-

Posts

636 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Edward Gore

-

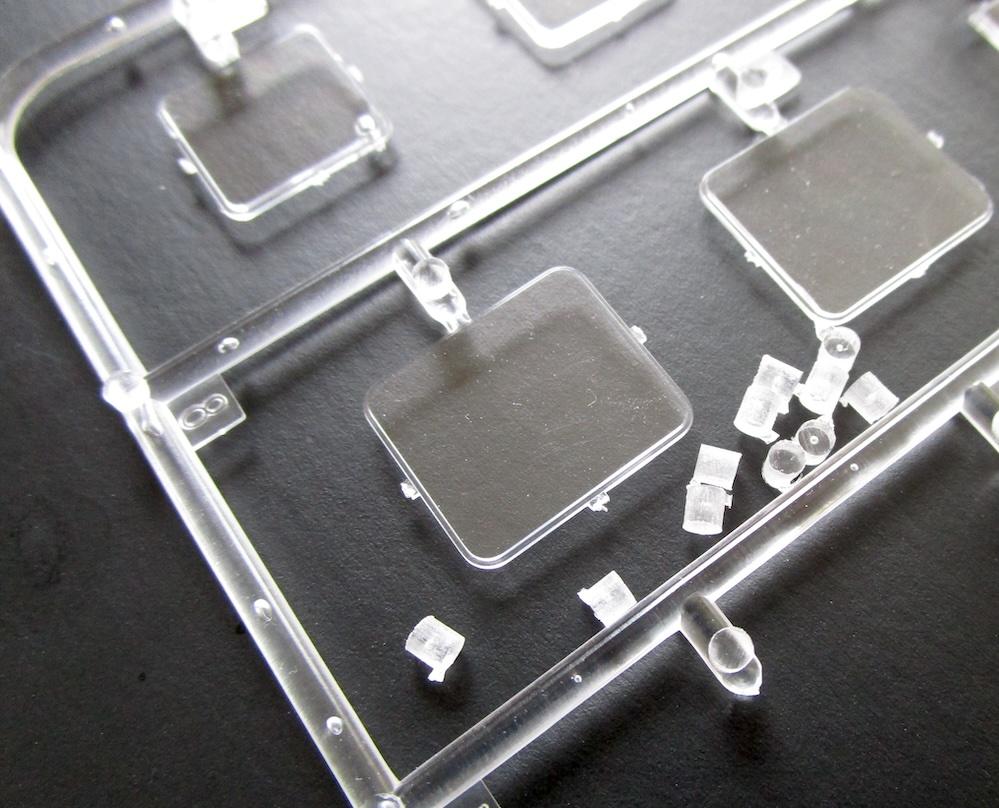

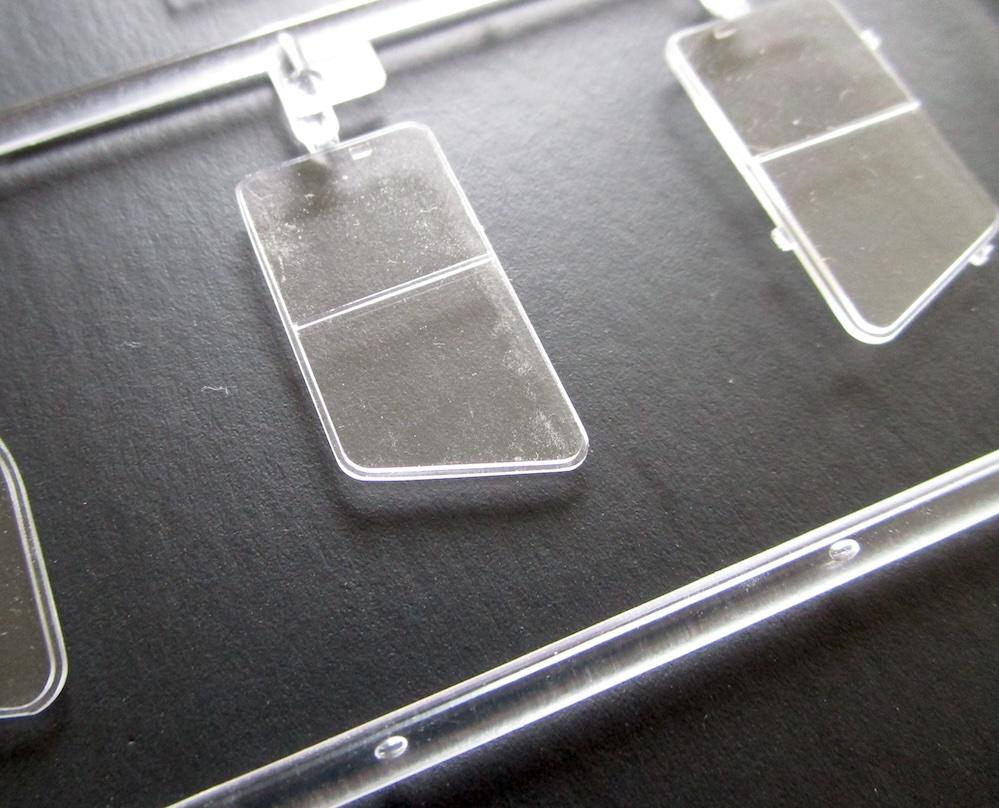

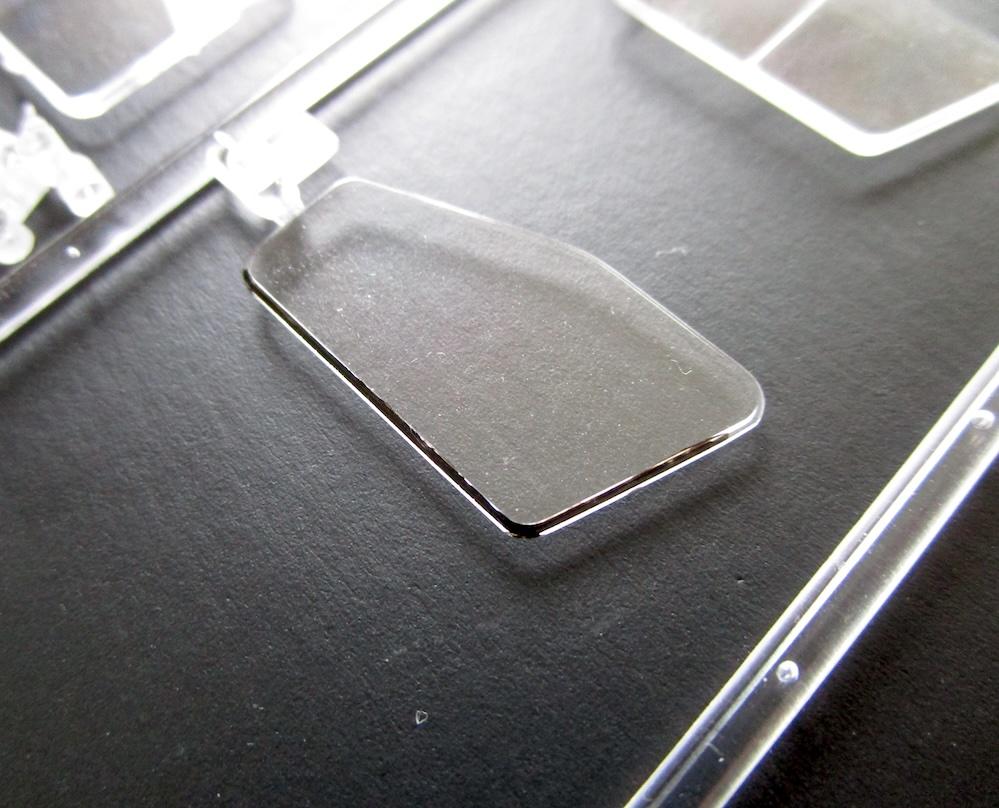

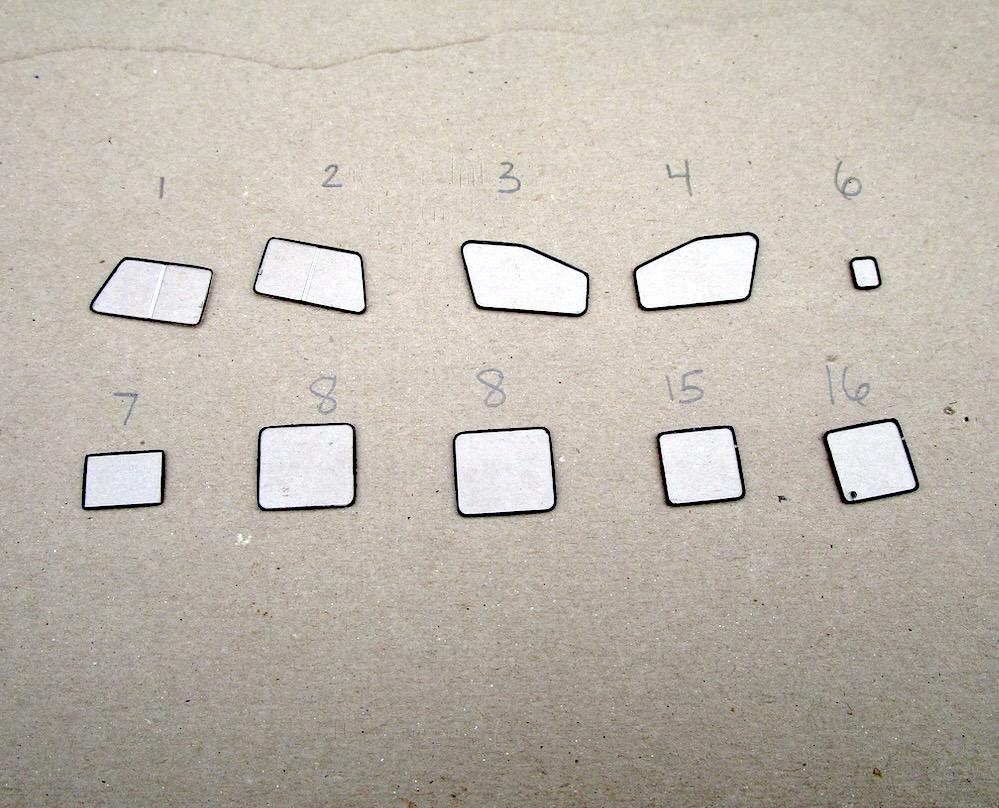

Started cutting all of the sprue bits from the ‘glass’ parts. There are a lot of them. Then sanding carefully with sanding boards. Then finally carefully painting the edges black. This will hopefully block the glass prism effect that would make it look toy and out of scale. This is just the dust from sanding the parts of all the sprue gates.

- 63 replies

-

- 1

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

@Gary Chastain @DRIPTROIT 71 Very kind words, Gentlemen

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

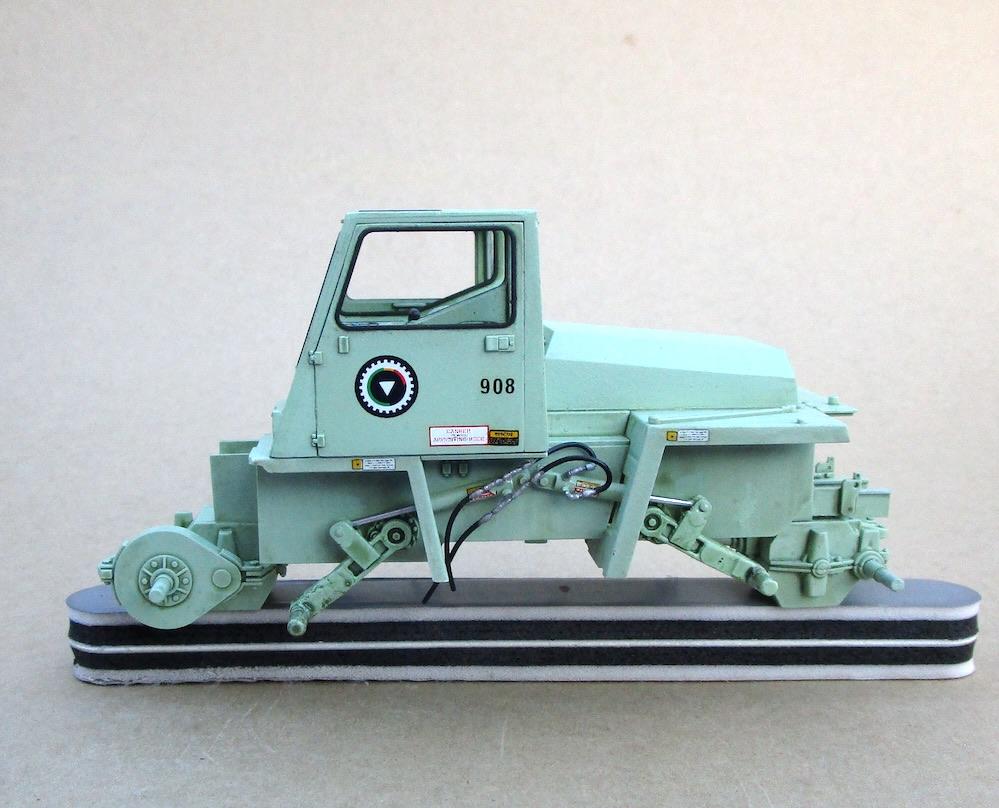

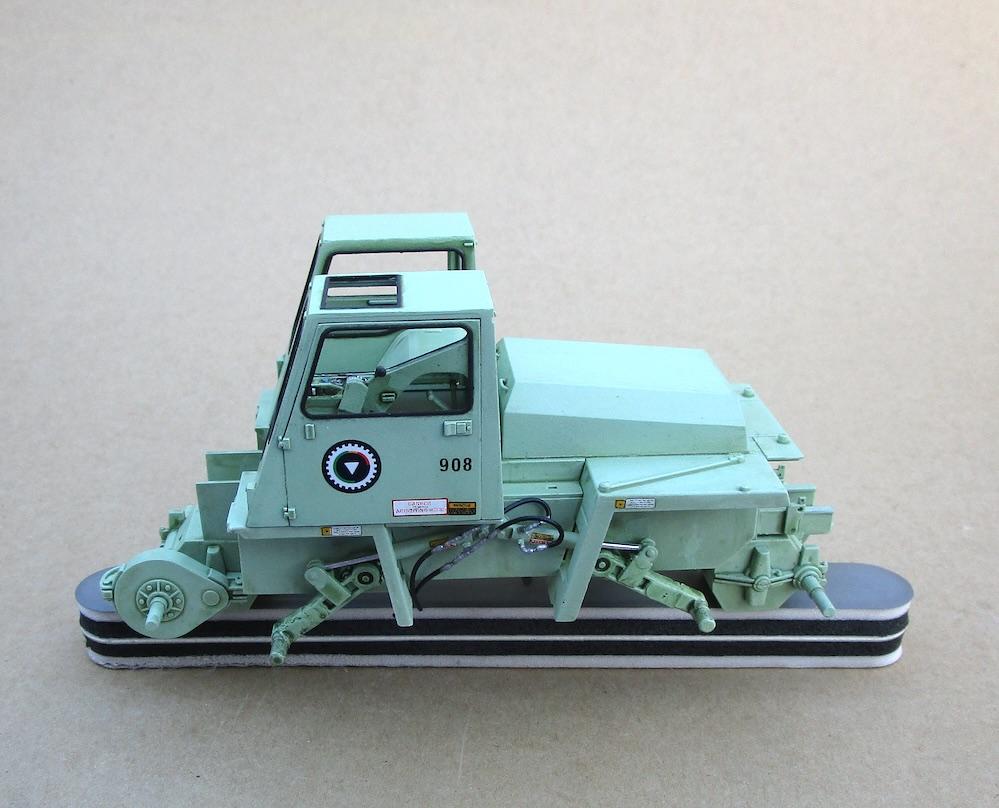

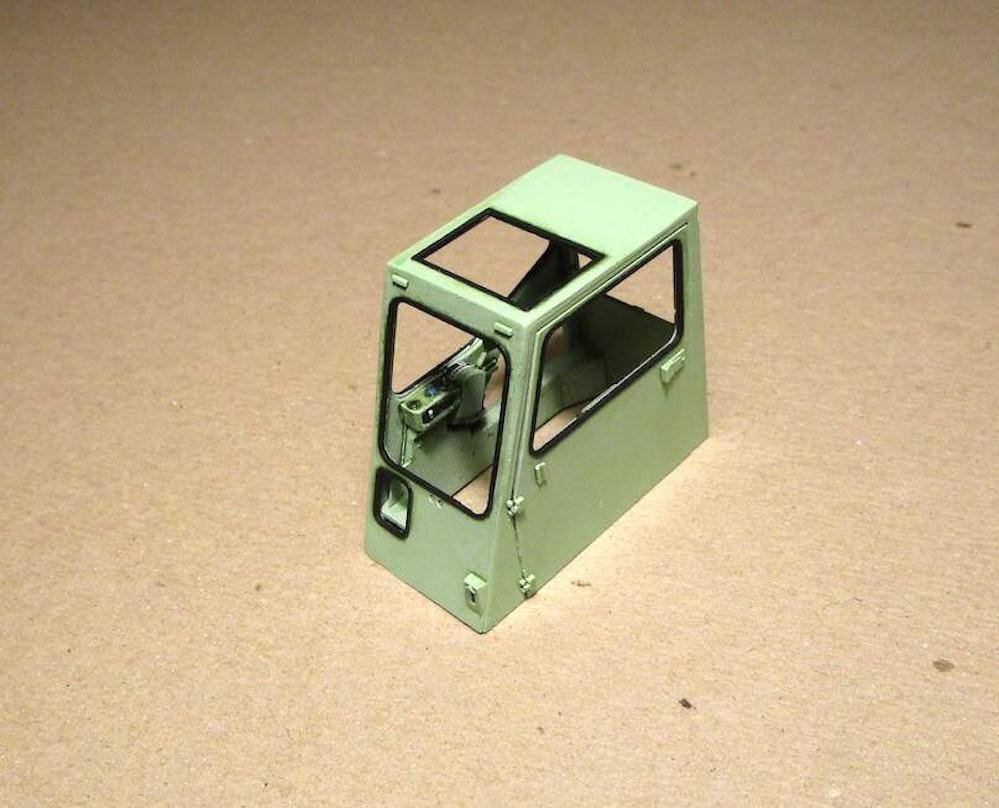

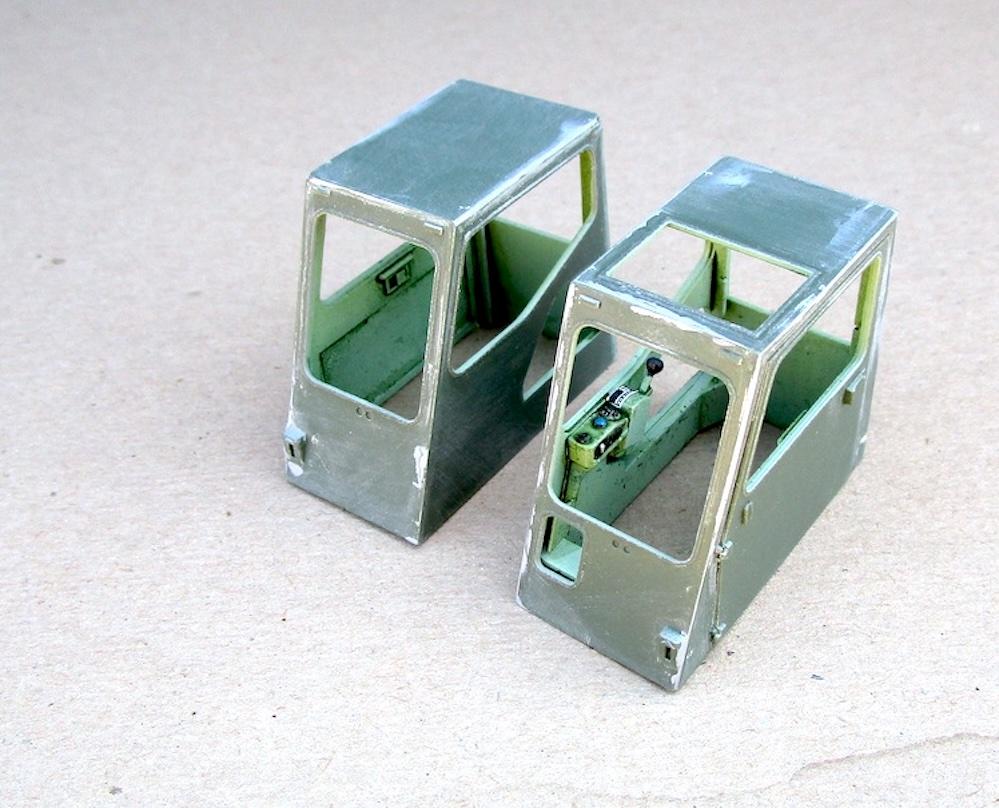

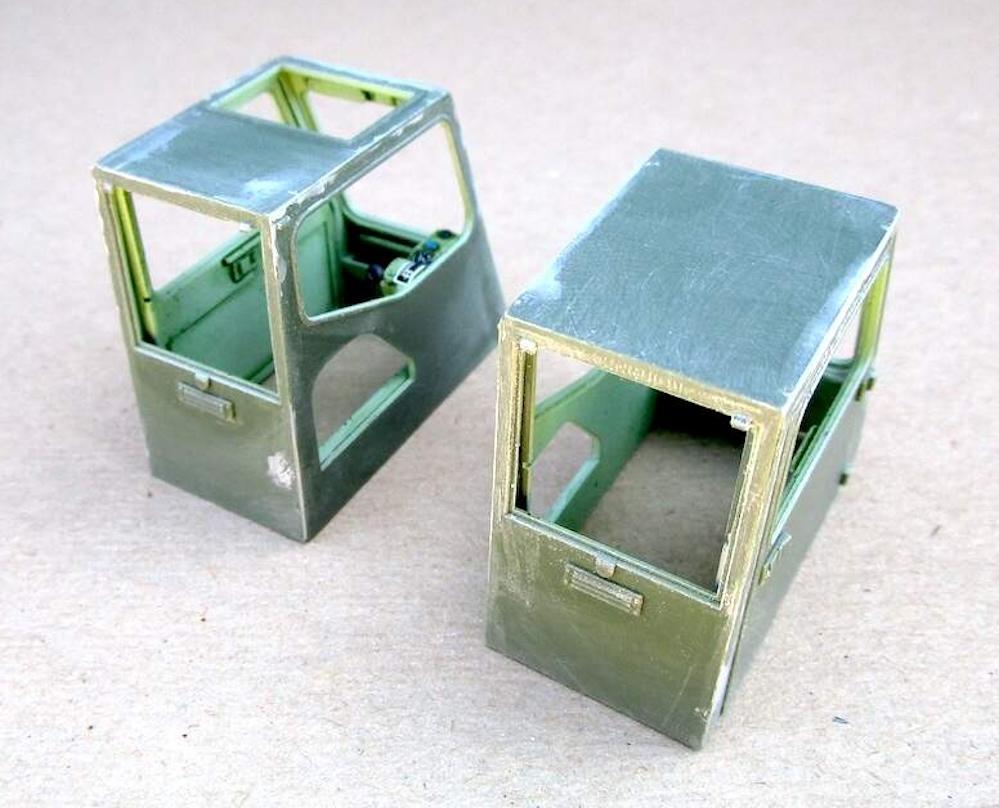

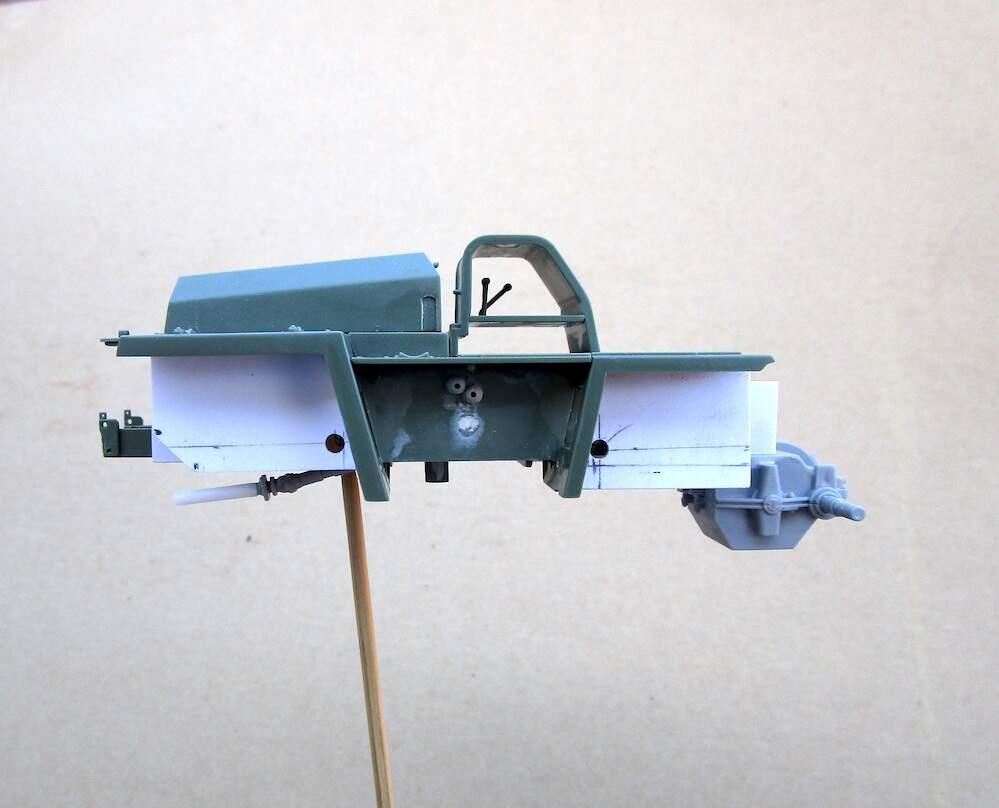

Dry fitting the cabs for progress assessment before glass parts are installed. Also added a few more decals to the cabs.

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

@cifenet @Bainford @Jürgen M. Very kind words. Thank you so much for the compliments and for checking out my model build.

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

Off-road thing

Edward Gore replied to eldiablo78's topic in All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Love this 😍 What dry transfers do you use? -

ongoing oilfield project

Edward Gore replied to cdntrucking's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very impressive scratch building ! -

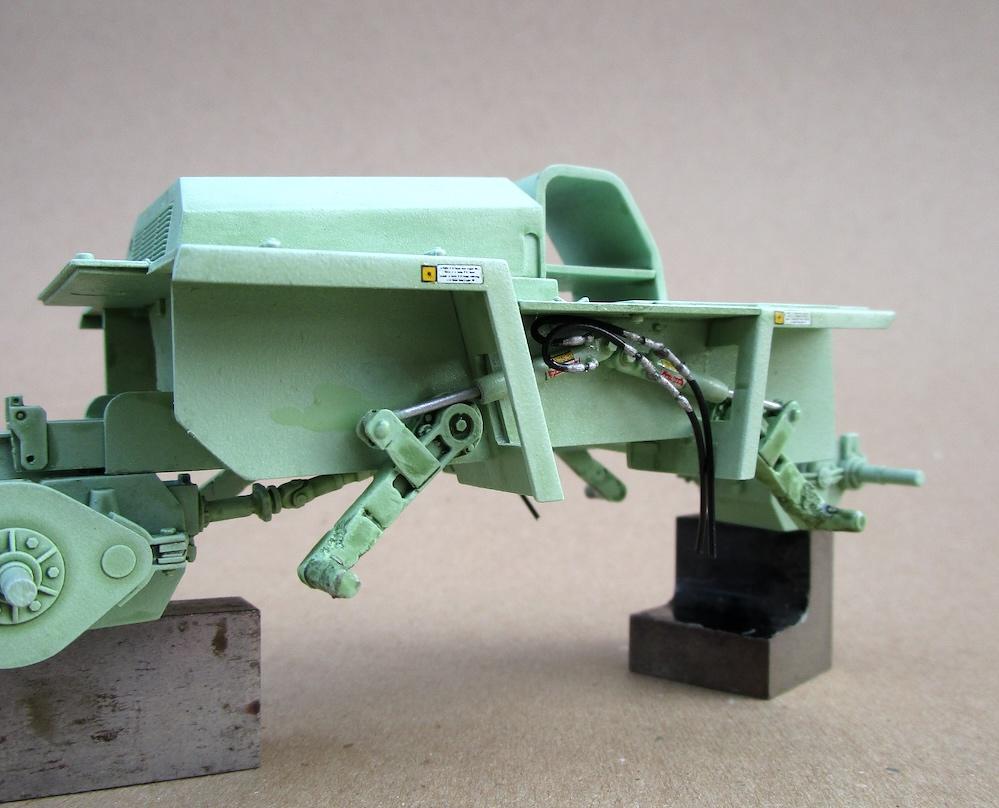

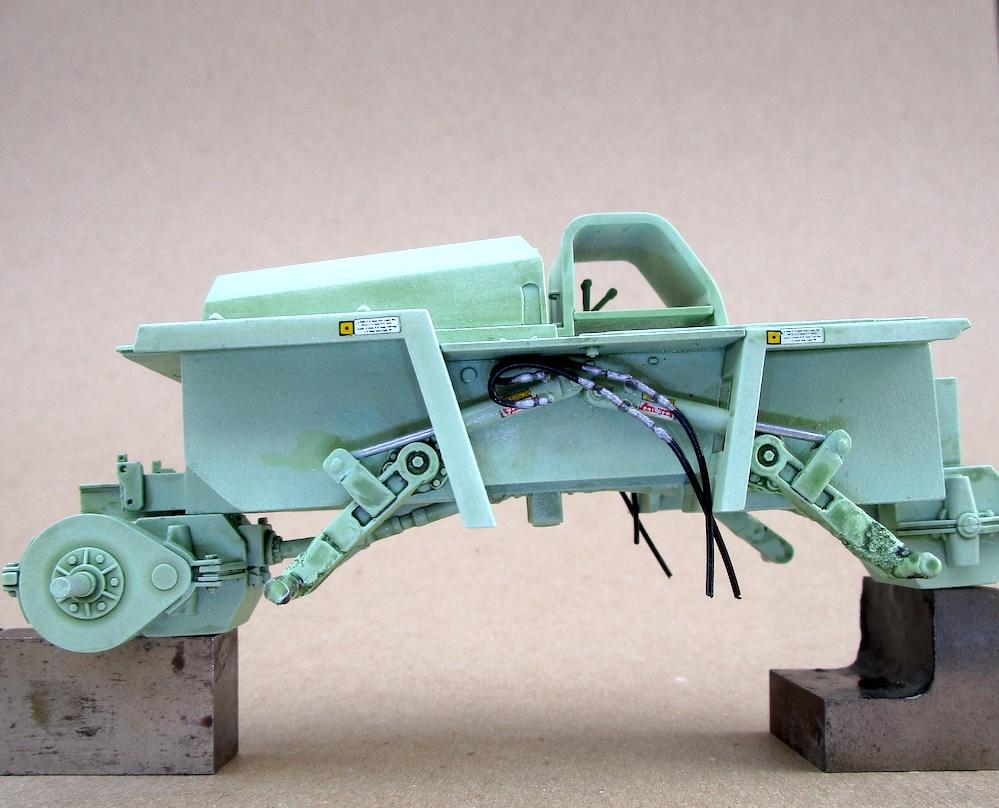

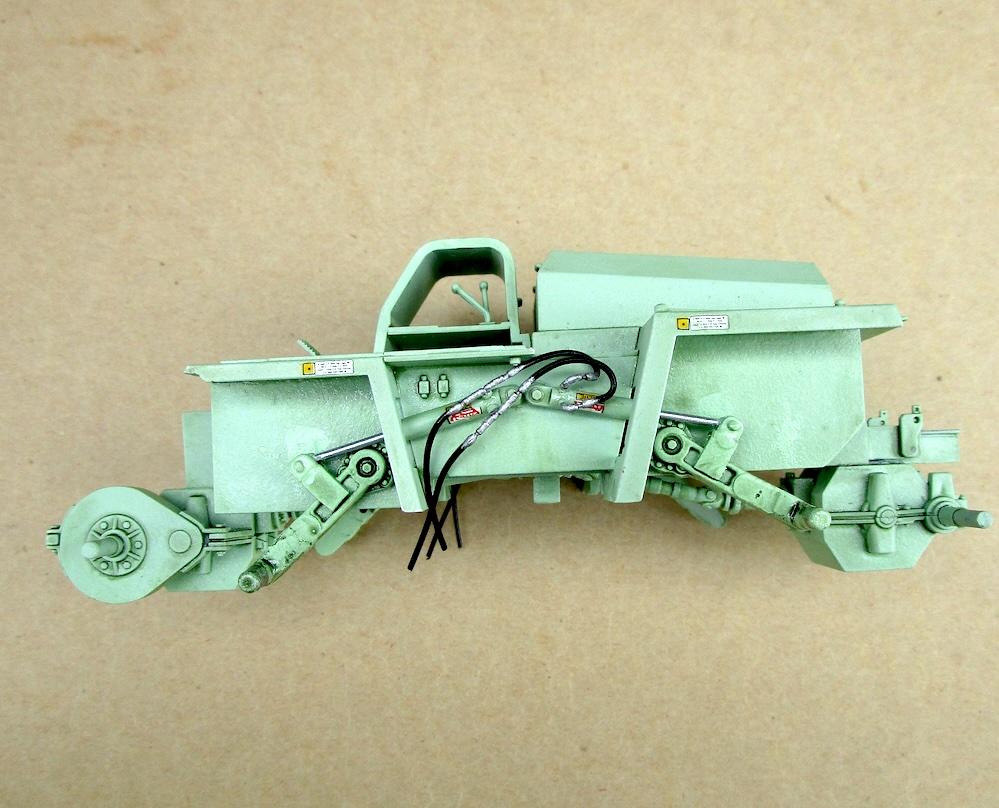

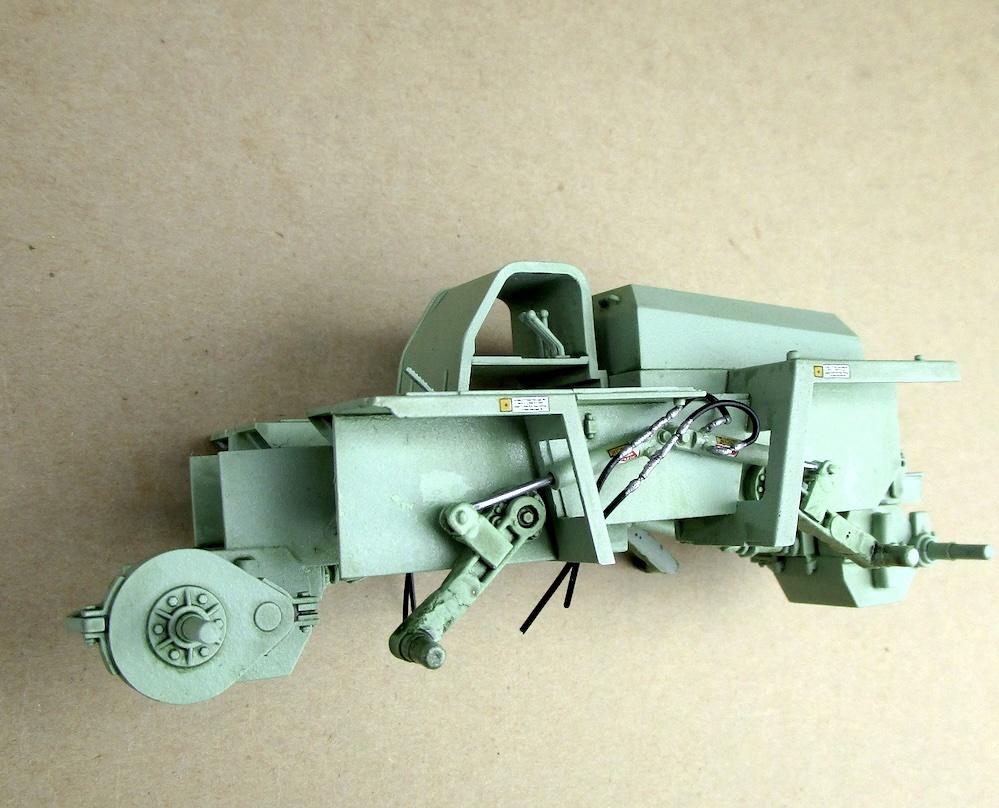

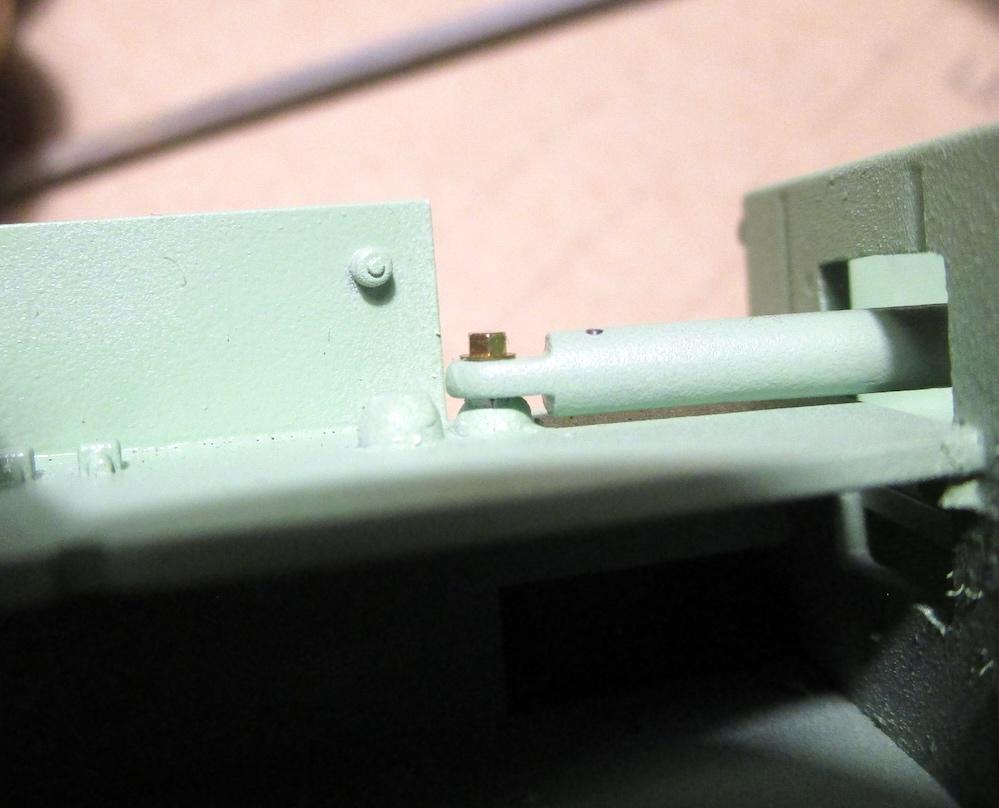

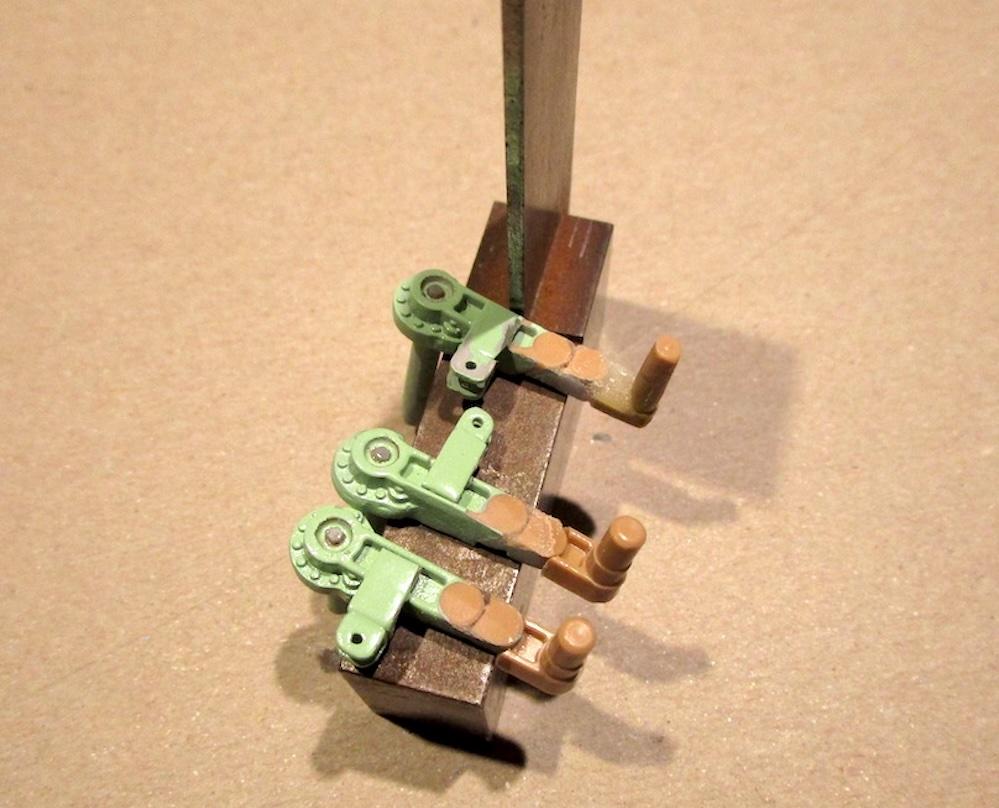

Gluing in the hydraulic lines for the road wheel arm cylinders. A few decals set onto position. Thanks for looking in ...

- 63 replies

-

- 1

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

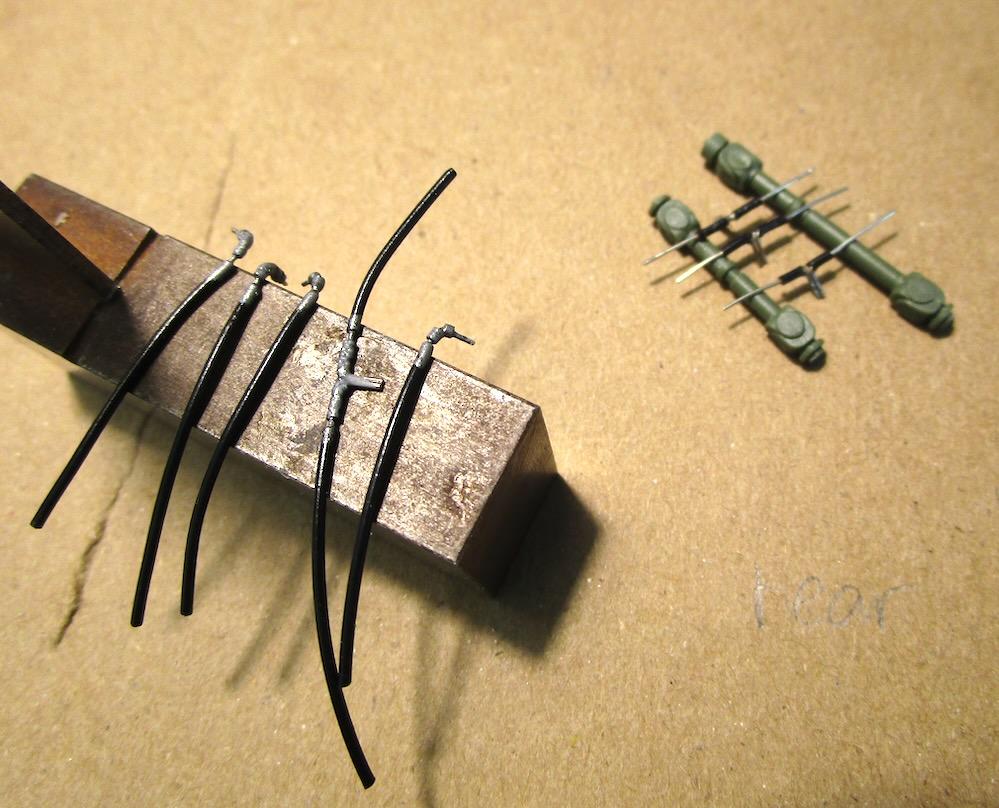

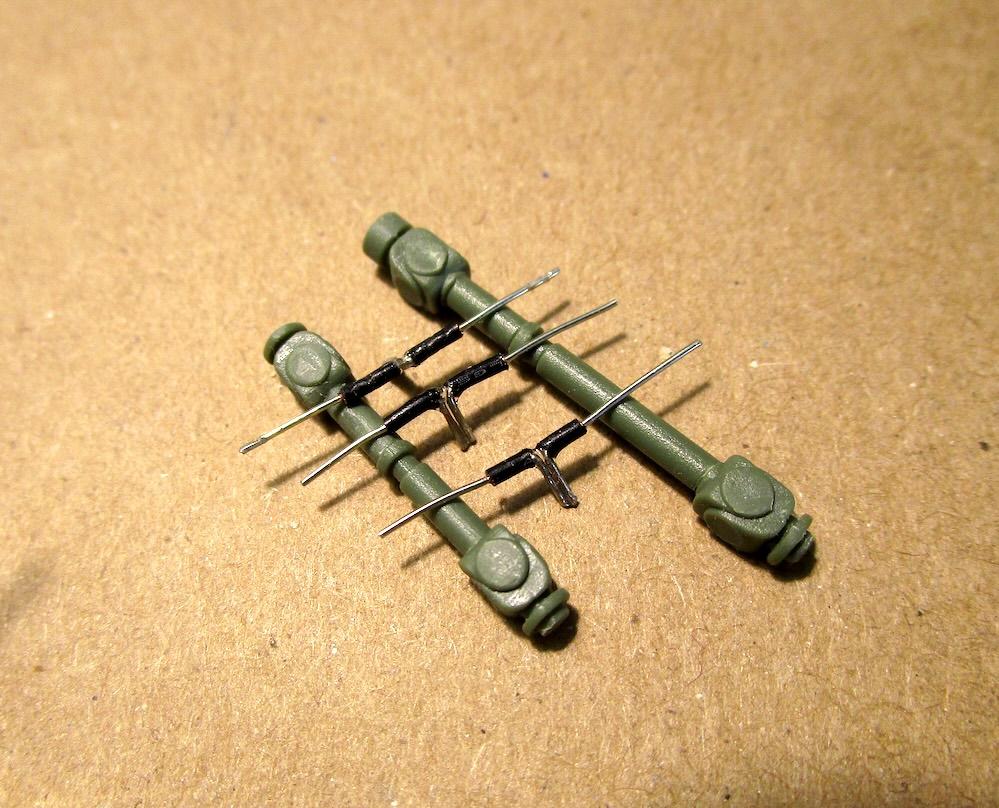

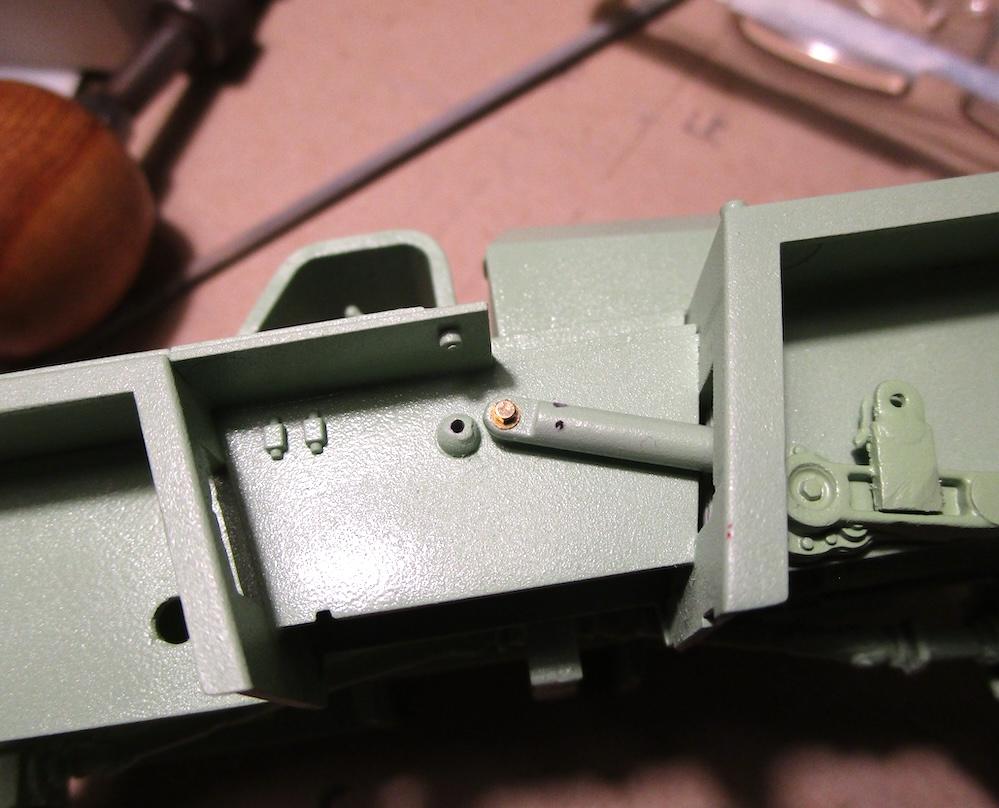

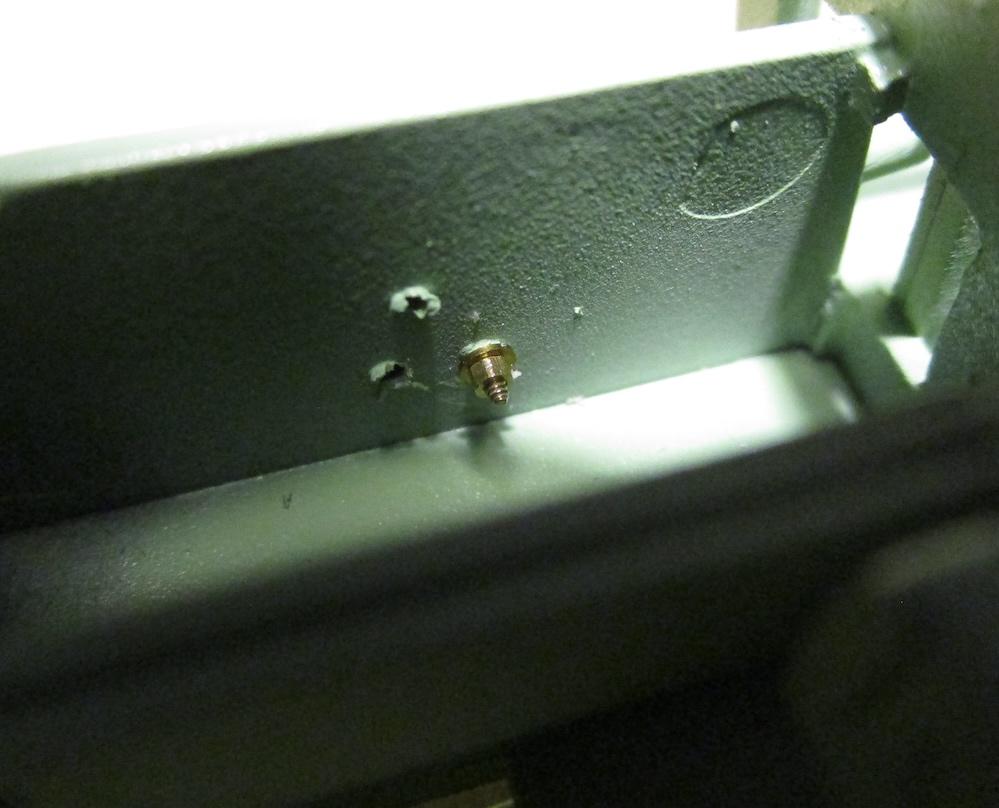

Working on the hydraulic fittings and hose. I'm making them from insulated solid wire so the road wheel arms can articulate and the hose will have the flex needed. The wire is removed from the flexing part then the insulation is reinserted onto the ends of the wire which will represent fittings and glue into the cylinders. The hydraulic cylinders are mounted with what looks like a giant bolt and washer fastener so I went shopping for Scale Hardware. This will also allow articulation of the road wheel arms with a strong fastener.

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

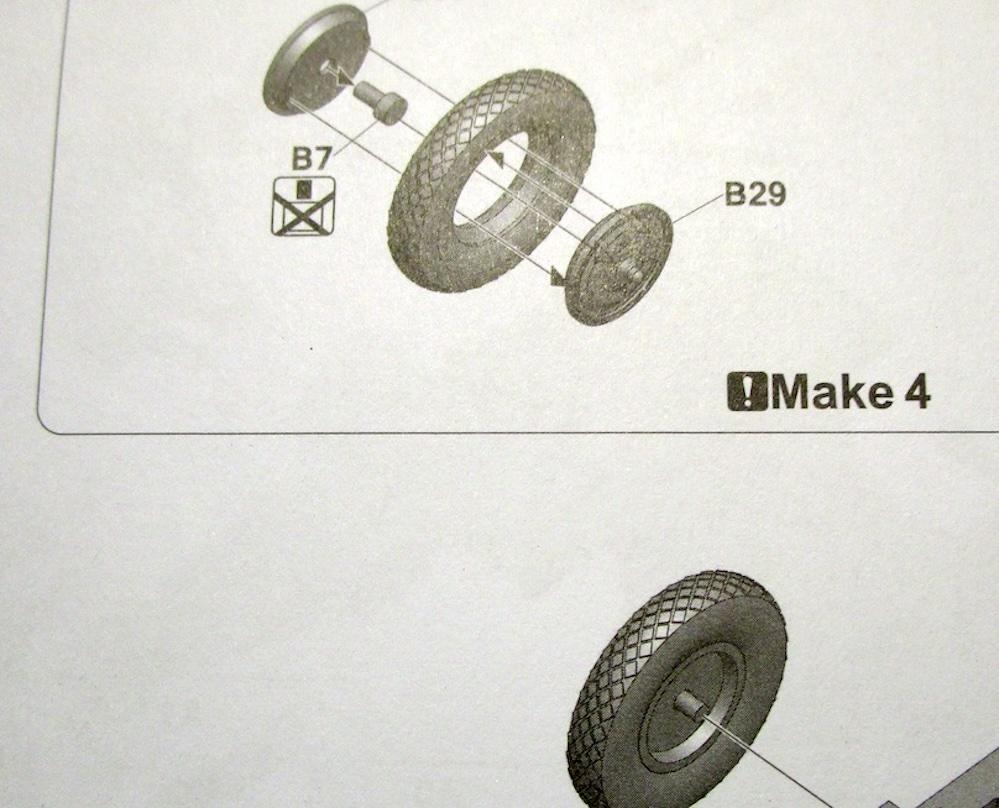

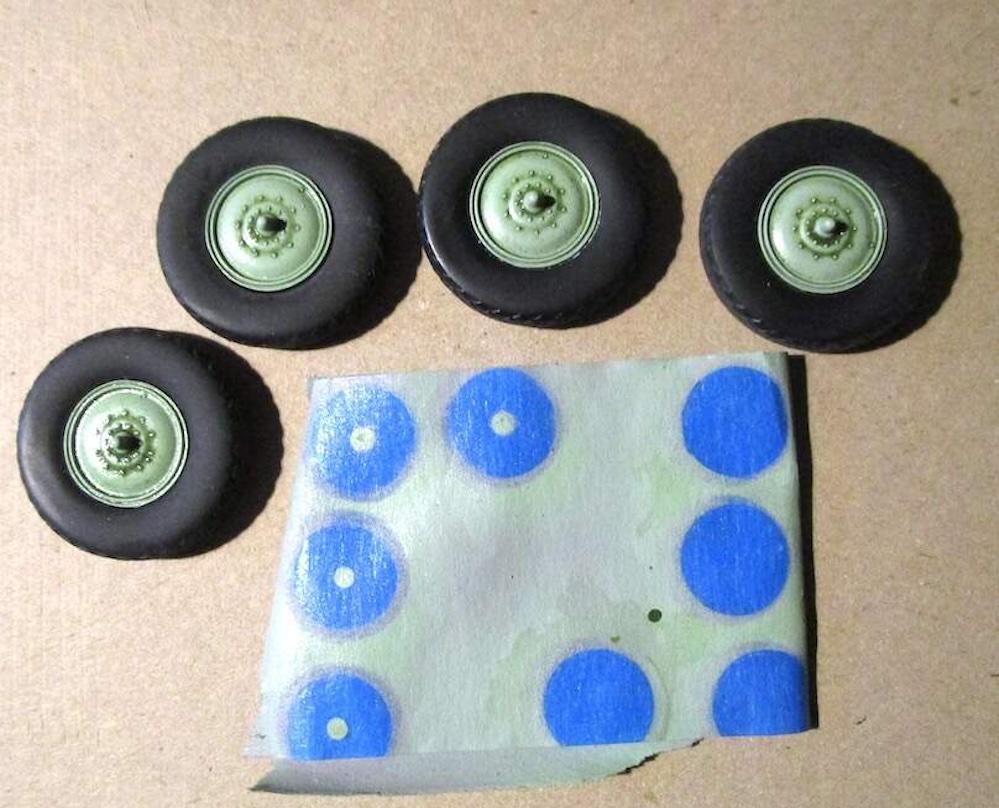

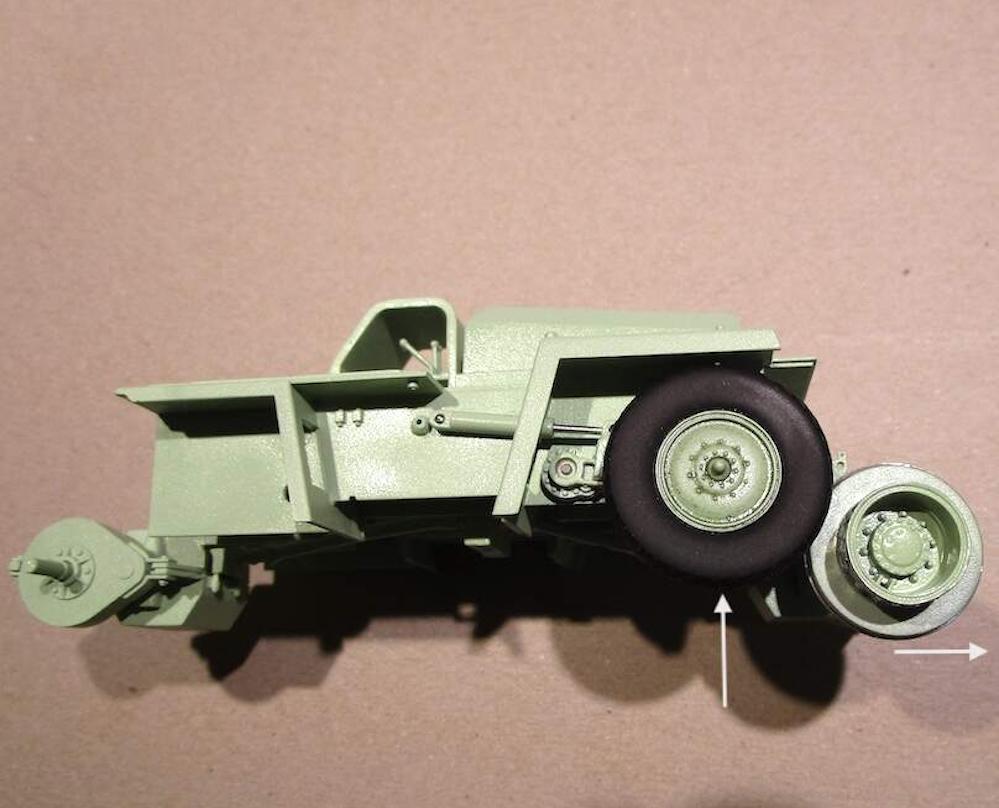

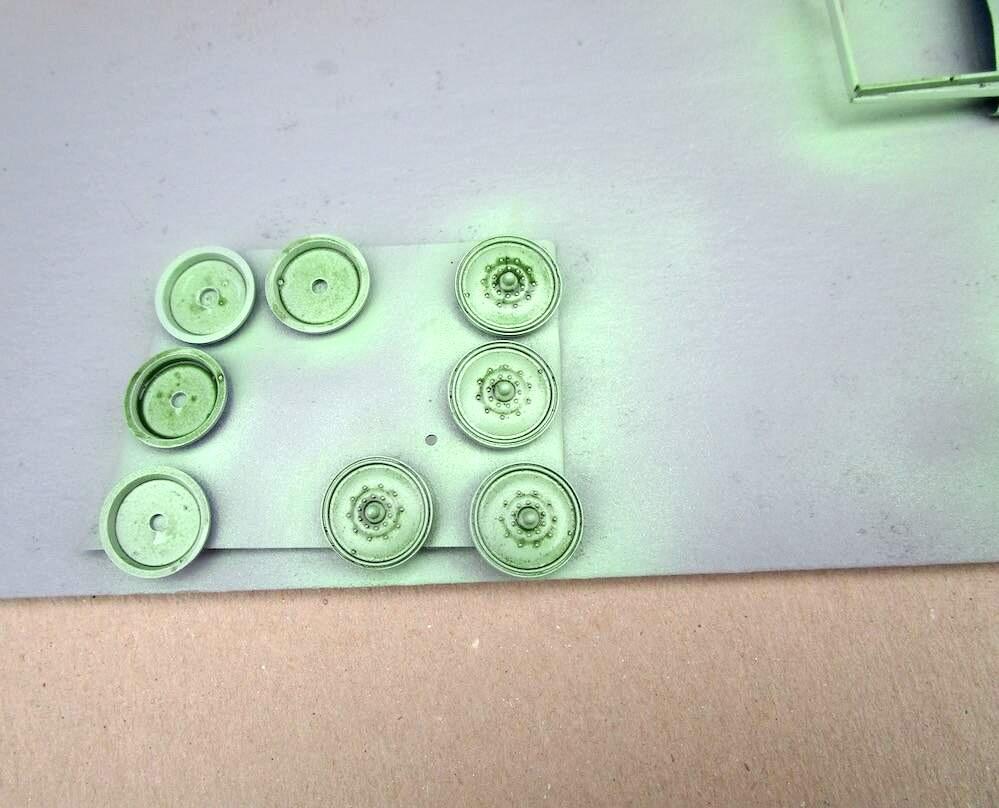

Road wheel assembly. these are the wheels that will drive on pavement off of the railroad. Dry fitting I discovered that the road wheel arms need to be extended further so the drive cones on the traction wheels will make contact like the 1/1 prototype. Traction wheels are slid outboard (rearward) during rail operation and the road wheels are raised up. Then if driving on the paved road the road wheels are lowered and the traction wheels slide inboard (forward) so the drive cones make contact with the rear road wheels to drive.

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

@gotnitro? Yes, I'm pleased with the color as well. Sponge method sounds, well sound. May try that next time. Thanks for commenting.

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

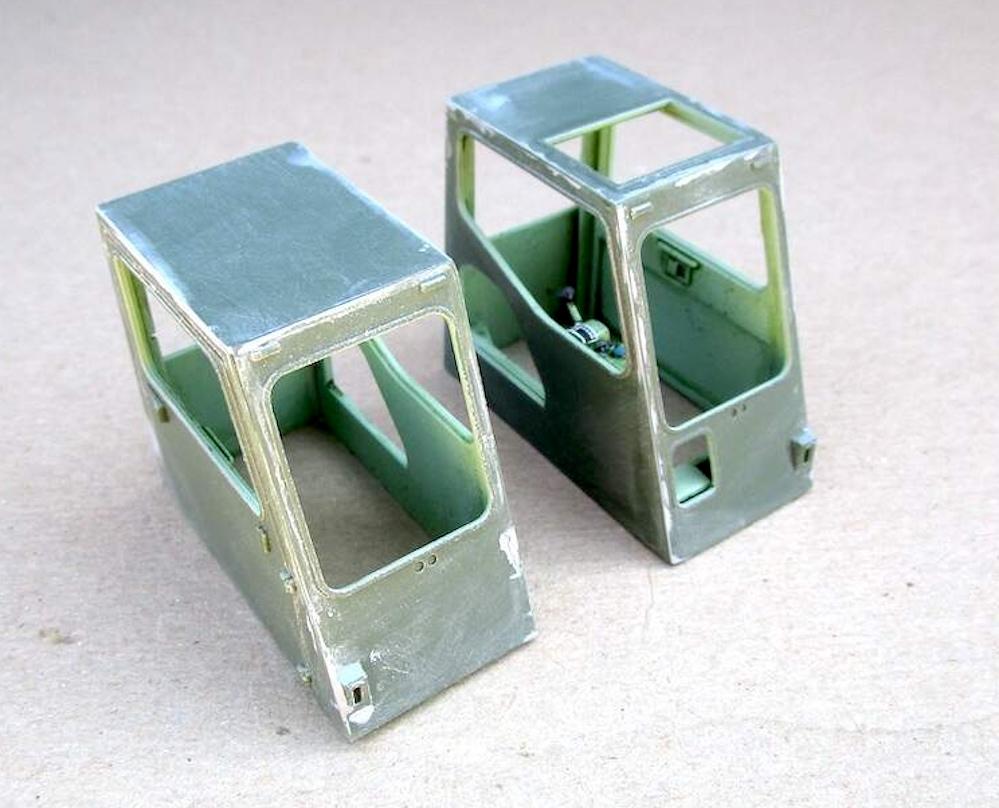

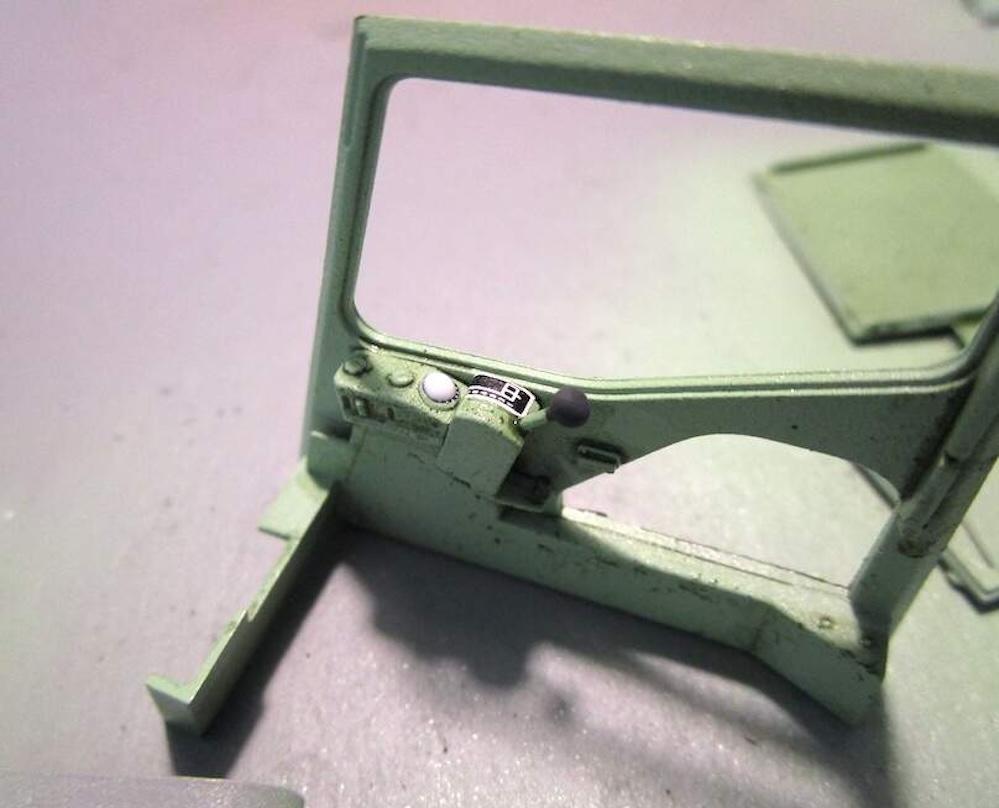

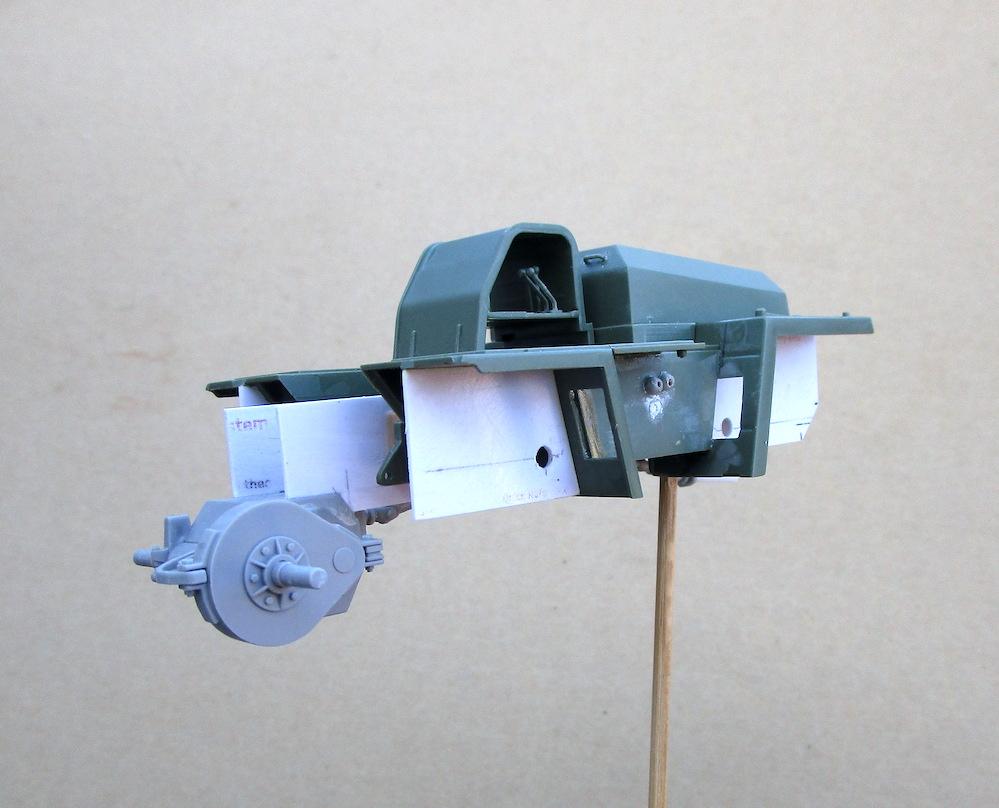

Window weather stripping painted on the driver cab. Painting the brakeman's cab today. I'm doing this before I glue the glass in place.

- 63 replies

-

- 2

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

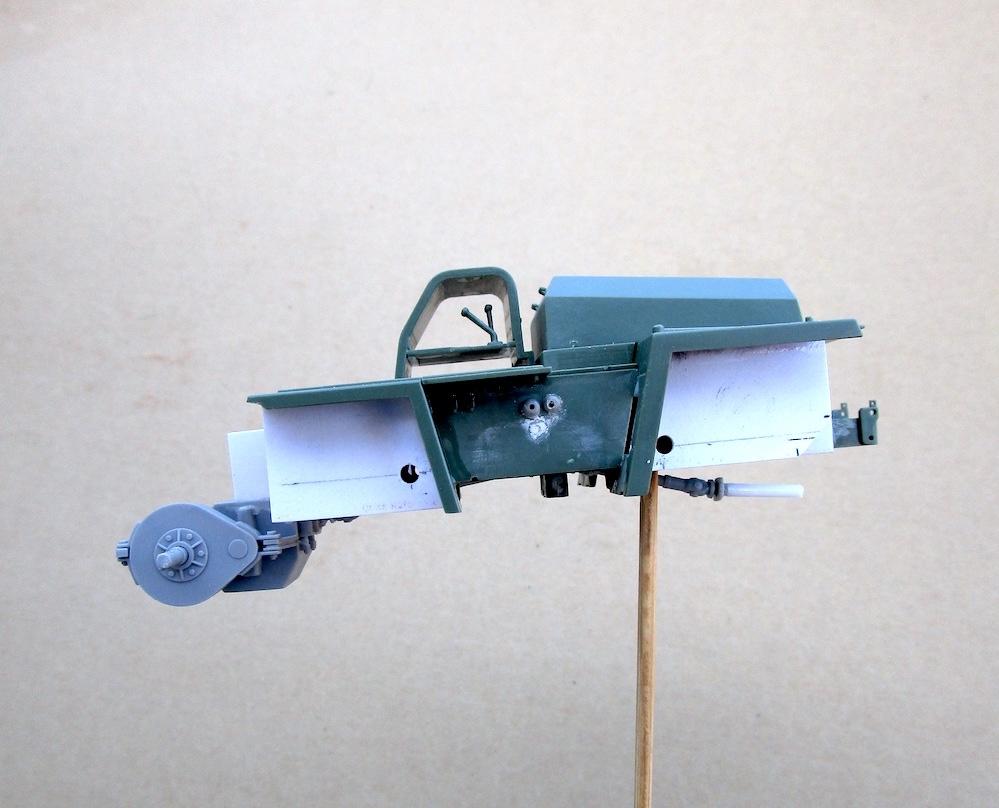

This was the only way I could figure out how to build and paint the cabs. Paint the insides first then build the cab subassemblies. Then mask from the inside to protect what I've already done inside so I can paint the outside. I still need to glue in all the glass, cleanly as well 🤔

- 63 replies

-

- 1

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

- 63 replies

-

- 1

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

Handmade pickup

Edward Gore replied to YEKUN's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Very nice scratch build. I just figured out what the rims are made from 👍💡 -

Hi @Scott Eriksen, Thanks for checking in! I'm still in to 1/35 armored stuff when I'm not building static stand alone rolling stock, sci-fi, figures, oddball kit-mash ups, oh yeah or cars and trucks 😁 Recently there are a lot of 1/35 kits from Academy, Amusing Hobby, Border Models, Miniart, Meng.... with full interior including engines, transmission, drive train, and driver compartments. A little pricy for those not interested in the 1/35 scale range starting at $50USD and up. My favorite builds of those kits are when they make them exploded view display builds 👍💡

- 63 replies

-

- 1

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

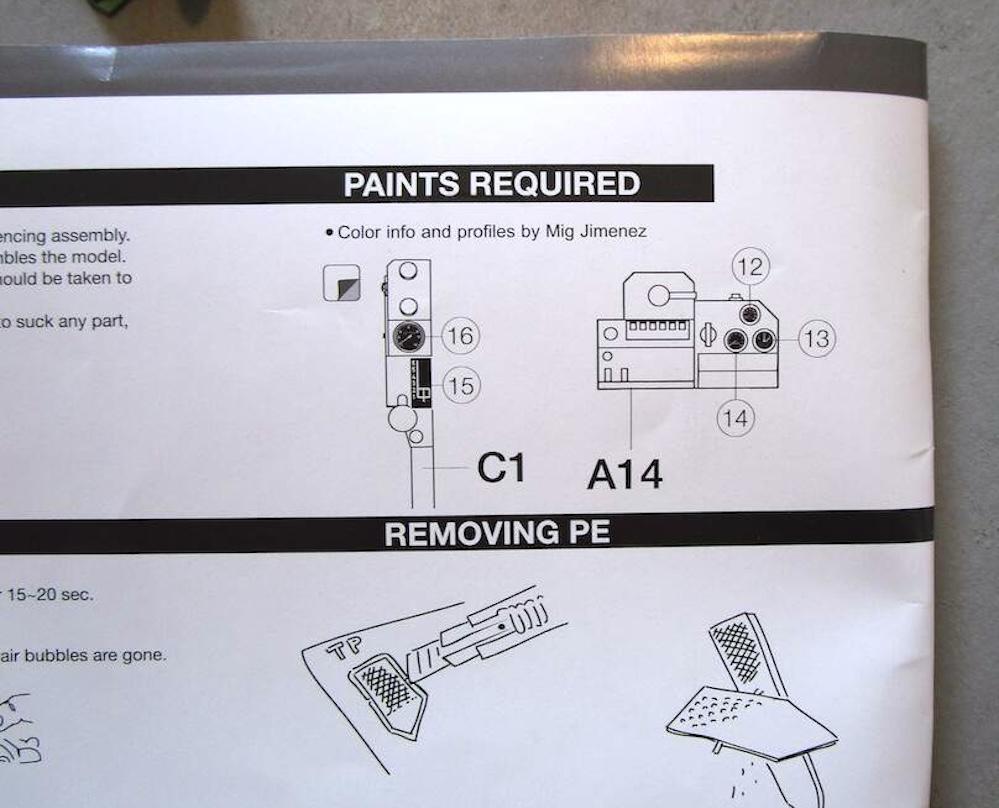

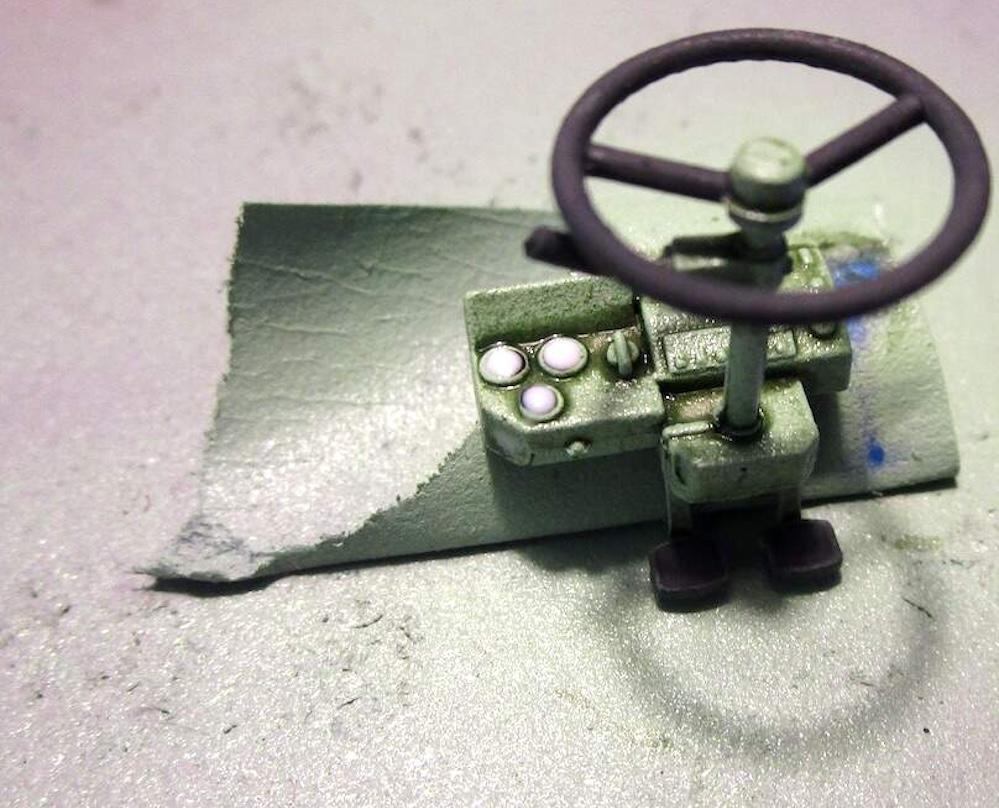

Thanks for the compliments. The dials and gauges are so tiny in 1/35 that I wanted to magnify them. Putting a sort of dome on each one did that I think. The weathering is actually accidental at this point in the build, Lol. Thank you for the compliment.

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

Interior detail getting done. Kit decals installed upside-down, probably. They are so tiny. Creating gauge lenses with a drop of Kristal Klear.

- 63 replies

-

- 1

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

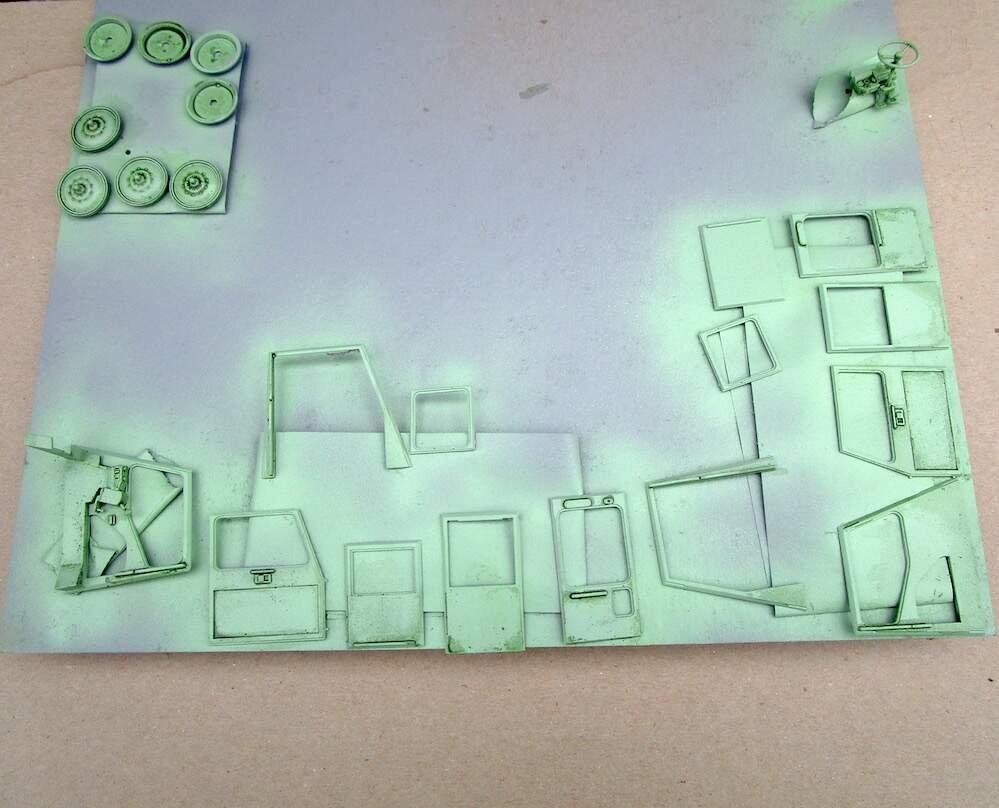

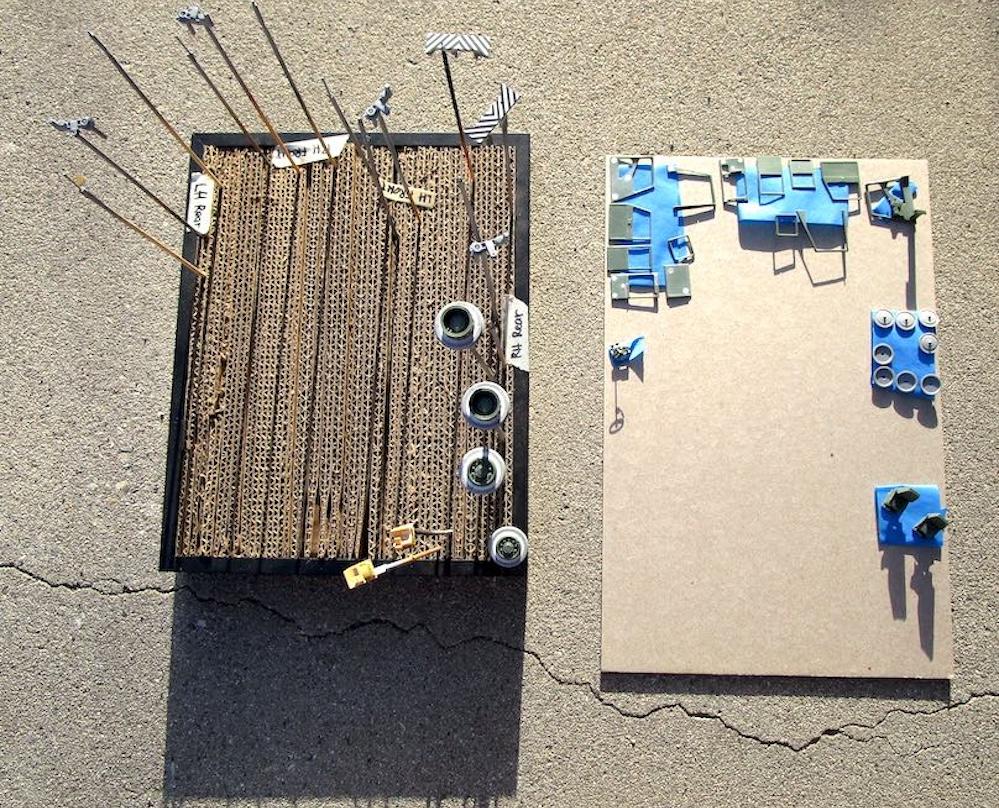

This model is based on the Trackmobile but is my own design using kits I already have in the stash. Trackmobiles I see online are usually yellow or orange so I want mine to have that sort of U.S. Forest Service green. Paasche, indeed it is!

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

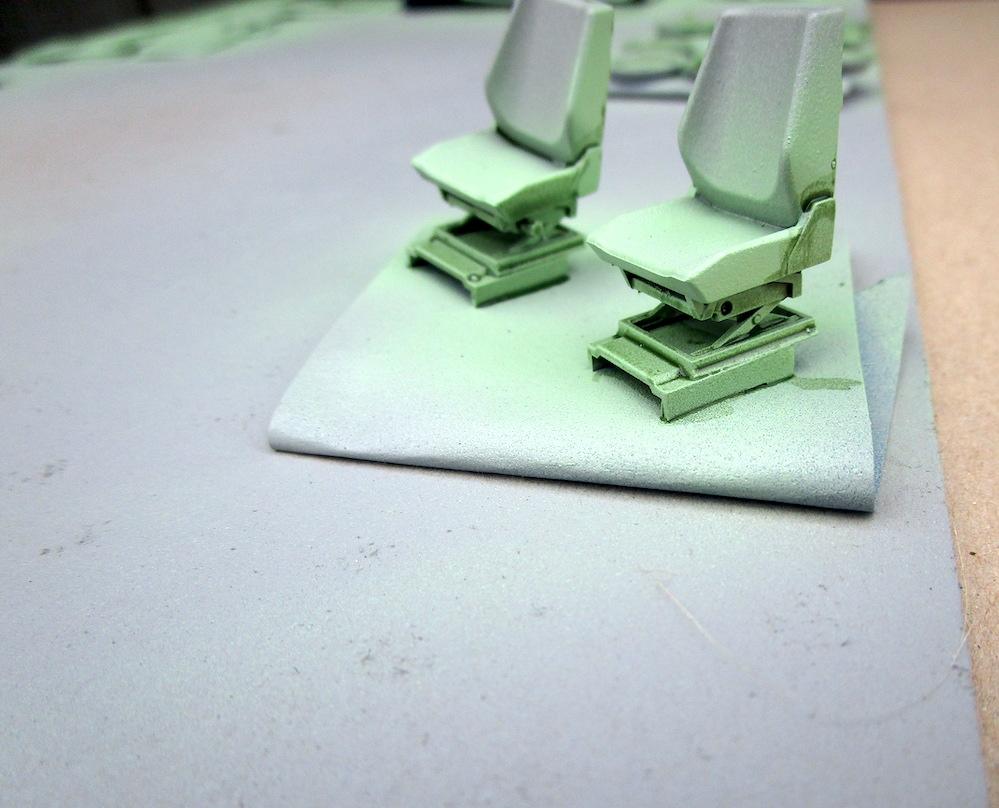

Added a pin wash of dark green to compliment details on the inside of the cabs. A little on the wheel hubs and seat mechanisms as well. Then masked and sprayed the drive cones ‘chrome’ to simulate polished wear. These will receive a pin wash of bronze and black later.

- 63 replies

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

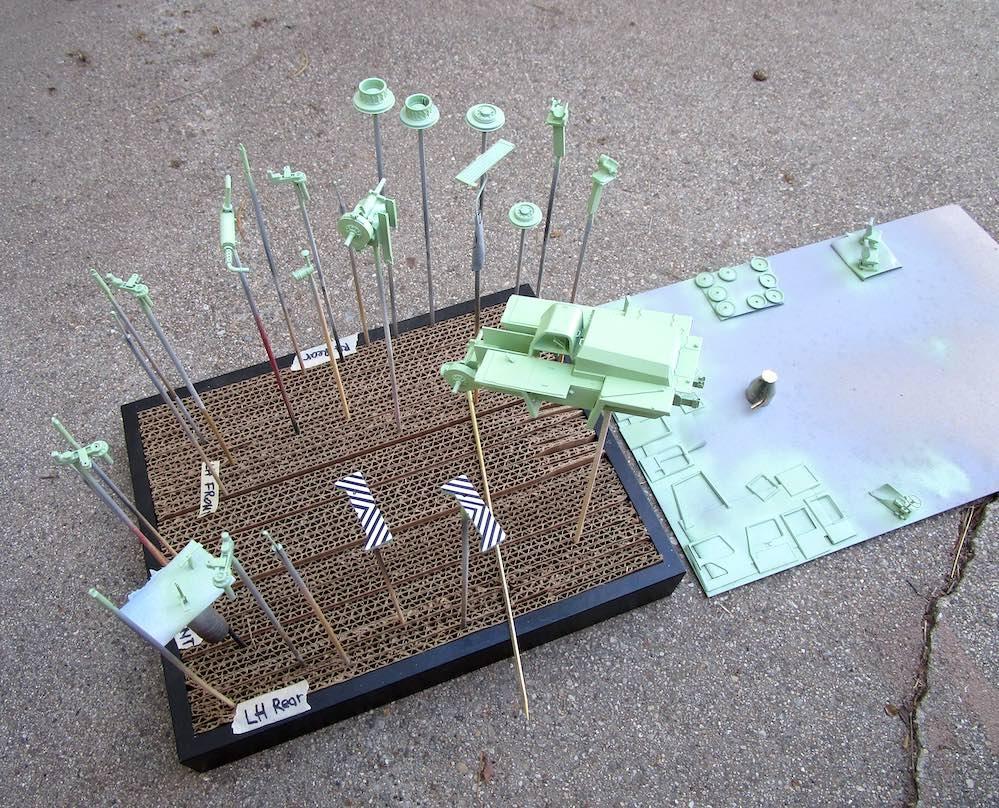

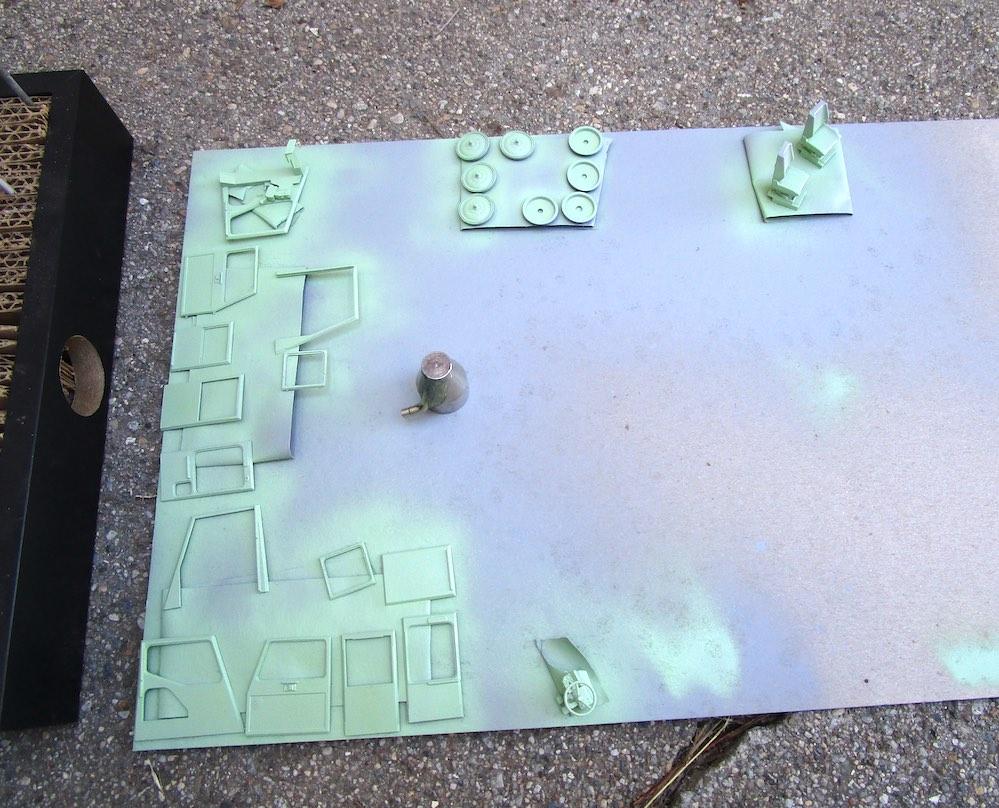

@cifenet, Thanks again for checking in and for your comments. Base color on. I had to decant an old aerosol can of OSH Safety Green and use the AB. Thanks for looking...

- 63 replies

-

- 2

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with:

-

This subassembly now has a sort of, Alejandro "Burda" Burdisio, or Ian McQue, design going on here. Now prepped for primer.

- 63 replies

-

- 1

-

-

- trackmobile

- tractor

-

(and 2 more)

Tagged with: