-

Posts

903 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by customsrus

-

-

11 minutes ago, Ace-Garageguy said:

It depends on the size of the parts, primarily, but there are other variables to consider.

In general:

"Casting resin" is usually formulated to reduce runaway exothermic reactions that can easily occur if parts the size of an engine block (in 1/24) are cast in a warm environment.

Runaway exotherms happen when the heat generated by the resin and hardener doing their chemical thing go into a "feedback loop", with more heat speeding up the cure making more heat speeding the cure making more heat etc.

The effect is anything from severe bubbling throughout the casting, to the whole mess bursting into flame.

I've had it happen.

Casting resin is also thinner, less viscous, too...which helps to fill voids and air pockets, and release air bubbles introduced during mixing.

Though you "can" cast parts with epoxies designed to be used as adhesives, you're better off using "casting resins" for casting.

OVERVIEW OF "EXOTHERM":

https://www.systemthree.com/blogs/epoxy-files/epoxy-exothermic-reaction

All that said, most molds for model car parts today are made from silicone, and the parts cast in them are usually made of some variety of polyurethane.

I’ve used alumilite in the past and some good results. I’m just wanting to do small parts such as wheels, motor parts, etc.

-

Which is better to cast small parts. Casting resin or epoxy resin.

-

On 11/21/2023 at 3:31 PM, Keef said:

Sent you a message

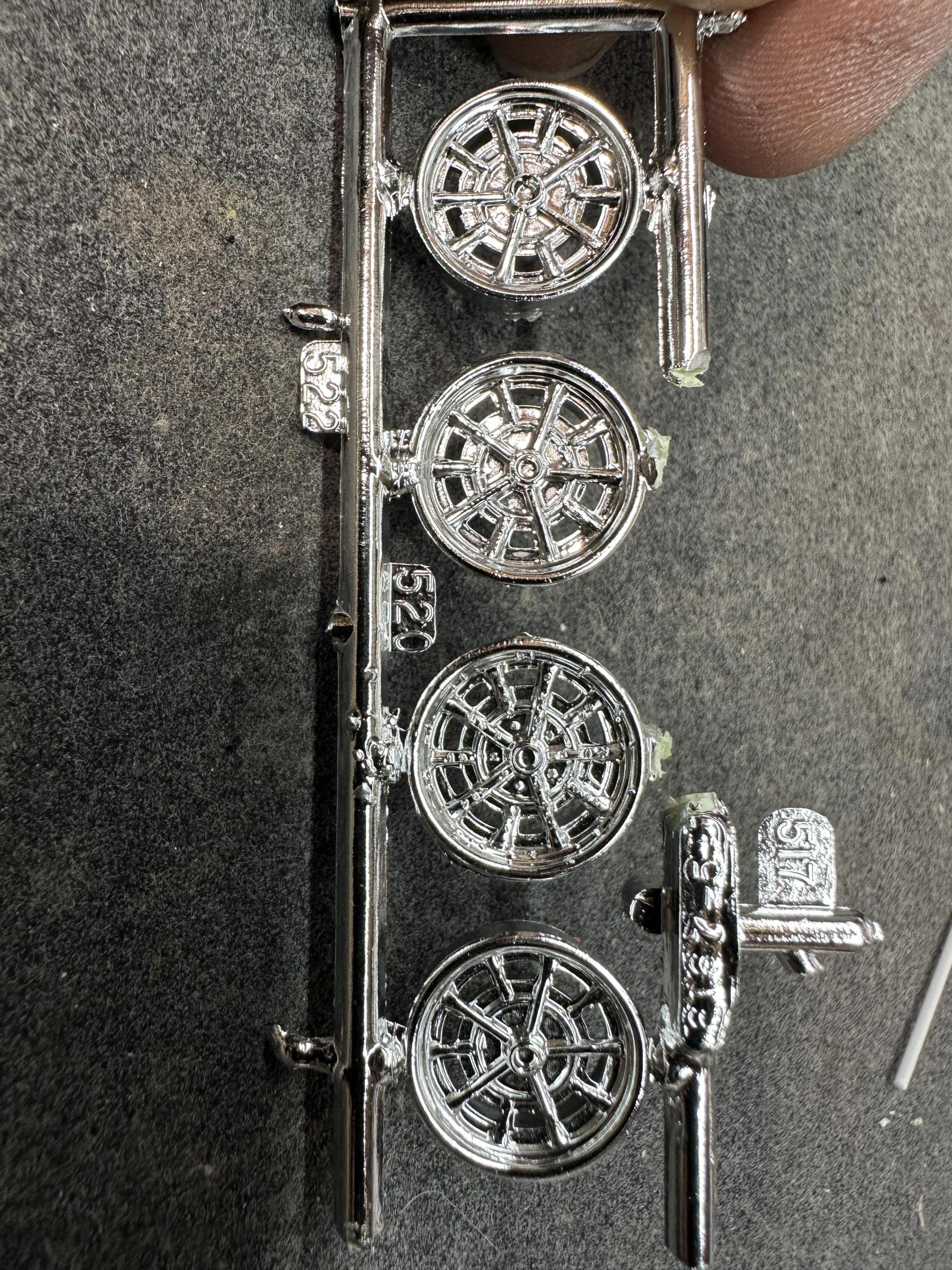

Thank to Keef for supplying the wheels needed. Much appreciated Keef. Hope to return the favor.

-

1 hour ago, Zippi said:

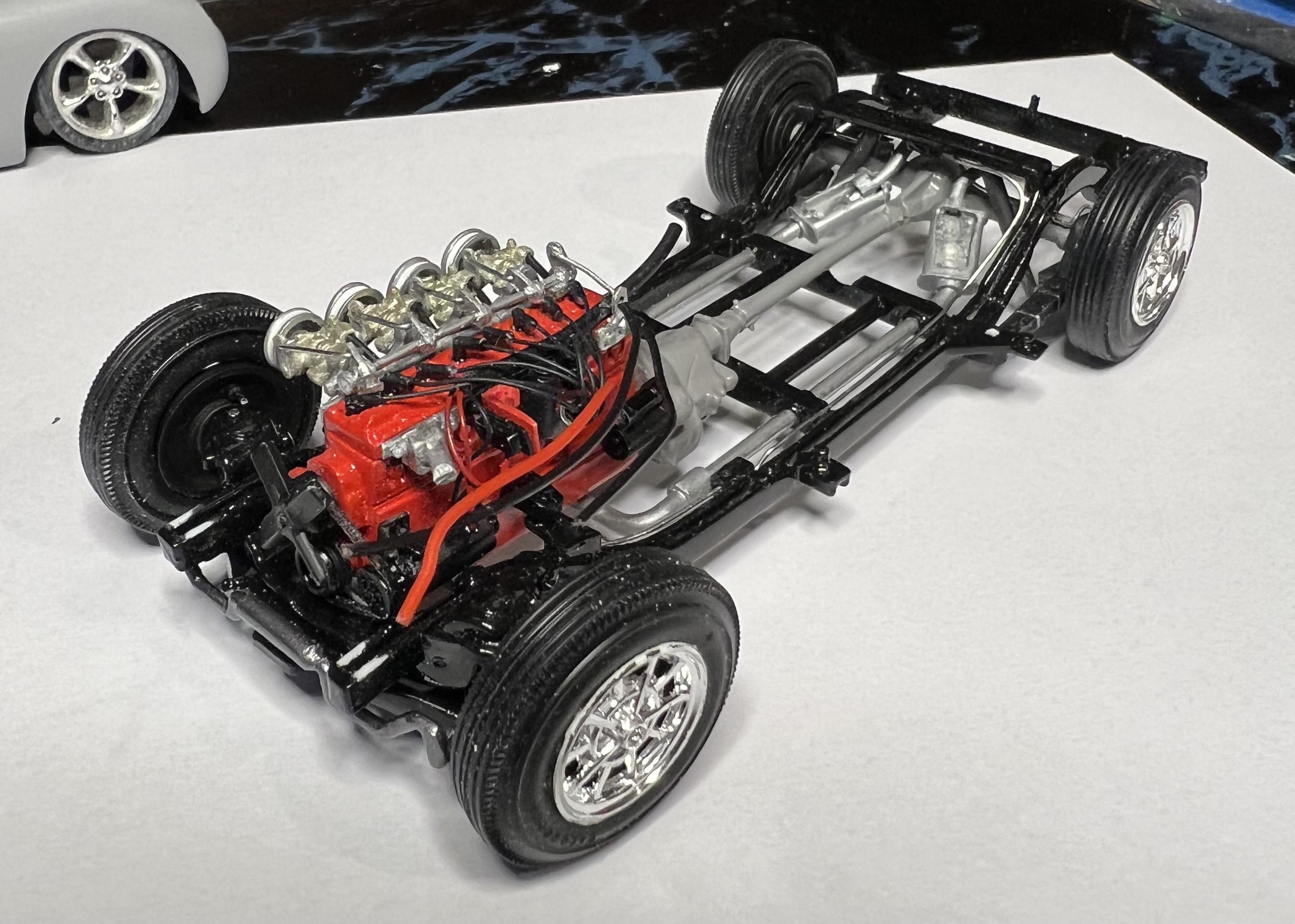

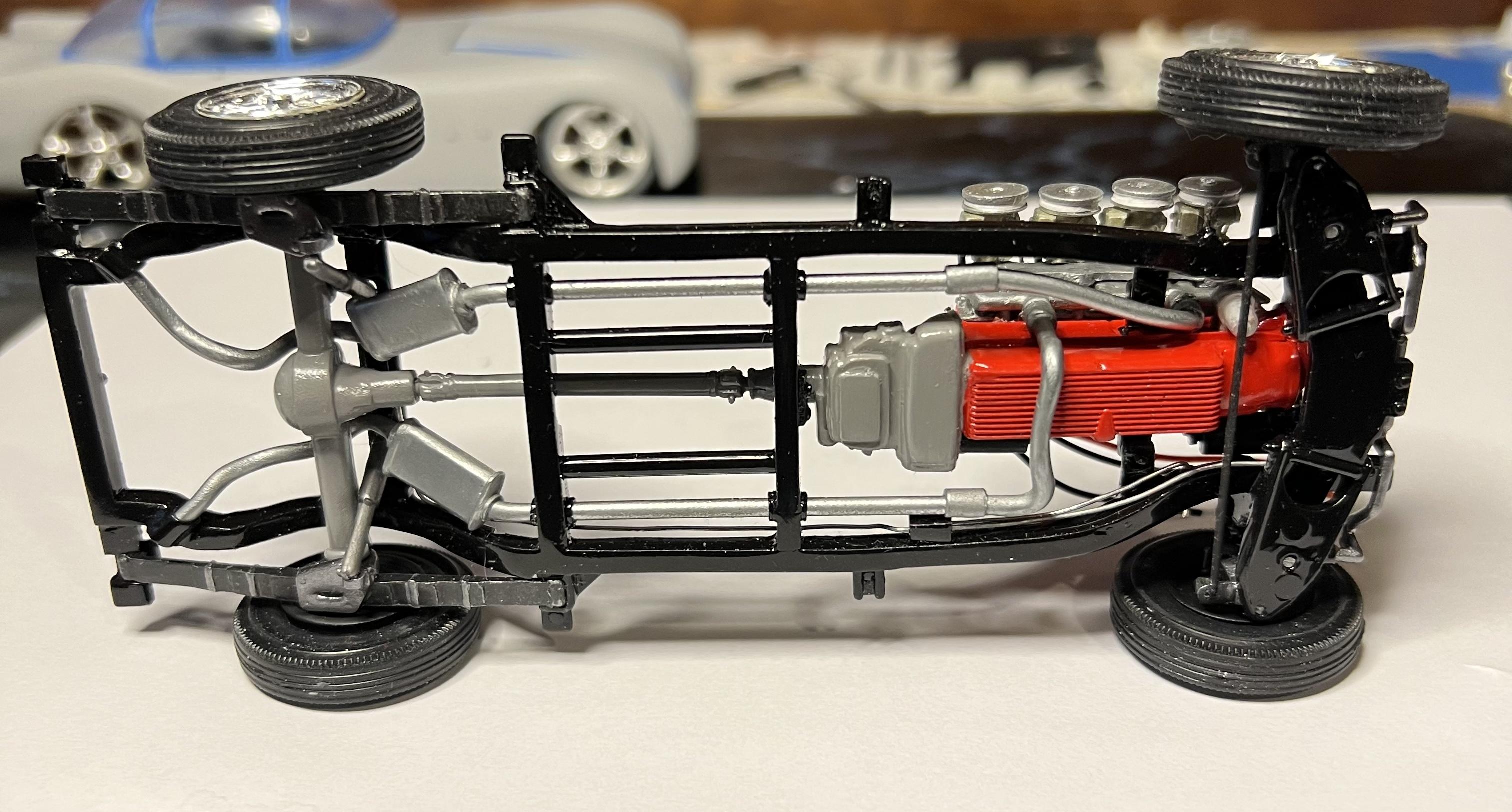

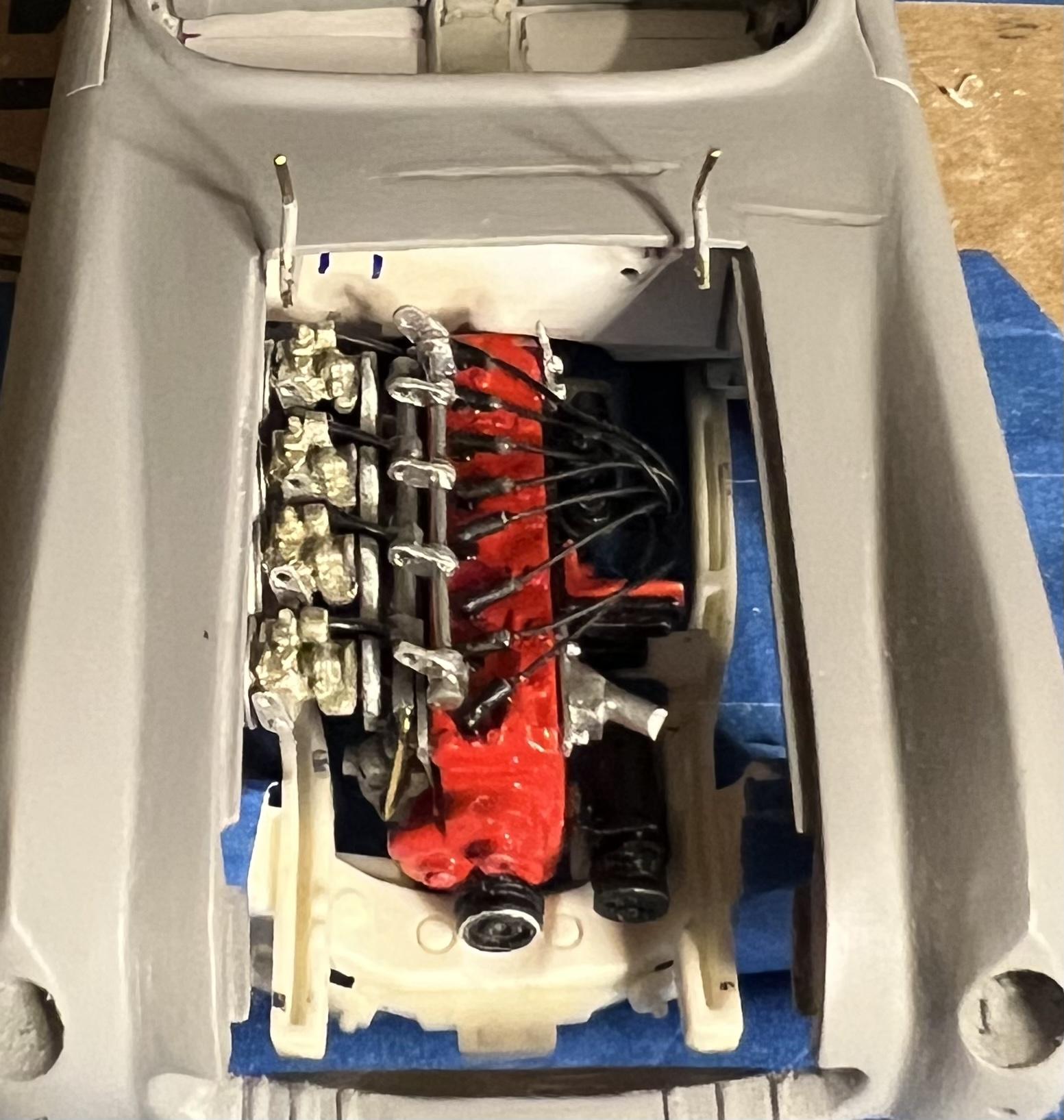

This 54 Pontiac is really starting to take shape. Lots of really nice work going on.

Thanks. I appreciate the comments.

-

12 hours ago, Ace-Garageguy said:

Cool cool cool. Coming along nicely. Your bubble-top is quite an achievement.

I especially like the Olds. I've always had a build of that in mind fer somewhere down the road.

And just FYI: PET, both clear and green tinted, is widely available as soda bottles, and is often used by modelers for vac-forming or heat-forming windscreens and other clear parts.

Another FYI: to get a really good vacuum-molded part, the buck has to be prefect. Not just kinda, but perfect.

And vac-forming is a black art, frequently requiring much trial and error. I have some commercial clear slot-car bodies that are like cellophane in some areas, plenty thick in others.

One more FYI: canopies for experimental aircraft (like gliders) are usually blow-molded, as suggested above, which helps to deal with thickness irregularities resulting in optical distortion. Several real-car custom builders have had to resort to blow-molding their bubbletops too.

As an aside, one of the top-end suppliers of aircraft canopies is rumored to have to throw out 4 for every good one they get...which partially explains prices that can be daunting.

Thanks Ace for the comments. I get a lot of inspiration from your builds. I have to make another buck for the canopy, previous one failed miserably. There is definitely a learning curve to vacuum forming. Eventually I might get it right. What type of material would you suggest on the buck. The buck I had was made of wood with a bondo thin coat applied to get it smooth.

-

13 hours ago, NOBLNG said:

Wow, nice work on that engine…and that Oldsmobile is fantasticly cool!😎

Thanks. Oldsmobile is not 100% accurate but I did the best I could.

-

-

-

7 hours ago, Keef said:

Yes the AMT 68 Shelby GT500 has those wheels. I have a set of them in my parts box that I didn’t use.

What would you need for them.

-

-

-

Looks good.

-

-

-

Some very cool and scary builds.

-

These a way cool.

-

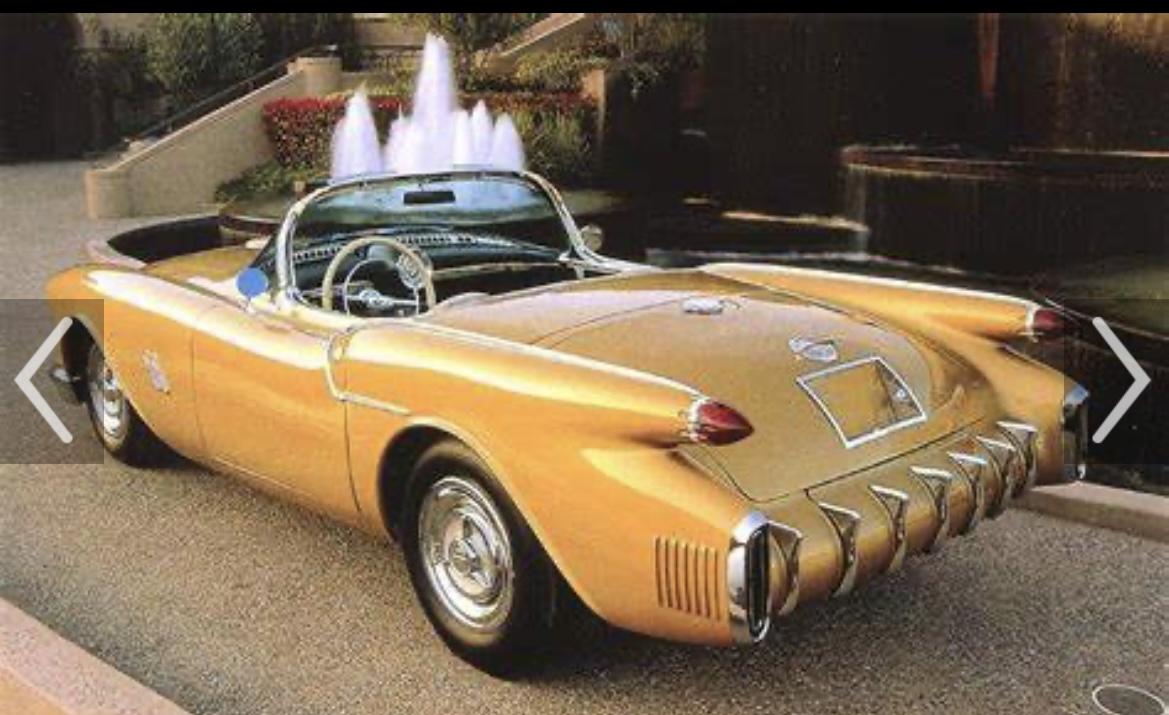

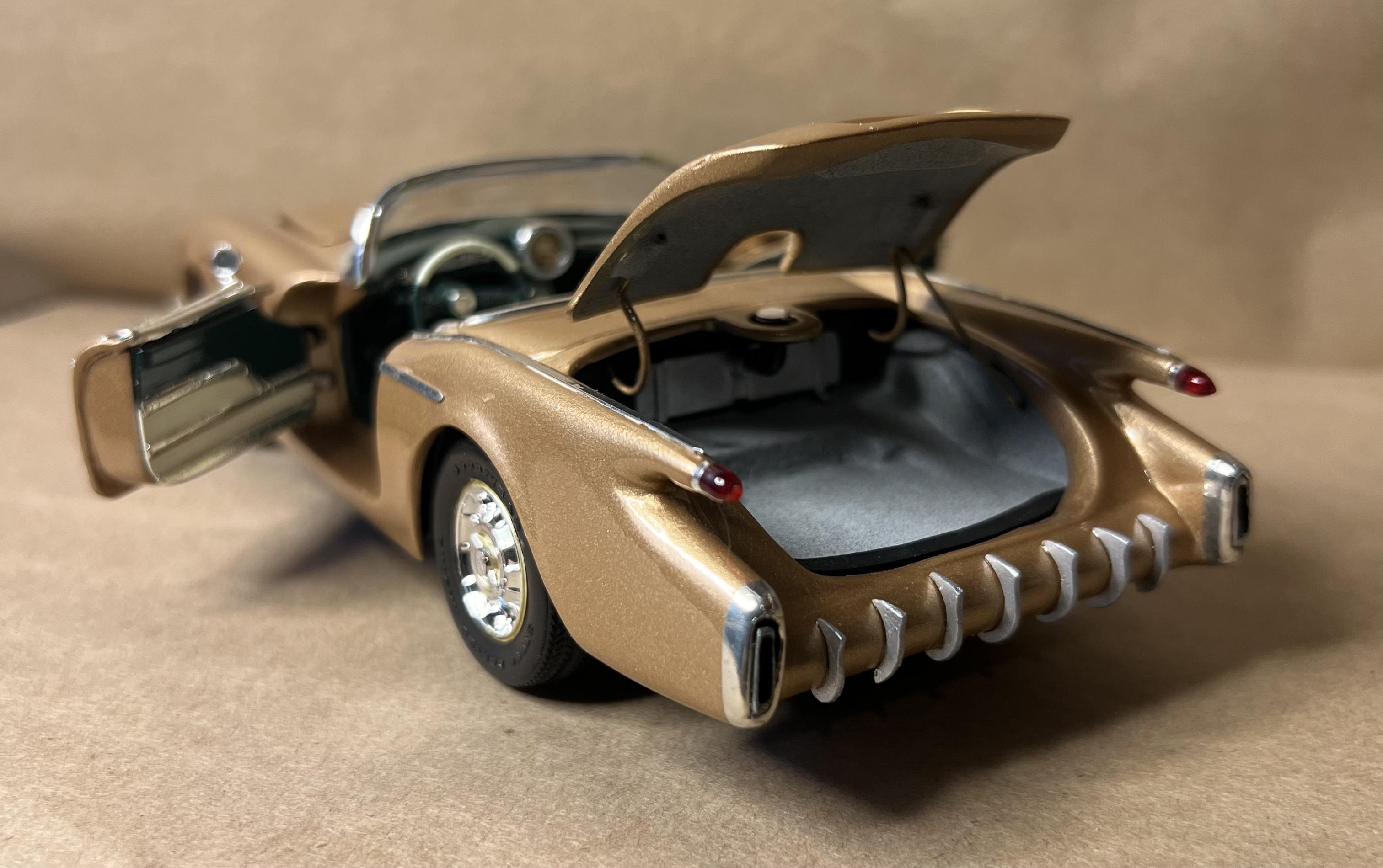

Great looking vette.

-

On 4/19/2021 at 10:49 PM, lordairgtar said:

Pretty darned interesting.

That’s what I was thinking. Definitely outside the box

-

Looks cool to me.

-

1

1

-

-

6 hours ago, Lunajammer said:

These are the kind of radical customs that really get me jazzed. Hope you stay with it and that the project is good to you.

Same here, always like a custom.

-

Very cool build.

-

Wow that looks really nice

-

Good lucking truck

-

1 hour ago, chryslerjunkandstuff said:

This is hands down one of the coolest WIP threads on the site, nice job!

I've always loved this, and every other 1950s Dream Car ever made..

I'd be down to acquire a resin copy of the stock version, should a batch of em become available some day..

Thanks for you comments. I did the Oldsmobile F-88 years ago. I attached a couple of pictures of the real car and my build. Thanks for looking

-

3

3

-

Casting or epoxy rein

in Model Building Questions and Answers

Posted

Thanks everyone for your comments.