Mike Holland

Members-

Posts

80 -

Joined

-

Last visited

Previous Fields

-

Are You Human?

Yes

-

Scale I Build

1:16 cars

Profile Information

-

Full Name

Mike Holland

Recent Profile Visitors

219 profile views

Mike Holland's Achievements

MCM Regular (3/6)

-

There you go! Excellent, make it fit. Respect.

-

Hi Dennis. OK, I accept that you're going darkside with this one. Dear Mr. Hemifever, yep, Chevies had a couple of cool ones, too. Post door cars rock! Actuallly, even bought a basket case back in early '75. '63 Chevy II. The motor was too insane though, built by a local shop in the DC area. Angle plug heads and w/ 13-1 compression just too idiotic. Sold the motor for more than I paid for the whole car. Such were the times. PS: it's OK to build Chevies. I like them as well. Mike..

-

I like it. What's cooler than an early 60s post door car? Nice works going on here.

-

William, I like it! Asking about the tonneau cover, your own creation? Looks great.

-

1:16 FED, brass, current project

Mike Holland replied to Mike Holland's topic in WIP: Drag Racing Models

Thanks Dennis, I love these old diggers. -

1:16 FED, brass, current project

Mike Holland replied to Mike Holland's topic in WIP: Drag Racing Models

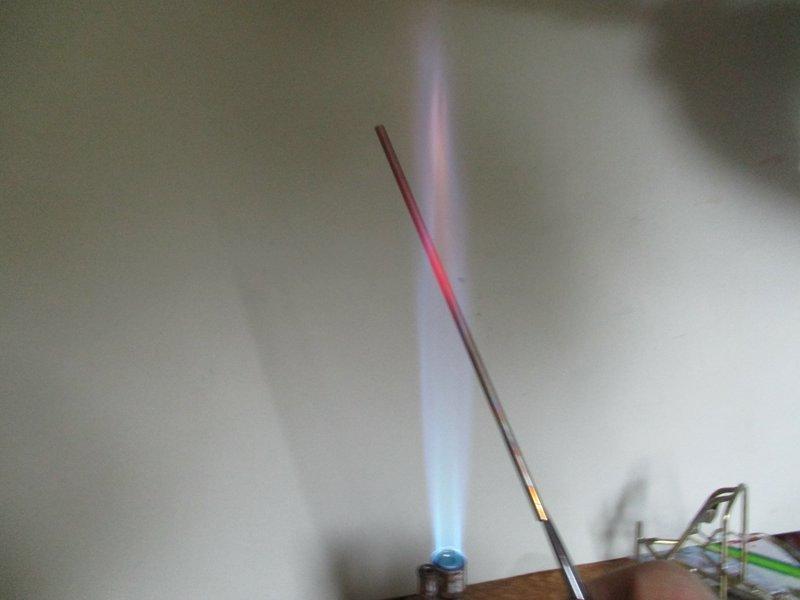

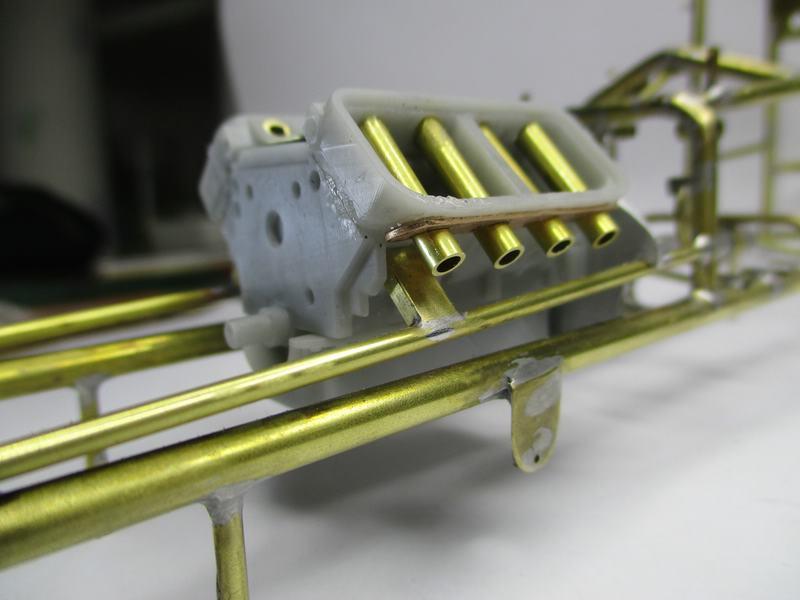

UPDATE: Motor stuff. Shown here adding some fuel line hardware and the zoomies. Motor will have the old school 4-hole injector hat. This time, making the 392 motor with the manifold injection lines running to the back, as with the 426 Hemi. Always wondering about this application, until seeing a photo of a 392 having all lines heading to the back. Interesting. Now, my personal dread! Zoomies. I'd rather lace wire wheels than do these! After building 10 of these brass models, finally have gotten wiser and things are so much easier and quicker with this method.....But 1st off, the old way. 4mm brass tube, thick-walled. Get a glass jar that has the correct, scale radius. Heat up until glowing red, then bend around the jar, for the radius, chop off as needed. Easy-peasy....lol! Forget about it. Here, the revised method. SO much easier and quicker. Slicing the 4mm brass tubes with a thick disc at high RPM, halfway through. About 7 cuts work for FED zoomies. Then, slip a solid brass rod in and bend according to your application. The solid rod prevents the tube from collapsing. Notice the brass rod sticking out. This feeds perfectly into the tubes already sitting in the heads. Now, after correcting the bends if necessary and chopping off the tube sticking out of the heads close to the flange, solder up or use your favorite putty to close the cut slicing. In my opinion, the 'slicing method' is easist and the quickest way forward. Why not? Zoomies are in my opinion a real live pita. 8 zoomies this way, 2 hrs. max. Here a finished FED from a few years ago, with slicing the zoomies....1:16 brass car.... Thanks for viewing. Mike.. -

1:16 FED, brass, current project

Mike Holland replied to Mike Holland's topic in WIP: Drag Racing Models

There you have it. Only chrome will be the rocker covers and front axle. Down low and digging in. 1965. -

Cheers to that, young man! This model was not my 1st absolute replica, but possibly my last one. But what a wonderful modelling experience. All of them. 3 FEDs and 2 FAs, the 3rd FA is in planning. A Bantam, 1:16, modelling the current fastest car in Europe. I have the 3D body, but it will need a ton of work, being way too wide and too tall at the doors. Body work is enjoyable though, time will tell. Once again Francis, your eloquence is the very best medicine out there, period. And I thank you most kindly for commenting. Mike..

-

1:16 FED, brass, current project

Mike Holland replied to Mike Holland's topic in WIP: Drag Racing Models

Thank you Francis. Yes the age limit is biting me once more. Actually, not much left to do with this FED. The front wheels are spoked and ready for paint. The motor is finished, only needing spark leads and fuel lines and paint. Bend a simple brass cowl and sides, and that's about it. Painting is a pleasure, not a chore. Just the silly monkey on my back that laughs at my own laziness. Your words are the best medicine for firing up the bench once more. Greetings. Mike.. -

Elliot, looking very nice! It takes some guts to do the chop and you've pulled it off, thanks for the detailed step-by-step sequence. Excellent! Mike..

-

33 Chopped Willys, 3D Body, what now?

Mike Holland replied to Mike Holland's topic in WIP: Model Cars

OK. I've been using such thin discs with a hand held micro motor for 50 years (dental). The 3D medium is new to me, I agree though the disc is overkill. I had no idea the thin sprue leads were so temp sensitive. My plan is now is to snip off the leads as far as I can get into the object, then start a slow dipping procedure in relative warm water and slowly start twisting the object around. Starting with the hood, which seems quite thick. Thinking step by step to get the feel of things. This is all new to me, thanks much for your input! Mike.. -

33 Chopped Willys, 3D Body, what now?

Mike Holland replied to Mike Holland's topic in WIP: Model Cars

@Elliot, thanks for the interesting presentation. I haven't a clue about 3D printing but love your short video.. -

33 Chopped Willys, 3D Body, what now?

Mike Holland replied to Mike Holland's topic in WIP: Model Cars

Hello Chris. Thanks for the info. There being still, a void along the bottom of the body where the running board would be, left side, just in front of the rear 'fender area'. Not a problem, I can fix this up. Now I understand about the warm water deal, thanks much for the info. Also the clarification concerning shipping/packaging issues. Now I get it. After paying $100 for this stuff, was not expecting the delivered project to be like this!! I have small clippers. Also, I like my trusty, diamond-coated separating disc, 1.2 " wide, quite thin, mounted in my hand held micro-motor. At 20k RPM, will slice through like butter. Chris, like many things in modelling, if you don't know, just ask. But geez....so much cash for such an object, has me wondering? However, the 2nd load of the same caliber, has the fenders and a chassis, plus a Ford 9" rearend housing. So, hoping to have not been severely ripped off. OK, I'm in Europe, so guessing am supposed to be wealthy? Laughing myself now. Thank you for your input. Mike.. -

33 Chopped Willys, 3D Body, what now?

Mike Holland replied to Mike Holland's topic in WIP: Model Cars

Thank you, Les. How hot the water? Like from the faucet? Which, in my kitchen, can't touch it. Will this be enough? Or, rather a pot of water, real hot, like cooking noodles? Please excuse, having knowledge about 3D motors and such, just never have dealt with the sprue leads like this before. Hence, having zero knowledge with this degree of unknowns. Thanks much for your help, immensely appreciated. Mike.. -

Hello folks, Just received this one in the mail. Not my 1st, 3d body from this fellow, just 1st time receiving 3d body/parts like this! Needing oxygen and stress relief after viewing the quite expensive contents. The designer was not the printer, another fellow did the printing. Granted, having countless 3d parts, motors and such, haven't received one like this, yet. Oh boy, some serious hacking needed here. Also in the box, the custom fenders, chassis and Ford 9" rearend. Plan is a very low riding custom car/drag car. Not building this one yet, will be my next project. One at a time. Thoughts? How do YOU clean this mess up? Mike..