djsmadplastic

-

Posts

84 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by djsmadplastic

-

-

LUVINN ITT!!!!

solid front and shaved down bumbers?

-

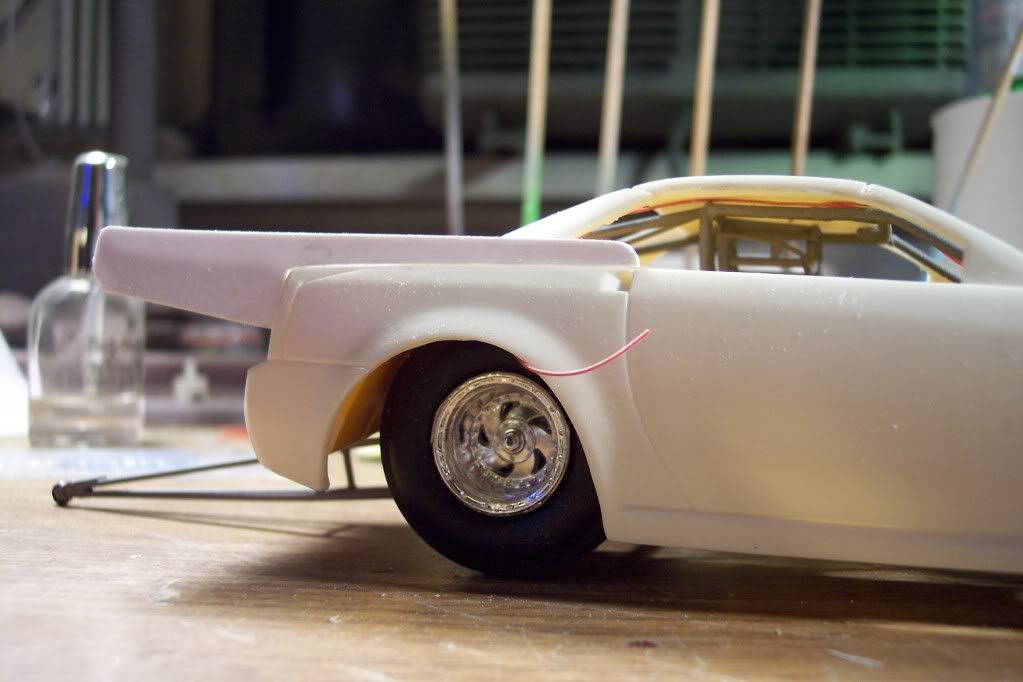

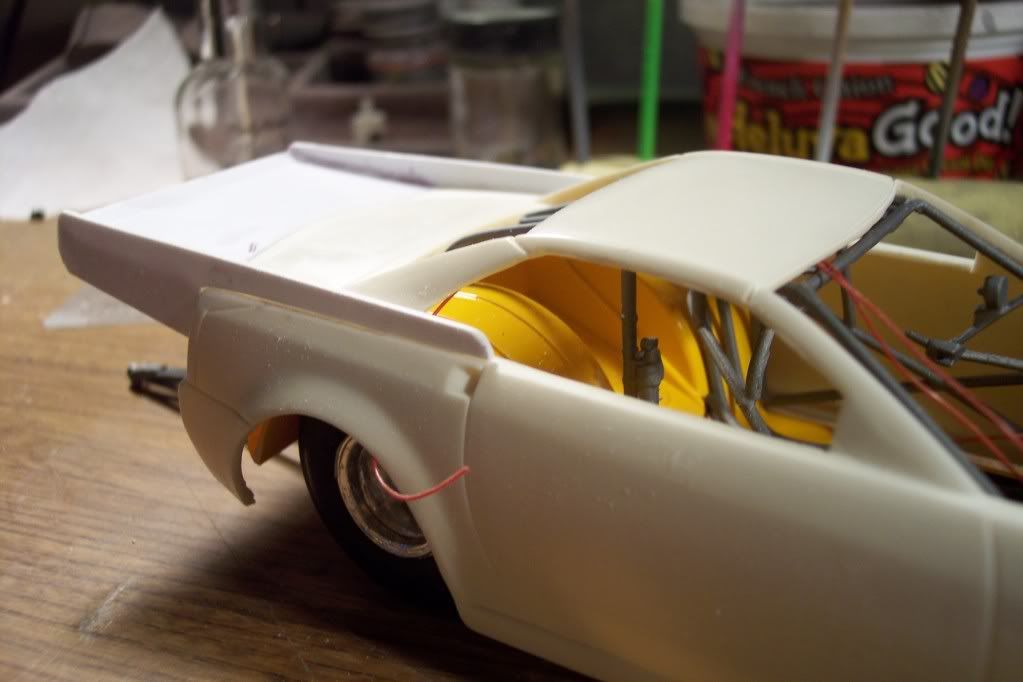

thanks guys,Had it in primer a couple of times now checking for high and low spots, think I got them all now. Put the rear valance on after these pics and tidied up the hood hole and have final primed (I hope)

Question time, re front end. Do you think solid panels behind the openings ( the surrounds will be made to look chrome-ish)? chop a grille to fit in the grill surround? and bumpers or not?

LUVINN ITT!!!!

-

Impressive!!!! You build your bodies simular to the way I build. Never thought about a 68 vette. Keep kickin ass!!!

-

Sorry about the no image pics. dont know what happened to them? 1rst time back on this site in a month or two. heres my photobucket link. http://s1028.photobucket.com/albums/y343/djsmadplastic/ or add 63%20 vette/ at the end of this link. thanx. D.J.

-

i can only tell you what i know. if some one out there has an uncle bob and he owns something different, great. the blown pro mods that I AM aware of, do not self start. the rules don't require it and it's a ton of weight to penalize yourself with. they still carry a battery (although not a physically large one) to power all of the electronic gizmos and doo-flickers. i was taught a pic is worth a thousand words. here's my thousand words.

Dave is correct. there is a small power source so you can run the fuel pump and ect. also so you can check your valves,springs to adust when your jogging the motor between rounds with out physically turning over the motor completly. Cant afford to waste that fuel.(ha ha).

will that help?

EDIT: the car pictured is a ADRL PX car. i did some quick research and NHRA pro mods are required to be self starting. although they allow the use of remote battery packs for starting only.

-

I love ProMods! And I love when I see something totally different in the ProMod world such as your Jag. Awsome points on imagination! great job,lookin to see more.

-

I used 00-90 look to be the right size. A there's on beating in just building all in fun. :I may need you to build me a body.

Thanx that would ge cool. what kind of body r u thinkin? Send me a message.

rts to look the same. I make a patterns that i like then cut it out. I cut 4 pices of plastruct and tape together, then i use washable glue stick and glue the patterns to the plastruct. Then drill out 2 holes and put the nut and boltin to hold the parts not to mover, cut out and drill and sand.

-

A picture is worth 1000 words

That is amazing. I love the scratchbuilding. You are doing a great job.

That is amazing. I love the scratchbuilding. You are doing a great job.STewart

I agree with the scratchbuilding part. Are those 0090s or 80s? I'll be Honest you got me beat. So far......LOL D.J.

-

Very nice work on the 69 Challenger, DJ

I forgot to add. Your doing an awsome job on your build.

-

Very nice work on the 69 Challenger, DJ

Thanks D.

-

Awesome start don.....is it supercharged, nitrous injected or turbo?

Havent decided yet. Still have to build chassis. Probably blown seeing now how i made the hood.

-

That is one sweet build. Go for it.

STewart

Thank you STewart!!!! Still tryin for that different,but correct look. Still have to add spill plates and Im thinking about spill plates on the rockers?

-

Oh yeah....lookin good. Knock it out!!

Thankx! And I'm going to do that!

-

-

Lookin good Derrick. Keep movin forward. Cant wait to see the progression and finished product.Good building!!

-

i was getting a little burned out on the top alcohol dragster so, i decided to take a break and do a door car. this will be an outlaw 10.5 car. not an upper rung car. something a little more in the lower tiers. based on an '82 camaro the car will be an all tube chassis, frt. struts and p/m style four link w/ a wishbone, M/W 11" rear, bruno/ lenco trans., 737" bbc w/ 2 stages of nitrous. american racing wheels frt. and rr. w/ hoosier 24.0/5.0-15 front tires and 33.5/10.5-16 outlaw rear tires. here's where it's gotten to so far.

conception:Amazingly beautiful!!

rear susp.:

front susp.:

motor:

car at ride height:

please keep in mind that other than the plastic kit body and the center section of the M/W rear(TDR) this is entirely scratch built.

hope you enjoy.

Amazingly beautiful

-

Happy Holidays To everyone!

-

Still working on the wing. So let me know with u think. And DJ i do not want to over power the car so i put a new motor in, have a look.

lol

lol

Awsome put Nos on it. Cool pic. Love it smart ass.

-

WOW now you have my attention! This work is great!

-

I,LL BRING THE HAMMER.

Mide as well hand the hammer over to me.Just kidding. I really would'nt hit you with a hammer I'll just make you sweat it out. Learn how to turn off your CAP LOCK when you message a personal mess. Mr Bad Gass engineer.

-

Don't be so serious it,s a model, it's not real GEES!!!! Have fun people.

A 14/71 blower is a big mother. U guy need to watch pro mods on TV, you'll see how big the engines rrrrrrrrrrrrrrrrrrrrr.

Thanks for look in Derrick

This is weird because I actually do race cars w/ my father & have seen up close A real Promod, let alone for the past 15 yrs. Been around the race track for about 30 to 40 years. No ones being serious, just giving input & opinions. Keep building strong & hard. You are good.

-

WOW WOW WOW

Is that a good WOW?

-

Rework the wing, i don't know, tell me what u thing.

The wing doesnt look like a winged express ironing board anymore(just messin). Looks 110% better. Please take this with heart your motor looks great but its overpowering the car.

-

Very nice, I like it. I'm with the others, give us more details. I'm artularly interested in how you bent styrene tube and molded the sheet.

Sorry to everyone for not giving updates. Been working long hours @ job. I bent the styrene rods w/a bic lighter. Just a little heat before it melts. For the tin work I didnt mold anything. The styrene was cut & glued w/ ca glue w/ insta-set the wheel wells were bent by rolling over my fingers then glued in place. I used templates from paper 1rst then cut out styrene for finished piece. Just gotta set & look a few times before it fits or looks good. Thanx D.J.

My old Camarrow

in WIP: Drag Racing Models

Posted

its been awhile but im gettin back into the game. I have a promod challenger and a Caddy. cant wait to show them.