-

Posts

283 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by CrazyCrank

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Morning guys Fitting of the dashboard to the windshield: First, I finished the dashboard, and then: - brush painted the top NATO black and varnished it matt. - I added six screws to the top (micro rivets, 0.5 mm The most challenging aspect was affixing the dashboard to the windscreen frame. This task wasn't planned in the instructions, as the original dashboard was supposed to be glued to the cabin. However, since I had completely modified the kit, it was not possible to place the new dash this way. There weren't many areas where the windscreen frame and the dashboard could make contact. The angle to be given to the dashboard in relation to the frame implied that these zones would be very thin. At the same time, we had to ensure the left and right edges of the dashboard didn't protrude too far outwards and forwards, otherwise the doors might not close. There were also a number of other issues, but I won't bore you with the details. During the pre-gluing operations, and even before the aforementioned painting stage, the windscreen frame split on the lower horizontal pillar at the rear, necessitating an acrobatic repair with cyano glue. Luckily, the chrome part was not damaged. But in the end, I managed to glue the dashboard solidly to the frame, precisely and correctly (more or less) compared to the real car, and the effect is nice and satisfying. Some pictures to show you the outcome : And some others of the body shell where I've temporarily put the windshield, just to have an idea of the rendering: I also repainted the chrome at the front of the windscreen frame because the original chrome had been damaged during handling. I used Revell chrome paint, decanted from the can and applied with an airbrush. Once finished, it had to dry for three weeks before I could handle it, even when wearing gloves. On the windshield, I still had to paint in matt black, on the chrome frame, the rubber seal, and this was no easy task. Indeed, although I had to re-chrome the frame, and had chosen REVELL chrome, which many would agree is easy enough to handle (with cotton gloves) after 48 hours of drying, without tarnishing, and that I left it drying for almost 5 months, hoping it will be strong enough......well .... I've been very disappointed while working ! To avoid touching the chrome frame, I'd even decided to superglue a toothpick on the front part of the dashboard, in order to handle the set safely. But, as I was carefully painting this famous joint, under a magnifying glass, with a 20/0 brush, using a water-based acrylic paint, I slightly overflowed on the chrome frame. 😡 Using a slightly dampened cotton swab, I gently wiped away the spill, but the result is that the chrome tarnished! 😡😡 All this to say that, once the joint was fully painted, I had to touch up the chrome a few times, and of course, the effect isn't quite as sharp as it was once it had been airbrushed. It would have been preferable to redo the chroming job on the frame, but, since it is firmly glued to the dash, it's too late (and almost impossible). Here are a few photos: At the naked eye, it's not so bad, of course 😔 Now, knowing I couldn't touch this chrome frame anymore, while I still had to fit windscreen, rearview mirror and sun visors, I wondered how I was going to handle this part to carry out these operations, without touching the chrome parts! And even more so, how I was going to fit the complete windshield / dashboard and steering wheel assembly onto the bodywork! I had to sleep on it, and in the meantime, I move on other tasks 1/ Making of a new interior rear-view mirror The kit part was ugly, and had to be replaced. I designed a new one in Fusion 360 and printed it in resin 2/ Making of new sun visors The ones of the kit were too thick and inaccurate, so I designed new ones, planning to make them working, I mean I wanted them to be lifted off lowered with real hinges ! I also modelled the mounting plates for these sun visors, which will need to be placed at the top of the windscreen frame. I painted chrome the inside mirror (s) and the mounting plate of the sunvisors and painted semi-gloss black the sunvisors. I managed to get the same slightly grainy aspect of the paint, to simulated the leather texture . I made the hinges for the sunvisors , using Nickel-Chrome 0.25 mm wire. On the photo below you can see the kit part provided to represent the mounting brackets and the hinge.... No way tu use this stuff ! And then, their mounting plates have been painted with Molotov Liquid Chrome: I achieved to glue the sunvisors mounting brackets onto the windshield frame. Bear in mind that each of them has a plate measuring 1.2 mm x 2.2 mm, topped with a 0.9 mm diameter eyelet drilled through the centre at 0.45 mm. In order to position it correctly on the windscreen frame, each plate has a small 0.6 mm diameter stud on the front, which fits into a corresponding hole on the frame. They still need to be securely and permanently fixed, and care must be taken to align the eyelet holes horizontally and in pairs. It was challenging but I managed to hinge my sunvisors and place them on the windshield frame 😎 The alignment of both sunvisors isn't perfect, the right one is tilted slightly downwards and to the right when lowered but I can't do better (I've already made 5 or 6 tries and broken as much sunvisors and 2 mounting plates, so, now it works, I dont't want to start again for an hypothetical better result !) What is still to do later, when I've glued the windshield onto the body, will be glueing the inside mirror and the steering wheel. See you later, stay tuned if you like- 115 replies

-

- 2

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

François, You never cease to amaze me🤔 ! My jaw's dropping 😮

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Morning happy modelers Doors inside panels: Painting: I painted the white parts of the door's interiors, using a mix of AK Pure White (60%) and AK White grey (40%). One dried, I had sprayed over the parts a layer of Mr COLOR semi-Gloss varnish. Then I masked the white part of the door's interior and sprayed 2 layers of AK Nato Black At last, I sprayed a layer of Tamiya matt clear, to gel a slight grainy aspect, convincingly reminiscent of the texture and colour of leather, as I did for the seats. Then I added the chrome-plated rod that runs between the top black panel and the padded white panel of the door's interior, taking inspiration of this photograph: I used a 0.25 mm Nickel-Chrome wire, 38.5 mm long for each door: I also added the chrome-plated rod situated on the top of the door, just on the exterior edge of the window slot, as you can see on this photo: I used a thin strip of Hasegawa mirror finish: At last, I made new handles: I removed the chrome of all kit parts and then was able to inspect them more easily. I noticed that they were all of a poor quality, if not absolutely inaccurate or of wrong or rough shapes, then comparing with ref. photos of the 1:1 car. So, I modified some of them when it was possible (bumpers, lateral air intakes, chromed decorative bonnet trident, etc.), and 3D drawn and 3D printed others such as doors handles, windows cranks, headlights reflector etc. Hereunder some pictures of my drawings for the inside door handles: The resin printed door's handle and crank and comparisons with kit parts I painted the handles chrome, the same way than for the grills and fitted them to the doors Is the job finished on the doors ?.....Nope ! it remains to add the exterior handle Stay tuned for new episode 😉- 115 replies

-

- 3

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Morning guys Work on the seats: - First, because of my modifications of the cabin, the seats didn't fit anymore. I've had to strongly sand them, where the plastic touched the edges of the cabin, in order to allow them to fit correctly. - Second: the shapes of the seats's profile wasn't correct, and, taking inspiration of the photos below, I modified their profile using Tamiya UV Light curing putty - Third: I re-scribed the grooves between each padding of the bottom and back of the seats, to deepen them a bit more, otherwise they'd fade away with the paint layers - Fourth: I started to prime the seats with an automotive filling primer, to reveal the defects. A lot of work was still to be done to get them satisfying . Eventually, the seats got their final shape after I cut slightly off the front part of their base, in order to obtain, on a profile view an empty acute triangular space, and on a front view, an empty space between the seat and the floor, as on a true car. This would allow later on to add the handles that permit to move the seat forwards and backwards. Difficult for me to explain with better words, so some pictures could help you to understand what I did. Furthermore, I took inspiration of the pictures below, and drilled two holes vertically aligned on the back of each seat. What's are they used for...I don't know ! After the painting job, a silver ring will be added around each hole, as on the true car. Then, I had to fabricate the metallic plates that join the bottom and the back of the seats, on inner and outer sides, and whose articulations with the seat's bottom allow to fold the back forwards. I could have modify the seats to get them foldable, but haven't done that....it would have been both very funny but also very pretentious of me ! To improve the seats, I first tried to fabricate from scratch the chrome plates : I drew first a template on a 0.2 mm styrene sheet, cut it off and used it to cut a draft out of a 0.25 mm tin coated steel sheet. I then used various files to shape the form in the metal....but I didn't achieve to get a convincing stuff.... It's a shame, because having those plates in true metal would have been a great addition. Anyways, I 3D drew the plates, using a picture from profile of the seat as a canvas, and 3D printed them. 3D drawing the plate allowed me to add the 3 screws of the vertical portion and the rotation axis situated at the front end of the lower portion. It just remained to paint them chrome . The plates would be glued with PVA thinned glue at the very end of the seats's fabrication. The most difficult job would be now to paint the seats satin-matt black with the paddings in white, trying to imitate the leather texture, and overall not to let the white color overflow on the black. I painted first the white parts of the seats, using a mix of AK Pure White (60%) and AK White grey (40%). Once dried, I sprayed over the parts a layer of Mr COLOR semi-Gloss varnish. Then, I masked the white part of the door's interior and sprayed 2 layers of AK Nato Black And then , again a layer of Mr COLOR semi-Gloss clear. But it looked too shiny for leather, so, once just dried, I sprayed over the semi-gloss clear a layer of Tamiya matt clear, and...miracle !: I got a mix between semi-gloss and matt, with as well a slight grainy aspect, convincingly reminiscent of the texture and colour of leather. A thought kept running obsessively through my head: How to make so small metal rings to place around the holes on the seat's back ? And I found a method: - I used 0.15 mm Nickel-Chrome wire (why nor steel ?: because it's too stiff, and magnetic !) - A dressmaker's pin 0.6 mm diameter - A mini chuck to holds the pin - my hands and strong magnifying glasses (my last one, recently bought after some advices ) - and toothpicks. Some photos to explain the process The rings I got from the spiral, detaching them one by one, under magnifying glasses, with the point of a new surgical blade, were not perfect ! No matter what ! I rounded them better, threading them on the point of a toothpick until they stick firmly and spining the toothpick between my fingers Finally I got 5 correct rings of about 1.0/0,6 mm diameters. I lost one, but I managed to save the four remaining and to glue them with a droplet of Micro Kristal Klear, exactly where I wanted them to be placed.😎 2 hours spent to making 5 rings: Unsaleable 🙄 But it was worth it Next, I made the handles that allow to move the seat forwards or backwards ! A steel rod 0.4 mm, bended with pliers At the top end, several layers of UV resin, placed little by little, to get a roughly rounded shape. At the end, I dip the UV resin sphere upside down into a jar of ivory paint, and that's it ! And at last, I finished the seats: Their chromed lateral hinges were glued in place, using Micro Kristal Klear. The rendering is really good, as you could see. I used Revell Chrome (and have let it dry one week) It remained to glue in place the handles that allow to move the seats backward or forward. They wouldl be installed only when I glue the seats in the cabin. Close view: all the defects are highlighted 😡 Normal view: pretty satisfying And backside view: Not perfect on this one, but with the naked eye, it does the trick 😉 The seats have been placed in my safe, to secure them until I"m able to fit them to the cabin. Stay tuned for next episode- 115 replies

-

- 2

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

You're right with your first statement, Kelson. And it's not finished, stay tuned for next episodes 😉- 115 replies

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Hi everybody Completing the engine bay: Last part. 1/ As I'was still waiting for the delivery of the material that will allow me to build a convincing windscreen washer fluid tank, I killed time by studying again and again the available photos of the engine bay of Elvis' BMW 507 as restored, and I noticed some little things that could be added or corrected: I've numbered them in red on the photo below: - There is, along the left side of the bonnet aperture, in front the brake master cylinder, a little silver cylinder, from which run 2 cables (1). I scratched it using 2 mm styrene rod and 2 short pieces of black electrical wire (0.3 mm) - There is also, running from an appendix situated over the right piston housing of the brake master cylinder, a thin hose or cable, that goes towards the left side of the engine bay (I don't know what it is...) (2). I scratched it with the same electrical wire - The steering box place above the left wheel housing is not black but actually aluminium color, so I painted it. I also took the opportunity to paint the screw heads on this box black, as is the case on the real car.(3 ) - Running out from the radiator cap underside, there is on the 1:1 car a hose that runs over the right edge of the radiator and ended somewhere in the lower part of the engine bay (I think it is a cooling radiator overflow breather ?): I scratched it using 0.8 mm electrical cable (4) - At last, I noticed that there is, on the top of the aluminium steering box a big red "knob" (n° 5 on the photo below). I don't know what this part is and serve. The same part exist on the right side of the car on the right wheel housing. I scratched them with short sections of 1.0 mm red electrical wire, whose top section were painted red as well.(5) And hereunder is the result: 2/ And finally, I was able to improve the kit part to make a new windscreen washer fluid tank The kit part didn't look bad, once cleaned and primed: But I wasn't satisfied, because: - 1/ the kit part shows a lower appendage, which I don't know what it represents, maybe the washer fluid pump ? - 2/ Overall, the tank should be made of clear plastic, as it is a transparent reservoir through which the blue colour of the washer fluid can be seen ! I decided to keep the lower appendage, but to replace the tank itself by something translucent I used a kind of "vacuum forming" without vacuum ! I 3D designed some sockets, male and female: And embossed a heated clear plastic sheet in between - The result: It was encouraging but the goal was not yet reached : the height of the usable part of this clear acrylic part wasn't enough: 2.5 - 3 mm when I need 4.5 - 5 mm Under the 3 mm level, the acrylic sheet was not smooth but crumpled. It's probably due to the lack of height of the moulds So I redrew the sockets, taller, and then I got a very usable shape. I cut the good length out of the draft and I filled it with resin: - first: 1 mm transparent resin at the top of the reservoir - UV curing - Then the remaining height with blue resin (transparent resin colored with droplets of Tamiya X23 clear blue)... I then used my Dremel and a 1.5 mm milling bit to dig the resin in order to get a hollowed part, similar to the kit's one, that I 'd be able later to put easily and correctly on the dedicated bracket in the chassis. The blue resin walls remained about 1 mm thick. It remained to add the reservoir cap. I cut it out of the kit part, sanded it, drilled it 0.6 mm on its centre, and glued it on the top of the reservoir. Then I scratched the metal frame of the reservoir bracket, imitating the kit part, with approx. 0.8 mm wide, and 0.2 mm thick styrene strips. I cut out the lower appendix of the kit reservoir and glued it at the bottom of the new one. A last, I cut a 2 mm section of 0.6/0.4 mm brass tube, in which I inserted a 0.35 mm transparent flexible tube, and I inserted the whole set into the hole I drilled previously on the reservoir cap. Little painting job, black, silver, and...that's it ! I'm sorry I forgot to take pictures at all the stages, but I've some to show you: At last, I installed this tank in the engine bay. it just remained to place correctly the transparent tube and the engine bay wouldl be completed...... That's all folks- 115 replies

-

- 3

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

I did ! You're not quite right ! it also will remain to place the wipers fluid tank (revisited) and its plumbing ! and also 4 or 5 more details that are not in the kit😉- 115 replies

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Thanks, Kanada Kustoms, ...have I crossed the border line ? 😁- 115 replies

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Morning everybody Completing the engine bay: second part - Improving some kit parts - installation 1/ I decided to improve the articulated part that joins the steering box in the front of the engine bay to the steering column, by cutting the kit part in 2 and articulating them together using a metal pin. As you can see, I damaged the end of the joint that comes from the steering box, so, I 3D designed and printed a new one: I assembled the now 3 parts of the steering column and box, and primed then painted the whole set semi-gloss blac 2/ Heating box The heating box didn't need any improvement. Priming: I painted it, using the same white as on the body, as on the true car, and then clear coated It 3/ Tool box: Priming: Painting with Alclad Aluminium 4/ There was nothing complicated about painting the windscreen wiper motor: - After cutting off the thingy that was sticking out, perhaps supposed to represent the electric cables that run from it... - Satin black paint (Tamiya lacquer), then masking and acrylic silver paint on the rear part At this stage of the assembly, I fitted theses parts in place into the engine bay: I glued in place: - the toolbox - the bonnet lockers - the wipers motor - The steering shaft - The Brake master cylinder, without its plumbing, which will be added later. And I just put in place the heating box, because it wasn't yet clear coated And then, I got to achieve the brake master cylinder plumbing : Up close: Awfull, isn't it ? Not so close, fortunately it's better New, taking inspiration of the picture below, I also decided to improve the bulkhead/engine plumbing ... On this picture, I've placed RED numbers from 1 to 7, to indicate the stuff I mean. FIRST, I modifed the engine plumbing that starts from the bulkhead : - Revell supplies only one only stiff plastic part for this plumbing - but we can see on the photo that there is a more complex system, composed of 3 systems (1,2 and 3) SECOND, I added: - The throttle cable (4) - The cables that actuate the 2 bonnet lockers (5, twice) - a cable running from the firewall to the connector on the central hose system, which probably acts on some kind of flap, but whose exact function I don't know (6) THIRD: - I connected one of the negative battery terminals (engine ground), with the engine (7) Fabrication: 1/ Hoses system 1: - 2 hoses with their clamps - 1 central connector 3D drawing and printing of the connector I used 0.4 mm steel wire to cross through the connector, in order to get 2 pins on which I could connect the hoses The hoses were made with 0.8 mm electrical black wire The clamps with fine strips of Hasegawa Mirror finish 2/ Hose system 2 3 D drawings and printing After painting job: In place: 3/ Hose system 3: Made only with the same electrical cable, bended to shape and glued in place. Almost invisible on the pictures, so.... 4-5-6/ Throttle cable 4 , cables for bonnet lockers 5, and cable for the hoses connector 6 I used the metal wires I'd stripped off from of the previous cable, 0.15 mm diameter, bended them to shape and glued them in place with droplets of CA gel And now some overviews of the almost finished engine bay What's missing in there ?..... See you soon, stay tuned- 115 replies

-

- 3

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Good evening guys Completing the engine bay - First part: 3D modeling some parts of the engine bay to be replaced 1/ Battery: The kit's battery wasn't correct, with its terminals and wiring directly molded on the case So I decided to make a new one. The battery and the terminals would be 3D designed and 3D printed and and the wiring would be scratched. I took inspiration of this picture: A Fusion 360 session for the battery: And then for terminals: The 3D printed battery and terminals: Battery painting The most difficult was to paint the battery caps yellow and then put on their top the yellow a micro-droplet of red, whitout covering entirely the yellow paint, to get finally about the same aspect than on the true car Obviously, for the hawk's eyes of the camera, it's far to be perfect, but at the naked eye, and from a reasonable distance to look at it, that seemed nice to me. The terminals were wired and painted: 2/ Bonnet's lockers: The bonnet's lockers supplied in the kit were very basic, so I made mines I took inspiration of the true car with the same picture as above: The kit's part: And my drawings The 3D printed parts were painted: Some Tamiya Lacquer Semi-gloss black, 4 droplets of Silver for the bolts...and that's it ! 3/ The Revell kit's brake master cylinder was absolutely wrong (and ugly too) So I drew mine, taking inspiration of the true one My drawings I primed and painted semi-gloss black the 3D printed Brake master cylinder and it just remained to paint dirty white the 2 fluid tanks, yellow their top and steel some nuts on it. To get the impression that the bottles are half-filled with fluid, I used the following method: - paint both tanks with an off-white, then dry (first picture) - and then apply Panel Line accent colour Brown, from Tamiya, to the lower part of the tanks (second picture) That's all for now. stay tuned for next episode- 115 replies

-

- 2

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

Wow François 👍🏼 Since I had the opportunity to admire your car up close and even had the pleasure of taking two lovely drives with my hair blowing in the wind, I can't wait to see this new project take shape. I'm back in France now, but I'll be returning to Montreal in January. I hope to visit you again.

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Hello happy followers The body shell was attached to the chassis. These parts were not glued yet, because I'd still a lot of work to do on the inner junctions, particularly at doors's level. In fact, however, the fit between these elements seemed correct, except for the rocker panel under the passenger door. I knew I could find a way to fix this. Fitting the body to the chassis wasn't easy, as I completely reworked these parts and "it didn't work like the kit plan". The bonnet was, of course, hinged to the bodywork, and the mechanism for raising and closing it was installed and was operational. There's a lack of lubricant : A few moments later, I noticed another problem with how the parts fitted together. The bonnet closed properly, but then its front part was raised by about 0.7 mm, as you can see from the photos in my previous post, which was very unsightly and unacceptable! What's more, while I was trying to find the reason for this, the left-hand hinge finally broke off as a result of raising and lowering the bonnet too much times. I tried to identify the cause of this maladjustment, using my spare bonnet - First, I tried to fit the spare bonnet from my second kit, without fitting the spare frame that stiffens it on its inner side: and then, this spare bonnet fitted on the body without any misfit. - Then I taped the frame to the inside of the bonnet, and tried again, and the same problem as with the painted bonnet appeared! It seemed to be the frame that was causing the problem at the front of the bonnet when you wanted to close it. One thing leading to another, I was able to determine that only a small part of the frame was responsible, so I removed it from the spare frame and tried the operation again.... And then, miraculously, everything went well, the fit was perfect and the bonnet didn't stick out once it was closed! I then carried out a risky and delicate operation on the painted bonnet, namely removing this same part of the frame. Once the operation was done, with no damage other than to the paint on the inside of the bonnet, the fit was better, as well. All that remained was to make a hinge for the left-hand side and hide the misery on the paintwork on the front of the inner part of the bonnet, what I did using semi gloss black paint (because it would have been tedious and risky to sanding the damaged part of the bonnet, moreover without having certainty to obtain a perfectly smooth surface) Once this done, finally, the fit was better : the bonnet raised now with only about 0.3-0.4 mm at the front, while I'd not yet fixed the hinges, what could reduce a bit more the defect. That said, I was not still frankly happy, because the bonnet wasn't still flush with the body. Fortunately, after multiple tests, I realised that sanding the frame on the inside of the bonnet to thin it out, would greatly improve things, the remaining fit defect having become minimal. So, I sanded down the inner frame of the bonnet as much as possible. Of course, I also had to repaint it and try to hide the defects caused by my repairs as much as possible. I took then the opportunity to add, purely on a whim, some sound insulation felt panels, made from cut-outs in a sheet of paper (0.11 mm thick), painted matt black and varnished matt. Purists will retort that, yes, such plates are found on all cars nowadays, but that this was not necessarily the case on cars of that era, and that in any case, on the few photos of the restoration of Elvis Presley's BMW, you can't see such accessories, any more than on most of the photos of other BMW 507s that can be found on the net. So my answer to them is: - yes, but there's nothing to say that they weren't added later on to Elvis's BMW, because I can tell you that having seen a video in which we see this V8 engined car driving, we also hear it, VERY LOUDLY! - that if you look hard enough on the net, you can find photos of the engine bay of some BMW 507s, where the body colour is not black, but the inside of the bonnet is black. So either there are felt panels for sound insulation, or the inside of the bonnet has been painted black to better absorb and eliminate the heat generated by the engine. For example, these photos: - And it's a restoration, the engine wasn't even available any more, nor were many of the original parts, and the artists who worked on it sometimes took liberties, so ... - And finally, I had no choice but to hide the misery caused by the removal of part of the frame after gluing (see previous posts). But the result of my work in the end, wasn't too bad (and I'm not saying that to reassure myself), but you be the judge: I made then a new mechanism for raising and closing the bonnet: The new hinge was drawn and 3D printed, assembled and painted and then put in place, not without difficulties, due to the lack of room to put my fingers in the engine bay 😅 I used this 3D printed part, a tiny piece of clear sheet (phone covering protection) that I glued on it, and the same metal stripped I'd previously crafted, and which slides into the "box" formed by the clear sheet and the 3 D printed part And now, some overviews of the achieved bodywork Stay tuned for the next episode: completing the engine bay Thanks for watching- 115 replies

-

- 4

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Thanks for this huge praise, Bugatti Fan 😎- 115 replies

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

- 115 replies

-

- 1

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Thanks a lot, Absmiami, for your wishes, and for liking my work- 115 replies

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

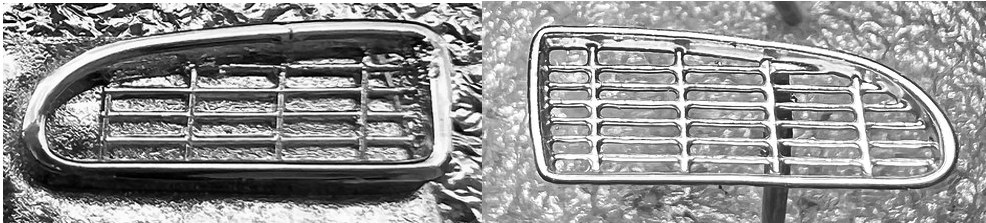

Hello everybody I've put in place the fuel filler cap Of course, all the parts I assembled for this fuel filler trap aren't supplied in the kit ! I 3D designed and printed them ! Work on the grille grilles: Indeed, I intended to improve a bit the two parts Revell supplied for the chromed grill... Those parts are very disappointing because the spaces between the chrome blades of the grill are not empty ! So, I begun to sand them from the back, carefully, until I almost reached the braces, by rubbing them on a 180-grain file. Then, I finished the job with the point of a scalpel blade, little by little. At least, I sanded carefully the blades using a thin strip of 400-grit sandpaper. WIP: And hereunder is the final result after 4 stressing hours : These modified parts took a bleach bath, and were supposed to be painted chrome later. BUT, as my mind is trained to track every defect, I (un)fortunately noticed that the kit parts for the grilles are inaccurate ! 😮 In fact the amount or horizontal blades on the kit parts is 4, while on the actual car, it's 6 ! 😡 So, it remained no other option than manufacturing new grilles ! I designed them in Fusion 360 I 3D printed in resin this design and got a nice result: The parts were painted chrome using GreenStuffWorld airbrush chrome, over a gloss black base (from ALCLAD) and I got excellent results : That's all for now ! Stay tuned for next episode- 115 replies

-

- 4

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

Marvel's Hydra coupe 1/12 scale full scratch build

CrazyCrank replied to François's topic in WIP: Model Cars

I'm very happy you received these rewards....your models and you definitely deserve it ! Congratulations 😎 -

Marvel's Hydra coupe 1/12 scale full scratch build

CrazyCrank replied to François's topic in WIP: Model Cars

I understand your great interest for this gorgeous model. I 'm a French modeler, and I recently crossed the pond, almost only to touch this model with my eyes in Canada ! It was worth the travel ! and François is also very welcoming ! CC -

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Thank you Mattilacken for this great comment. Yes it's tricky, but within everyone's reach with a little determination and patience- 115 replies

-

- 1

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Thank you so much for this praise, Pico 😎- 115 replies

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Hello everybody Sorry for not posting anything for almost a year; I've had serious health problems again in the meantime, and have very little time available. So I'm picking up where I left off, and the next few posts will take you through to the completion of the assembly. Improvement of the steering wheel: The kit part has good shapes, but all is too thick, so, I began thinning the part, using a scalpel. On the picture below, you could see the beginning of this job: on the right only, thinning has begun. Unfortunately, I forgot to take pictures of the achieved job. After priming and painting: You could notice on this last picture that I've added some grooves between the 2 "horizontal" struts on the left and on the right side as well. I took inspiration of this photo: Purists will notice that there is 13 grooves each side on the real steering wheel and that I added only 9 ! Why ????....Because I can't count past 10 😂..... more seriously : because I made this mistake ! shame on me ! Clear coating: I had in my stash some spare metal transfers from my Tamiya Mercedes Benz 300SL, and, particularly, a chromed ring, a bit too wide, but would do the job to represent the ring on the BMW 507's wheel centre. I've still to paint semi-gloss black the vertical struts of the steering wheel situated between its horizontal ones, and add at each end of them a fine chromed strip (Hasegawa mirror finish), taking inspiration of the previous picture of the actual. car. The steering column : - I've cut off the indicator control lever, on its right, much too thick ! - And replaced it by a scratched one, using 0.3 mm piano wire and at its end, a droplet of UV curing resin, plus a tiny washer (PE part from Tamiya MB 300 SL detailing kit) - A little touch of ivory paint at the end of the indicator lever, for covering the resin and... that's it ! The ref. photo is the same My interpretation: Assembly and some additional details: And, having received my rivets, I placed six 0.5 mm flat head rivets on the top of the dash: I just placed the wheel near the dash to take the picture : The handbrake handle has been chromed and is now in place: I've added the superior knobs which heads are painted te same color than the bodywork. I cheated and used Hiroboy 1:24 toggle switches. They are metal made. I drilled two 0.4 mm holes at the right places on the dash and inserted the switches into them. Then, a little drop of white on the heads, and ....that's it. Maybe they are a little bit oversized if you look at them from profile view, but at the naked eye, it looks pretty nice. Making of a BMW key ring: It's amazing how little things can take so long to get done 😮 I 3D drawn and printed this: A pretty disk with an eyelet , and on the disk, 4 sections of the same size, 4 "pie slices", that are slightly dug in the disk, and in which I could "pour" some blue and white paint, without overflowing too much. 3D drawings: The 3D printed parts The key ring painted silver plus the slices, 2 blue, 2 white 1 And then, several layers of Gauzy agent, to create a nice shine and give thickness. On this picture, the Gauzy agent hasn't yet dried and look a bit "milky". Once fully dried, it will be totally transparent (Initially, I used transparent nail UV resin to give the best shine and relief, a bit like a curved glass. It worked perfectly but the slightest manipulation of the UV cured part led to dulling the resin, so...) I've also printed some ignition keys. It remained to do the more delicate job: linking ignition key and key holder with a very thin metal wire to simulate the chain, without breaking the eyelets of the key holder nor/or the ignition key (My first key ring made with UV resin has been broken during this process) The keyring is now attached to the ignition key 😎 It took a long time because I had to start over several times. Either I broke the eyelet on the key, or the eyelet on the keyring, during the delicate operation of creating a chain between the two with 0.15 mm wire. As a result, each time I had to either repaint a key, or - and this took longer - repaint and varnish a keyring! The total length is about 7 mm: 2.2 mm for the keyring, 3.5 fr the ignition key and the rain for the chain My eyes won't be able to work on this 1:24 scale for much longer ! And it took its place on the dash: That's all for now, guys. Thanks in advance for your comments and criticism 😎- 115 replies

-

- 2

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

Marvel's Hydra coupe 1/12 scale full scratch build

CrazyCrank replied to François's topic in WIP: Model Cars

Once again, François, you've produced something absolutely "marvellous" ! CrazyCrank, from MTRL -

Marvel's Hydra coupe 1/12 scale full scratch build

CrazyCrank replied to François's topic in WIP: Model Cars

Dropped my jaws on the floor, again ! 👍 -

BMW 507 Cabrio 1957 - Elvis Presley's one - Revell old kit 1:24

CrazyCrank replied to CrazyCrank's topic in WIP: Model Cars

Hello everybody Today, I'll show you how I made and assembled all the dashboard components - part 1 - The dash was semi-gloss clear coated - The decals have been placed, not without difficulty because those ones were very fragil. Used a lot of Microscale Microsol to soften them, but damaged a little bit the central one (not visible at the naked eye) - Once dried, I sprayed a finale layer of 1K Gravity clear over the decals .... et voilà ! Next I 3-D drawn and printed a new handle for the handbrake (the lever I thought it was a starter, placed under the dash on the left side) It will be painted with Molotov Chrome I 3-D drawn and printed the different knobs of the dash and radio They will be painted ivory. I 3-D drawn and printed a new passenger handle (placed on the right side of the dash, on the right of the glove box). It will be painted matt black The meter's glasses have been improved using drops of Gauzy agent put on the decals. Once dried, it's fully transparent and shiny I've scratched the gauge's bezels, the elements of the fake glove box hinge, and the chrome frame of the speaker and radio with Nickel-Chrome 0.25 mm wire I've already glued the bezels of the 3 meters and fabricated the fake hinge for the glove box. All those little bits of Nickel-Chrome 0.25 mm rod have been glued using Gauzy agent (from AK), instead of Micro Liquid Tape, because it's much less thick, dries faster and if much more transparent. The thin mesh of the radio speaker, at the top center of the dash, was simulated inserting in the hole a rectangular piece of thin mesh (0.1 mm It has not the right number of rows (30 would be needed to be accurate) but looks good imho. The grill is in place, and the meters's bezels as well: Then, I painted chrome all the dash knobs that I'd resin printed. And next, I brush painted ivory the buttons, under magnifying glasses I had also painted chrome he passenger handle, because on its top end, there is as well a chrome bezel, and I've painted the handle Nato Black (AK 11360), which looks like a black leather. The result is really nice : The dash knobs an radio buttons were placed on the dash. To highlight them, they have been painted light ivory instead of Pearl white, as the body. We can see, on the closest photo, their chromed bezels The handbrake handle was painted chrome and put in place: Stay tuned if you like, and thanks for watching and criticising. ?- 115 replies

-

- 1

-

-

- bmw 507 cabrio

- elvis presley

-

(and 2 more)

Tagged with:

-

I do love your highly detailed engine bay ?