-

Posts

98 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by IbuildScaleModels

-

-

On 5/16/2020 at 6:22 PM, Tom Geiger said:

Agreed! I have no machining background and have no interest in working a lathe or mill. Also had no interest in learning home photo etching.

I do have ancient CAD skills where early on I was pulling decals off a pen plotter in the early 1980s. Today I make a lot of decals in computer graphics and print on my inkjet.

I have an interest in Cricut and 3D printing, but my model building isn’t at a volume where I’d make the investment right now.

I do think we all need to employ any skills and tools that we care to. And if we choose otherwise, hey it’s just a hobby. Let’s do what interests us and makes us happy. Otherwise it’s called “work”!

Haha it is work for me. But fun work... so for me it is a career. Plus I love the challenge of doing harder things. I don't do it for competition though. Competition does nothing for me. But I do love going to competitions to get inspired.

-

8 hours ago, Bugatti Fan said:

Gary, there is nothing wrong with 'old school' techniques at all. Basically like any other method, no matter how sophisticated it is after all a means to an end.

Your Bugatti T57 stalled project. Don't let the fact that LMM and Renaissance have kitted this in resin put you off as you already appear to have the body well sculpted. I think that you can buy sets of wheels in photo etched from either company.

Justin, you have made a good point about most probably getting their first experience of machining by using lathes at school or college. My very first experience was a wood turning lathe at school when I was 13.

Noel, and that's kind of my point. If we have the experience, why do we go back instinctively to the lathe before mill? Like I said, for me it was just logical in regards to costing it out. If I went with the mill I would have to buy a rotary table, and a 3 jaw chuck. I buy the lathe and I can make the rotary table for the cost of the metal and time investment. OR, I could just drop the money for the parts. I guess it is different for everyone, and everyone has a different budget and learning curve. Also, I really like the table top machining guide by Joe Martin. Reading it like a novel too. Even if it says not to. HAHAH!

-

1 hour ago, Gramps46 said:

I have been following along with this thread and am really impressed with what you all have accomplished. My take on scratch building is a bit different in that my efforts have been to make bodies that did not exist and had to be made from scratch in 1/24 scale. Now granted, these are really old school techniques before todays technology was available.

Bugatti T57 - this project got stalled when both Le Mans Miniatures and Renaissance released resin kits of this Bugatti

Shelby King Cobra - used the slot body back fill technique

Corvette SS - Andy Martin picked this wooden buck up and ran with it.

Jaguar C Type - a Bill Koons Images vacuum formed body built into a full up model for Fred Cady's collection.

Hot dang! That is real 3d modelling! That old school method is something I need to learn. Very impressive.

-

On 5/11/2020 at 2:39 PM, Bugatti Fan said:

Pat (Landman in Ontario) your Taig lathe looks incredibly very much like the Peatol Miniature lathe that I mentioned in an earlier post. Could it be the self same machine under a different brand name? Last time I saw one was at a Model Engineering Exhibition about 20 odd years ago and if my memory serves me correctly you had to buy the basic machine and add things like the motor etc.

Justin in Montreal, I think that most people go the lathe route first simply because it seems the logical place to start only having 2 axes X longitudinal and Y front to back. A milling machine has a Z axis (vertical) also to contend with. Having said that it very much depends on what sort of things one wants to make from the outset that will determine which machine to go for.

As modellers there are many different small machines available to us like miniature lathes. milling machines, circular saws. fretsaws. wood lathes. routers, thicknessers etc. Have a look on Proxxon's website to get an idea of their awesome large range available. Having mentioned Proxxon before, and before somebody asks, I have no connection with that company. It is just that they have a very comprehensive range of miniature machine tools especially designed with model makers in mind. Don't take my word for it. Just have a look for yourself.

Dremel also have a range of accessories to make their tools more adaptable. One that comes to mind is an adapter to make the Dremel tool into a miniature router, so some of theirs may be worth a look if you already have a Dremel. Their tools seem to come and go over here in the UK. but I understand that they are a mainstay hobby power tool and very popular in the US. I bought one some time a go over here and it is a good bit of kit.

Yah the dremel is a mainstay in most north american homes. I have mine somewhere in storage since I moved a while back. Instead of the dremel I have been using a smaller handheld rotary tool that gives me more control.

The reason why I questioned the lathe route, barring the 3 axis vs. 2 axis argument, I believe that most of us have already lathe experience either from back in high school, or having one at home. Pete cleared up that turning metal and wood is basically the same thing, using the same techniques but with sharper tools. Chatter still happens on wood or metal. Learning how to tool/machine (i always misuse those terms, so please forgive me if I do) is apparently simple. Even from what I have read in Joe Martins "tabletop machining guide". Mind you the comment that follows this is "even though you can use the tool, doesn't mean you are good at it."

I just thought possibly that there was another reason for the logical progression in machining from lathe to milling aside from the learning curve. Like I said previously, I decided to go the lathe route not for the learning curve, but due to cost related issues.

And hell yah, proxxom does have a P*ss load of model/hobbyist geared tools. Proxxon, Sherline, and Taig were my main choices. Unfortunately, being in canada and requiring financing to aquire any one of these brand names was only possible through the official Canadian distributor of Sherline. So, I went with a Sherline lathe package. Ordered it this morning... Now have 5 weeks lead time before it gets to me. So in the meantime, more building with my hands and writing replies on forums as I look for more information.

Justin

-

On 6/2/2013 at 3:36 PM, Ben said:

Just wondering if anyone here has this paint booth and if so, how often do the filters have to changed? Does it have a high volume motor for dispersing the fumes? http://www.amazon.com/Master-Airbrush%C2%AE-Portable-Airbrush-Extension/dp/B00B2TESUQ/ref=pd_sbs_ac_1

Have it. It just takes minor fumes away. It needs a more powerful fan. Fortunately you can buy 2 of them and stack them together and that does the trick.

-

44 minutes ago, Chariots of Fire said:

I'm glad to see so many doing things with a lathe. What a great tool it is. That and learning a bit about soldering small parts has made a big difference in how I approach my scratch building. Another material I found was Renshape. It is good not only for making patterns to cast from but it is great stuff to carve. With no grain it is strong in every direction. And when it is milled there is no fuzz around the edges of the cut. I was very fortunate a couple of years ago to be able to purchase a 2" x 4' x 24" block of the 450 grade for very little $$. Oh. And it takes primer and paint with no problems.

Man, don't even get me started on soldering! HAHAHA. I went to brass as soldering silver is a PITA! Then I discovered that brass makes heat travel more evenly and faster than silver. DANG!!!!

Talking to a machinist friend of mine locally who does large scale train builds and restorations, he said stick with steel as it is the cheapest and greatest metal for parts. Unfortunately for the tiny stuff, brass and nickel-silver is the only way to go.

And I see that a lot of people here went the lathe route first then milling route. I am still curious if it is a lack of skill and confidence issue or it is really a cost issue. I say this not to offend, but really to question. For me I am taking the lathe route, only due to cost reasons. If I start with a sherline mill, the accessories to convert it to a lathe and get the other tools to make things work will be almost double the cost of going the opposite route. I wonder why that is. Also as Pete explained to me, you can always make your own tools. And from the 200+ videos I have watched in the past week about machining, yes this is true. Francis has also helped me making my decision, and seeing his work is amazing also!

I am always humbled by seeing the skills of the builders on this forum!

-

On 5/8/2020 at 12:52 AM, Pete J. said:

If I were to guesstimate, I would say you are pretty much spot on, but I would think that with end mills and other bits and pieces, I'm pretty close to double the original purchase in accesories, but then that is well over 10 years of working with the machines.

Pete,

From our discussions and research I have done on my own; if planned out well, the tooling can easily cost 1/3 of the initial investment. Mind you, the materials is where it will bite you in the ass. I am saying this because you can make all the tools you need with the right setup. Knowing that, and if you have the skill, the tools you can buy versus the tools you can make, the cost ends up decreasing exponentially. But of course this is choice vs. simplicity and ease of access vs. time investment.

For stupidly determined people like me, I would go the time investment route and hell, I would probably go the ease of access route from time to time. Just the fact that I have decided to invest in a sherline vs. making a lathe or mill myself (due to lack of tools) shows that I am taking the accessibility route. The cost of making your own desktop mill (if you have a drill press, tap and die set, reamers, etc.) can cost about 100$. Making a desktop lathe can cost about the same....

Here are a couple of useful links to do so (I was going down this route to start):

https://www.vintageprojects.com/machine-shop/hobby-lathe-plans.html

https://www.vintageprojects.com/machine-shop/turret-lathe-plans.html

https://www.vintageprojects.com/machine-shop/lathe-modelling.html

https://www.vintageprojects.com/machine-shop/tap-holder-attachment.html

https://www.vintageprojects.com/machine-shop/drill-vise-mill.html

https://www.vintageprojects.com/machine-shop/lathe-tool-slide.html

https://www.vintageprojects.com/machine-shop/low-speed-drill-press-plans.html

https://www.vintageprojects.com/machine-shop/power-hacksaw-plans.html

Majority of these plans came from Popular Mechanics back in the 50s.

Yah, I'm going to be building a few of these...

Justin

-

4 minutes ago, Pete J. said:

That has been a main theme in the topic. It is certainly not for everyone. For years I used a variable speed Dremel and some files. It made the Sherline all the sweeter when I finally was able to spring for one.

Just one thought, since I bought them, I have found many uses far beyond just modeling. I don't know how many things I have repaired around the house, Heck I even turned a few Christmas ornaments.

HAHA Pete! I agree that the sherline is a hobby machinist's tool that can be useful for fabrication of other tools and parts. But of course it raises the question... more money to give room for expansion? Or less money for a tool that does exactly what it needs to be used for? It's a tough ballpark to be in... Hell I am even debating financing one, not my favorite option, but from there I can make a milling machine smaller and more suited to my needs. Kind of a contradiction, I know. I might get one just to build a smaller mill/lathe setup, then sell off the sherline. One thing is for sure, you can go big and scale down, but hard to start small and scale up especially when it comes to tools.

Justin

-

On 5/1/2020 at 9:59 PM, CabDriver said:

I’ve been casually considering a lathe - what kind is that and what kind of budget does one need to get going?

I would love to buy a sherline, but for the size of parts I make, and the price of a sherline, it really isn't up my alley. I am researching the parts I need to make my own micro milling machine. The size of this and the functionality of it will hopefully be comparable to a early 1900s watchmaker mill.

As for the budget on a Sherline, just the mill runs about 800$ USD and the lathe runs about 500$ USD. I have 6 kids, so money often does not get put into my hobby. Hell even dropping 100$ on Albion Alloys for brass tubing and brass rods was expensive for me. Hence the build it yourself attitude, and the idea behind this forum topic.

Justin

-

-

-

-

-

-

On 4/21/2020 at 9:07 PM, Tom Geiger said:

I remember Joe Cavorley saying that anything you wanted to scratch build was nothing more than a series of shapes. Break it down to the basics and start there.

One thing that helps me is my “Shape Box”. It’s just a big box full of odd junk. Broken kit parts, half a VW fender, angles or curves whittled off bodies I was modifying, small piece of plastic with an interesting pattern engraved in it, big old staple removed from opening a box.. just toss it all in this bin!

I'm amazed at the stuff I turn into something else when I need to make something!

Being a modeler is never throwing away an old pen without saving the spring... and examining the rest of the parts!

I like that... Shape box... Reminds me of how they teach you in 3d modelling

-

-

Francis, you are too kind! And thank you guys for believing in me. It humbles me to see how guys like you, who make such fine models and spend so much time doing so, compliment my work.

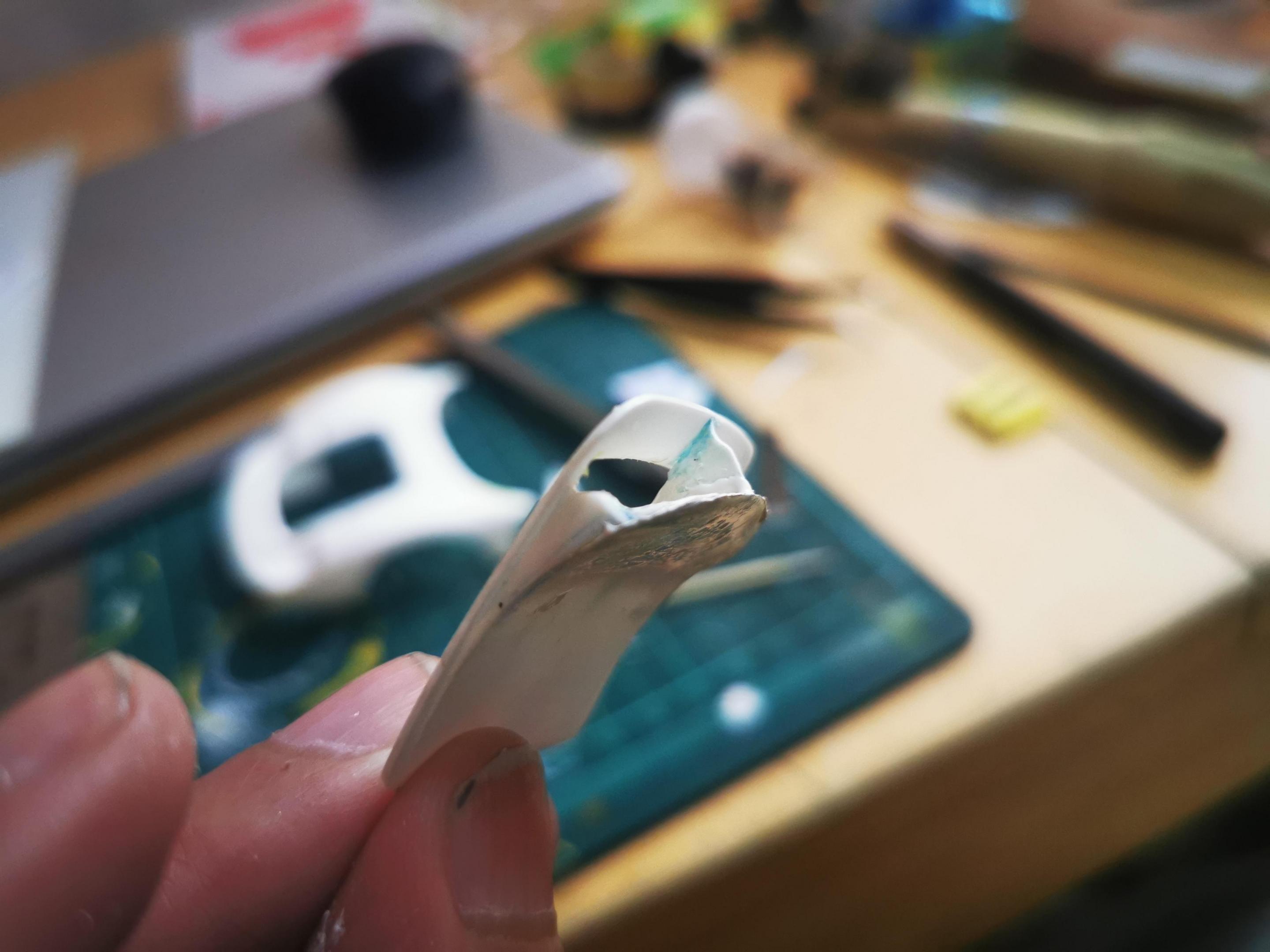

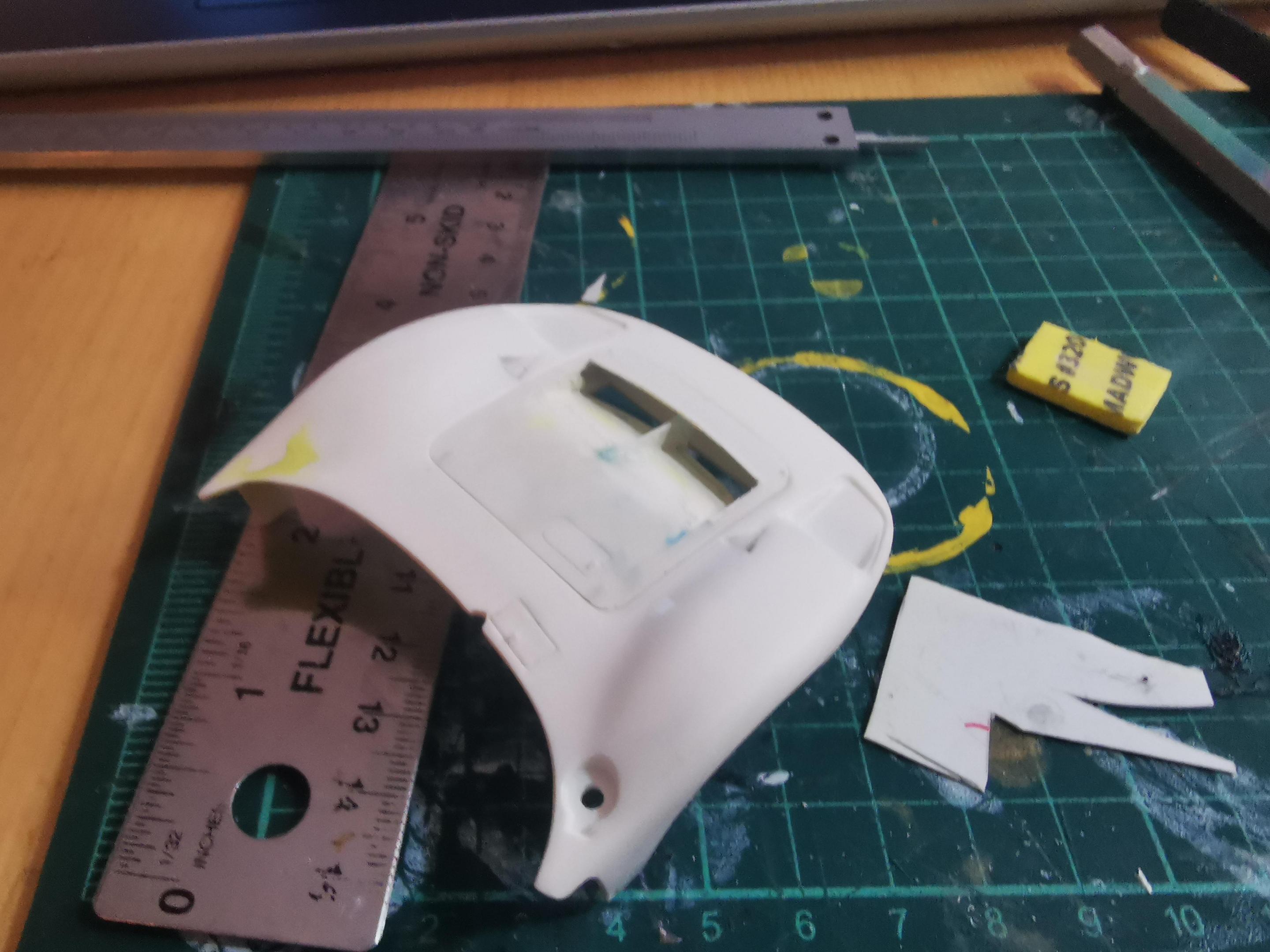

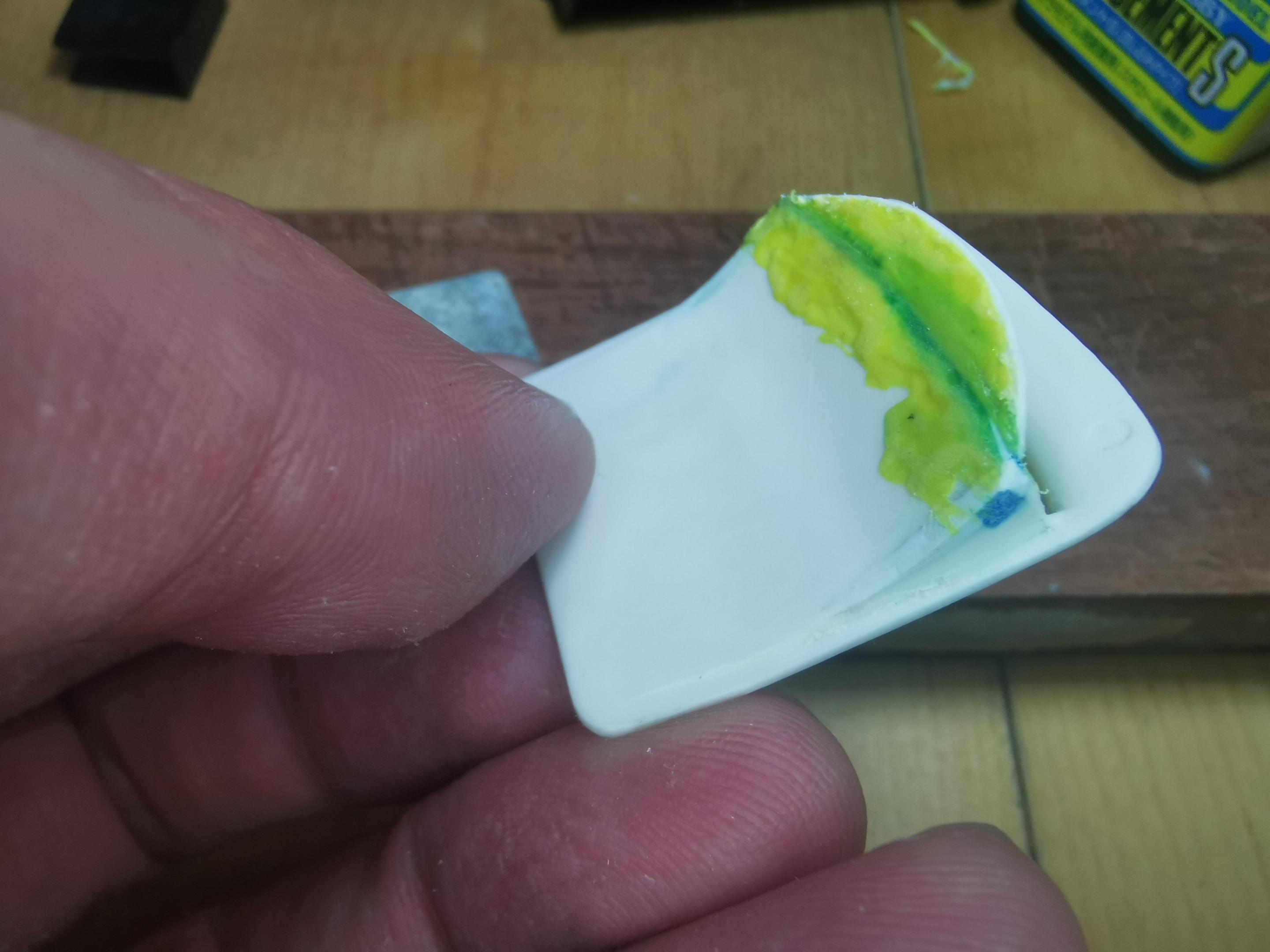

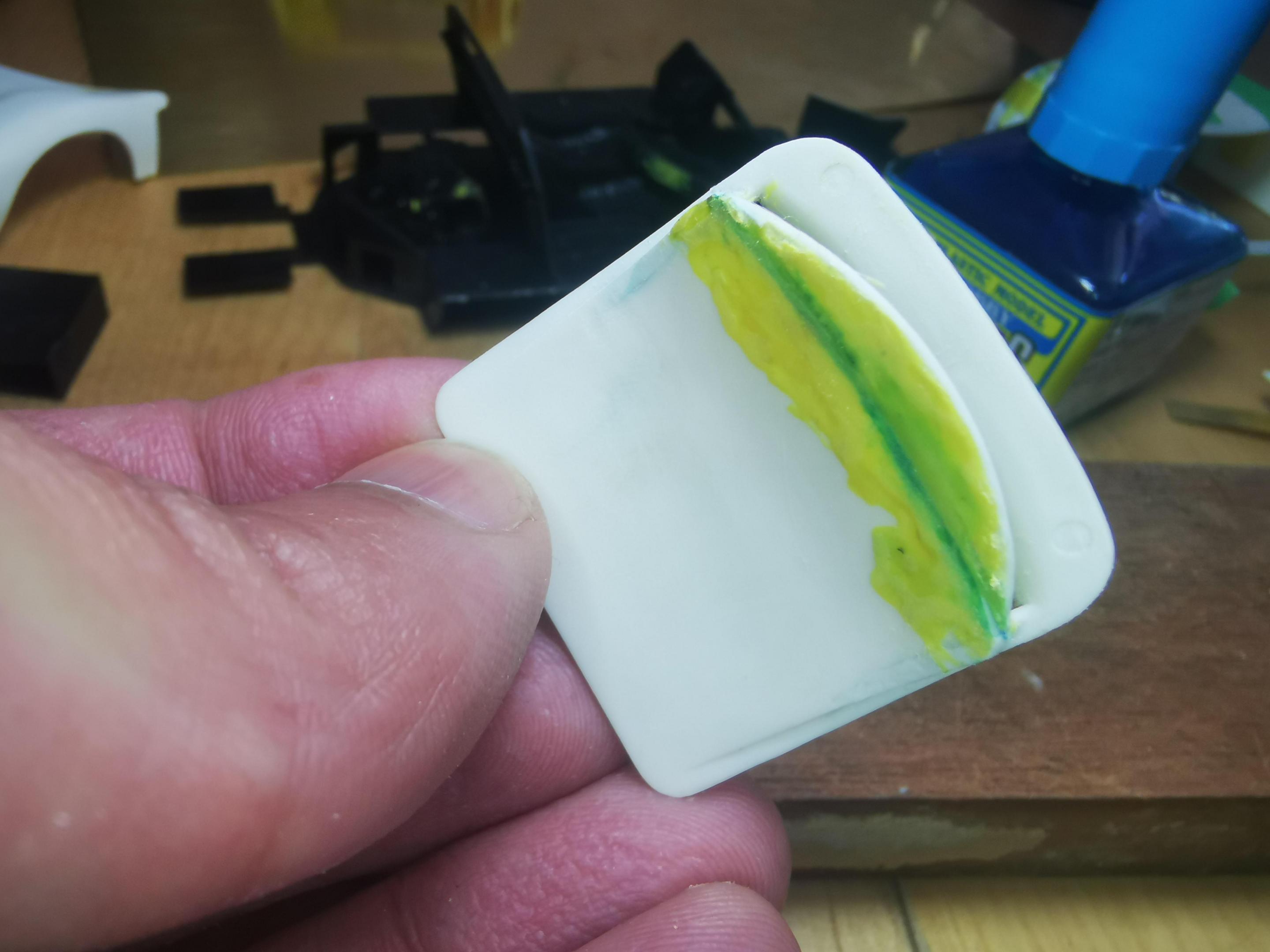

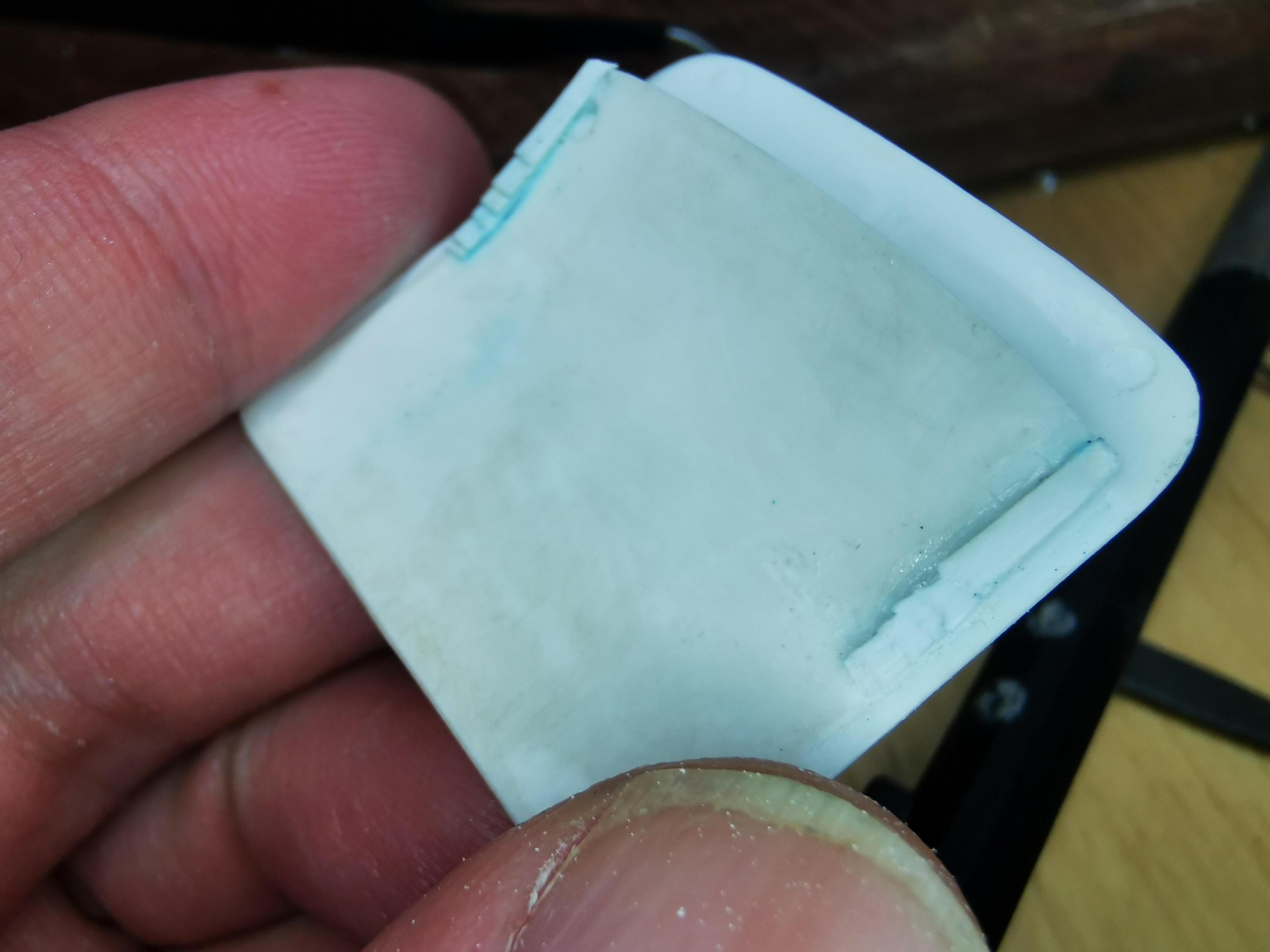

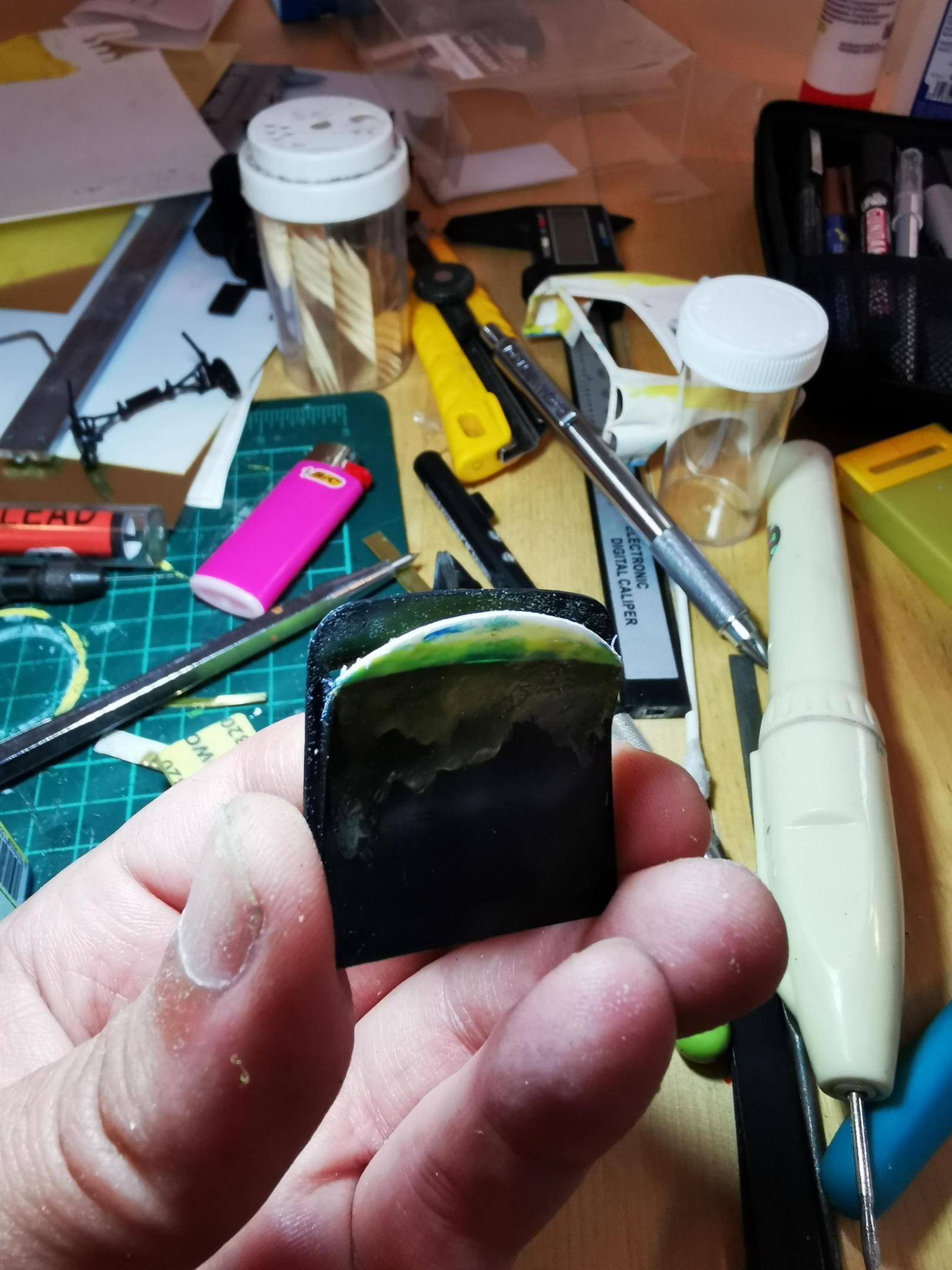

Just an update on the hood... Just need to say oops! I heated up the hood over the stove to get more of a curve in the hood and ended up warping it! ?

At least Gramps and Rex sent me some spare parts that I will now have to use.

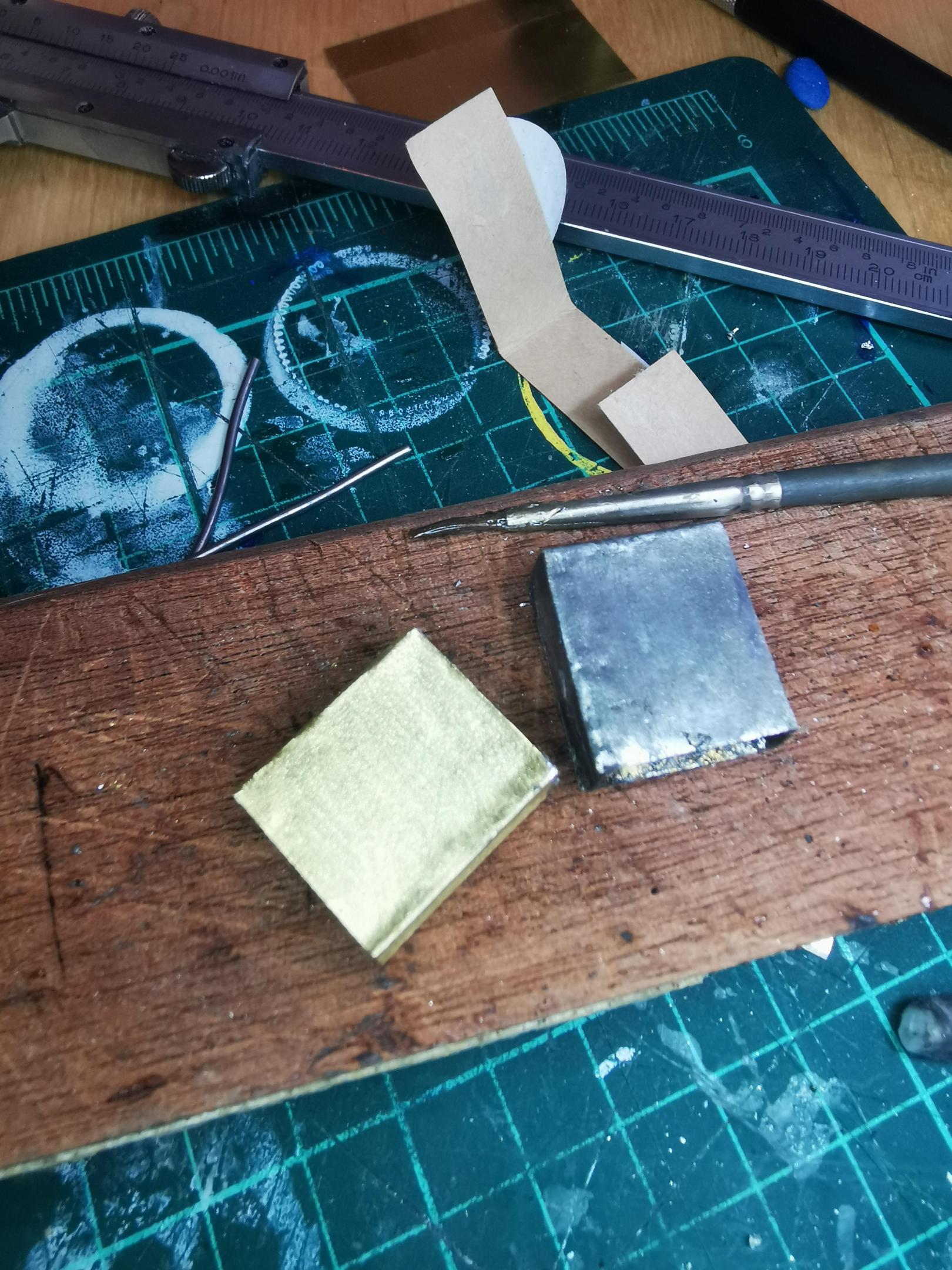

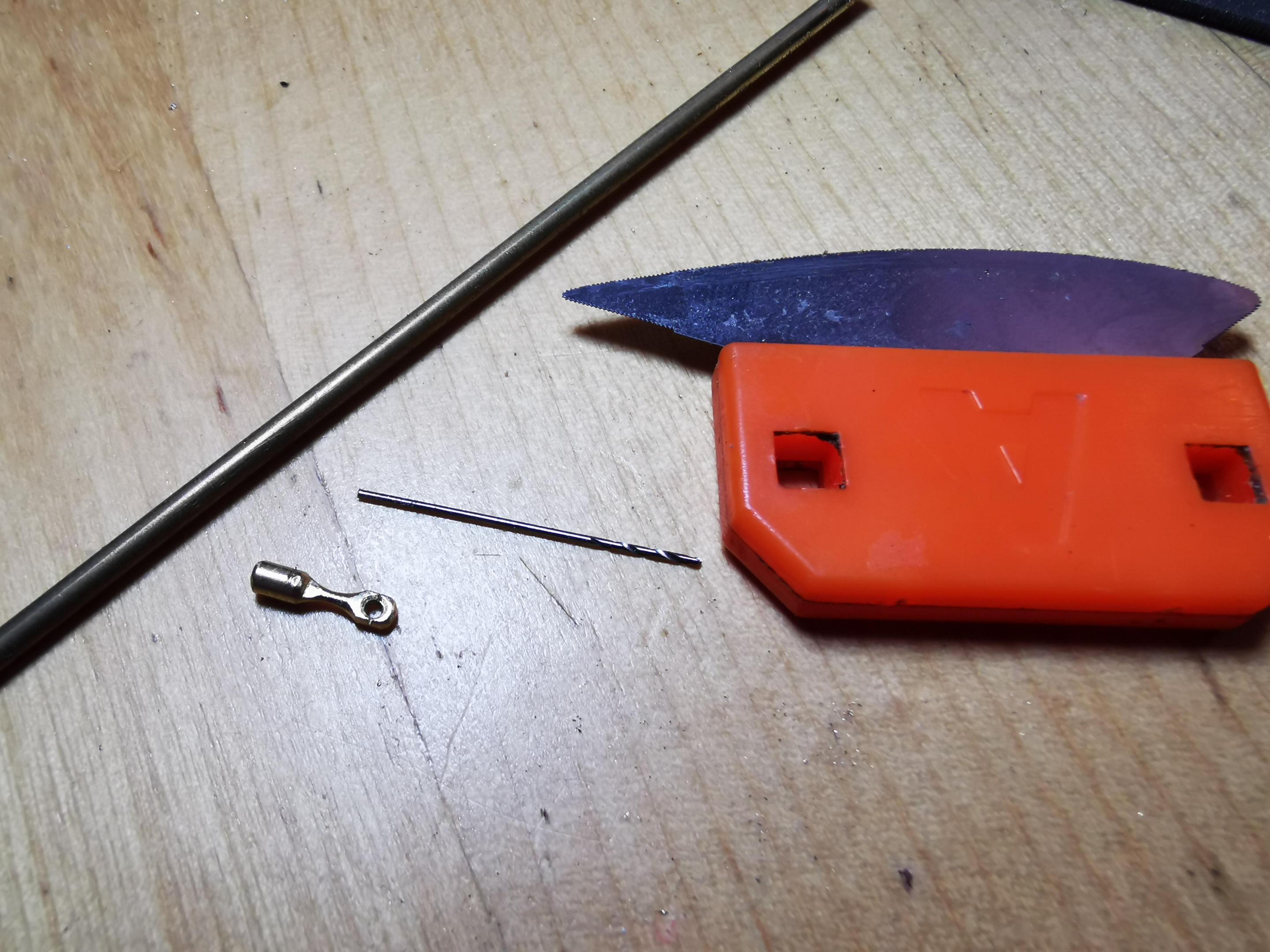

Also at the same time I am slowly cutting away at some brass to make the front upper suspension...

I am using Albion Alloys 1mm brass rod for the suspension. I started using the 1.1mm brass tubing as it was the right size but once I put a bend into it, the tube just became completely deformed. So a bit of a compromise needed to happen. I should be able to use the 1.1 tubing for the rear suspension as there are 0 bends and all angles. Just a hell of a lot of cuts to make.

Enjoy and keep building!

Justin

-

On 10/26/2018 at 1:10 PM, comp1839 said:

i'm very happy to say, this is an article about my street rod. took 5 years for me to complete it, as far as it is, in the article. there are a few upgrades in the works including, painting it all one shade of satin black, an engine upgrade to 730 cubic inches and EFI. just go to one of the links provided. same article is on both sites. i hope you enjoy it.

https://www.dragzine.com/features/pro-mod-to-pro-street-dave-shermans-wild-1937-chevy/

https://www.rodauthority.com/features/pro-mod-to-pro-street-dave-shermans-wild-1937-chevy/

you certainly may voice your opinion. just remember it is my car and i built for me to enjoy.

That is a badass ride! You guys look lovely! Stay well and keep building!

-

Tim, thank you thank you! I do enjoy the details. I just want it to look as realistic as possible so that the people who know this car look at it and say 'hey check, there's the correct oil pump. Oh hey look at that...there's a... (finish the sentence)"

Bill, thank you also! I have yet to mold/cast the number lights, make a radiator fan, put the ventilation tubes in, build the oil pan, put the wiring in... seems like a lot of stuff to do. I will get there.

-

5 minutes ago, redneckrigger said:

I primarily use a variety of plastic parts and shapes, Evergreen, Plastruct, etc. I use epoxies, CA, and regular styrene cements. I do use some various materials such as aluminum and brass, but use CA to attach them. I have not yet tried soldering. But, I have found that I have always been able to figure out how to make something from styrene, so far! When it comes to trying to replicate a 1:1 part, I tend to break the desired part down into pieces, just like the real piece would be fabricated from metal in the 1:1 world.

That's exactly what I try to do. I look at reference photos for hours on end trying to get the right viewing angle, see how it breaks down, that kind of thing... But then comes the building part... ?

-

-

1 hour ago, Deathgoblin said:

Only problems I have with scratch building is just having hammer hands.

Big fingers and tiny parts do not mix well

Big fingers and tiny parts do not mix well

Hahah... How about working on a piece and it goes flying and then spending 10 minutes finding it??

-

3 hours ago, STYRENE-SURFER said:

Ive never had good luck bonding small bits of dissimilar material together with CA or even Epoxy type adhesives.

I stick to styrene as a medium. BUT there are lots of examples here on the forum of superbly talented modelers

doing just that.

One skill that I envy is the ability to source just the rite parts from just the rite kits and assemble them with not as much trouble.

I don't have that kind of model kit knowledge for this on my own but ask here and you will get immediate information.

I'll give these examples that may give you something to think about.

Sourcing small styrene tubing is limited, so try drilling rod to create the look. You need quality drills to do this but not as hard

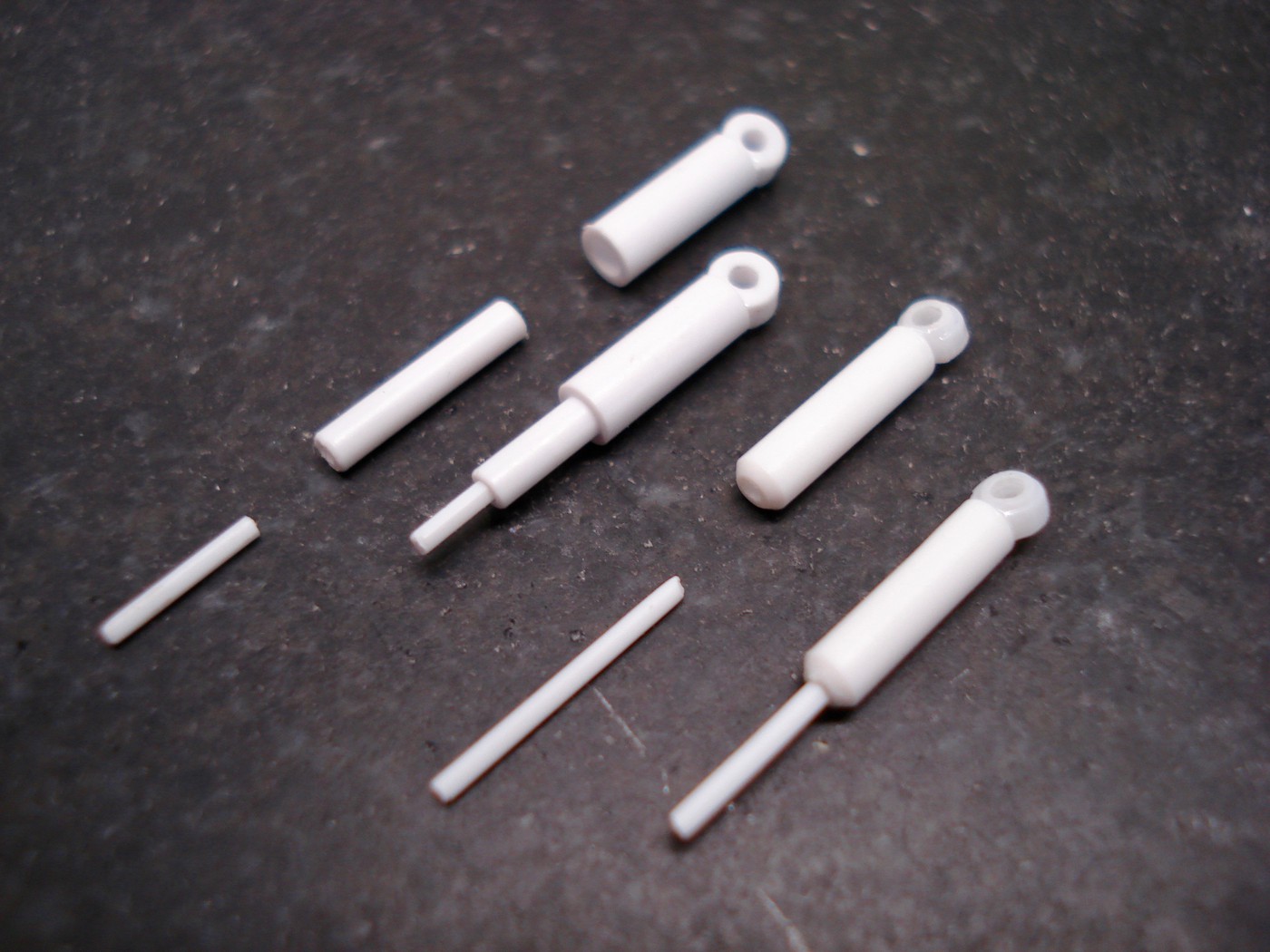

to do as you may think. These shocks where made from Evergreen rod. Drilled out to the correct size.

I discovered you can also create strong parts to support some weight by imbeding small carbon rods inside (here in a small motor mount support made to look like square tube) method could be also used for long unsupported frame rails.

Picture is sort of an explanation showing the carbon rod, plastic channels and caps to create the dimension desired.

This is only how I prefer to do things, I'm sure other more experienced and talented modelers will chime in here.

Thats the beauty of this forum. ?

That is an awesome tip! I prefer to stick with styrene but like I said I can't find the sub 1mm styrene tubes. But wow,I will definitely use the graphite to reinforce trick. Thank you. I hope others chime into this thread. I am looking for for new tips and tricks to better build.

Justin

-

Any of you, aside from me, run into issues with scratch building?

My biggest issue is that if I stay with using plastic for my builds I run into one huge limitation: Strength VS. Rigidity

Say I want to build a radiator fan and I want to make it to scale. So then I find myself using 0.1mm styrene sheets. Ok cool... No problem right? Wrong. Once I start using sheets that thin they tend to be flimsy, because hey, it's plastic and as thin as a sheet of paper. So the alternative? Use metal... But then when I use metal, it doesn't always bond well.

I can already hear you guys saying "just use ca glue with tin" but then I run into strength issues. Ok so use brass instead... And I can solder that. But when I mix aluminum with brass in a build I need another solder type.

Or if I want to build a wishbone suspension, I need a plastic tube thin and small enough to fit in another tube... And again, I run into the issue of strength VS rigidity. Not only that try finding 0.3mm plastic tubes... Almost impossible.

The alternative? Albion Alloys... They have amazingly small and useful metal tubes. But it gets expensive and quick.

So what issues do you run into when you scratch build? What do you do to resolve them? And most importantly how do you keep the costs down?

Keeping the costs down is my main reason for scratch building, second reason is that the part I need doesn't exist so I have to make it.

sm.jpg.9bc708810d4d7d7289664e15f554f36f.jpg)

The issues with scratch building

in Tips, Tricks, and Tutorials

Posted

Just as long as you don't start talking in cockney slang i'm ok... man that rhyme scheme talk blows my mind...

Oh yah.... I feel that! That's one of my main drives. I spoke with Jerry Kieffer the other day on the phone. If you don't know who he is look him up. He too is a firm believer in "don't let anyone tell you it isn't possible. They are either jealous or haven't figured out how to do it. Because of that, they would rather tell you that what you are trying to do is impossible."

I'm a stubborn mule when it comes to stuff like that. Everything is possible. If I haven't figured it out yet, I will find a way.

Yup... time. Time is always a killer. Especially seeing how much time I put into research alone. I have easily spent over 300+ hours researching the Ford GT40 MKII for my build, and then another 300+ hours plus the numerous videos I have watched and learned from regarding milling/turning. Lathe work was always a no brainer to me, guess I'm lucky like that. Now turning metal... that's a different story but the principles are the same with the inclusion of tolerances and speeds you turn at and why. Hell making a screw is just mind boggling. Making a gear... mind flipping... Making a cross slide...just...just... what the F***?

So yah. The time it takes to make stuff... that's another reason why I don't compete.