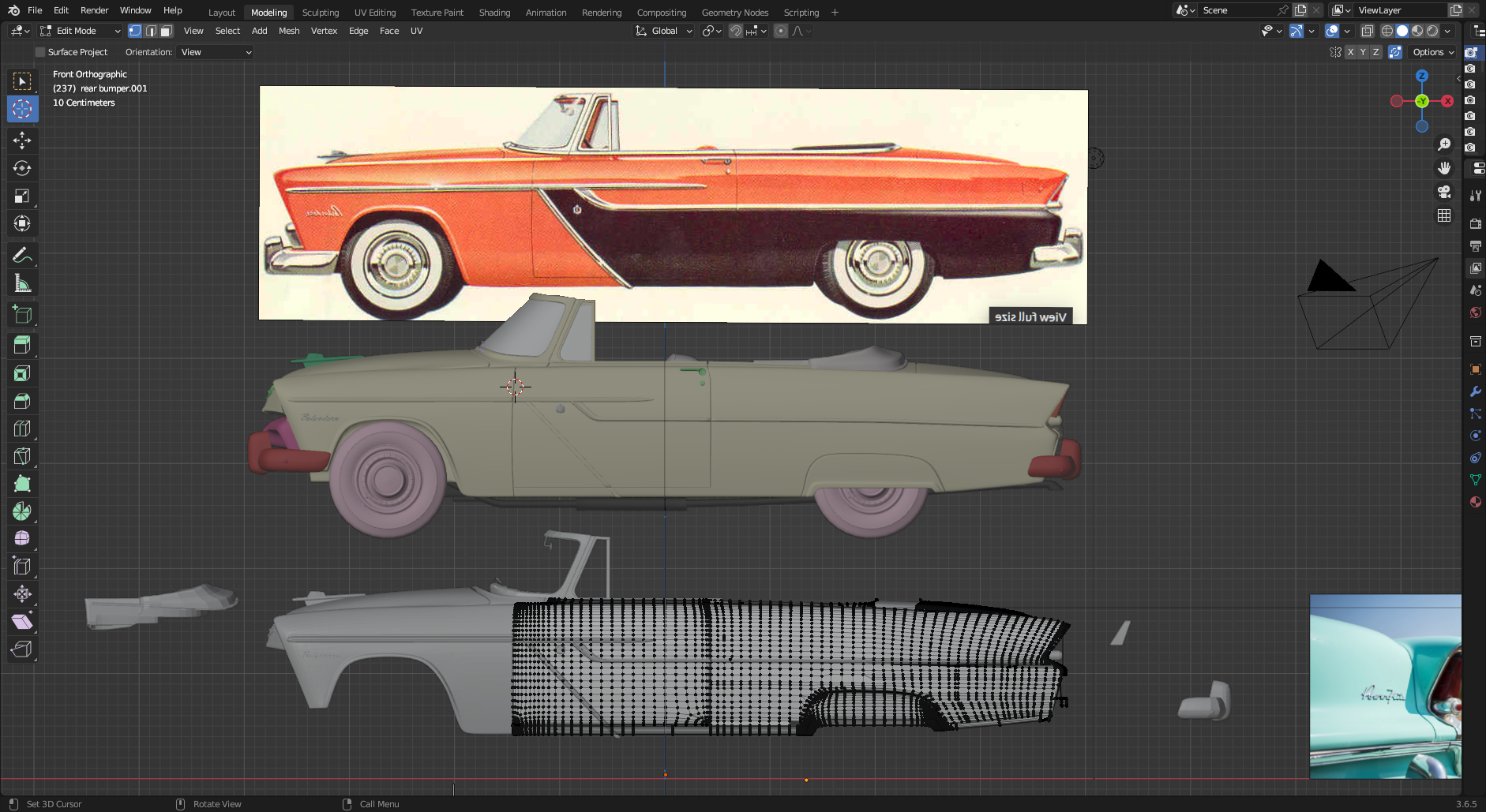

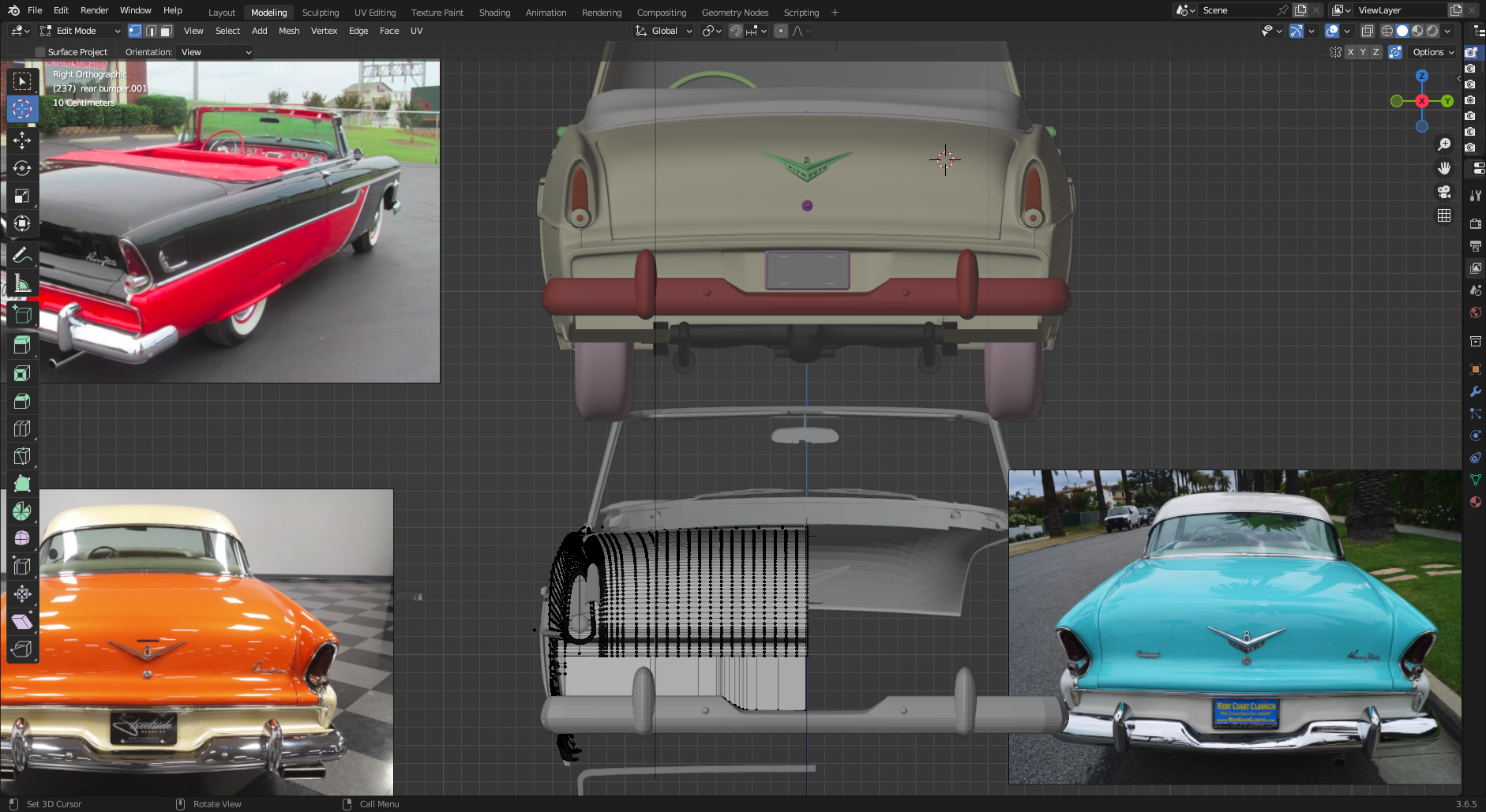

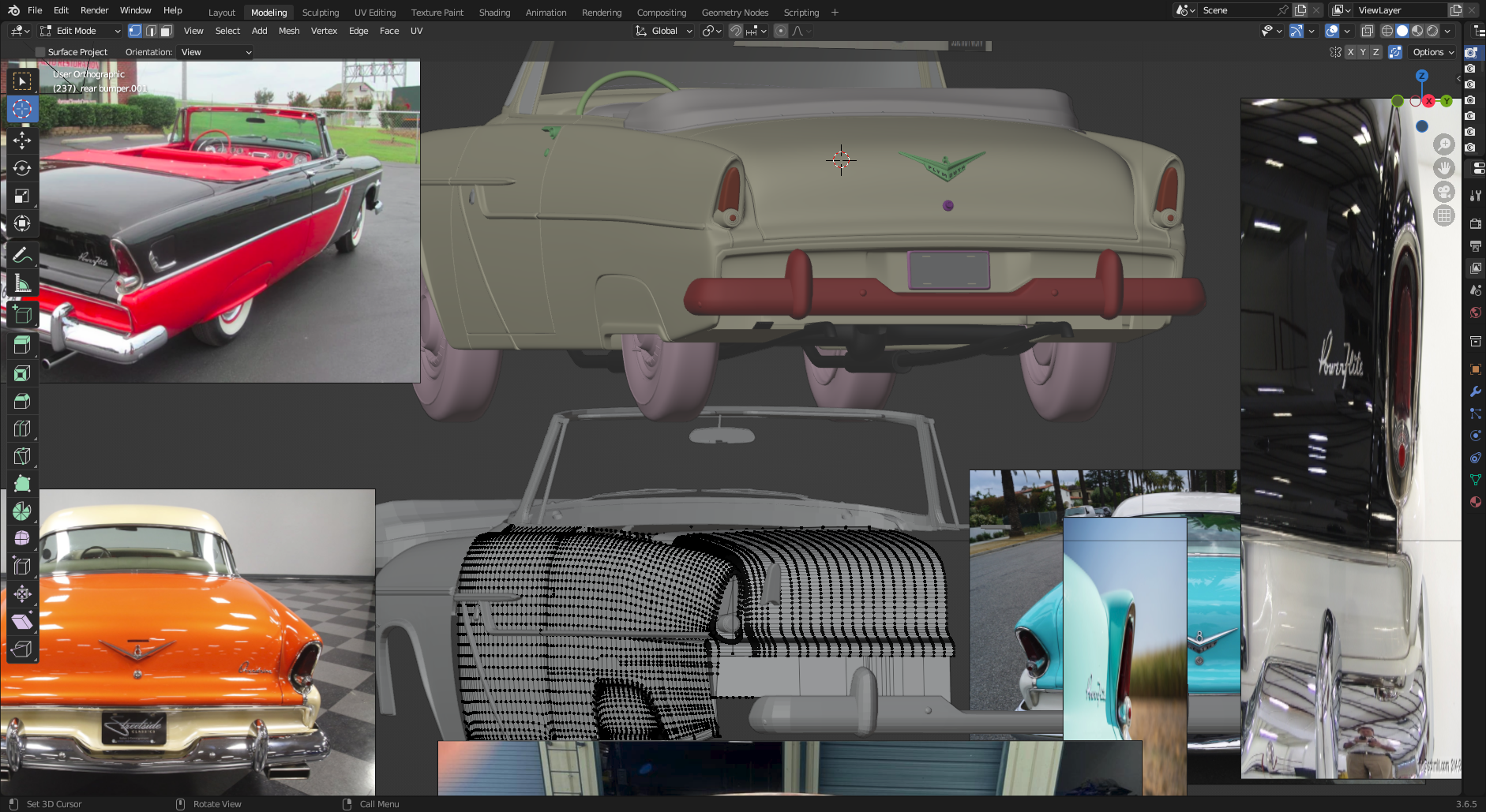

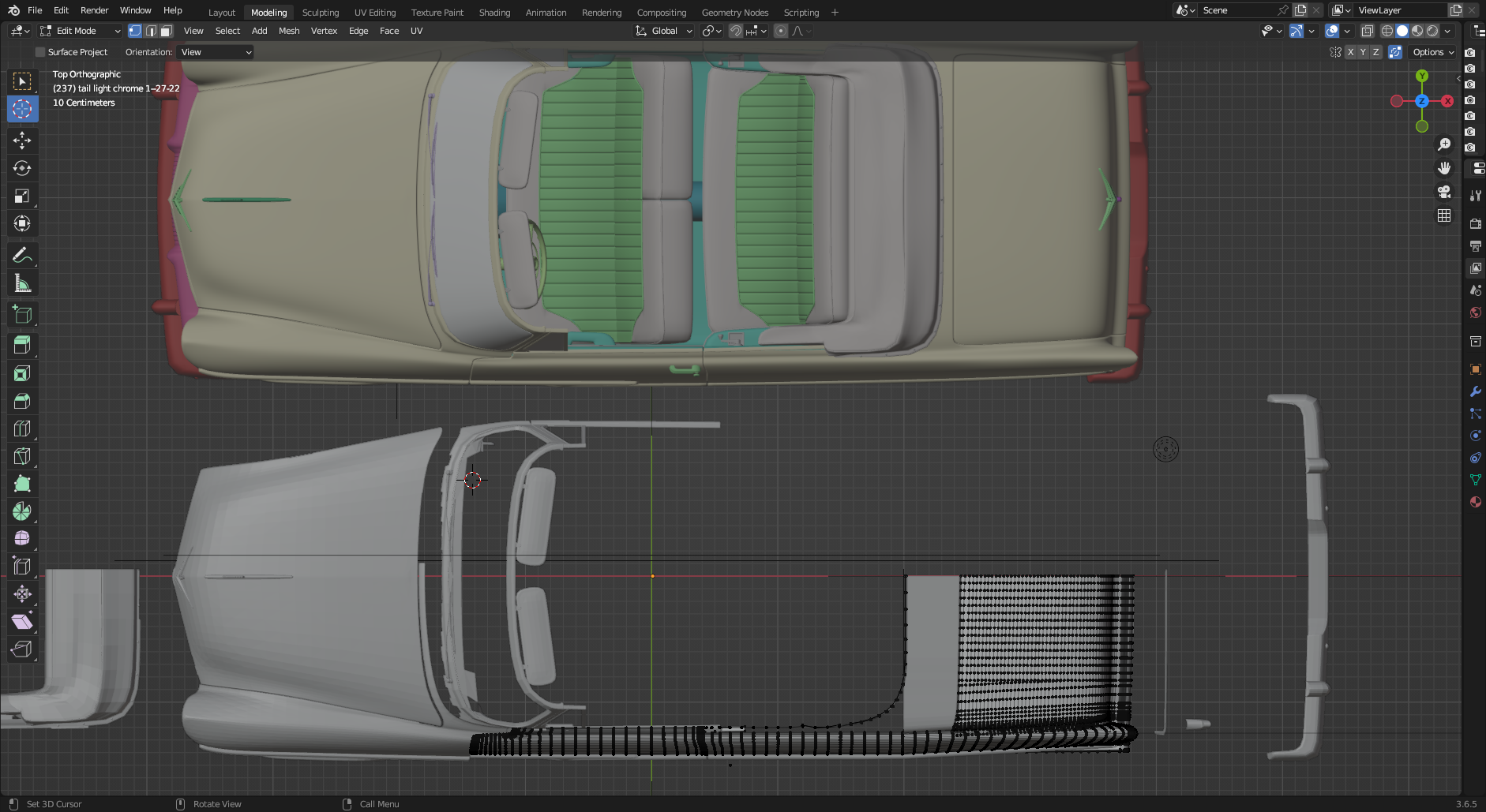

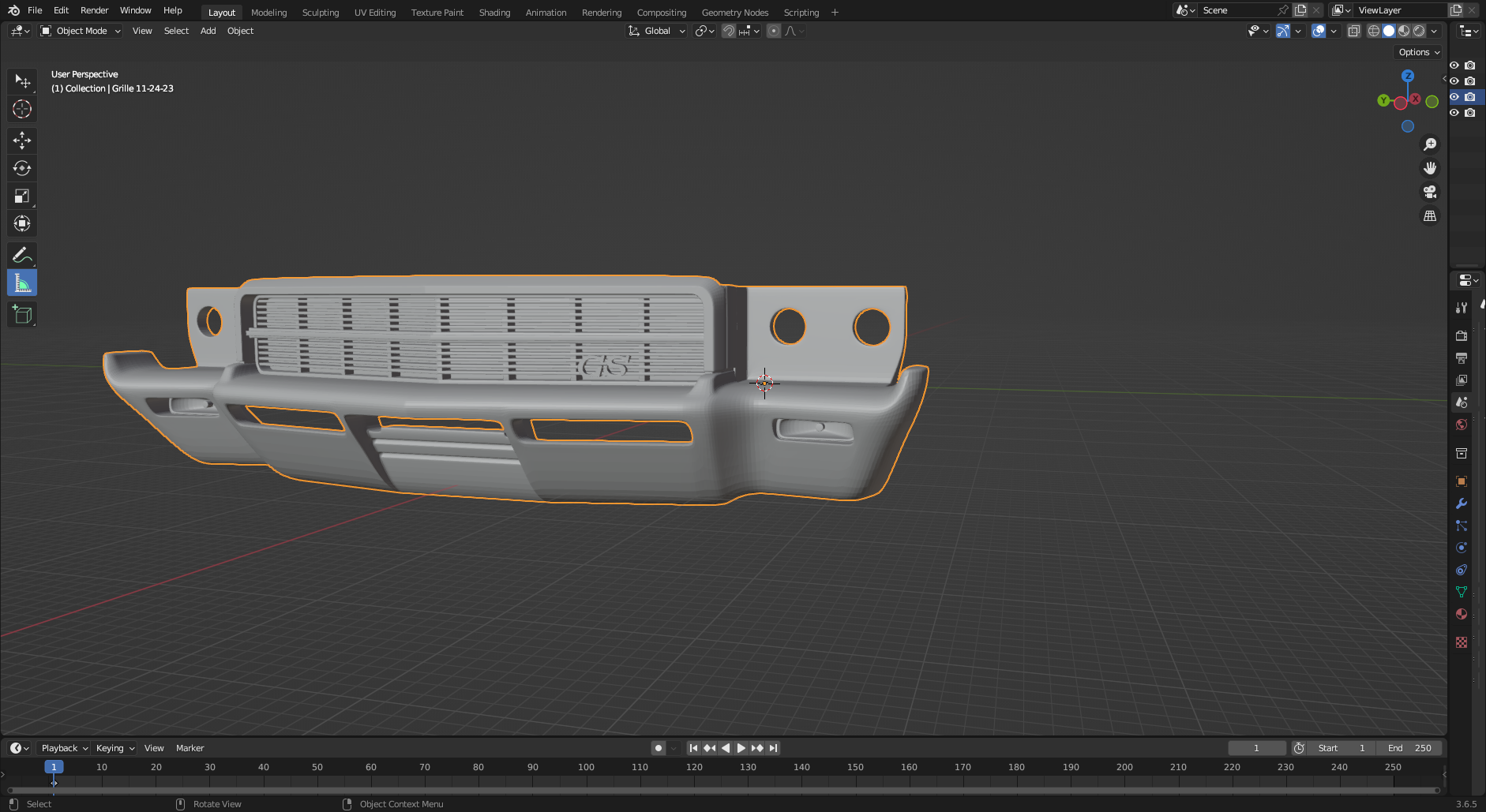

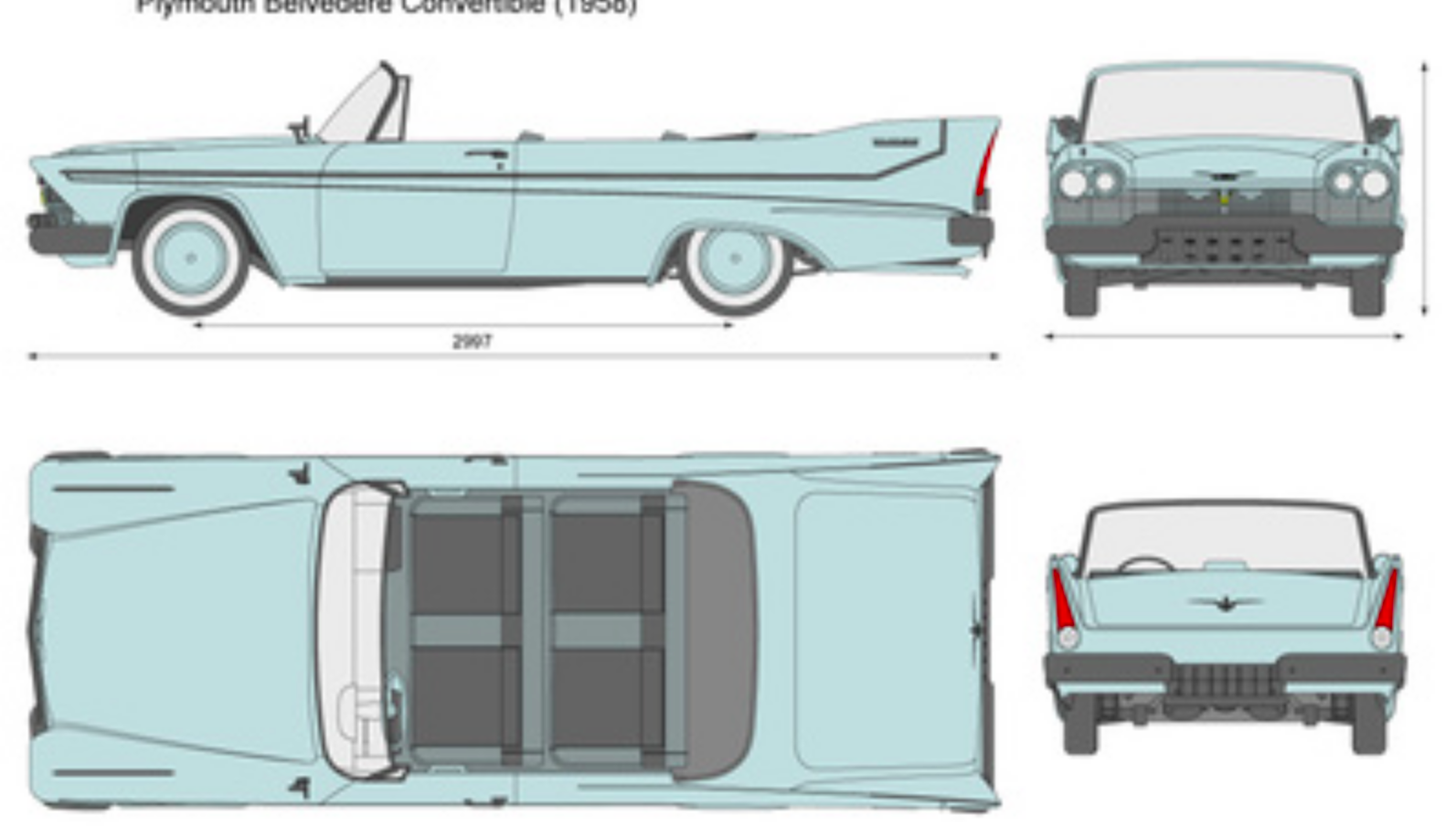

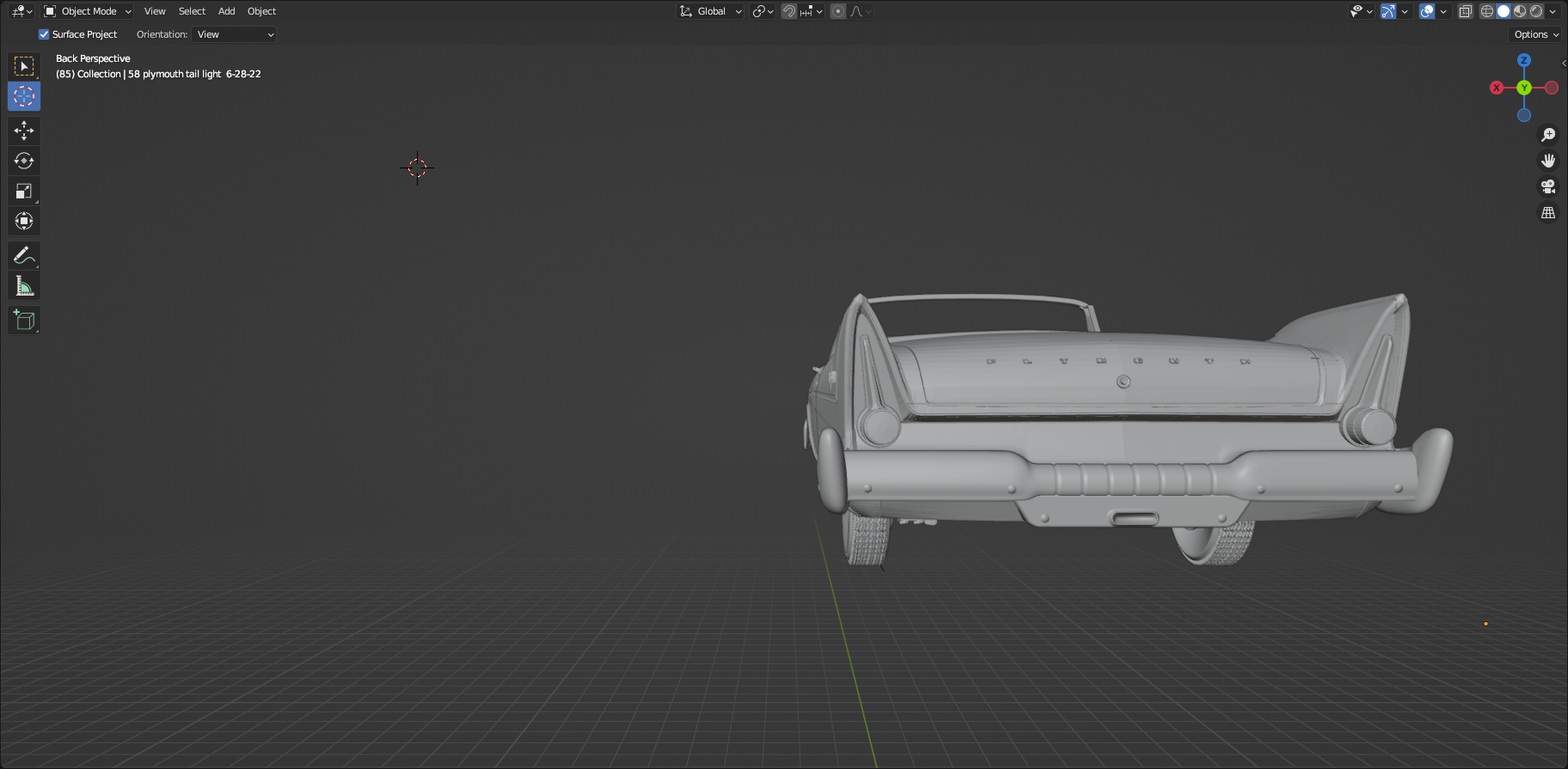

I get burned out from working on the same file and change to a different one. The Olds J2 engine is progressing well, but I switched to the 55 Plymouth Belvedere convertible that I posted a few pages back. I have redone the side from the start of the front door to the tail light as it was curved too much. The rear end from the tulip panel on back has been totally redone. Again, because of too much curve in the wrong place. The side chrome was redone as it was incorrect. The tail light chrome has been redone. The tail light lens needs redoing. I also need to fix the lower bottom of the rear fender and put the chrome on the back. The car on the top was the one I started with. The one on the bottom is the one I' working on. The area with all the lines and faces is what I have changed. I have a promo 4dr of this car. It helps a lot.

-

55-56 Mercury taillights

my66s55 replied to Lunajammer's topic in Model Building Questions and Answers

-

Dan's working on this for me. 1936 Buick Century coupe. Buick used the smaller Century and put the larger engine in it. Buick used a straight 8 over head valve engine. The car was very fast. www.macsmotorcitygarage.com/buicks-factory-hot-rod-the-1936-century/

-

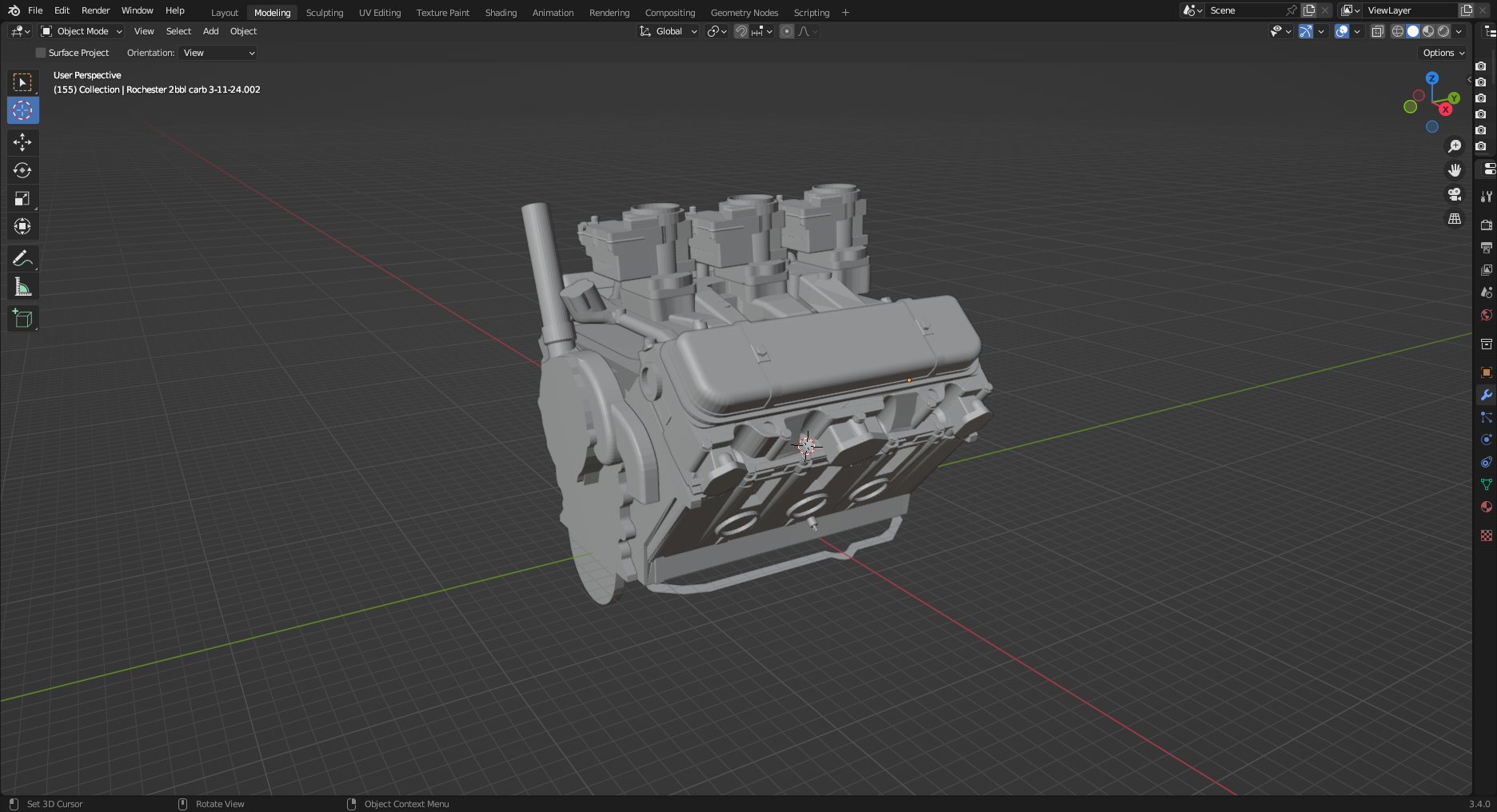

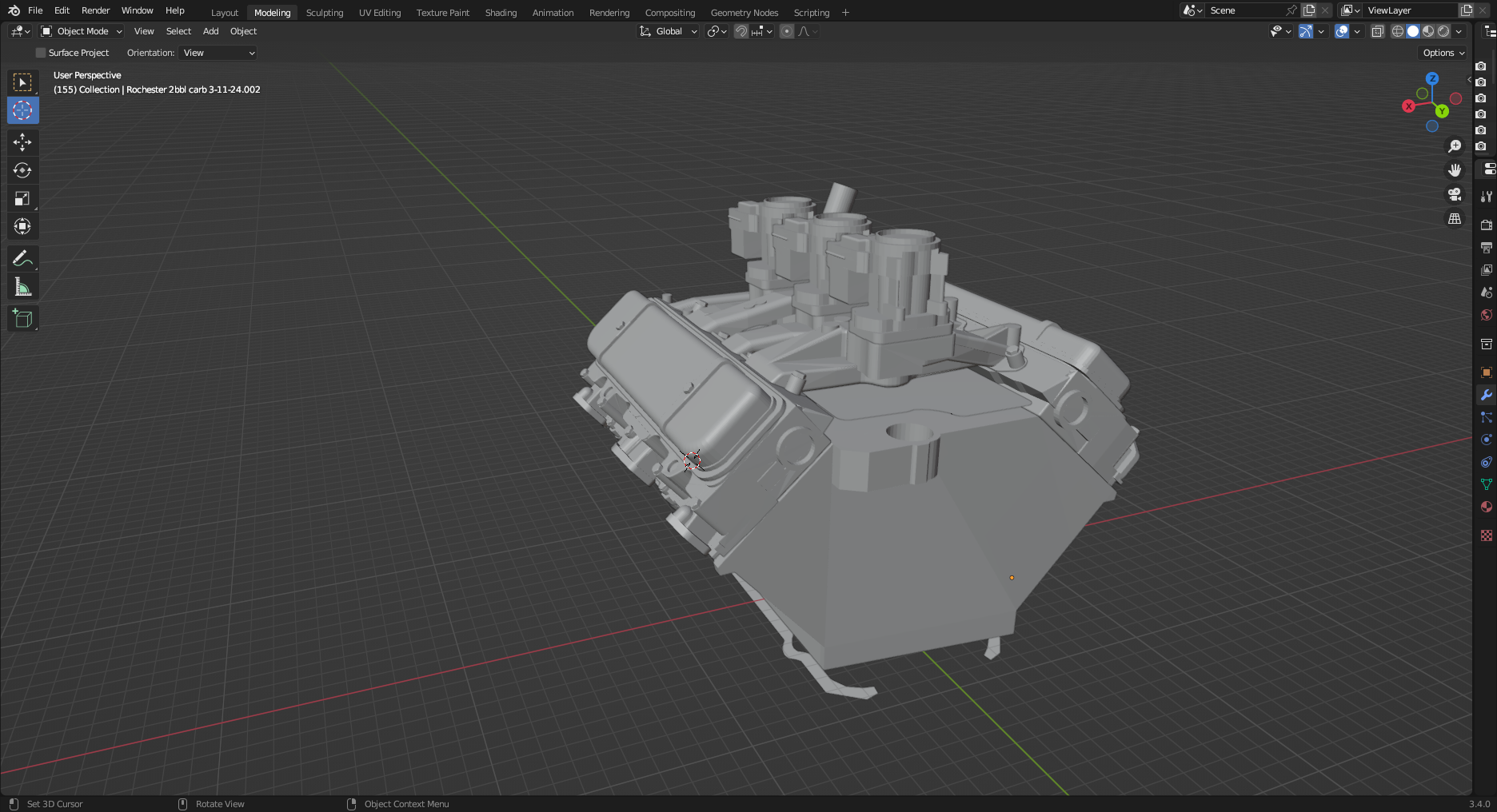

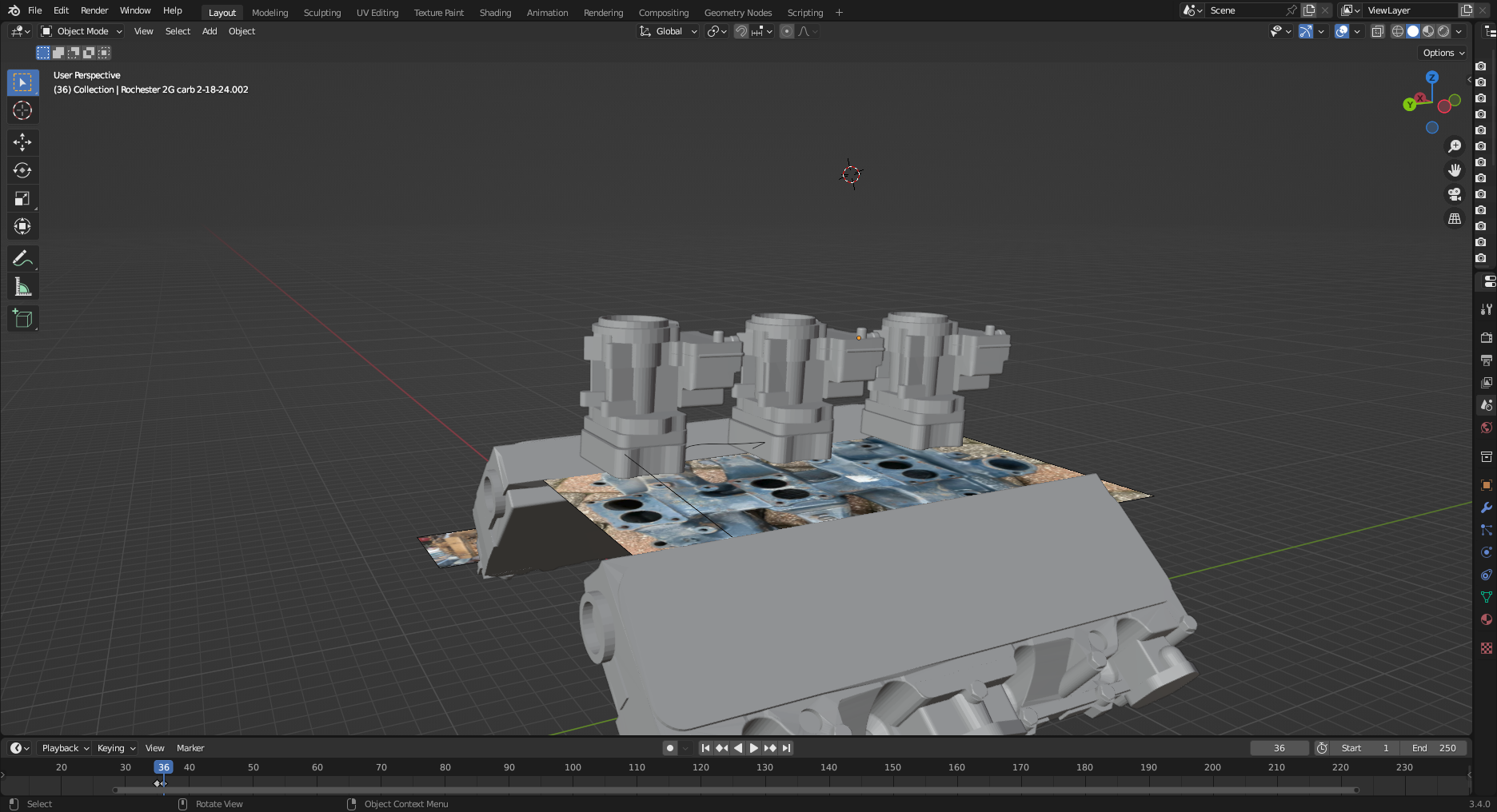

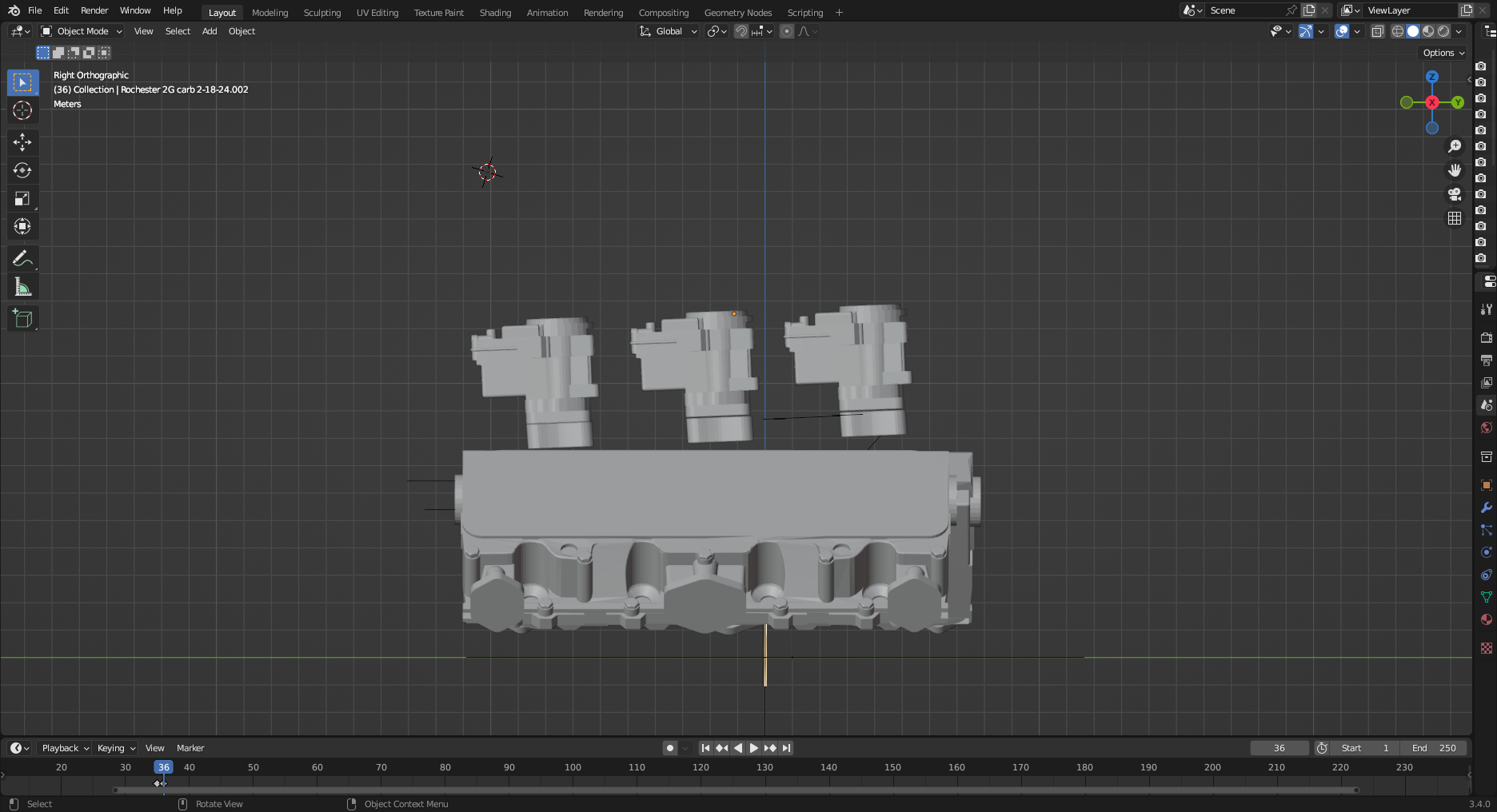

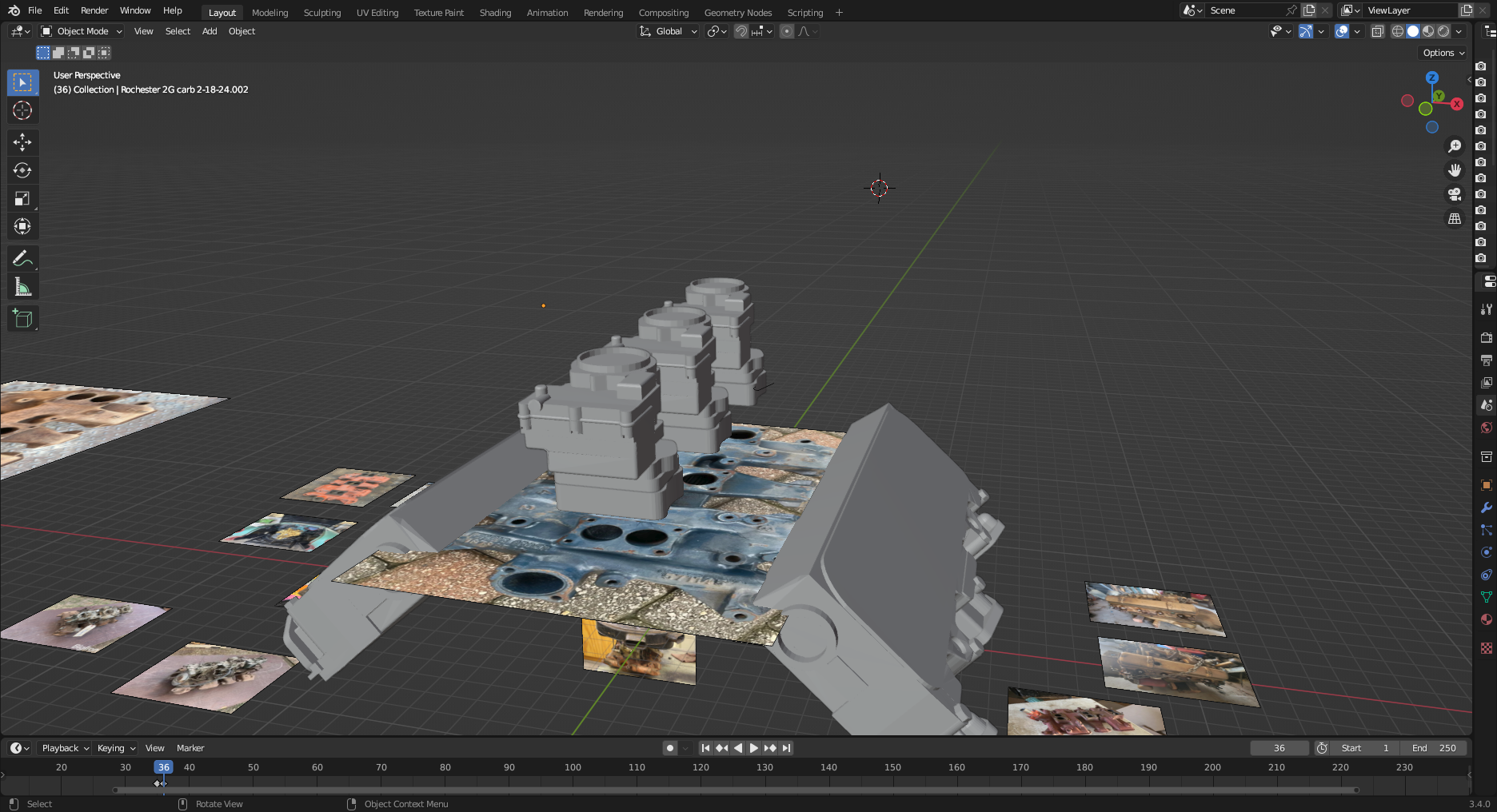

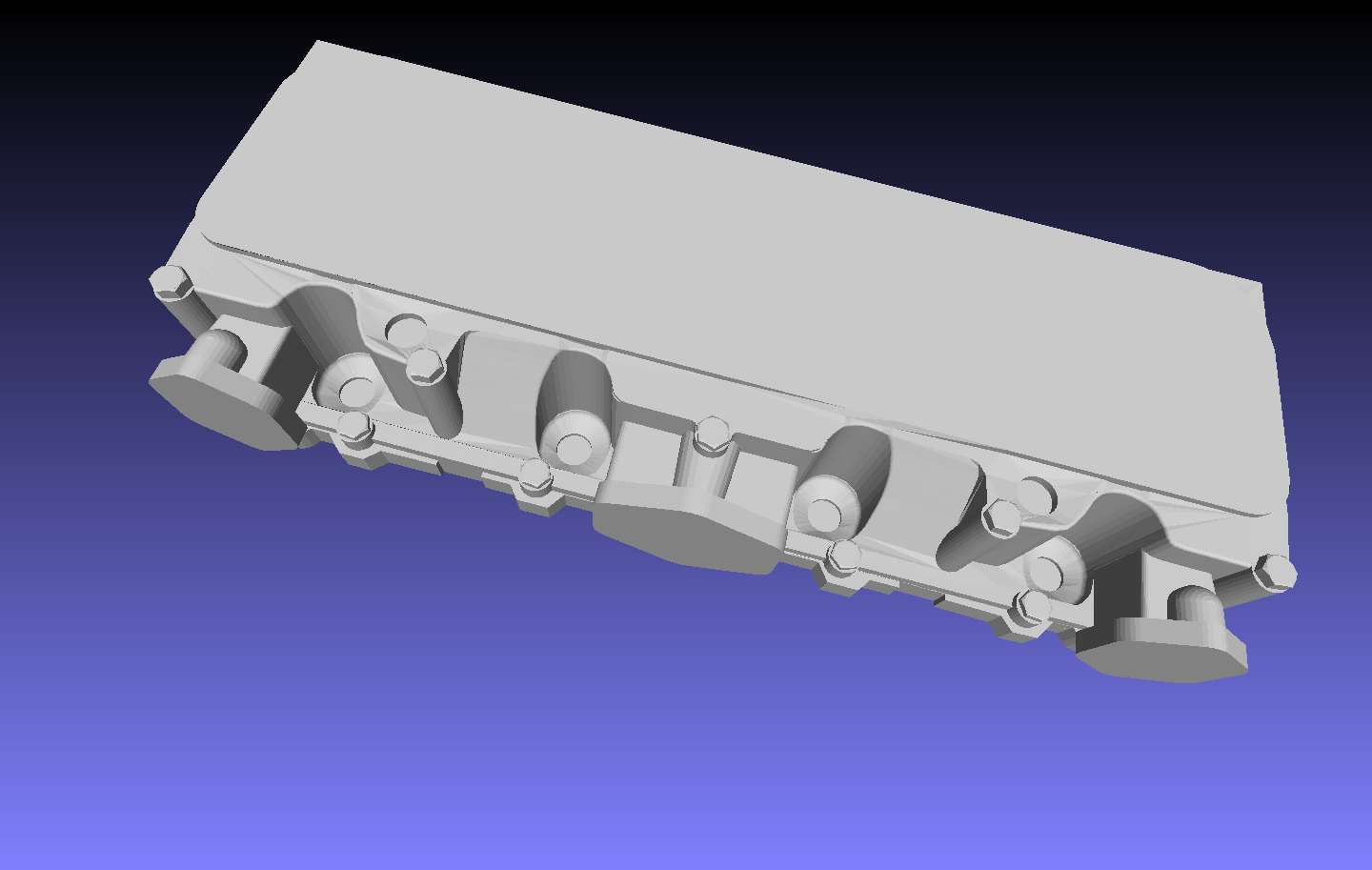

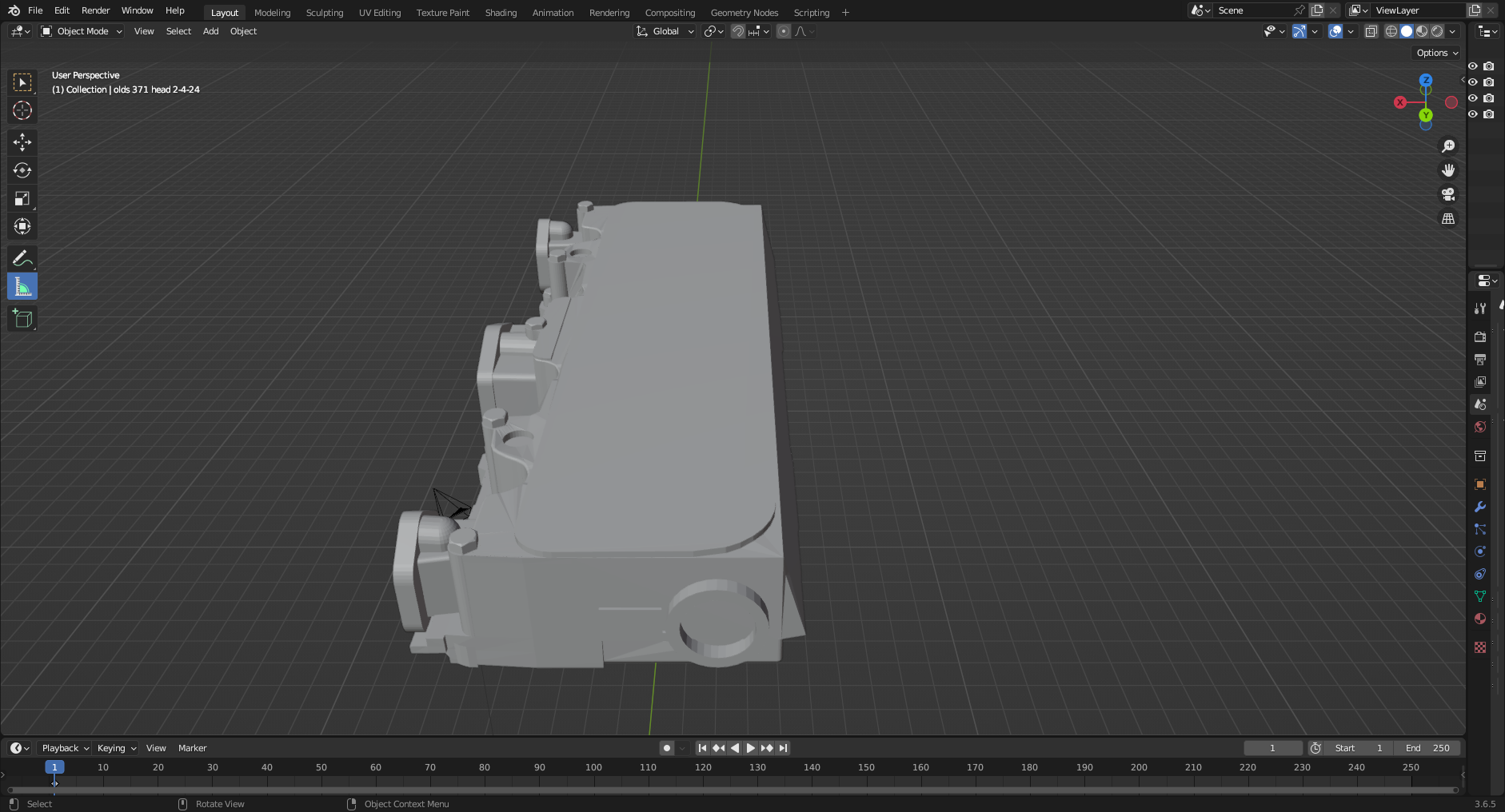

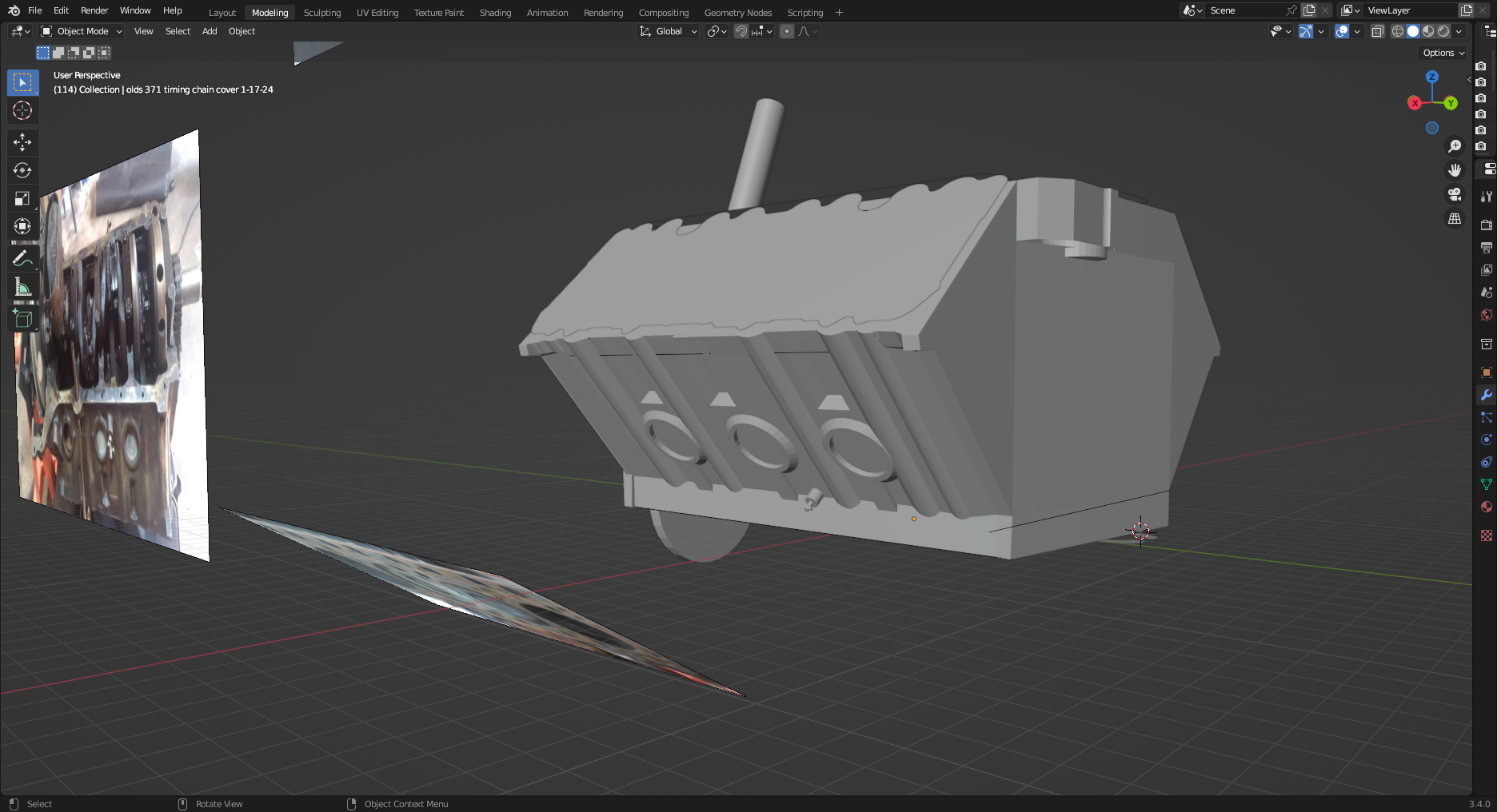

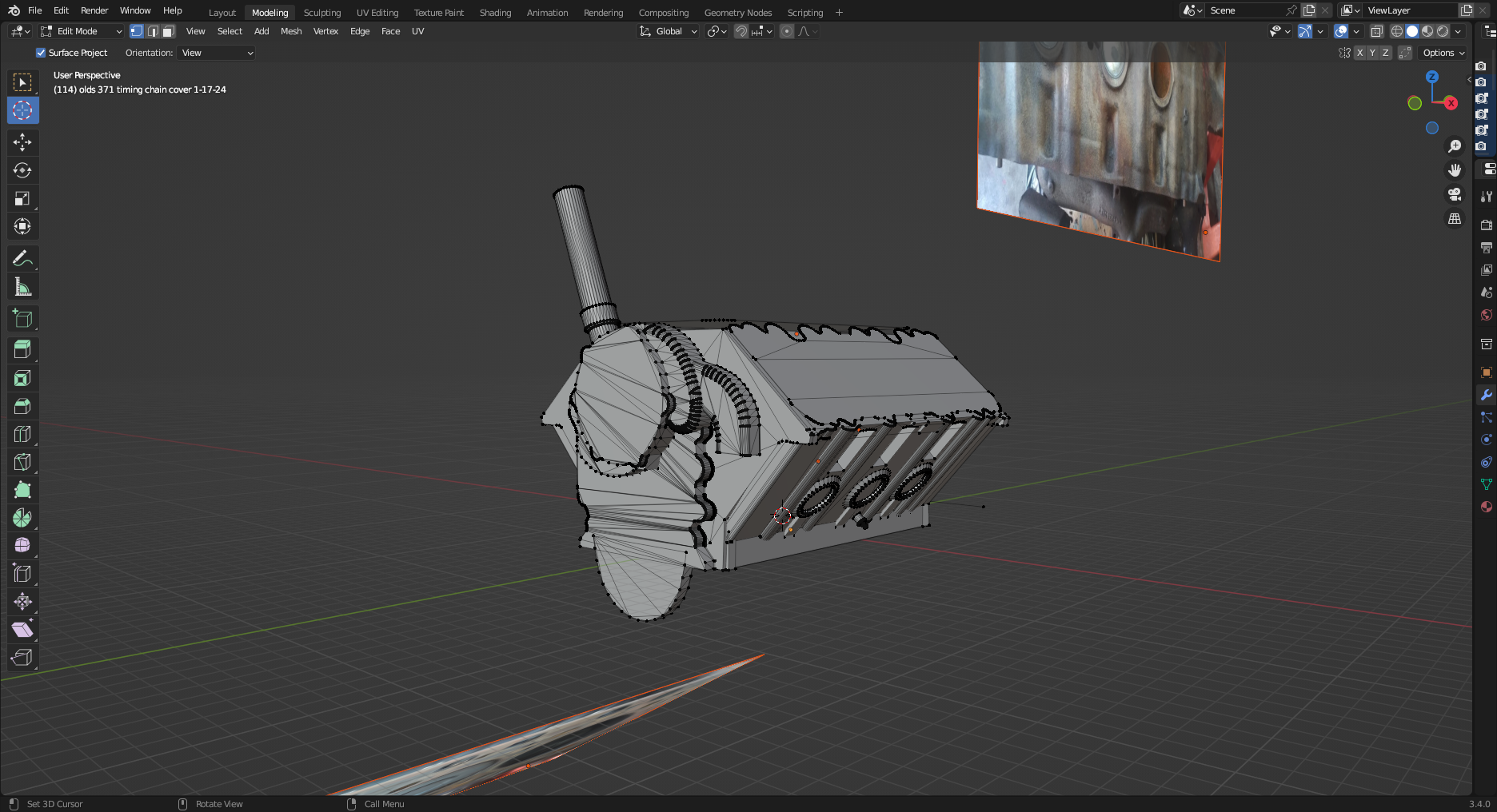

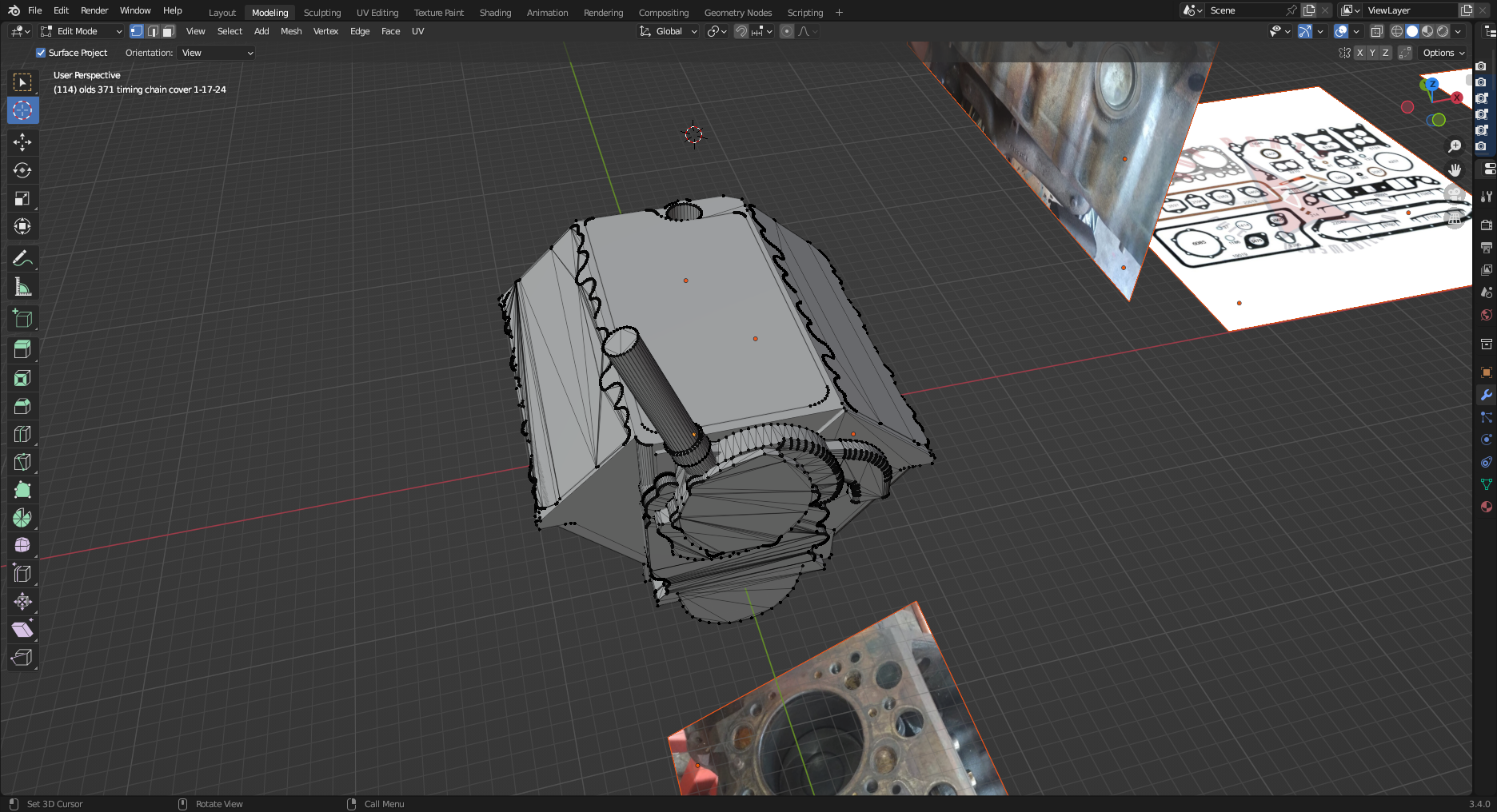

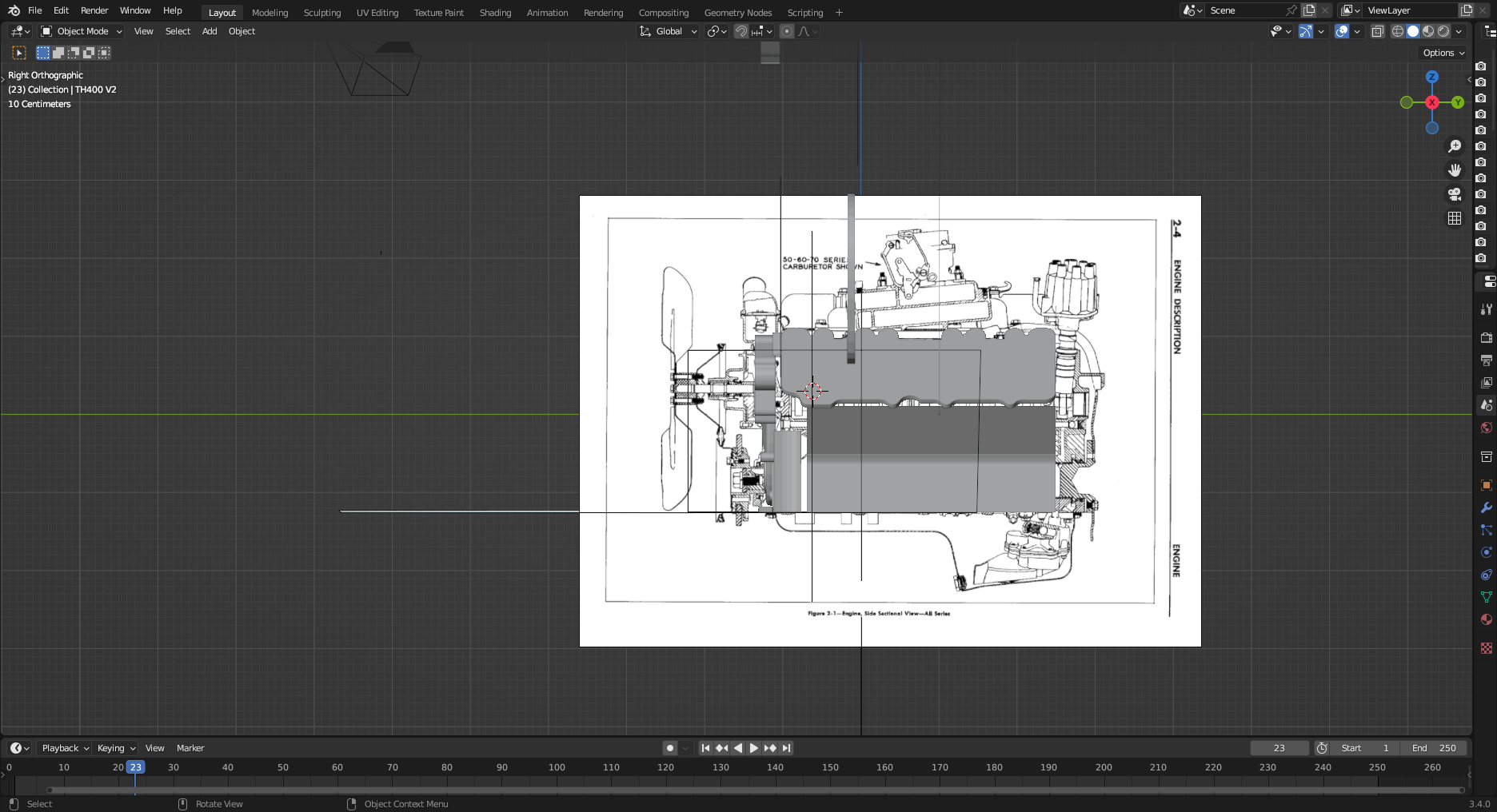

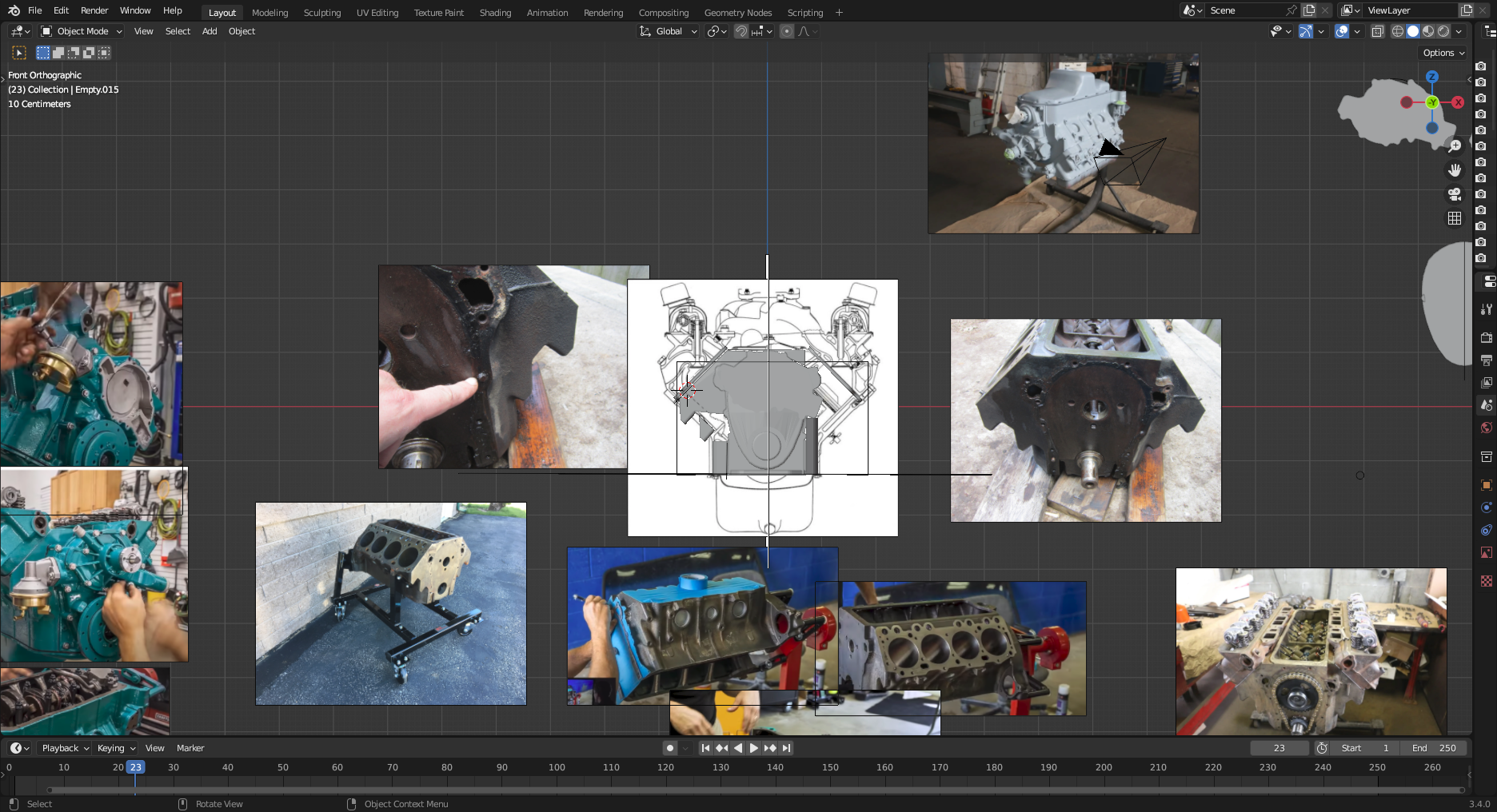

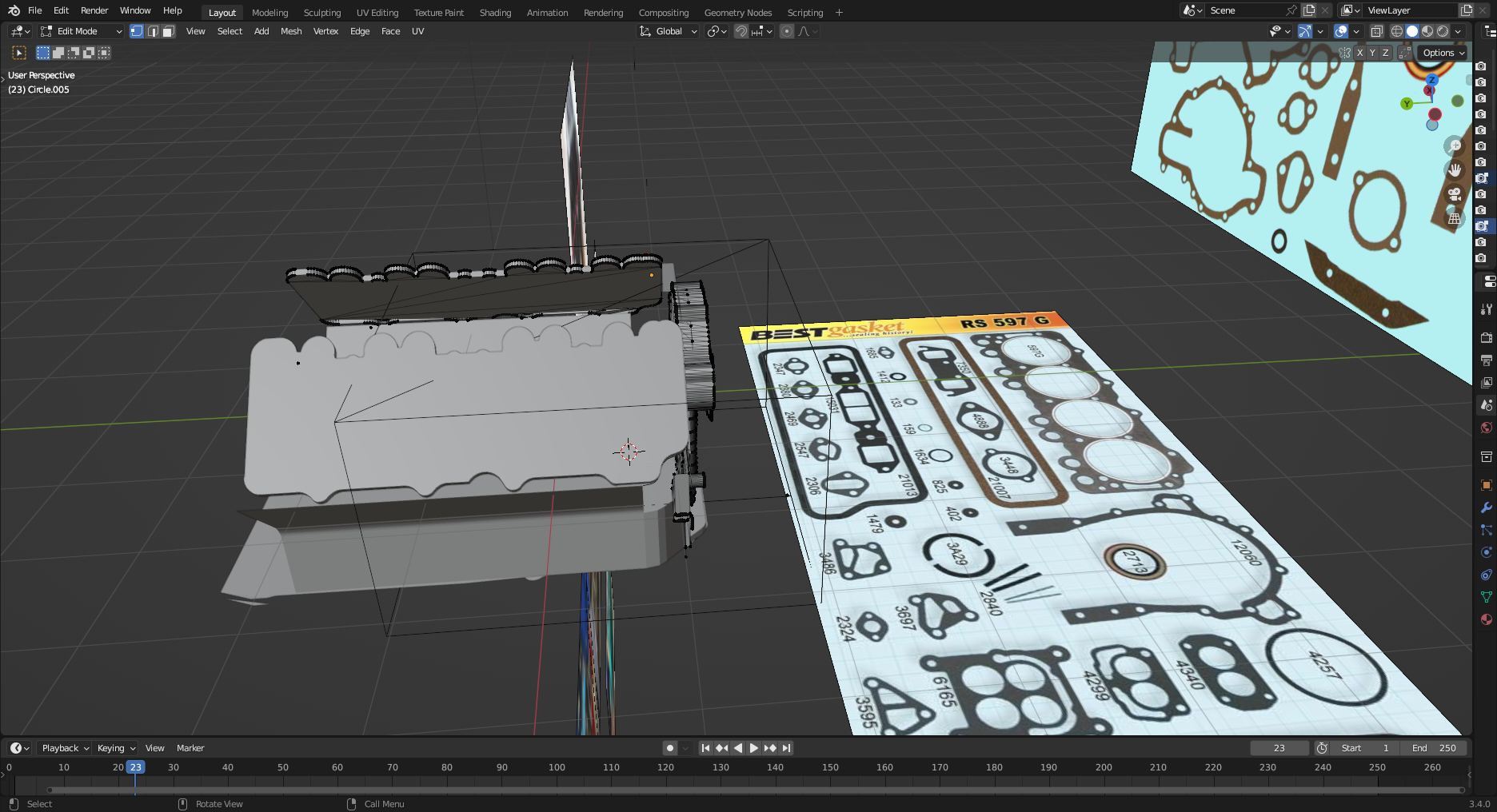

The first generation Olds engine is by far the the hardest one to create a 3d file for. The heads took awhile to get right. The tri power intake manifold was a real project. Compared to the Pontiac tri power manifold, the Pontiac is much easier. Here's the J2 engine so far.

-

Scale 3D printed or resin 2bbl carbs.

my66s55 replied to 1st 700 Quad's topic in Car Aftermarket / Resin / 3D Printed

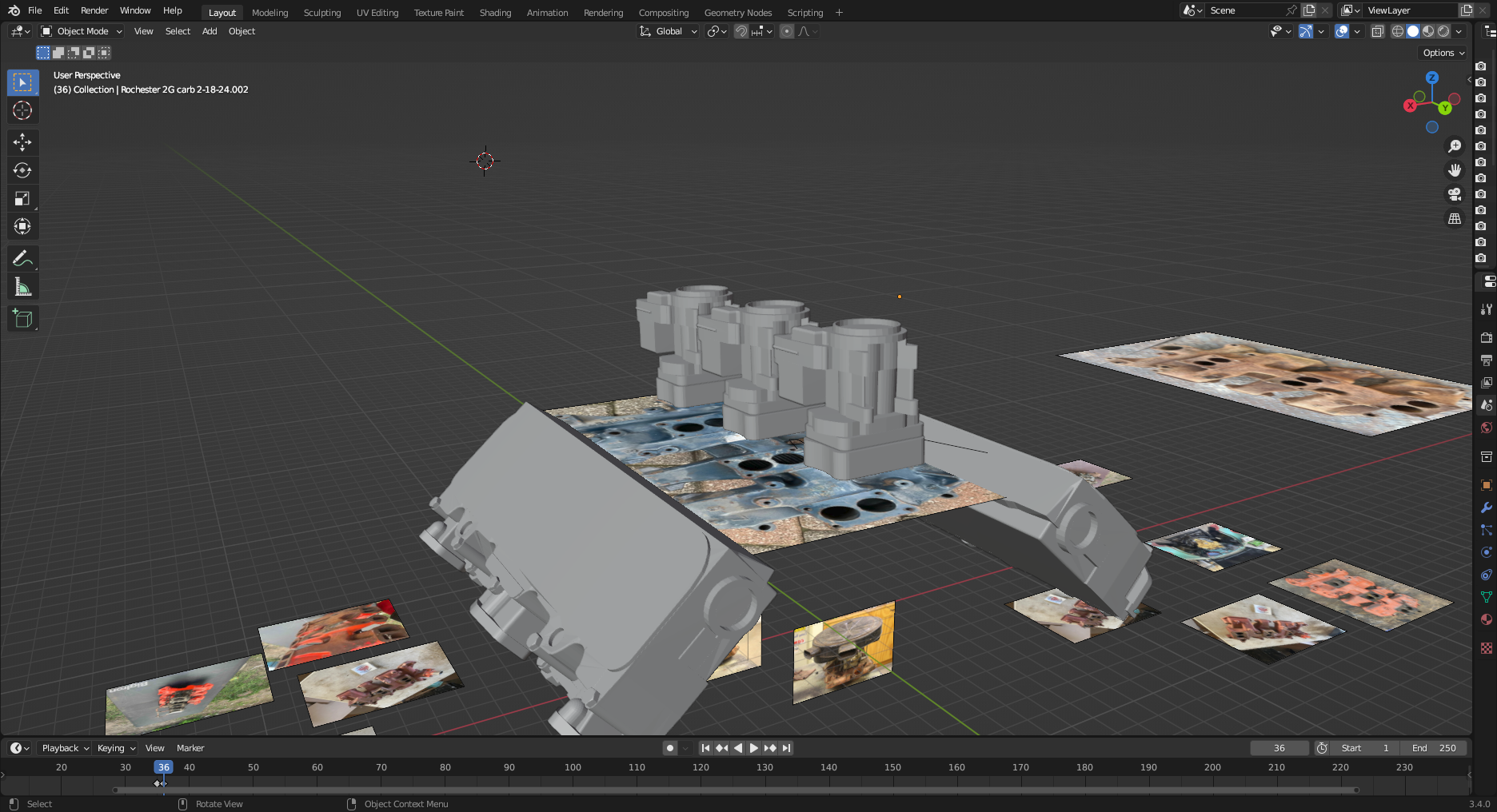

I have some Rochester G2 2 bbl carbs that go on the Olds 57-58 J2 engine I'm creating. Their not quite done yet, but will be by the end of March. -

Cheaper alternative to Molotow chrome markers

my66s55 replied to Monty's topic in Tips, Tricks, and Tutorials

-

You asked about 3d printing them. I draw the emblems up in Blender and if needed, i can print them out individually. The custom Royal name and tail fin emblem on my 57 Dodge and the three emblems on my 69 Buick Grand Sport were all done by me.

-

I started working on the Olds J2 engine intake tri power intake manifold and decided to do the Rochester 2g carbs first. Did my usual reference search and came up with good pics of the one used on the 57-58 J2. These aren't finished yet, but they'll do for what I need right now. I'll start working on the manifold tomorrow. These carbs were used on the Chevy, Pontiac and Olds in the later 50"s.

-

65 yes. 64 no.

- 1 reply

-

- 1

-

-

Hamata1972 started following my66s55

-

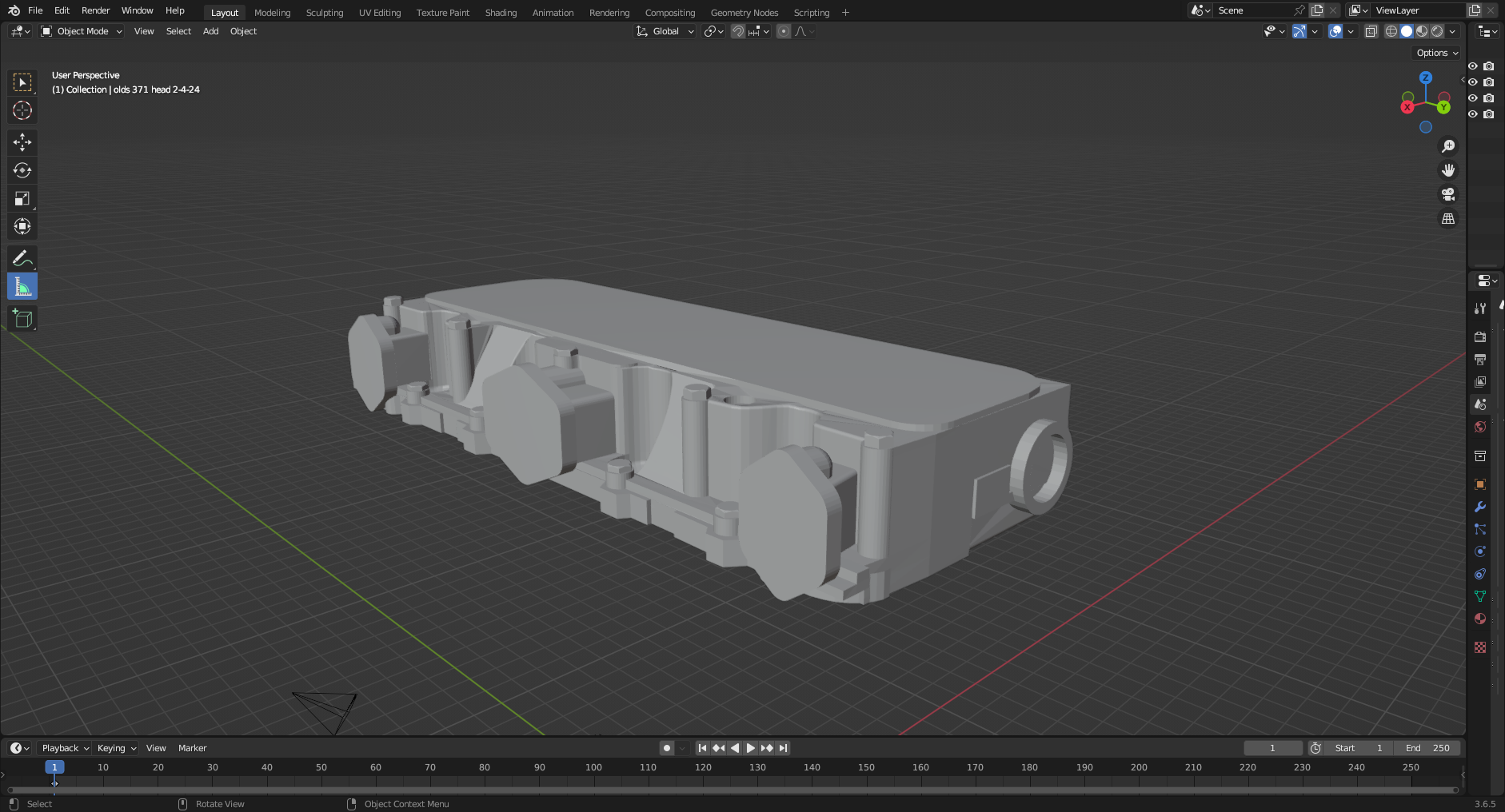

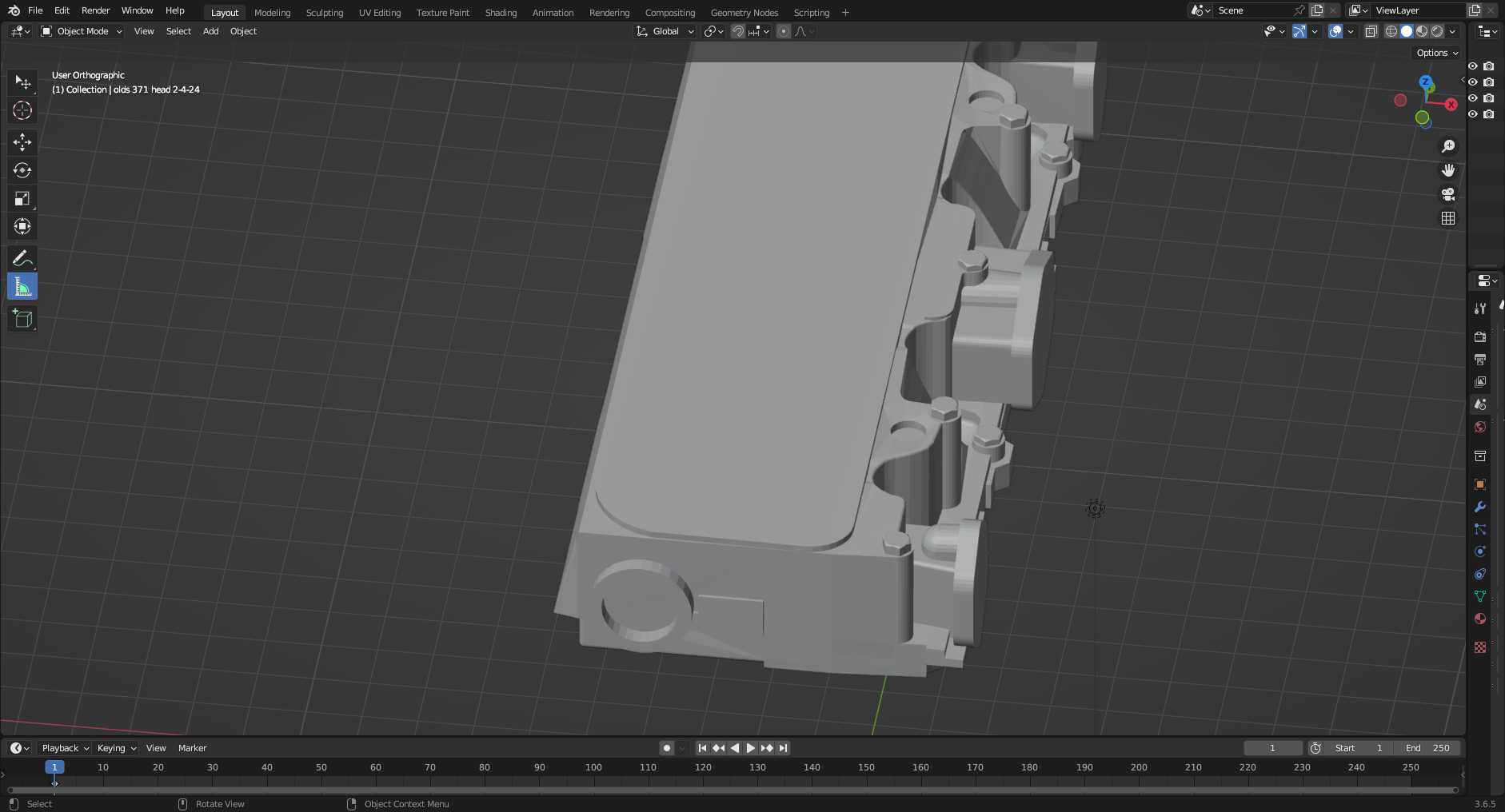

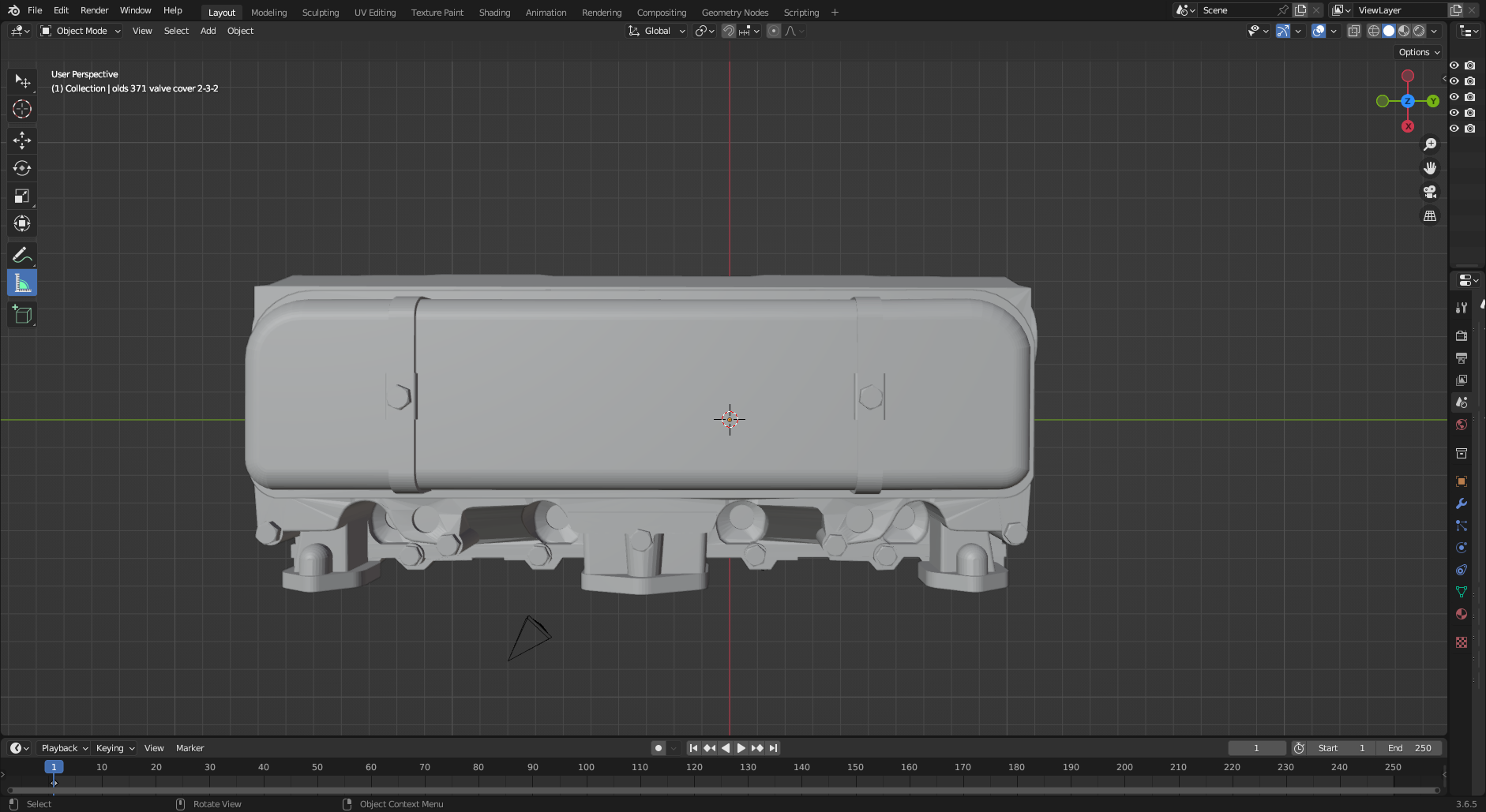

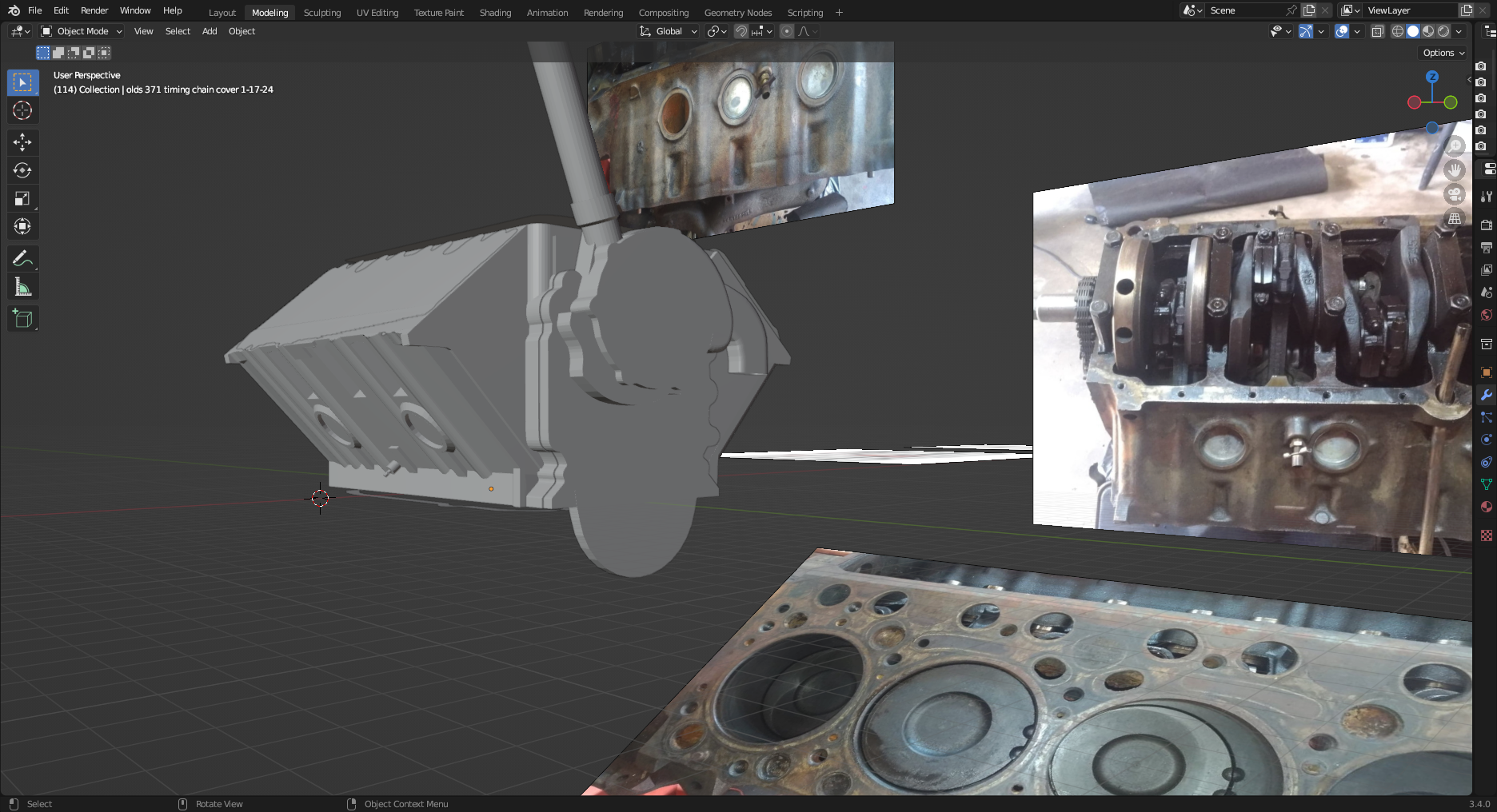

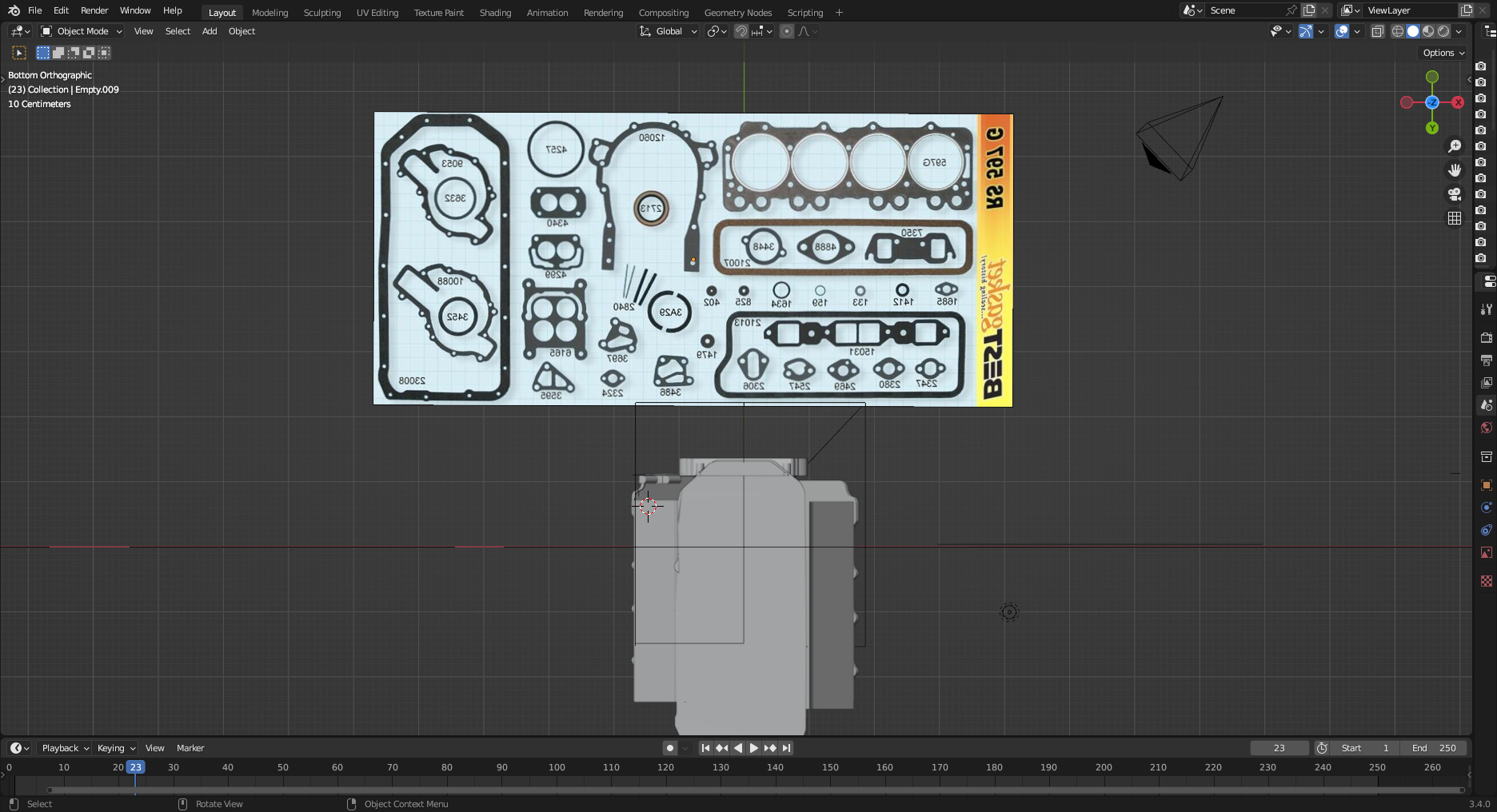

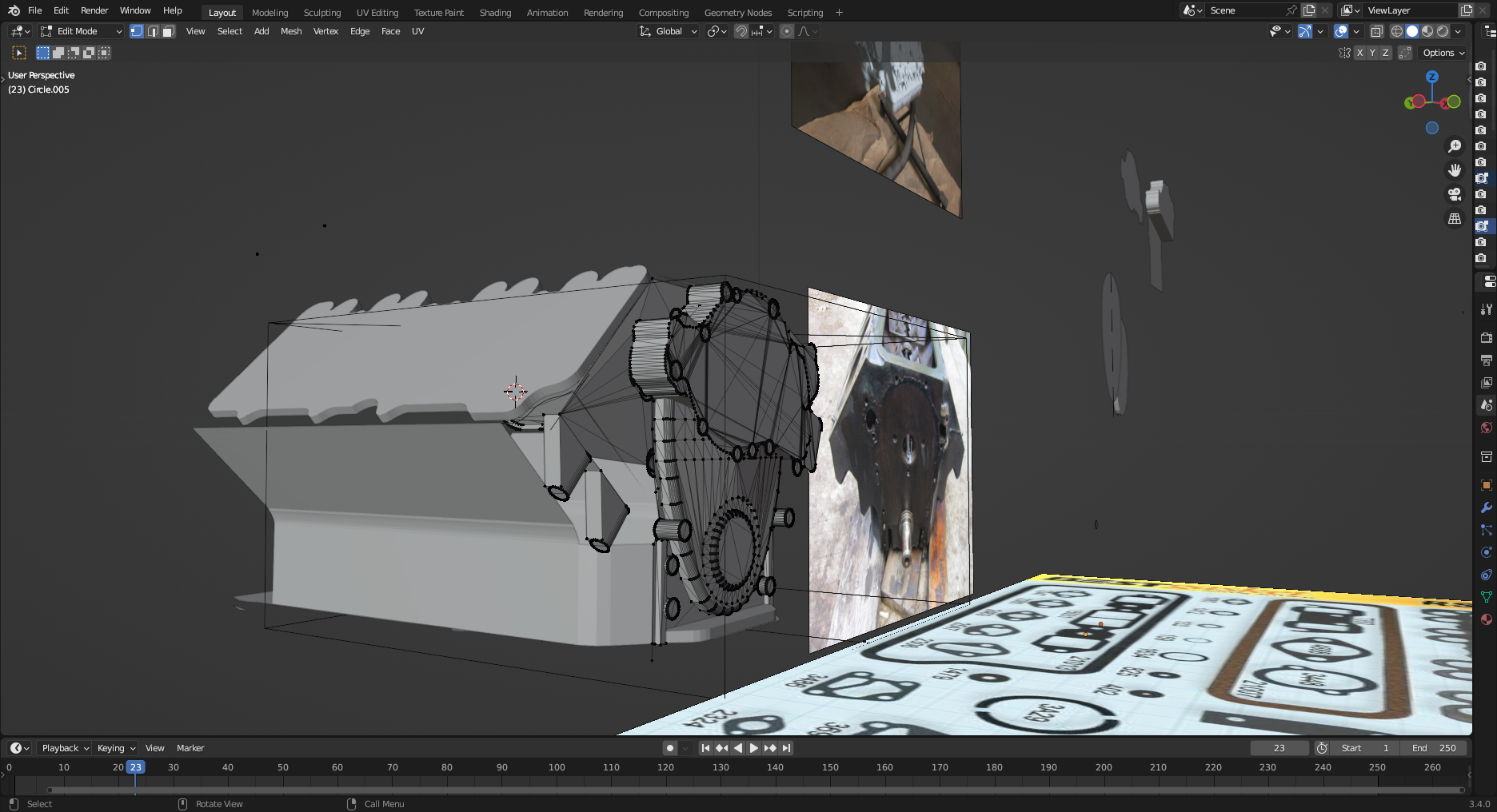

The Olds 57-58 J2 head and valve cover are done. Here's pics alone with a couple of the many reference pic's I use to create them. These were very time consuming to do.

-

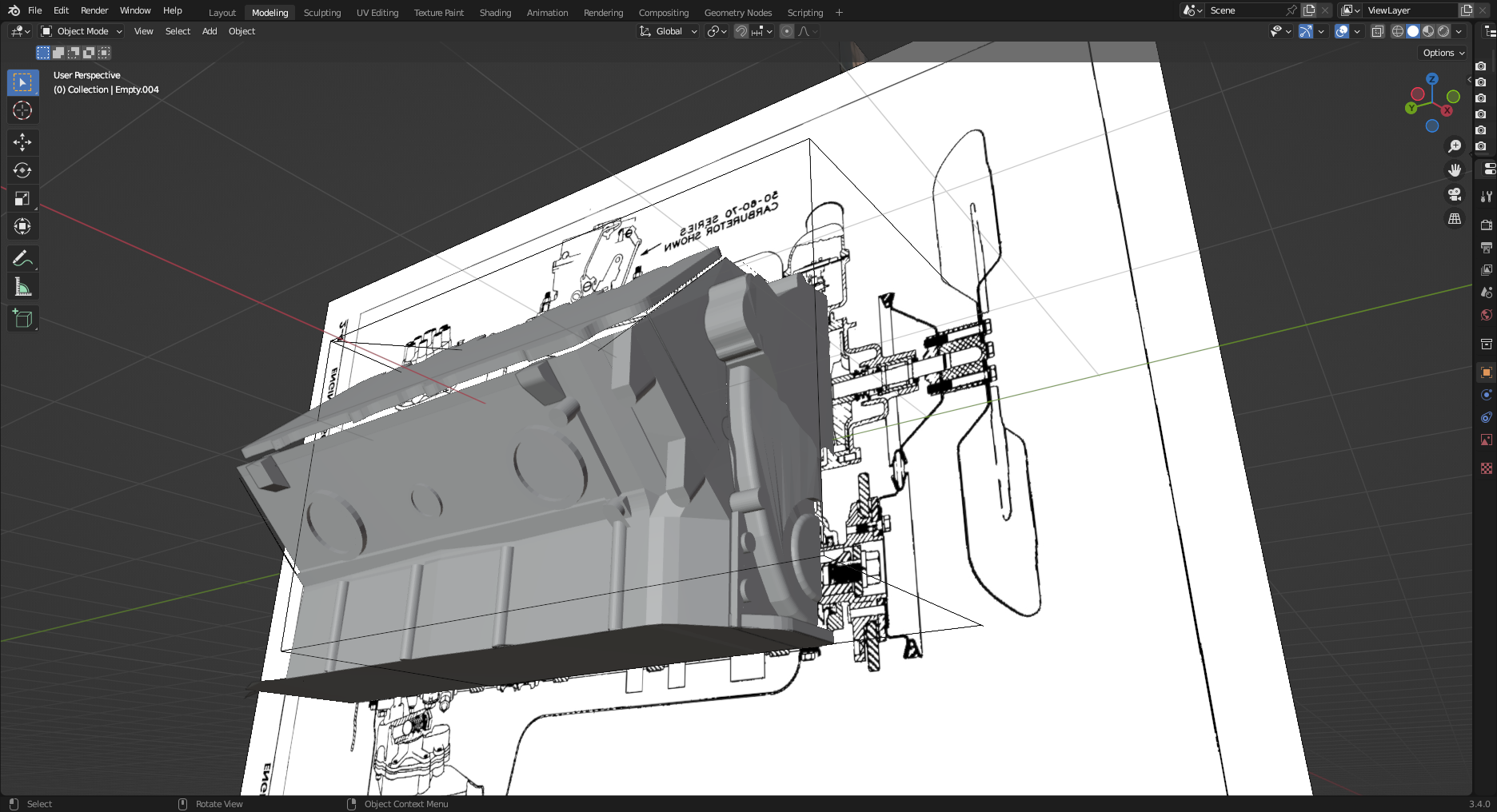

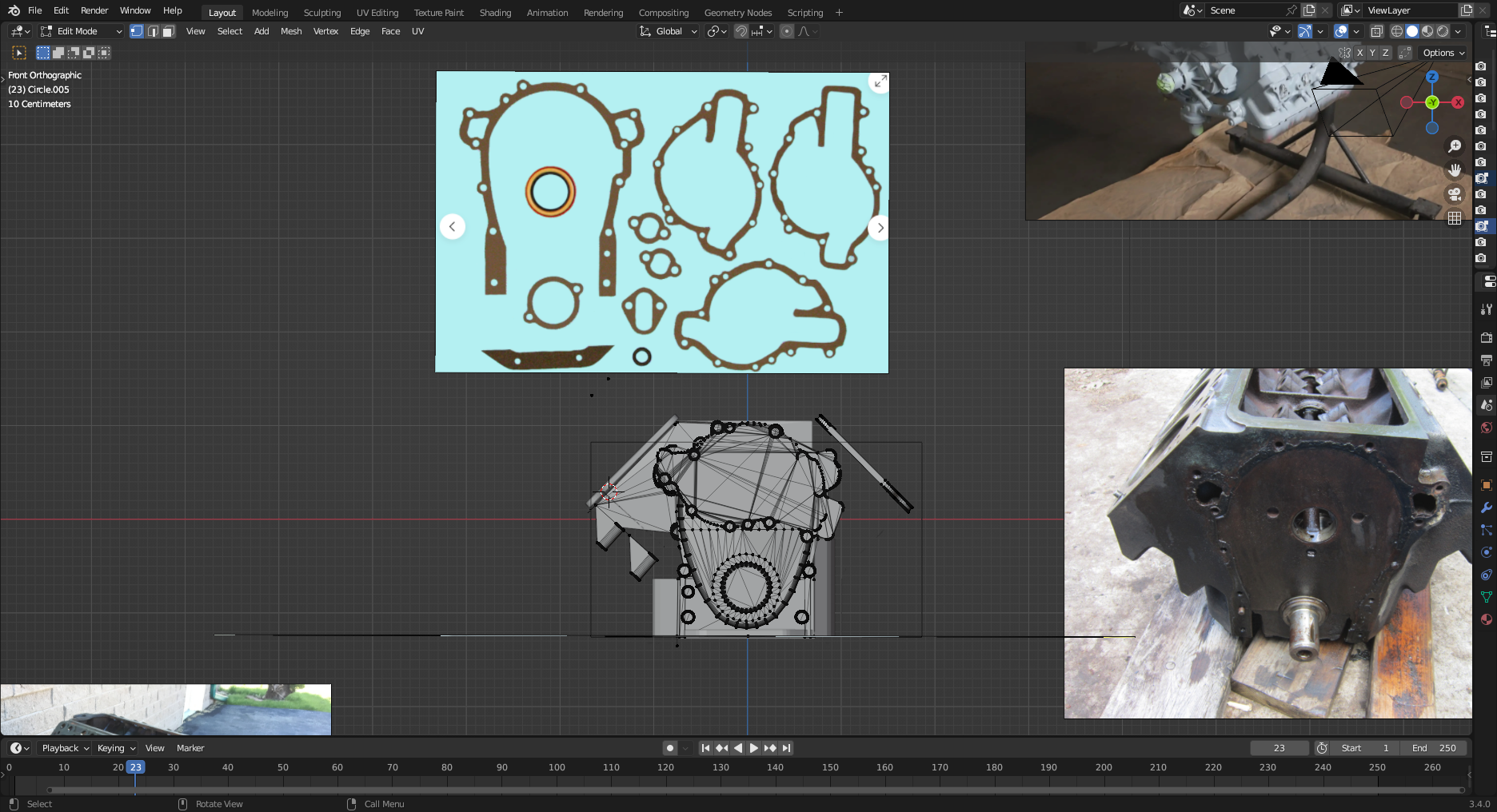

Just a small update. I'm working on a couple of engines currently. One is the Buick nail head and the other is the 1st generation Olds. I did some more work on the side of the Buick. It's a bit tricky getting the sides right. The Olds are a different story entirely. The 303 and 324 have one configuration on their sides and front, the 57-58-371 have a different configuration on their sides, the 60-61 371 have another side configuration and there is another 371 side configuration that I haven't figured out yet. The 394 has it's side and front configurations. Here's what I have so far. The timing chain covers are the basics and not complete. the Buick the 57-58 Olds 371

-

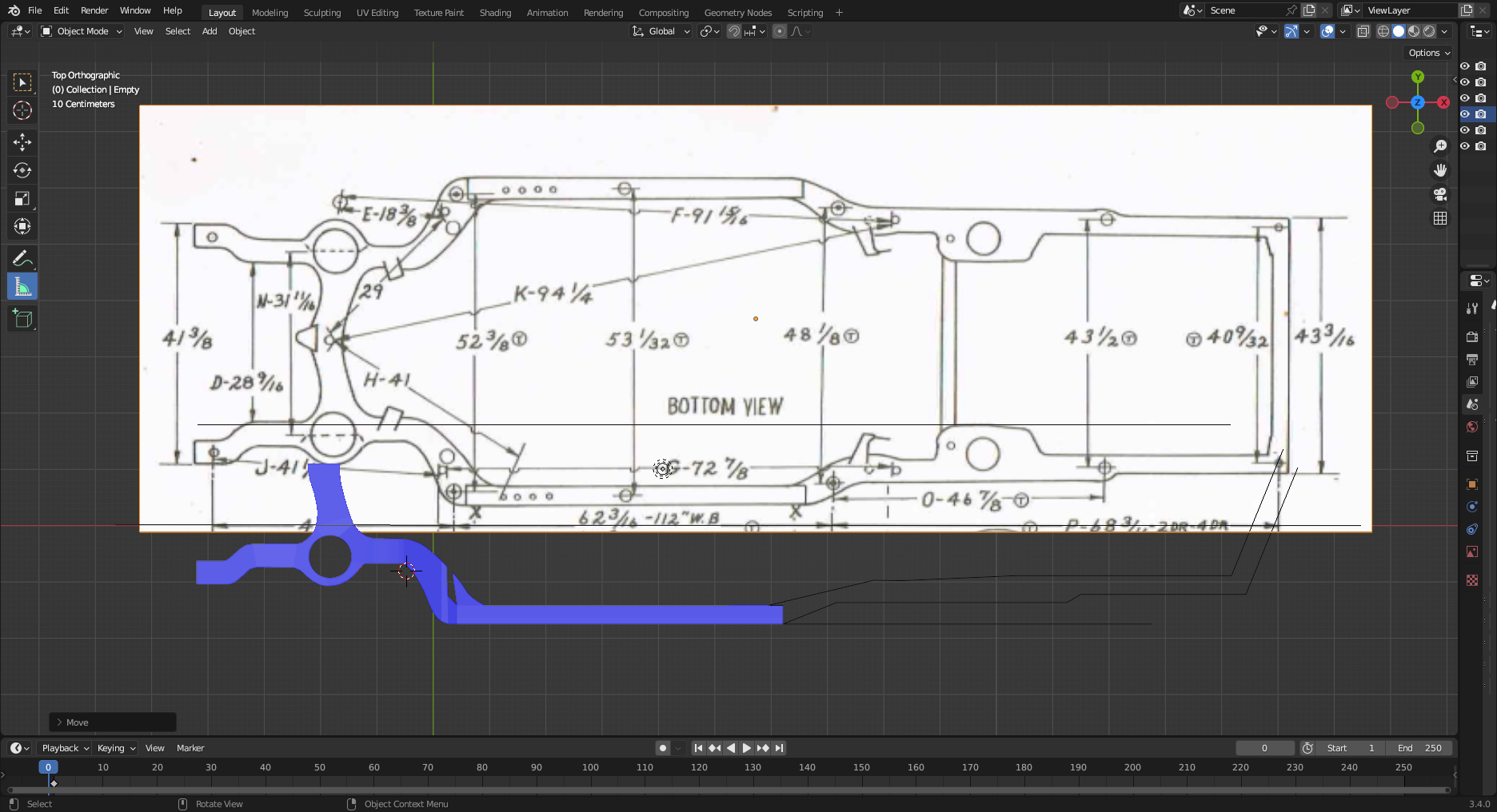

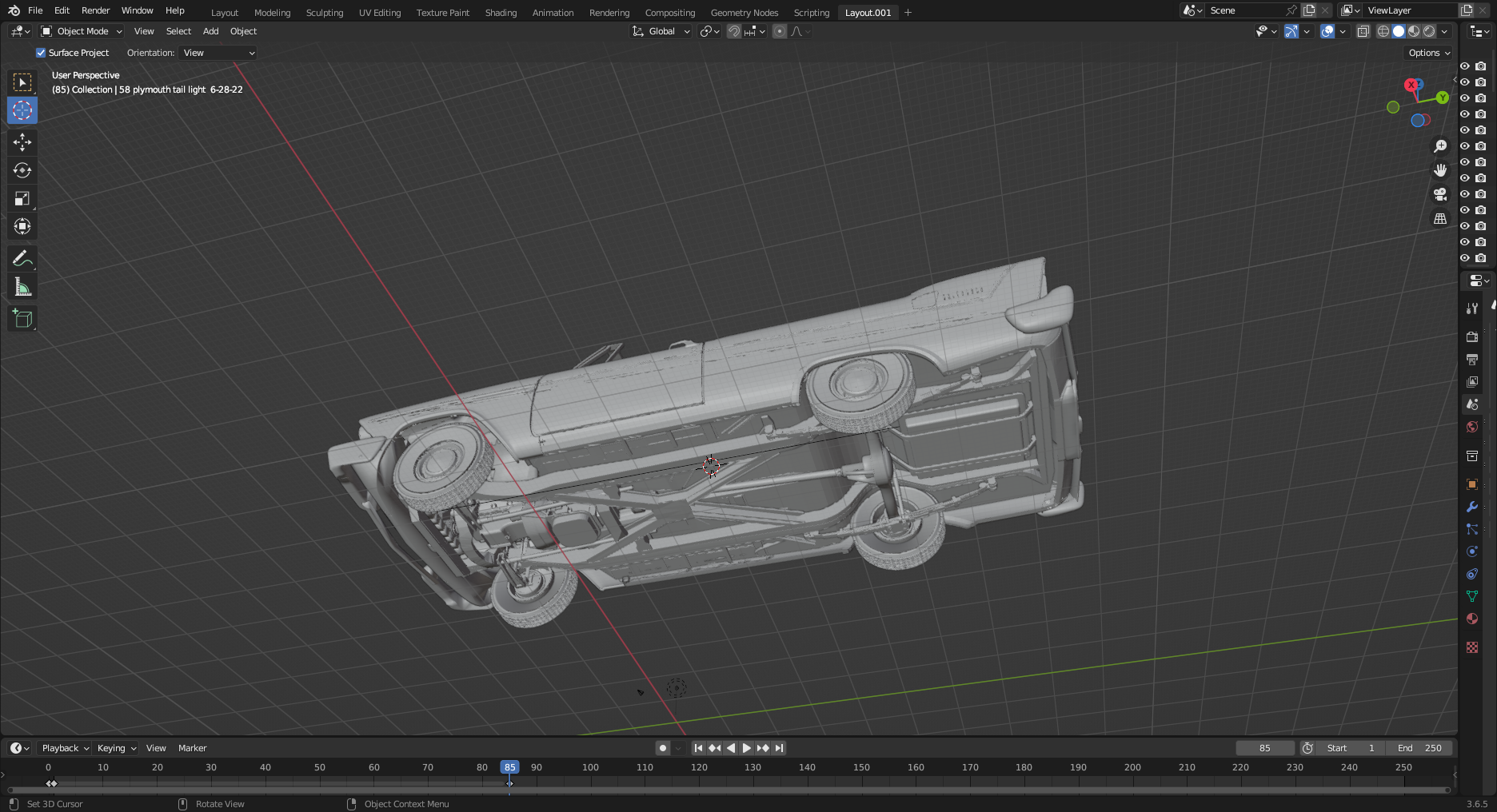

My latest 3d projects have been on a 69 Buick Skylark 3d printable file Andrey had for $10 on CG Trader. It'a really nice file. Included are an interior, chassis and suspension. The dash and front seats are decent but the side panels and rear seat need help. The rest is total Micky Mouse for what I want. I put the Grand Sport 400 emblems on it and will put a nail head 401 with a TH 400 automatic with it. I printed it out and it came out perfect. Unfortunately, I tripped over something 16 days ago, fell and shattered the ball in my right hip joint. I can't take a picture of the body so a made screen shots of it. I.m just now getting back to normal. The start of the engine is also below. And I started the frame h

-

My experience with Andrey files is quite different. I stopped using Windows in 2010 and never looked back. Windows requires a lot of memory. Linux doesn't. I can do everything I need with 16 gig of memory and never have a problem. With Andrey's files, I have to open each one in Chitu and create a stl file. Otherwise Blender will not open them. I just moved a file to another folder and Chitu opened it perfectly. I don't know if this process will correct your problem or not.

-

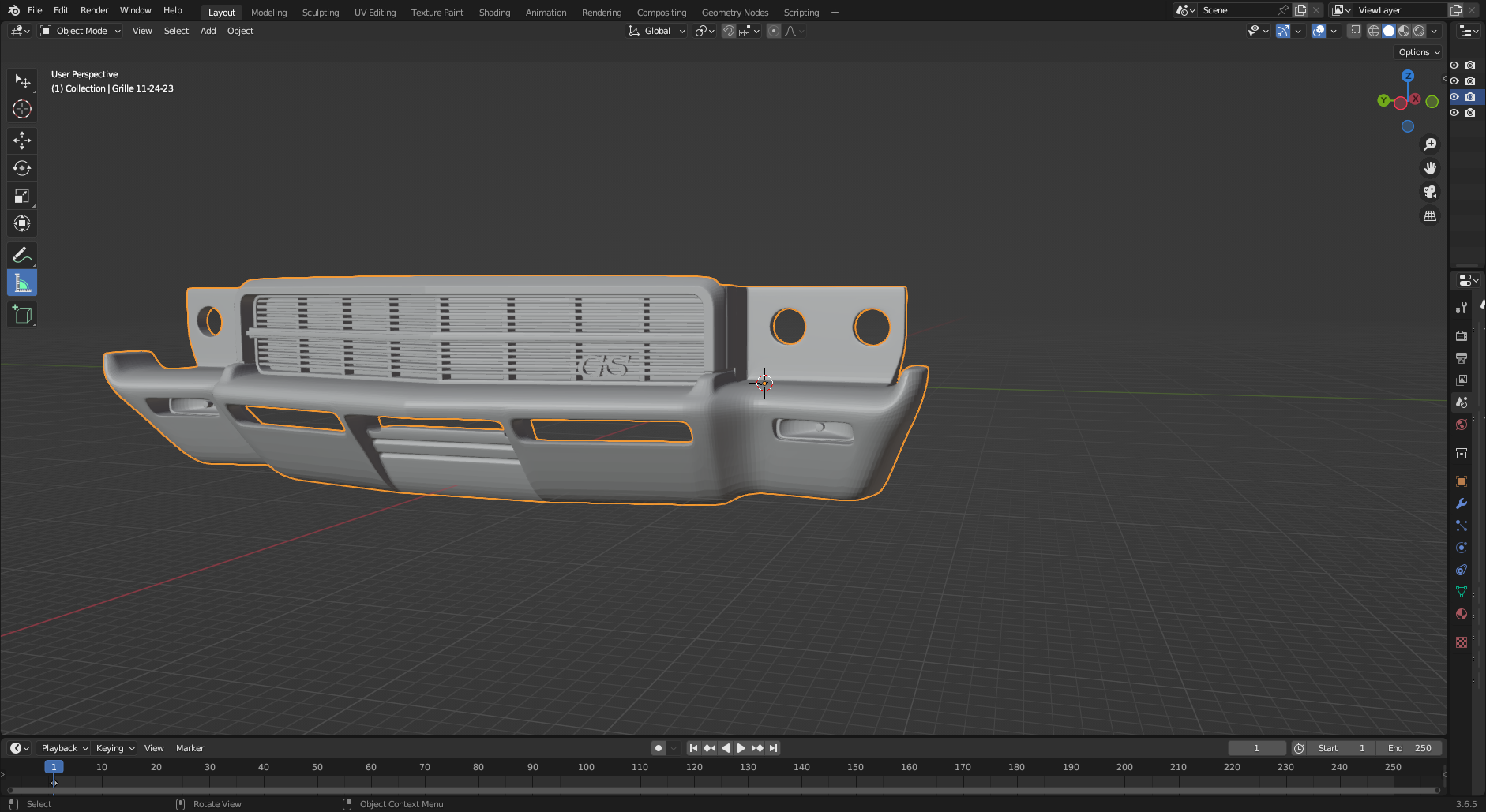

I've been busy working on various different car files. I'm currently working on the 58 Plymouth file Mr. Excessive found. I've got the body ready for a test print. The windshield top needs some work, but I print the windshield frames separate. The original file had errors starting with the windshield cowling being way too curved. I replaced that with the one from my 57 Dodge. The curve on the back on the hood has also been corrected. Here's a pic of the original and my correction. The drawing pic shows it correctly. This is the Belvedere convertible. I haven't touched the interior yet. The floor and rolling chassis from my 57 Dodge have been modified to fit the Plymouth. I'll put mt duel quad poly 318 and torqueflite trans in it as shown.

.thumb.png.e64ca4fead948adbdf6a111229b6cf2f.png)

.png.986d75e1206e9d5e4012c77f526ef53c.png)