MachinistMark

Members-

Posts

1,298 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by MachinistMark

-

Thanks. Been slow going this week. Busy at work and pooped when i get home haha. Did get the rest of the intake and exhaust piping painted so hope to put the engine in the frame once and for all soon. Might try to detail it up a little with some hoses but finding good clear photos of the twin turbo cummins has priven difficult. Oh well.

-

Revell Kenworth K-100 Flat top

MachinistMark replied to Kenny900's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Building this one too... Not stock. Build thread is a few posts down on this pages actually. Ypure off to a great start. -

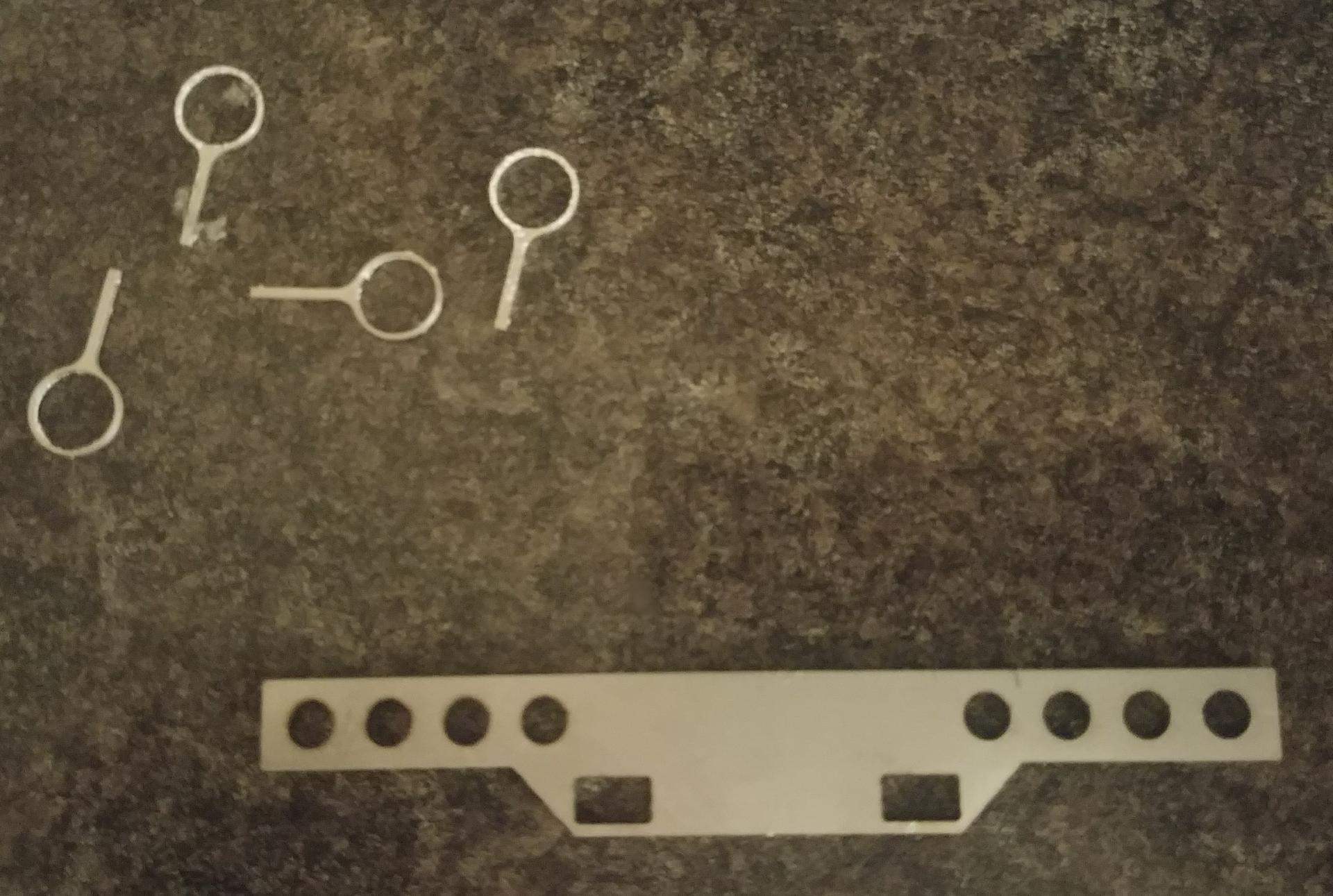

Yeah. I drew it in cad and cut it out on the cnc laser I run at work. Had one of the ypungfellas we have at the shop bend the ends up for me, then polished it. It's 304 stainless steel. Sanded it with an orbital sander starting with 150 grit paper, then 240, 320, 400, 500 grits, then onto the buffing wheel and finished with autosol metal polish and a microfiber towel It's not an easy material to work with, stainless. But not sure is pretty