-

Posts

364 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Mike Williams

-

-

On 4/12/2024 at 8:59 AM, ChrisR said:

Great build!

Thanks much Chris for commenting, glad you approve. Mike..

-

On 4/12/2024 at 8:23 AM, Straightliner59 said:

Daniel, you've built a very similar car before, your Jr. Dragster, aluminum body. Are you really thinking the same, basic type, with 'The Surfers' car? I agree, these boys were different, and very quick. I've collected lots of photos and literature about these guys, was also considering a replica. Just proper tires and wheels in 1:16 aren't easy to come by. If you can find the correct parts...Do it! Mike..

-

23 hours ago, AmericanMuscleFan said:

Hello Mike and thanks for your great question! I don't use any coolant, it's a disaster and I want to keep my work space as clean as possible. I compensate with more small cuts at high speed and always use 2 flute cutters for aluminum. I only use very hard T6 type aluminum because soft aluminum cannot be machined, it produces a very ugly finish. For holes, I almost exclusively use carbide drill bits at the highest possible speed my machine can give me (I think it's about 2800 RPM with standard pulley). You have to stop often and feel the progress of the drill and back off when there are no more chips coming out of the part, it is no worse than breaking a carbide bit in your part, it is ruined and you have to start again.

I hope I answered your questions well.

Francis

Yes, I understand. Many thanks for the insight. Drilling soft metals is a mess. Thank you!

-

1

1

-

-

Francis, I'm interested in learning of the milling speeds you apply. Sure, small holes are fast and without liquid cooling. The larger cuts though, must have some kind of cooling applied, of course considering the size of the cutting bur. Do you draw back without cooling, or dig in with milling oil? My old days of milling small scale things, were all done very high speed, with lots of oil.

-

1

1

-

-

On 4/10/2024 at 2:23 AM, PappyD340 said:

Awesome build!!

Thanks Larry! For me, only wanting to model pre-70s FAs and FEDs. Make them low, down and dirty. Yessir! Mike..

-

On 4/9/2024 at 12:14 PM, Yeah Nah said:

Another amazing big scale metal FED Mike. That colour......😮

Dear Garry, so nice to read of praise, so much fun to build the 1:16 FEDs! Just in this scale, gets difficult to hide mistakes. But yet so much fun to model these long cars of old. The colour...YES! I love House of Kolors paint on bare brass. Sorry though, the nose shows some dust, now enclosed in a decent environment. Mike..

-

1

1

-

-

On 4/8/2024 at 11:18 PM, Richard Bartrop said:

Nice work!

Much appreciated, friend! I'm an older type modeler, but still trying to make it happen. Thanks for your commenting and praise. Mike..

-

On 4/8/2024 at 10:53 PM, Straightliner59 said:

Simply gorgeous, Mike!

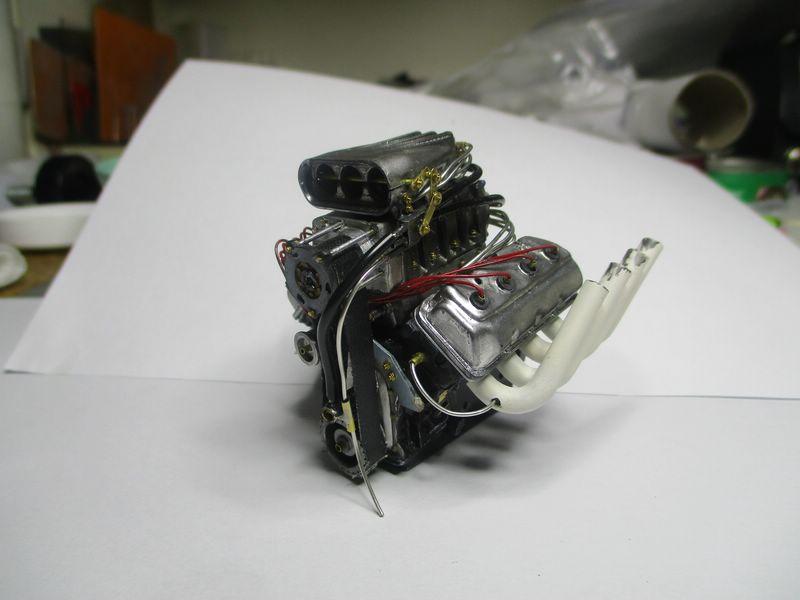

Thanks Daniel! We both love early FEDs. After bailing out from Roger's other car, decided to do a 426 motor instead, with a full body though.The chassis is spot on. At least this small chassis issue was good! lol. Mike..

-

1

1

-

-

On 4/8/2024 at 7:53 PM, M W Elky said:

Wow you’re workmanship is outstanding

Glad you approve, Michael! Lets me smile.Thank you! Mike..

-

On 4/8/2024 at 6:21 PM, ColonelKrypton said:

Very, very nice.

cheers, Graham

Cheers to you, friend. I greatly appreciate you commenting, makes me proud. Mike..

-

1

1

-

-

On 4/8/2024 at 7:28 PM, Straightliner59 said:

When I started building my Surfers' chassis, based on Roger's advice regarding a tubing diameter, I took my spring-micrometer to a craft store, and measured every spool of brass jewelry wire, until I found .055"! Eventually, I met his approval, but it took about three rebuilds. Truth is, Roger lee is likely the only guy who would ever notice that a chassis tube is a few thousandths off. But, like you say--that's important, to us! I'll get this thing back out, before too awful long...

Daniel, I understand you. After all, we both learned a lot. Am I right? Yes! Please get on with this true scale project. Mid 60s FEDs still kill me. So far, this is looking like a winner! Nasty motor dump, short WB. Loving it already. Mike..

-

1

1

-

-

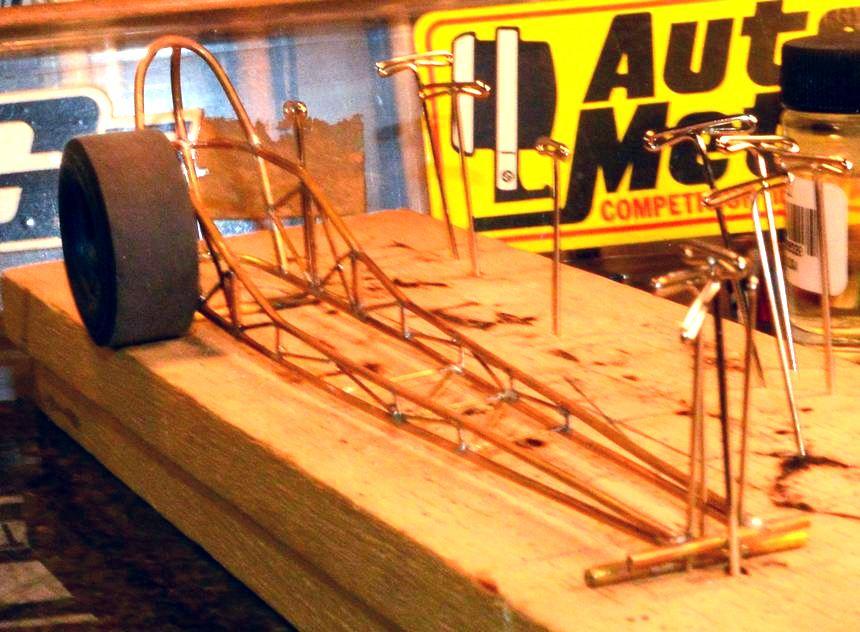

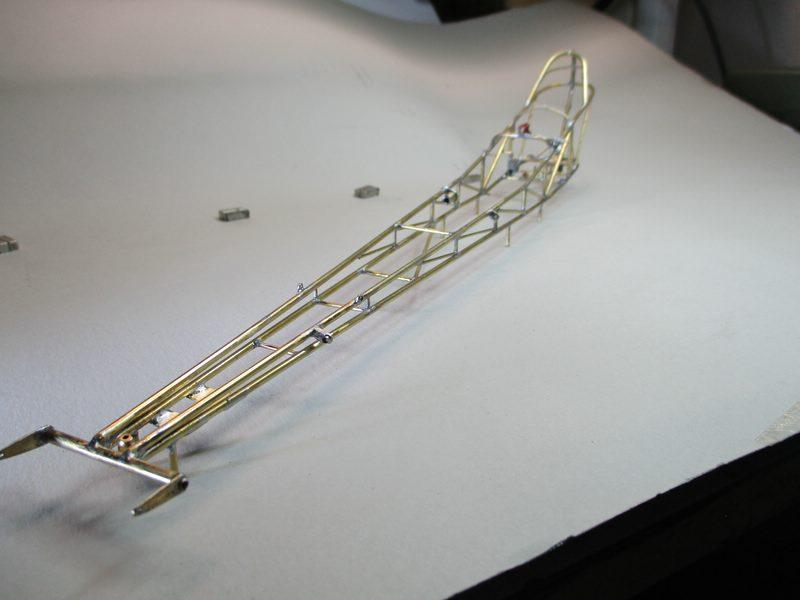

Built a few years ago, a scale 1:16, 175 inch, brass FED. Original plans. Wire laced fronts, brass chassis and body. HoK, Brandywine on silver base.

-

4

4

-

-

Wonderful! Congratulations! CT, you're a fine modeler, but also a real car guy. Your input allows us modelers an insight to the real cars we love to model. We can all be grateful that fellows, whom offer knowledge as well as real life thoughts, as yourself are also winners! Be proud! Thank you, CT!

-

Oh man, I hear that! This went on for 2 cars. Then suddenly, in my opinion, excessive and unnecessary critique came about, proving these attacks to be unwarranted. This angle is not right, tubing too thick, the bend is way off....oh my! Yet I only answered with pics of his own, original plans.

Daniel, I finally bailed out, offering effusive thanks. True is, a fantastic scratch build modeler and very helpful real race guy. I'm very grateful for the experience. I don't build out of scale. For a lower rear hoop on the chassis, wanting to be real scale, I found a perfect material! Coat hanger wire! Solders up nicely with the usual stuff! Just saying. Thanks for commenting. Mike..

-

1

1

-

-

On 3/30/2024 at 7:35 AM, Straightliner59 said:

I missed this, until now. Sorry I did, too! As always, your metalwork is superb! She's a beauty, my friend!

Hi Daniel, this is Roger Lee's car, being the Brissette car from '64 to '65, original plans from Roger. You know how this works out. Thanks for commenting. Just one thing now, gotta love simple fuel dragsters, 1965! Mike..

-

1

1

-

-

Oh my! I can only write now, smiling from ear to ear.

Wonderful work. Mike..

-

Niko, excellent model. Respect. I've viewed a few Gassers. This is on my top list! I like especially the shiny metal on the motor, wonderful contrast. Detailing is spot on. Compliments. Mike..

-

17 hours ago, AmericanMuscleFan said:

I'm very happy to see this beauty resurface Mike!

I remember seeing you working and posting your updates on this one and it was a great source of information (and still is) for anyone who loves brass construction and ways to work with this wonderful material. The effect of the red paint on the bare brass is incredible and your wheels are pure art, the way you went about making them is just brilliant. 👌

Hello Francis! Oh my, I've forgotten to have shown this car previously! Meantime, other brass cars are finished.

I agree, the House of Kolors paint on brass can be very interesting. Still, older now, good paint has to smell! After all, we're painting metal. Mike..

-

Wonderful project. You did good.

Mike..

-

Hello CT! Finally back again, very pleasing to view your wrecked and bashed model, truly a view to behold! I believe, the best models, as well as real cars, only need some fine, TLC. You've shown us the way. Excellent attention to detail, utterly believable. Compliments! Mike..

-

I like especially the attention to panel lines. This will be a huge plus, later on.

-

I'm very happy to view your work, real time.

Mike..

-

On 3/11/2024 at 2:13 AM, cifenet said:

Fantastic model you got here! Excellent work making it look awesome.

I'm really happy you approve. Still, this car is one of my faves. Mike..

-

On 3/10/2024 at 9:18 AM, Bugatti Fan said:

Beautiful build. Chassis frame in brass and the detailed engine really look good. The thin wire wheels are something to behold adding to the realism.

Thanks much. I do feel, small things can make our models look better on the shelf. Just try to go another step forward! Mike..

1964, Brissette FED. 1:16, brass, scale build.

in Drag Racing

Posted

Hi Carl, I'm liking your approval. Appreciated.