drummerdad

Members-

Posts

183 -

Joined

-

Last visited

Previous Fields

-

Scale I Build

1/24

Profile Information

-

Full Name

Dwayne stephenson

Recent Profile Visitors

drummerdad's Achievements

MCM Friend (4/6)

-

Photo etching at home

drummerdad replied to drummerdad's topic in Car Aftermarket / Resin / 3D Printed

I went back and talked with Preston (my friend at work), and he is pushing me to get a small tabletop CNC machine. They are around $400 for a decent sized machine. Im not trying to make anything fancy like wheels, just flat parts, similar to those I would make with photo-etching. This is very close to what he does with the panel machine at work. So, I think Im going to try this first. Learn to do the flat stuff, and maybe I can start more complex things later. No chemicals, so thats a plus. But I know it will have its own troubles. -

Photo etching at home

drummerdad replied to drummerdad's topic in Car Aftermarket / Resin / 3D Printed

Thank you all for the replies. It helps with the decisions I need to make. As far as the drawings for the photo-etch, Ive been talking to a friend at work, and he said it was pretty simple. He runs the panel pro we use for overlays at work. I work for a helicopter completion center, and we make formica overlays for circuit breaker panels and instrument panels and things. He runs the panel machine that cuts these overlays. I dont exactly know how he plans to do it, but he said if we could find an image, we could download it into a free program, and scale it and add tabs. I was planning on having him help me with the first run or two. And I have watched a bunch of videos on YouTube about it. Thats one of the reasons I was looking into it. I have actually watched the very video you posted Bill, so thank you. I guess thats probably what Im going to have to do, build my own kit. I think for now Ill just have to find a way to make some of the tabs by hand. Its going to suck though. They are pretty small. -

Photo etching at home

drummerdad replied to drummerdad's topic in Car Aftermarket / Resin / 3D Printed

This might raise another question. What other types of cutting can be done for brass? Laser, CNC, photo-etch? Lasers are expensive from a quick search. About $900-1500 for an engraver. I dont know if the engraver will actually cut. Then I have to worry about learning software, or an autoCAD style program. Photo-etch looks like I can do it, and afford it, but the only kit available (Micro-Mark) is sold out. I might be able to assemble my own kit, but I dont know what to get. CNC would be great, except I would have to worry about the software (again, maybe even autoCAD). I would also need bits. IF I could learn to use it, I could maybe even cut other parts. At the end of the day, its just a hobby. I dont make money, I only spend it. I cant justify spending $1500 for a tool Ill only use for model building. I have managed to sweet talk my very understanding wife into taking a chance on a 3D printer. But the truth of the matter is, this is only because the cost to have parts printed by someone else, even if there is a person that exists that will print something for you, is many times what I will spend on a 3d printer set-up before I finish these 1/8 scale models. -

So I have officially reached the "I guess Ill have to do it myself" stage of life and modeling and have decided to try photo etching at home. Ive been back and forth for a year or two, but I have been making progress on the 1/8 scale Camaro and I am in desperate need of chassis tabs and a few little brackets. I went to Micromark and the kit they sell is sold out. I searched and didnt see any other places selling a kit. So, does anyone know where to get a kit, or do I need to build my own kit? What are you guys doing for photo etching? As far as I can see, no-one is selling 1/8 scale phot etch tabs and brackets.

-

Who doesn't love a mock-up? Let's see yours!

drummerdad replied to Belairconvertable's topic in WIP: Model Cars

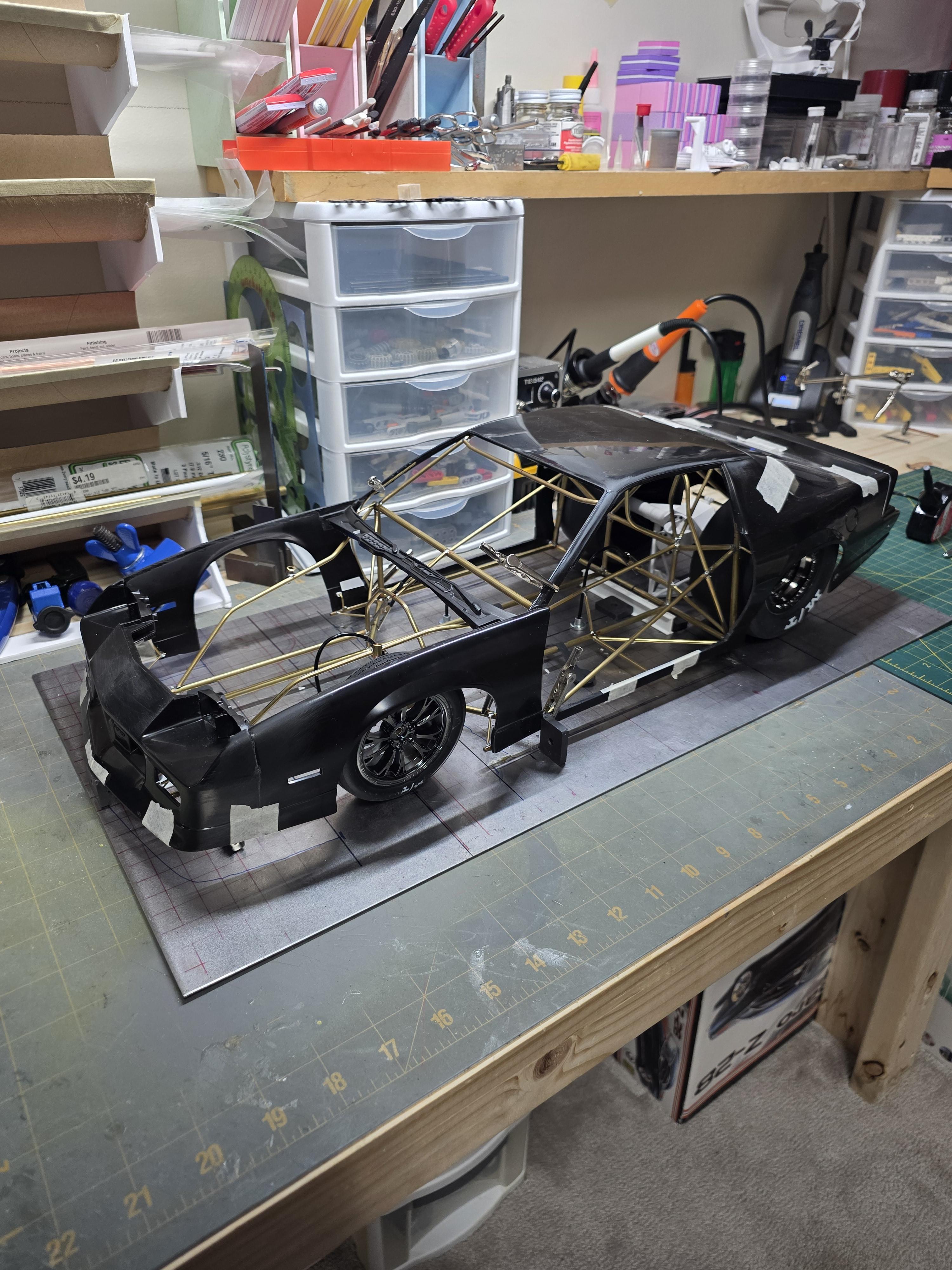

Here is a 1/8 scale camaro I'm working on. This is a learning project. I'm learning to solder brass, and I'm fabricating the engine and rear differential from styrene. I'm not super happy about the wheels. They are for 1/10 RC cars from the local hobby shop. I'm looking at getting a resin 3d printer soon so I can start printing parts. I've reached out to dozens of people about making wheels, and Noone wants to do it. So, I'll attempt it myself. It's very slow going. I'm learning skills to build another 1/8scale model in the future. Wish me luck. -

3D Printing Storefront Directory

drummerdad replied to Mr. Metallic's topic in Car Aftermarket / Resin / 3D Printed

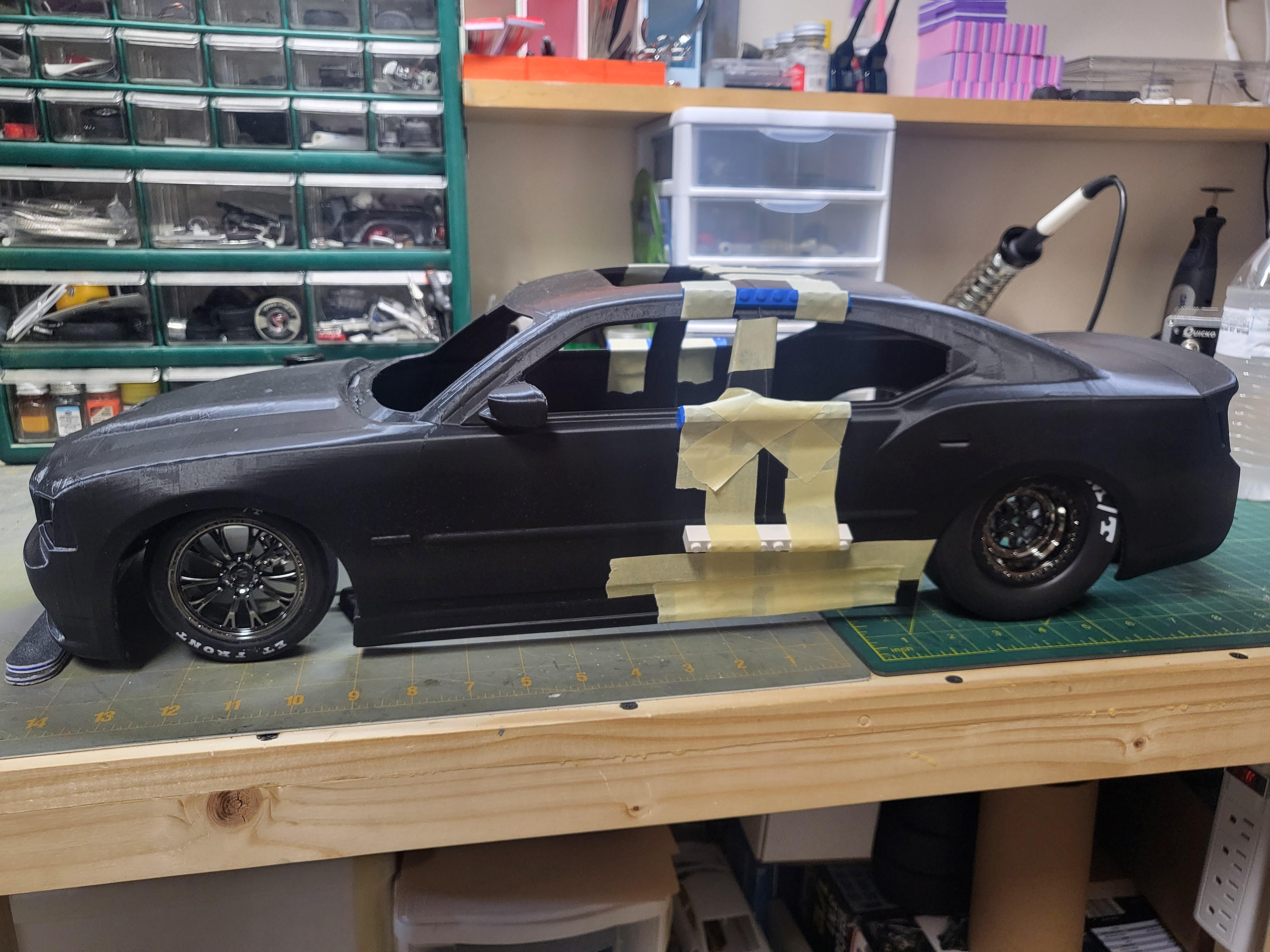

Okay. This might not be the place to put this, but Im not ready to start a build thread. I have learned I am doing it backwards--I have been building the base of the cage, and adding the suspension and wheels and tires, engine, etc..after I build a majority of the cage. I have watched a few channels where they build actual cars, and they start with a jig, bolt the suspension, engine and wheels in place, mount the body and build around that. I'm going to take some time and start looking at parts, and maybe build a jig. In the meantime, here is what I bought. It's a 1/8 scale 3d printed body of a 2007-ish Dodge Charger SRT-8, which is just like my car (except mine isn't an srt8, its an rt with the road and track package). I'm going to make a pro-mod out of it. I've never seen a pro-mod made from a 3rd gen charger. As for the body, it looks like what I would expect from a 3d printed body. Lots of lines. And the halves are split in a weird place, but I think I can manage. For what I am doing, this will be perfect. There will be quite a bit of body work, but that is to be expected. The body is a little warped, but the box was half crushed. Nothing is broken and I think I can pull it together and make it straight, so I am happy. It was not the fault of the seller, he had it packaged well. Ill just get some clamps and maybe make a wooden fixture for it. It took about 2 weeks to get it, and it cost about $205. That's with tax and shipping. The guy is on ebay, and his store is called revolutionus. I asked him if he would do custom sizes, as he mostly does 1/10 RC bodies. He said sure. I gave him the wheelbase dimension from my actual car, and he already had the file to print. Easy. I will try and go back and get a 1/16 or 1/12 67 Dodge D-100 in the future, but for now this will have to do. -

3D Printing Storefront Directory

drummerdad replied to Mr. Metallic's topic in Car Aftermarket / Resin / 3D Printed

This body will come in at least 2 pieces according to the auction. Its also PLA, so there will be some work involved in getting it to look good. I know I would need a massive printer, but I don't plan on printing bodies. I know thats what everyone says, and I might change my mind eventually. But the way I see it, these large models are expensive and time consuming. I cant build one in a year, or two. This will take 4 or 5 years if Im lucky. I'm not as consistent or serious as some of you guys. I just dabble, and I get un-motivated so I swap kits, and shelve others...Its a mess. My goal with the printer was to print all the details items, like wheels and tires, seats, carbs, engines, batteries, etc...If I bought all of that for the Iroc Im currently working on, it would cost several hundred dollars. I can get a smaller printer, buy some files, and start figuring things out. I can print for any scale at that point with the files I have already bought, I just have to do the math. This wont be a quick process either. I am currently working on three 1:1 projects as well. I'm not rich, so everything has its priority and 3d printers are low on the list. But, Im going to try and make this happen, and get some of these model ideas out of my head. -

3D Printing Storefront Directory

drummerdad replied to Mr. Metallic's topic in Car Aftermarket / Resin / 3D Printed

A small update. I found a guy on eBay who prints 1/10 scale RC bodies. I reached out to him, and he as agreed to print a 1/8 scale body for me. I will update with pictures, probably in another area, when I get the body in. He has a bunch of bodies on ebay. I also inquired about an additional body, and he agreed. It'll be a little bit before I get the other one though. Ill give all the details including the name and price when I get the body in. I want to check the body to make sure its acceptable before I recommend him as a source. I'm also going to go ahead (I think) and buy a resin 3d printer and cleaning/curing station. I will have to learn how to do the smaller stuff, like wheels and tires, shocks, seats, engines, etc.... It's going to take a while to gather all the stuff, and get ready.. Then I have to learn how to do it. With the market being the way it is, if Im going to keep building these kits, Im going to have to suck it up and learn to print. The cost of two sets of wheels and tires for a 1/8 scale model will pay for the 3d printer and all the accessories. -

3D Printing Storefront Directory

drummerdad replied to Mr. Metallic's topic in Car Aftermarket / Resin / 3D Printed

Are there still people on this forum willing to print for others as a (paid) service? I have tried to get things printed by friends, and they didn't turn out good enough to use or they were out of scale. It's hard to get someone who doesn't work with scale models to understand what is important in the final product. If they are printing trinkets or gizmos for home use, the quality doesn't have to be crazy. If you are printing an 1/8 scale drag slick and tire, it needs to be very detailed. I have reached out to people of Facebook also, but they only seem interested in printing figurines for games or things like that. I am currently working with 1/10 scale drag tires for RC cars from the local hobby shop. They are the right size, and they look good from the front, but the tire shape is off, and the back of the tire wont work. Im using them for setup and looking for another solution. Plus they were like $95. If anyone is willing to print wheels for 1/8 scale or 1/12 scale models, contact me please. We can talk and discuss pricing. I have already bought files online for this. -

3D Printing Storefront Directory

drummerdad replied to Mr. Metallic's topic in Car Aftermarket / Resin / 3D Printed

Shapeways going away from store fronts really sucks. I haven't posted in awhile...Im just busy and doing my thing. I lurk occasionally. Mostly Ive been learning to solder so I can get my 1/8 scale Iroc going. And just as Im getting ready to set the suspension up, I go to Shapeways to buy wheels and tires and get this surprise. Is there any way to get large tires printed? I bought some files from 3d cults, and tried to let some friends at work print them. The goal was to make sure I could in fact buy a file from an online source, and print it...eventually buying my own printer. But so far 2 friends have tried and failed. If they cant do it, I probably cant either. I have reached out to another guy at work, so maybe he can get it done. I have also looked at 3d scale parts. He has some of the best stuff I have bought, but in the 1/8 scale stuff I don't want the wrinkle wall tires. This is frustrating. -

Do you also have 1:1 project cars?

drummerdad replied to ctruss53's topic in General Automotive Talk (Trucks and Cars)

I have a ton of pictures. Im not sure I can post them all here. I lowered the truck by adding a mustang 2 front suspension with coil overs, and a triangulated 4-link in the back. I have a complete build thread on the dodge forums and the sweptline forums. I agree they are very tough. The frames are big and heavy. I boxed this one, and after the mods, I couldnt lift it. I had to use the engine hoist. -

Do you also have 1:1 project cars?

drummerdad replied to ctruss53's topic in General Automotive Talk (Trucks and Cars)

I am currently working on a few things 1:1. My sons 67 dodge D100, and my 07 Charger RT. Isaacs 67 is a 4speed short box 318 short bed sweptline. I added a mustang 2 front end, a triangulated 4-link and front disc brakes. I swapped the frame, and shortened it with custom cross members. My car is a stock 07 charger RT. I have a new zero mile engine to go in it, along with an MDS delete kit, new cam, complete exhaust and a torque storm supercharger. It should make about 500 wheel HP when Im done. -

I dont want to derail this build, because I am in awe of you guys who do these super detailed builds. But how do you all get the solder joints to stay so close together? I have attempted a few small brass bar joints and its fine, until I get bars or parts really close together, then everything just falls out. Is it the resin making a eat bridge? Or do you guys make fixtures for every joint that needs it? Is there a thread here with details on how to pull this off? I tried a fixture, and some of those manipulator arms to hold things, and it never hold it exact. I also tried heatsinks.

-

Some of the 3D parts have better quality than others I have found. However they are better than the resin parts I have bought. It might be the same thing, where the supplier makes all the difference, but I have not been impressed with resin parts. Im trying to improve on my fabrication skills. Its cheaper than resin and 3d parts, but it takes awhile to get good enough to make a good part.

-

Thanks for the kind words guys. I have bought a few 3d parts from Shapeways...I think. I go to a few 3d sites, and I think they have stores on Shapeways, who prints the parts. It works out good for me. It is a 1/16 scale firebird.