Ferbz

Members-

Posts

532 -

Joined

-

Last visited

Previous Fields

-

Are You Human?

yes

-

Scale I Build

1/25, 1/24

Profile Information

-

Full Name

Ferby Miguel

Recent Profile Visitors

5,499 profile views

Ferbz's Achievements

MCM Ohana (6/6)

-

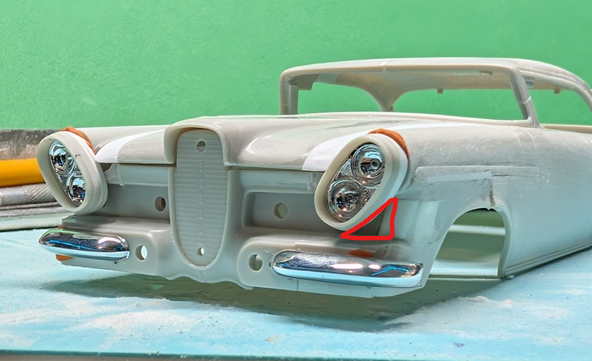

Latest update: I've decided to go with these simpler split bumpers that are in the old AMT Parts Pack. In order to use them in good conscience tho, I decided to also narrow the gravel pan/bumper mount area by removing a small pie section and angling in the front half of the lower fender sides. I had planned to fill in the grill cavities that wrap around to the sides so this was done at the same time. I also plan on filling in the gaps between the outer front corners and the headlight buckets next (see red triangle). I will also try to move the inner ends of the bumper panels outward so they'll closer match the inner bumper ends (see red arrow). Speaking of, the bumpers might need to be frenched in a bit with a small lip around them. We'll see. I'm thinking I'll very likely use another pair of these split bumpers for the rear somehow....but one thing at a time so I dont get overwhelmed! lol

-

Not much actual work done lately, but I have been contemplating some solutions for replacing the big, bulky factory bumper. For years I've been wanting to use either of these bumper sets from the old AMT Parts Pack on a project. The angled dagmars I know are caddy units while the other ones I know I've seen but can't place them (Buick?). I like both of these but will likely try something else, hopefully this weekend. Plans call for filling in the grill openings that wrap around the front corners, then using some kind of screen mesh for the openings that flank the center horse collar grill:

-

Love all of these tail light ideas! None of these look too crazy or overstated....very nice! Thanks for sharing 😁Once I have the front end squared away, I'll move my attention to the rear👍

-

You're probably right. A few well placed custom changes here and there often go a long way. Less is almost always more! I rarely go hog wild with my custom builds but this one is making me think a little more aggressively than usual with the restyling. There are quite a few things that bug me about the original styling of this car that I'll attempt to 'fix' if I can. I've been thinking about that rear end and yeah, it is indeed wacky. But there's got to be something I can do back there. I'm thinking whatever the solution ends up being it should include something that will relate it to the front end, even in some small way....

-

The mesh is some model railroad brass material. I wish I had a brand name for you but it was scrap material I found at a small local hobby shop back in Austin, Tx. I've been meaning to try and search for it online at some point. The ends of the light bar are the chrome 59 Caddy lens custom units that come in the AMT 49 Merc kit. I cut a pair of them away from the custom unit then glued them to the ends of the light bar:

-

Thanks! Early on I was double thinking the factory headlights/buckets as they dont look as cool as what other 1:1 custom car builders actually used, like the 58-60 Lincoln units. They are more space age-y and cooler, and I'm sure I could source some resin or 3D printed versions of them, but I want to see what I can do with the stock Edsel units. Ha! I'm sure a cut down 32 Ford grill would work, but the factory Edsel 'horse collar' is actually a pretty cool shape in my eyes so I'm going to keep it.

-

Thanks1 Yeah I was feeling like it IS alot of work only for it to feel almost factory looking and not full custom. Too late now lol

-

Yeah man, go for it! 👍 I dont have any pieces from the fenders since I used my dremell tool to grind away what needed to be removed. As I recall it was about 3/16" or more that got removed total. You'll want to measure on your own to ensure the amount that looks good to your eye. I also snuck up to the amount as well since I wasn't sure how much I needed: grind a bit, fit check, grind a bit, fit check again, etc. And yes, I didnt think about wheel/tire room until after I made my changes! lol The wheels/tires I want to use still fit, but it's pretty tight. All good tho I think since I plan for this to be a curbside model with no removable hood or engine/chassis detail. I may cut away the tight area of the inner fender wells, or modify them by cutting them and moving them inboard a bit.

-

Chopped/channeled 50 Ford Custom Pickup

Ferbz replied to Ferbz's topic in Model Trucks: Pickups, Vans, SUVs, Light Commercial

Thanks so much! 🙂👍 -

Thanks! I try to make my mods as clean as possible. I find that it saves me the extra effort of fixing a cut that was not executed or measured well or cleaning up a hastily done change. There are still unforeseen or unplanned things that happen, and that constant struggle of getting the left and right sides to be exactly alike lol

-

Thanks man! Onward and upward!😁

-

Thanks! I wasn't sure if it was going to work like how I processed it in my head. Sometimes reality slaps me in the face when I try to do something that seemed totally doable in my imagination lol

-

Thanks! Yes, its feeling very much like a prototype. Kind of like one of those period concept cars😉 Altho I dont like the big, blocky factory bumpers so I'll chuck those in favor of something else I like....😁

-

Update! Plan A of thinning out the front fender tops by cutting away the inner halves of the fenders, trimming the tops down and moving them outward is working out for the most part (whew!) The hood was widened using sheet styrene. Everything is just roughed in at this point. Smoothing the headlight buckets into the fender fronts and other fine tuning will be next. Oddly enough, this is not looking very 'radical custom' to me, but is feeling very stock-ish lol Will all this crazy work stand out in the end? Stay tuned...

-

Ferbz started following 55 Chevy Kustom

-

This will be really cool! I think 55-57 chevys make killer traditional customs even tho they're not super popular custom subject matter these days. Looking forward to seeing this progress!👍