-

Posts

2,651 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Codi

-

-

That's sharp Tony. I love Fords and yours is just so right in so many ways. You should be proud with how it turned out. Cheers, Tim

-

When i was a teenager Daniel, my best friend had one of the originals. Just an awesome car. The pics you found on the interwebs are just fantastic and I look forward to following along on your undertaking. Such a great concept car to pursue. Cheers, Tim

-

That is looking so sharp Nicolas. Can't wait to see more of your build. The brake upgrade is spectacular. Cheers, Tim

-

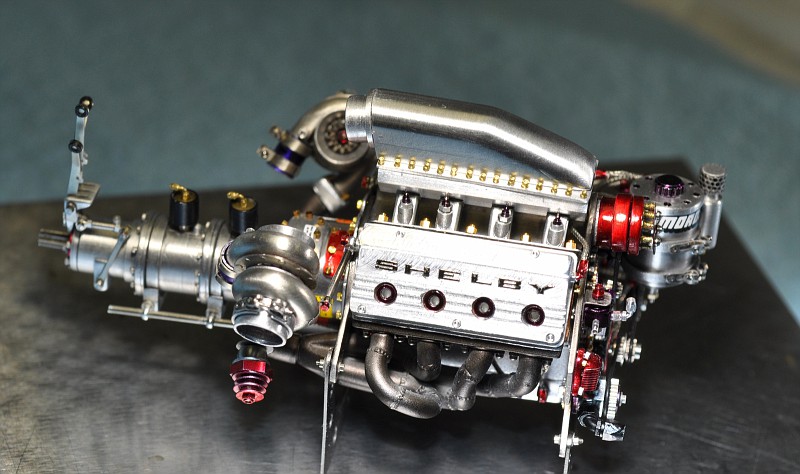

Appreciated guys, one last pic for you before I button it up the next few days once and for all. I am going to have to change the valve cover breathers as they're all wrong for the dry sump setup on the engine. I'll make a pair that route to the puke tank I just made. Cheers,

-

Thanks again guys. Michael, no, I like the contrast of the brass and alum. on the bolts. John, thank you for the note......that's the highest compliment a builder could receive in my opinion. Greatly appreciated.

So, got the intake off and the new one sitting on top. Nothing lined up per se and a few details to address AND lousy pics (better ones later) BUT I was so pleased with how this turned out I just had to share. Comments welcome. Cheers to each of you! Tim

-

Small update on the intake. The brass butterfly is made and there are 30 small bolts (cosmetic, not actual screws) on the top plate / portion of the manifold. The entire intake is a smidgen over 1". The small lip that the bolts are affixed to is only 1.15mm wide. I've done some mock-up visuals with the engine itself (pretty sharp I think) and now it comes down to removing the old one (not sure how to get that off since I used CA glue) without damaging anything else. The throttle body needs drilled for the butterfly shaft and a few small details added. Next pics will be of the intake ON the engine. (assuming all goes well) Cheers, Tim

-

Clayton, thank you sir.....that's quite the compliment.

Chris, that's great news...be sure to get the rotary table, 3 and 4 jaw chucks, and the tilting table among the tools you'll be ordering. Must haves! My mill was a 5400DRO setup in metric as you know. Get the collet sets too that allow for a bit more precision in your machining. Whatever you spend on your mill, be willing and prepared to spend all most as much on various tools and endmills to get you going. Starretts "last word" is a must have a setup tool as well. I could go on, but you have your own ideas I'm sure. Thanks for your note on Henry too!

Yeah Henry, that pic got my attention as I'm going to have to prep a list on how to assemble the entire thing so that I can be sure to access other pieces I'll have to install. Avoid painting myself into a corner as they say.

Eric, I've been spending some time considering what color to paint it and I think I have a good idea so that it looks realistic, cool and complimentary to the rest of the metal work that won't be painted. Thanks!

Art, been too long. Glad you checked it out and I've been keeping my eyes open for more on your sprinter. soon I hope! cheers to everyone, Tim

-

Wow, talk about stepping outside the box......that should be a fun build and I'm especially looking forward to your teaming up with John on this one. I'm sure you'll prove that once and for all, 1 + 1 = 3 in this instance. Will most certainly follow along. Cheers, Tim

-

Eric, great choice of colors and your floor mats are killer....along with the rest of it. Gotta be having fun with this one. Good luck on the rest. Cheers, Tim

-

Len, thank you for sharing your pics.....all of your albums and photography are outstanding. I truly enjoy perusing them when you post!!! Cheers, Tim

-

Thank you fellas. Chris, when will we see some more of the funny btw? Well, today I machined the puke tank. Dual inlets from the engine, one drain on the back end, roof top vent AND what I really liked making was the "glass" oil level tube on the side of the tank......yeah baby!! This think sits on TOP of a penny it's that small. You can see how tight it is in the cage too. Getting so much closer to a final back end mock-up after I finish up a few small things on my new intake. Cheers, Tim

-

Thanks Henry,Scott and Joe.........I waited what seemed forever for the tool and once I got this part done, couldn't help myself. Had some ideas on how to do the throttle body and couldn't wait to see if they would work out. The tolerances are down to just thousandths of an inch with what you're seeing here. I consider this a more than worthy replacement for the intake on the engine now. The hardest part will most likely be the removal and fitment of the new one. Tomorrow is the Mecum auction in Harrisburg with my 6 year old daughter.....no bench time for me. Cheers guys. Tim

-

tool I've been waiting for arrived today finally. here's the top of the intake done except for a few machining marks I have to remove yet. Next I'll make the plate that bolts to the lower portion of the intake and affix the top that you see in these pics. Then the throttle body. cheers, tim

-

Tim how will are you doing the 'glass on the underside? I would be interested.

Continued working on the Mustang which might become a modern funny car instead of a promod. Anyways, it's getting closer each time I putty and prime it. comments welcome. cheers, tim

Sorry guys, this thread has gotten a little screwy for some reason. hopefully you can follow along.

Joe - "Henry" is priority number 1, got way too much into it now AND it's still fun for me to build so........it's gotta get done first and foremost...

Bob - On the taxiway is an early MPC Mustang that I modified the body by moving the rear wheel wells back 3/8" and closed up the blower opening on the hood. it's going to be an early "phantom" 70's REAR engined funny. That one is the very next car I'm delving into after I complete the Henry. Here's a pic of the modified body:

Len - this is the stuff I used on the hood earlier when it was a promod and then changed up to a funny. There's a builder that did a WIP about 12 months ago that did a Mickey Thompson blue bonneville, 4 engined car. He glassed his and I did some research and decided to try it. I can only say it adds a LOT of structural rigidity to the body. I've included a pic of the resin (use the "finishing resin" as it's not as thick and I got the 3/4 oz. glass from Hobbico and the 1/2 oz. if from Hangar 9 ) It's pretty straightforward to use. I've included a pic of the hood I chopped off and you can see the glass on the underside. It's best to smooth out the surfaces that you're applying the glass to before application. I didn't do that on this hood as you can see. Wear a mask and do it in a well ventilated area. It's strong stuff and not meant for lungs or eyes.

The previous hood that was chopped off and glassed earlier.

-

Thanks Branndon for the comments/compliments and regarding my henry build as well. Glad you're following along.

Andy - That's pretty sweet what you posted on that rendering. How about one for a funny?

Today I spent some time re-shaping the rear wheel openings. Their shape had to be completely re-worked and lowered. Next I'll sand the under body and get the inside of the car fiber glassed for some additional strength. With all the cutting I've done it's a good precaution. I have a rather lengthy list of body mods / tweaks that need to be done but this is such a filthy dust filled job that it's a treat to do it out on the patio. Comments welcome as always, (still no tool yet to finish the intake for the Henry build, I'm hoping it shows up by day end. Cheers, Tim

-

yeah Branndon, nobody was more disappointed than me when ford announced their decision last year....nothing like staring at 8 camaros, 4 mopars (whatever they call em') and the rest being toyotas (with the exception of the ONE mustang left in the field, which btw is VERY competitive even without fords support this year) I too can only "guess" as to what they MIGHT look like, but I ask everyone to consider Mikes comment above regarding today's cars being more recognizable in the first place versus what they have evolved into today. Thanks for the positive comment too! cheers, Tim

-

Joe....you're still funny even with a change of address.................thanks for following along even though you have a pool and new house to entertain you now.

Mike...DING DING DING............everyone, read what he said because I 100% agree. And I'm not making excuses for what I'm building as it is not 100% accurate with regards to what the current funny's look like. I HATE the look of the current cars due to their slab sides etc. Their shape is totally dictated by aero, just like modern F1...which i also despise after being a fan for 35 years. I can't watch an F1 race anymore because the cars are basically UGLY. Just ugly. So I'm building this car with the idea that it WILL be immediately recognizable as a 2015 Mustang and only a Mustang. Not a Toyota or whatever else the NHRA is trying to pawn off on us today. And they wonder why their attendance is down. Just like F1. They've forgotten who the customers is, it's the fans. Not the car manufacturers. Anyways, enough of my soap box moment and I want to thank Mike for his comment, it's all the encouragement I need to keep plowing forward with this one. BTW, I was very pleased when I measured the dimensions of this car and compared it to the 2014 NHRA body dimension rules. It meets ALL the dimensions so far. A lucky accident, but still......yeah! Cheers, Tim

-

THAT'S exciting Scott. I just know that you'll have a spurt of creativity and productivity that will rival the best of the minions. And that Pocher F40 is pretty darn sweet too.

Cheers, Tim -

I figured my choice would be met with a bit of surprise and disappointment. But in defense of my decision to change it up to a funny car, I do like to build different things and not the same thing over and over. So, i just had to change this up. today was some solid progress on the roof and b pillars in particular. I can "see it" coming together and I think it's going to be pretty cool when done. The engine on this should be pretty cool to make as well, but that's another subject......

-

Nice all the around Joe.....now when you're done playing "house" maybe you'd like to get back to the reason we read your threads.......

cheers my friend

cheers my friend -

I hope that tool shows up soon as it seems that idle hands are the work of the devil so I keep hacking on Frankenstein. I made the decision to make it into a modern funny car instead of a promod afterall. Never made one so I thought it would be a fun build at somepoint. The valance / rocker panel was revised and yet it is still 1/8" too short so I'll have to fix that. The big challenge is the roof. It's a mess now but it's on. I have to make the rounded tapered back as close to the way the big boys do them. I'm considering brass possibly to do those sides. Have to see as I go along. I had the car in a "good place" to be a promod but I just couldn't help myself. It's only plastic right? Cheers, Tim

-

Continued working on the Mustang which might become a modern funny car instead of a promod. Anyways, it's getting closer each time I putty and prime it. comments welcome. cheers, tim

-

Probably a week till I can finish the intake Henry. I had to send a tool out to be modified. I will post some pics of the Frankenstein mustang i have been hacking on the last few days. Thanks for asking! Cheers

-

Brad, it's the natural progression I believe. You'll get the brass thing down pretty quickly I'm sure and then you'll be like...hmmm...what's next...a mill perhaps? You're going to get the bug bad I'm afraid.

It's a slippery slope. Cheers and THANK YOU for the help on the decals. I'll look for your note. Tim

It's a slippery slope. Cheers and THANK YOU for the help on the decals. I'll look for your note. Tim

Monogram Chaparral 2D

in Model Cars

Posted

WOW Steve. I love this car and your build in particular. Just perfect. I've got to go back and stare at your pics some more now, so if you'll excuse me............tim