-

Posts

1,579 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by redneckrigger

-

Thank you all! I’m finally finding a bit of dexterity coming back, and had a good night at the bench last night. The most importing I can take away from this is if something doesn’t feel right, get checked out. Life is too fragile and precious to let our pride and macho attitude get in the way. Building stuff is great therapy, for the dexterity and the mind. But none of that works well when you’re looking at the dirt side of the grass! Will have some build updates pretty soon!

-

To all who have given me good thoughts, I thank you. Yeah, this was a wake up call. The docs seem to have a good plan going forward. The aim is to try to keep the little ones from becoming a big stroke. So, different meds, salt free diet, (yuck), other dietary changes, weight loss, and it should be good. I am giving it a good go at it as the alternative sucks! I find my right handed self having some dexterity issues with fine tasks, (left side lower cerebellum damage results in right side deficits), as well as the balance issues. I can get out to my deerstand, but trying to fabricate and assemble small parts is proving to be a bit of a challenge. But, this too shall get better! Just put some time in tonight taking all of the winch drums out of the upper to start making the cable guards for them. It was ............................ok. Will I be setting time records? Not of the fast variety! But, this hobby is not about completing a build at least for me. It is about the joy of being able to partake in the build. And that joy is still being fulfilled. More updates to come soon! Thank you ALL for the good thoughts.

-

Got out of hospital yesterday. Feeling okay but do have a deficit with right side fine motor function, strength and balance. But, can still function not much differently than before. Just have to watch my balance on stairs and uneven ground. No big deal there as I’ve had to do that anyways due to my back issues. So, new meds, and life’s adventure continues. Old age is not for the timid or faint of heart. Back to the modeling bench tonight…..after I get out of the woods!

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Jamie Rahmoeller…..MOLUMINUM

redneckrigger replied to redneckrigger's topic in General Automotive Talk (Trucks and Cars)

You can find updates at Jamie’s Journey on Facebook -

Have been looking for an original ‘63 Pontiac Tempest hardtop for years. Saw a couple on eBay at astronomical prices well into three figures. Figured I’d never find one. Then was just perusing Facebook Marketplace about two weeks ago and there it was. Unbuilt, all original, parts still on trees, decals, original box, everything except one original tire that wasn’t there. Holy cow…..and for less than a new Round 2 kit is going for. It has a new home now! Wow!

- 39,197 replies

-

- 5

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Good question…….. not quite sure what’s gonna transpire right now. Have been having headaches so doc sent me for CT scan which didn’t show anything for headaches but showed I had previously had two small strokes that I had no idea had happened. Then I had another one yesterday out hunting and my hunting buddy witnessed it. So I am still in the people repair shop getting diagnostics run on the old man brain. Hoping for no long term deficit and that they can prevent the little ones from becoming big ones. Hoping to be able to get back to the crane and building in general but that is a point in question right now! Sure would like to come out there!

-

Thanks. Don't know how she put up with me for over 50 years. She has a bucket list as most do. One of the things was to see a Broadway musical, so we checked that off her list, twice! Had no idea that I would also enjoy it so much either! I f I knew how great it would be, it would have been on my list as well!

-

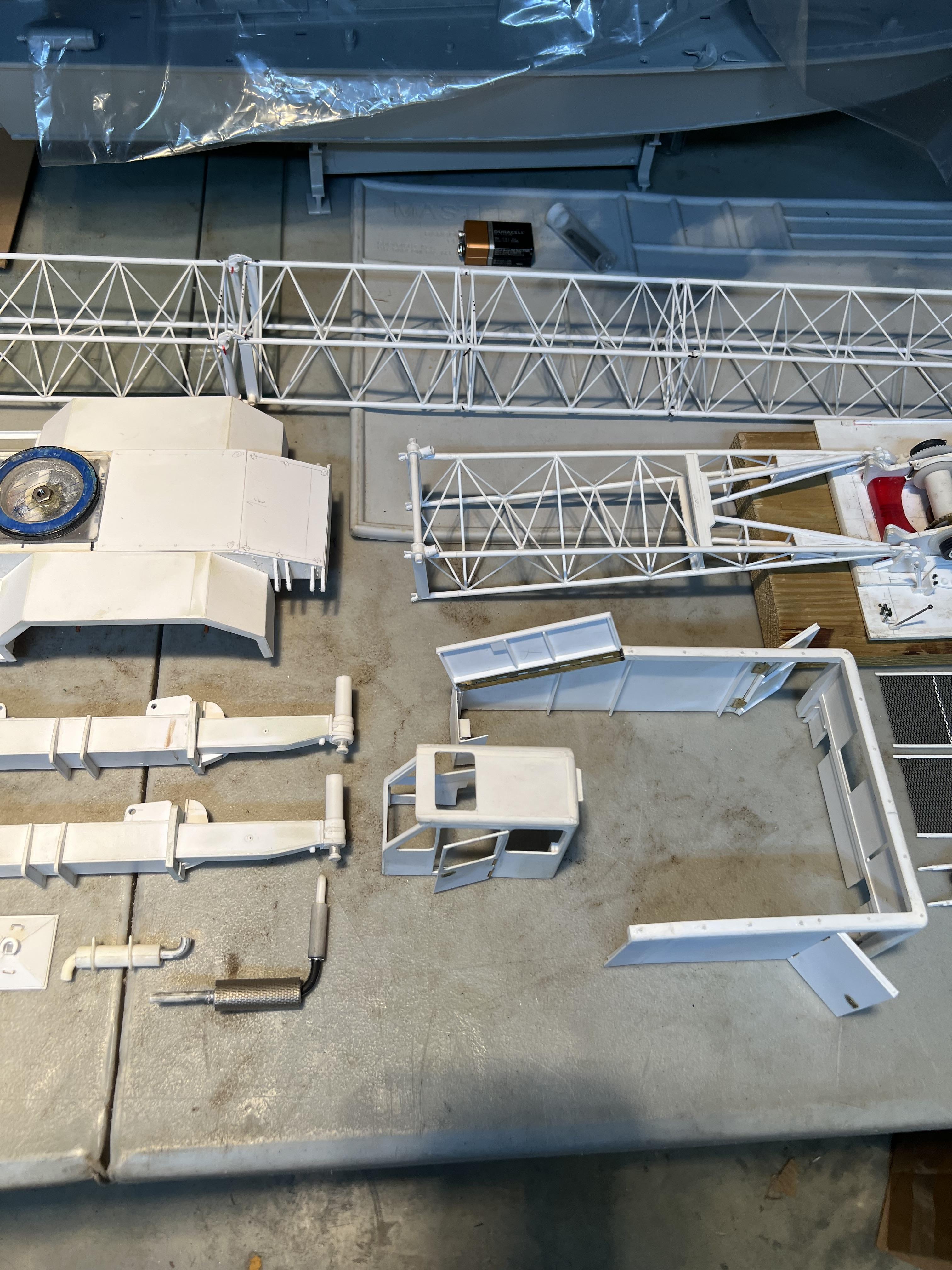

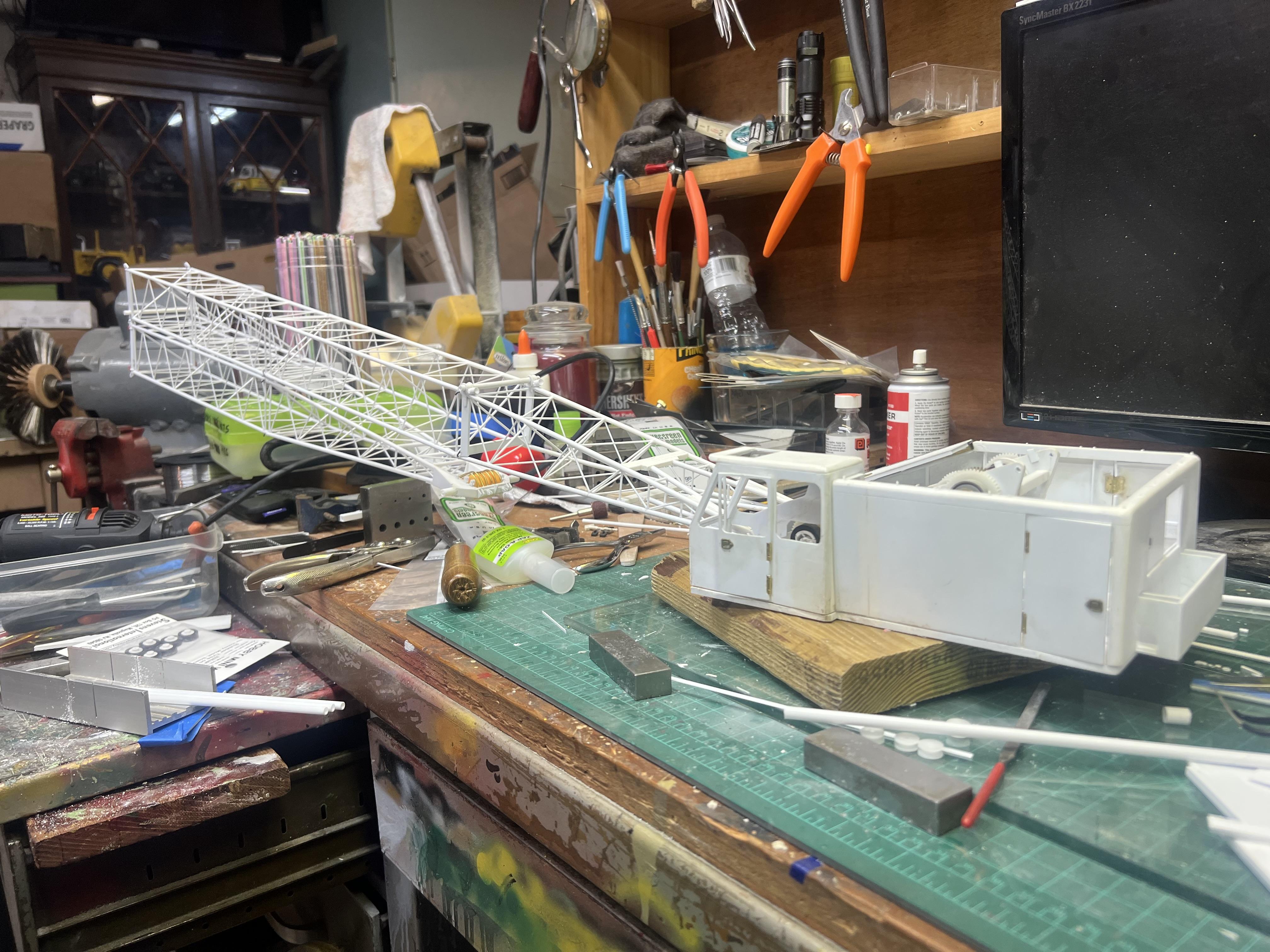

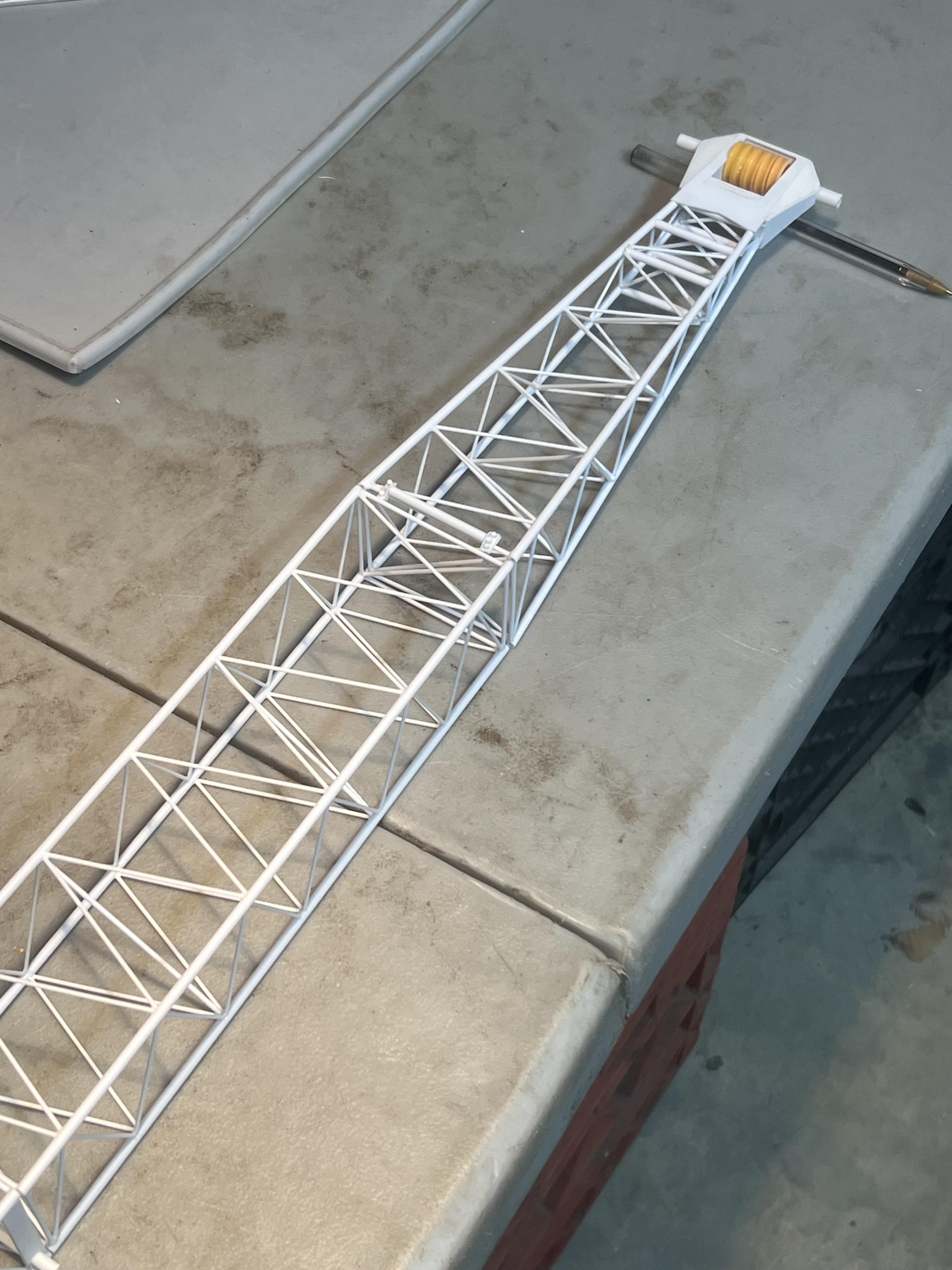

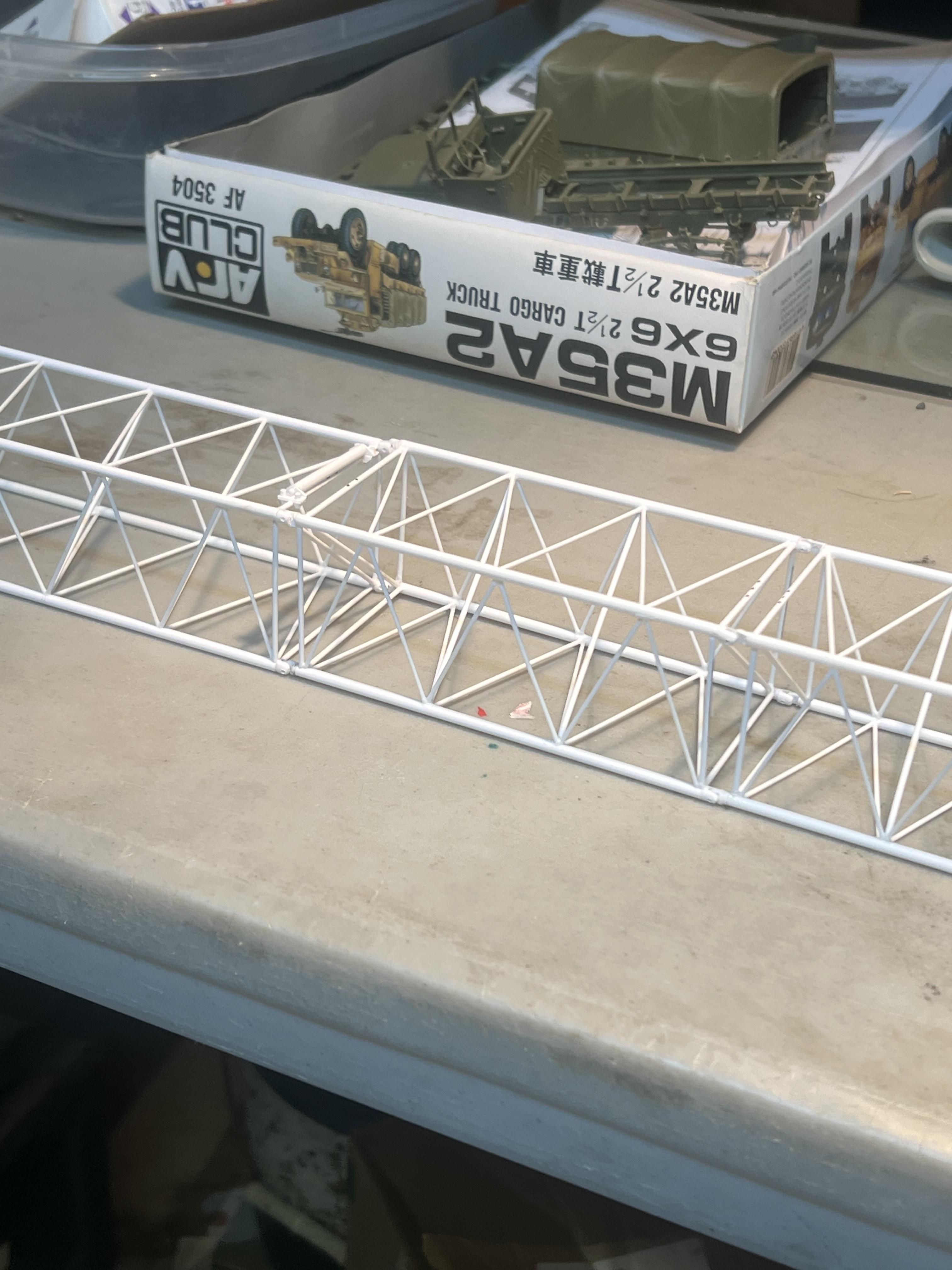

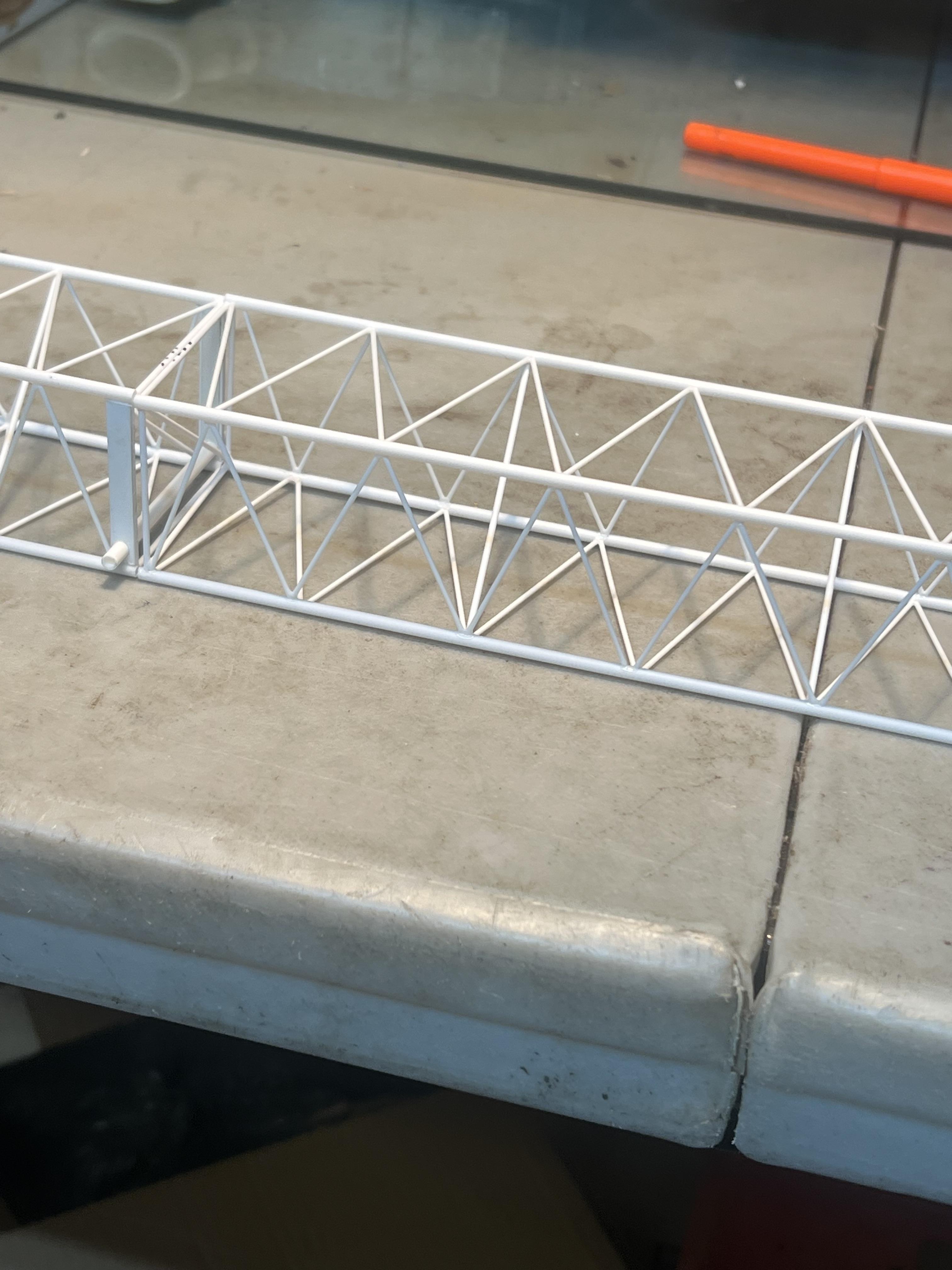

Thanks for the great words. The boom is all styrene, so is ultra light, but still incredibly rigid. It is for static display only so it won't be posed with any loads on it. So, with the light boom, and static display only, no real heavy counterweights will be needed. The entire boom assembly weighs less than 3 ounces! Nevertheless, the counterweights will be made from Ren Shape material, which is heavy enough that the upper counterweight alone will most likely weigh more than the entire boom. Ren Shape is an awesome material that can be cut or milled to about anything, that was recommended to me from Charlie Rowley, probably the best modeler I have ever known. So, there is still lots more to do!

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Western Star 4900 FA plow truck

redneckrigger replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

The details are amazing. You have a real knack for it. I think the window rubbers came out great. On my crane, I’m going to have to make the actual rubbers and make them overlap the window opening. I then paint them black and assemble to the cab with the glass going in behind it. Kind of a pita but it works. I like your work better! Looking at your build, if photographed with a realistic background it would be about impossible to tell if it were real or a scale model. Cant ask for much more than that!! -

Well, if it hadn’t folded as planned, it very well may have been quite ugly! Actually, I do not intend to have it folded but want to show it raised and extended, but I just had to try it at least once! But, all kidding aside, as with all huge projects, planning is important. I really think I have spent almost as much time researching and planning as building! And I think I enjoy the research/planning as much as the building.

-

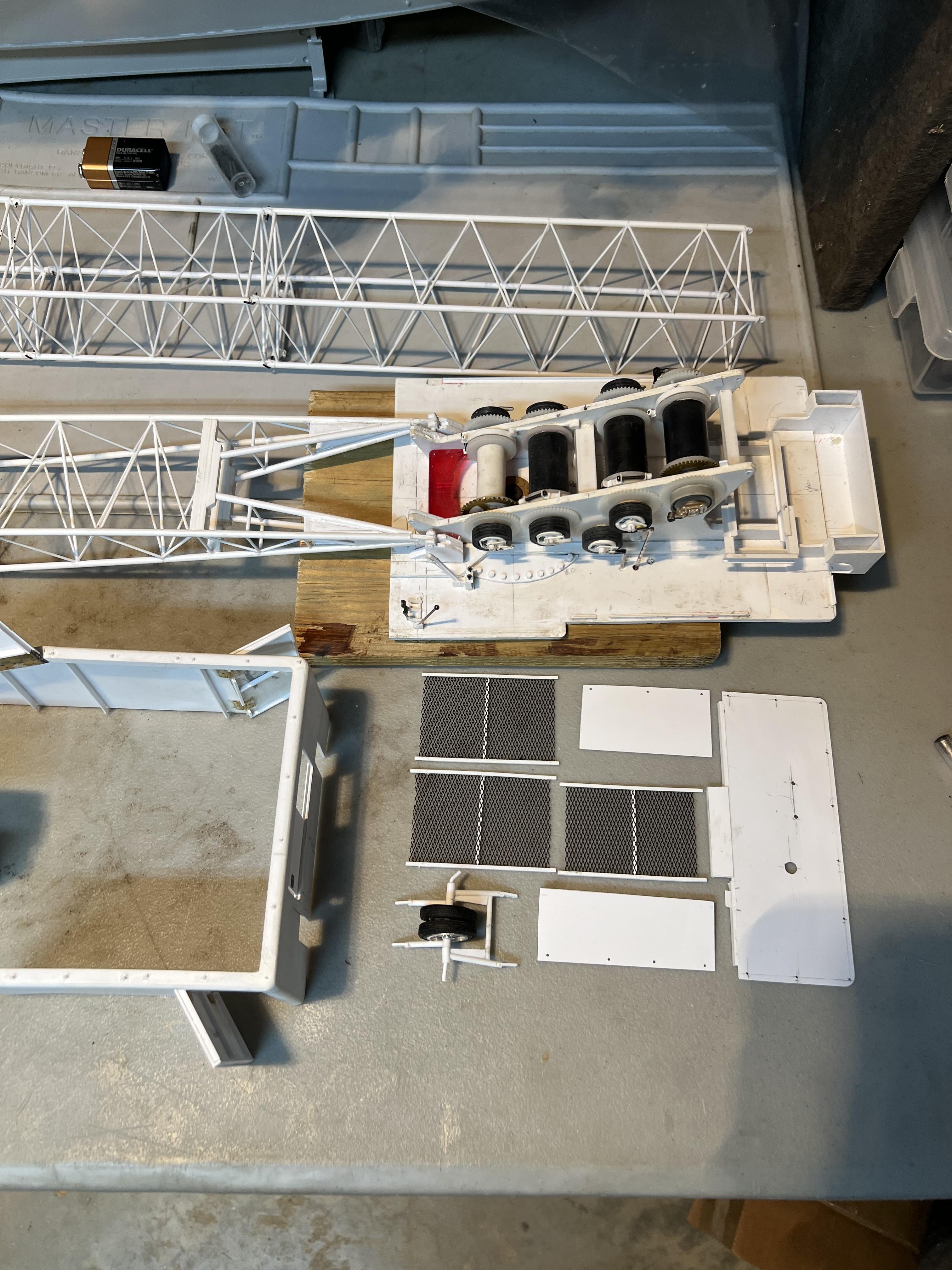

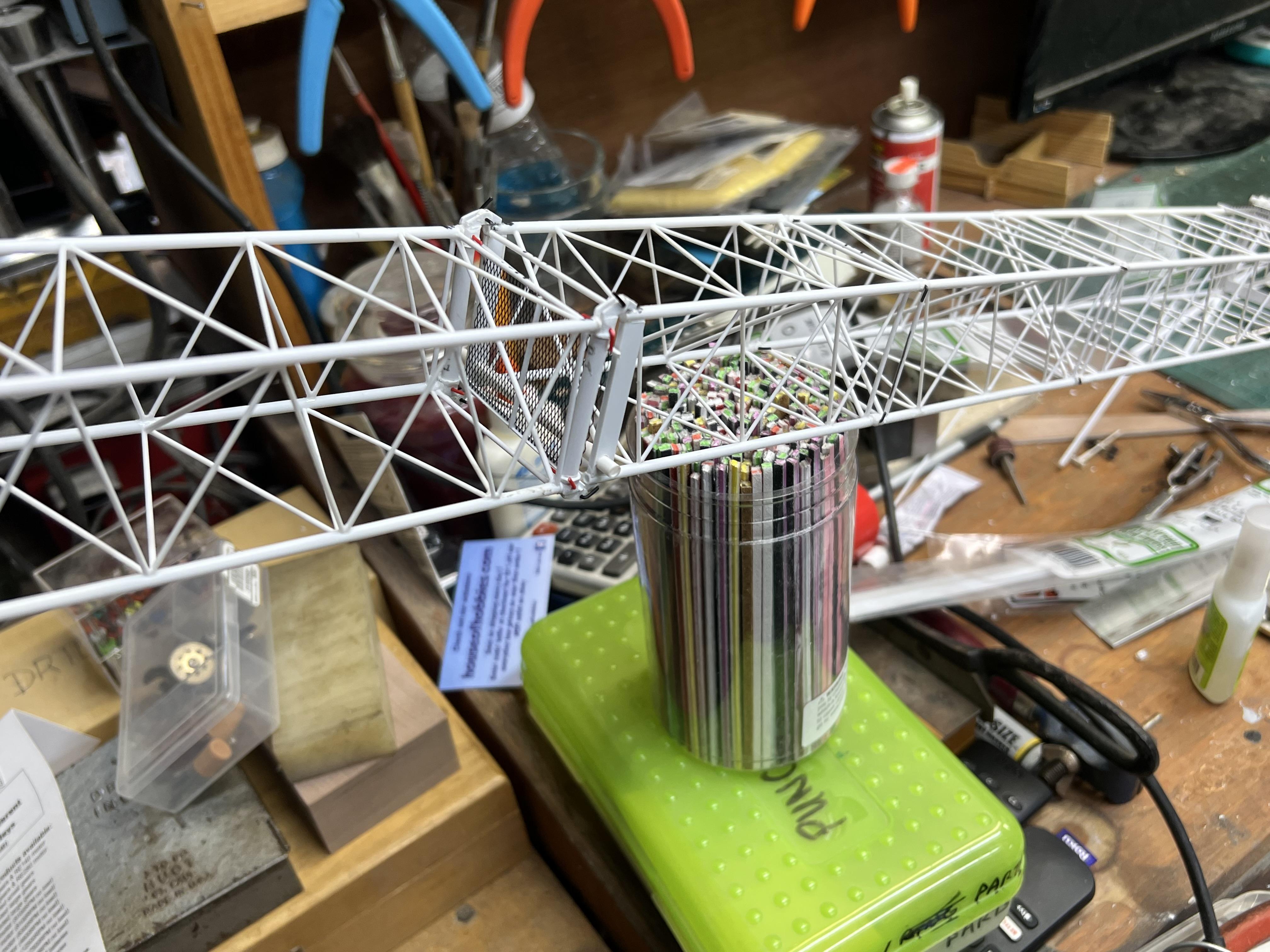

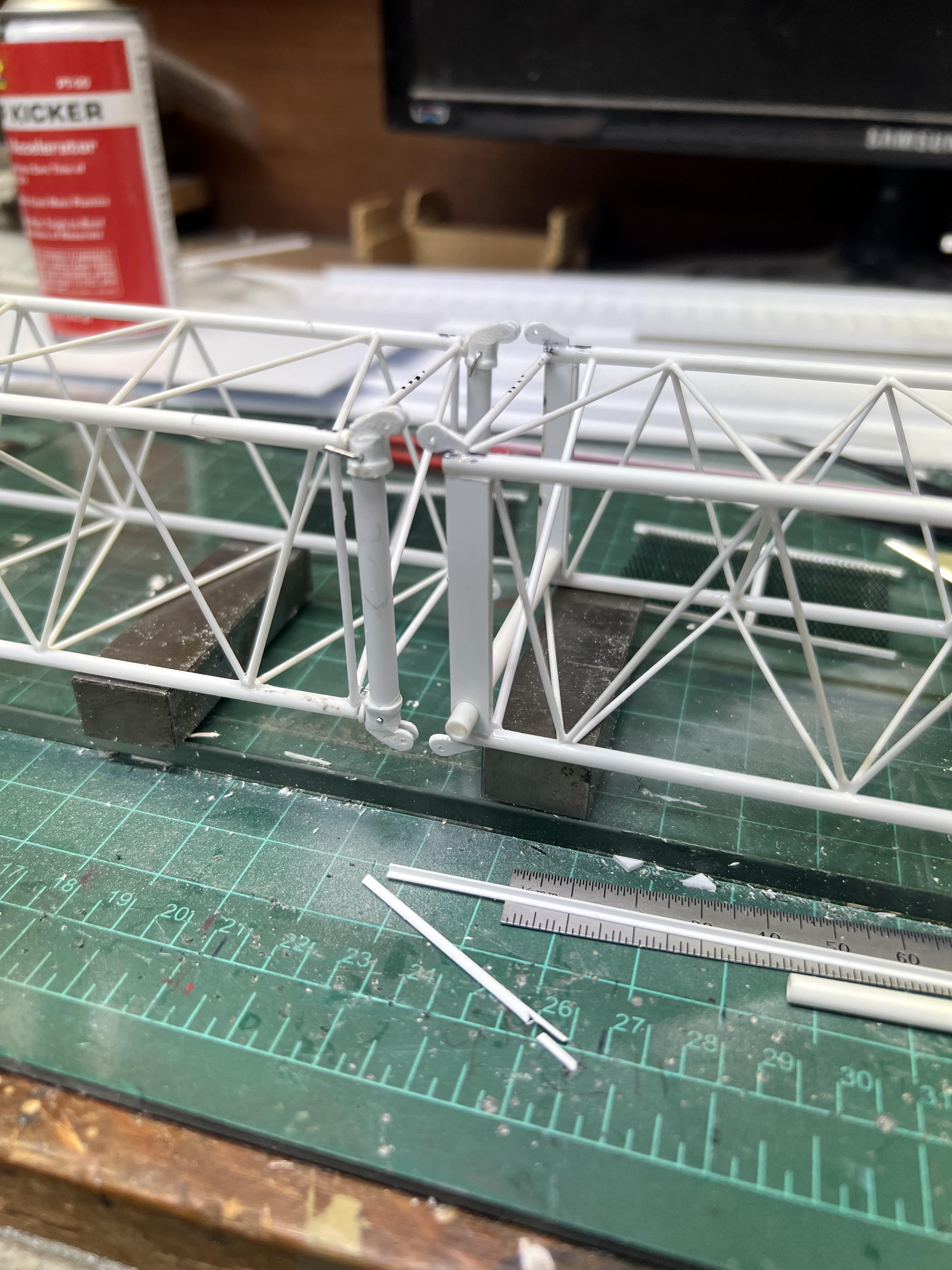

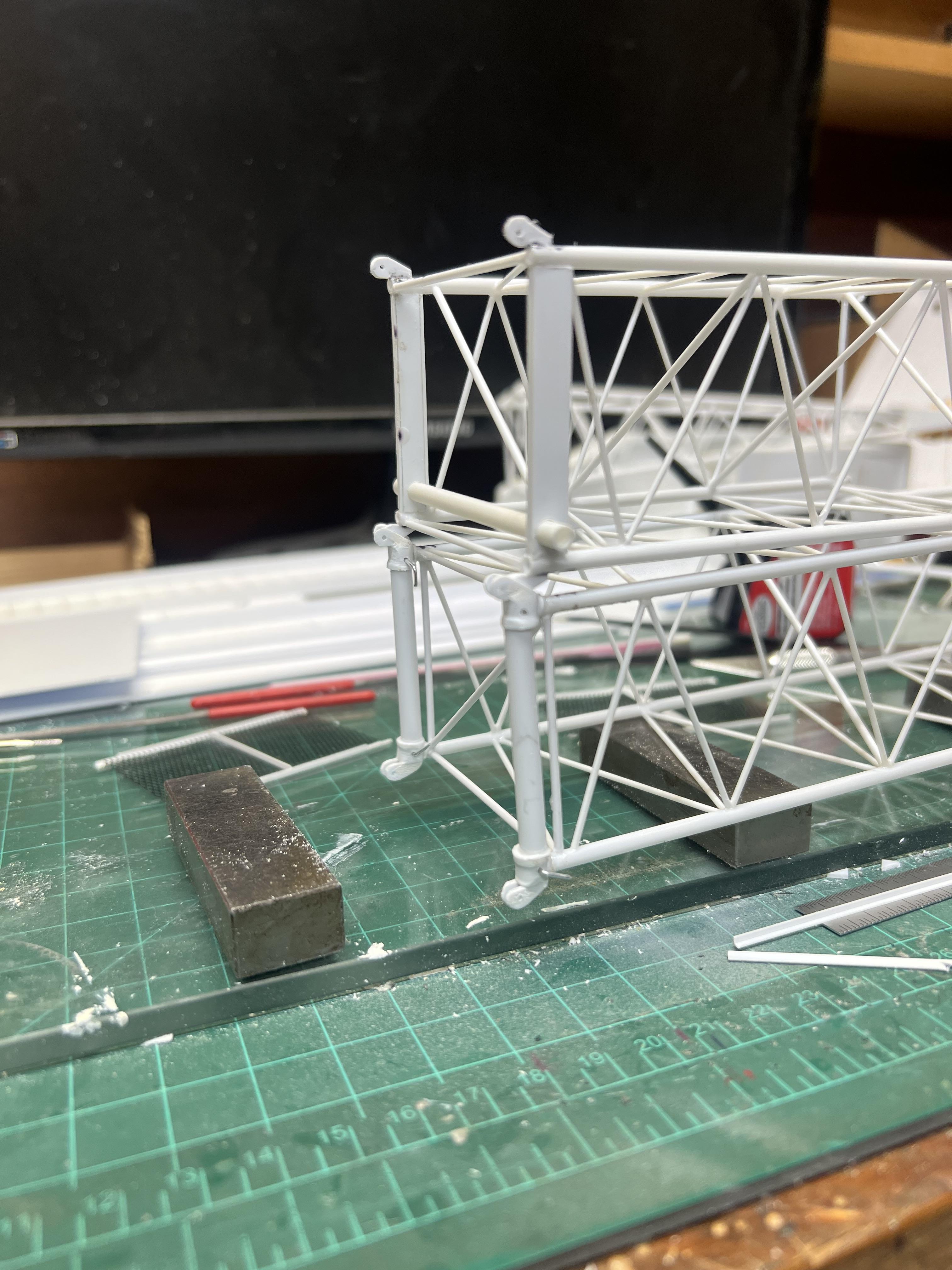

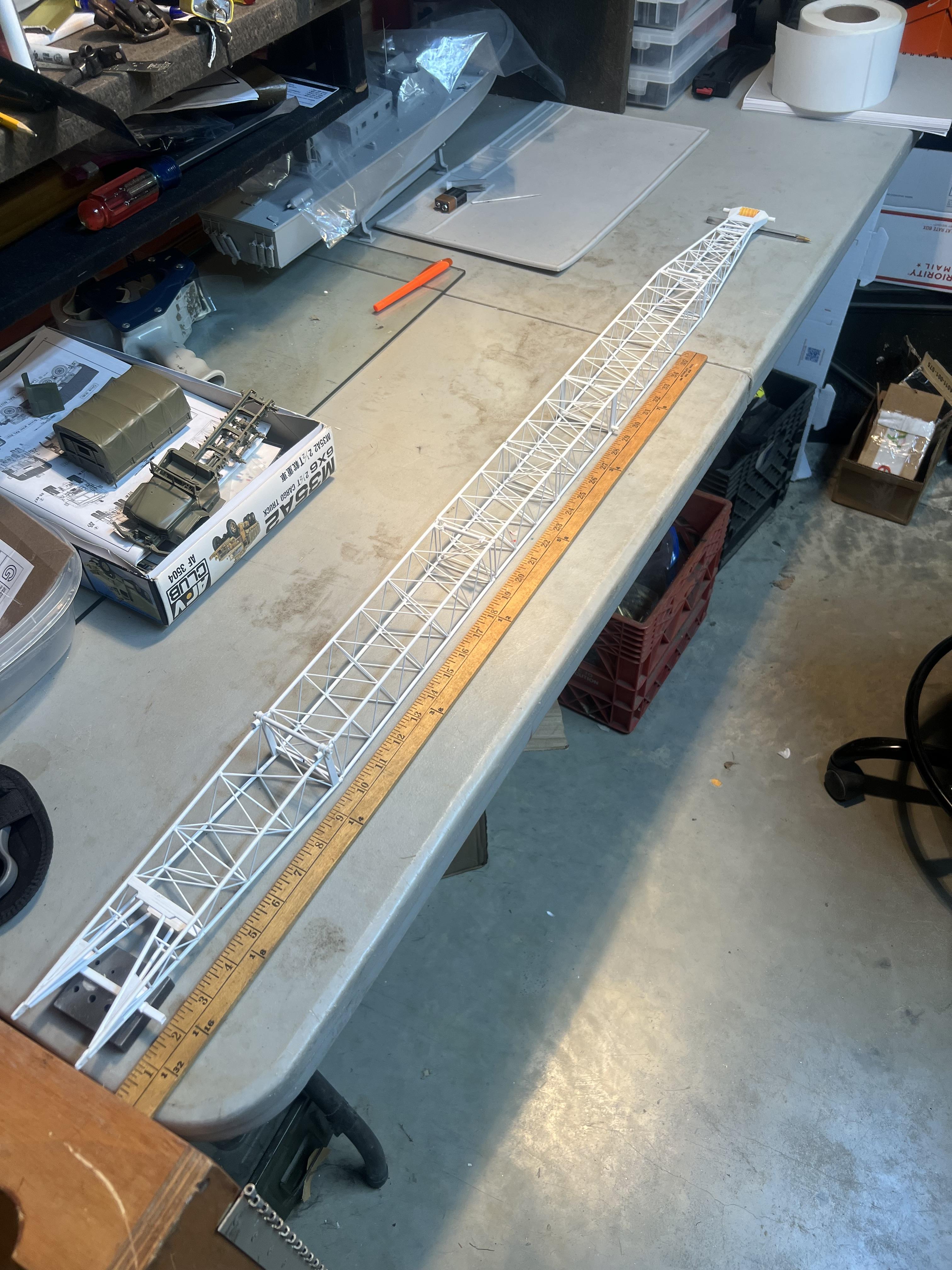

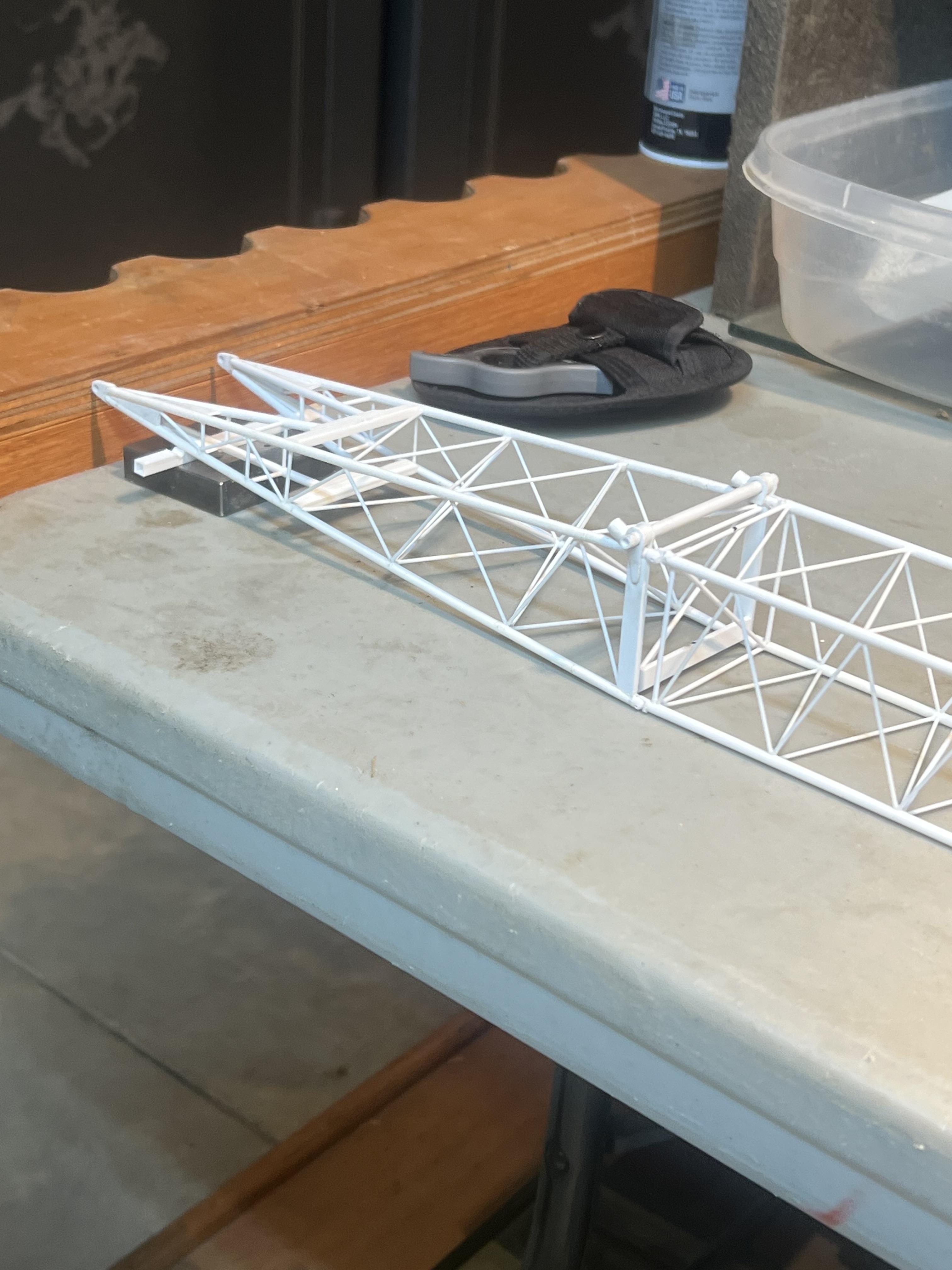

Well, reached a milestone in this project today. I got the boom folding points all done and installed and for the first time, got the entire 100’ of boom all assembled and pinned together. And then, of course, I had to try the hinge. And it folded perfectly. Shown is the boom attached to the upper assembly, which I have mounted on a work board instead of the carrier. And then it finally hit me, where the heck am I going to put this monster when it is done?a. Sure am happy I decided to only build 100’ of boom! I still have to make all of the pendant attachment points, the bridle, the live mast, the boom backstop, the bail, the counterweights and their removal system, and an endless list of little stuff! But this is a huge point in this build. Thanks to everyone’s words of encouragement! I hope to display it with the boom raised, and for transport I am thinking of quick attaching cables etc, so that the boom can be in one 4’ piece. Time will tell……LOTS of bridges to cross before that!

-

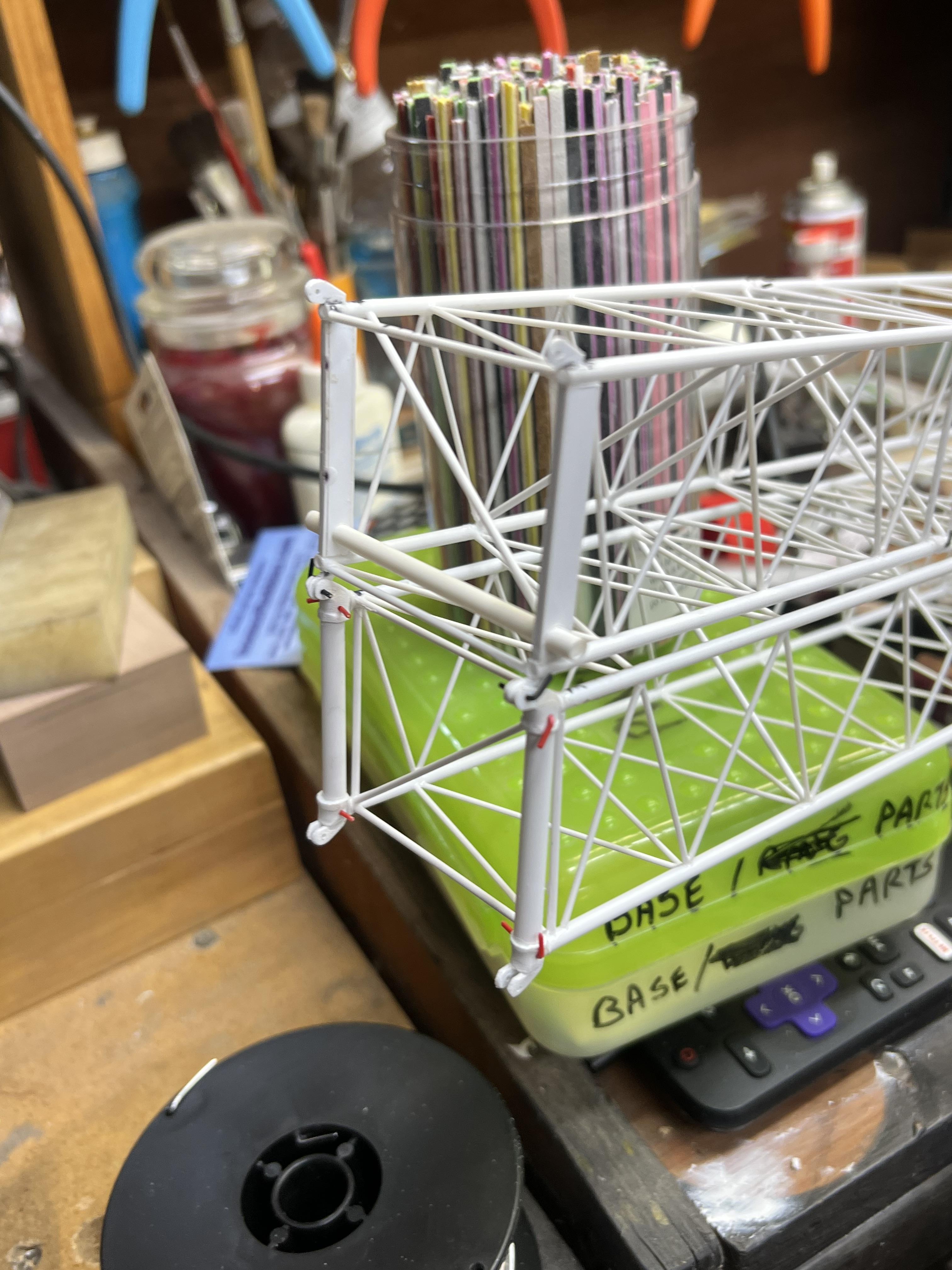

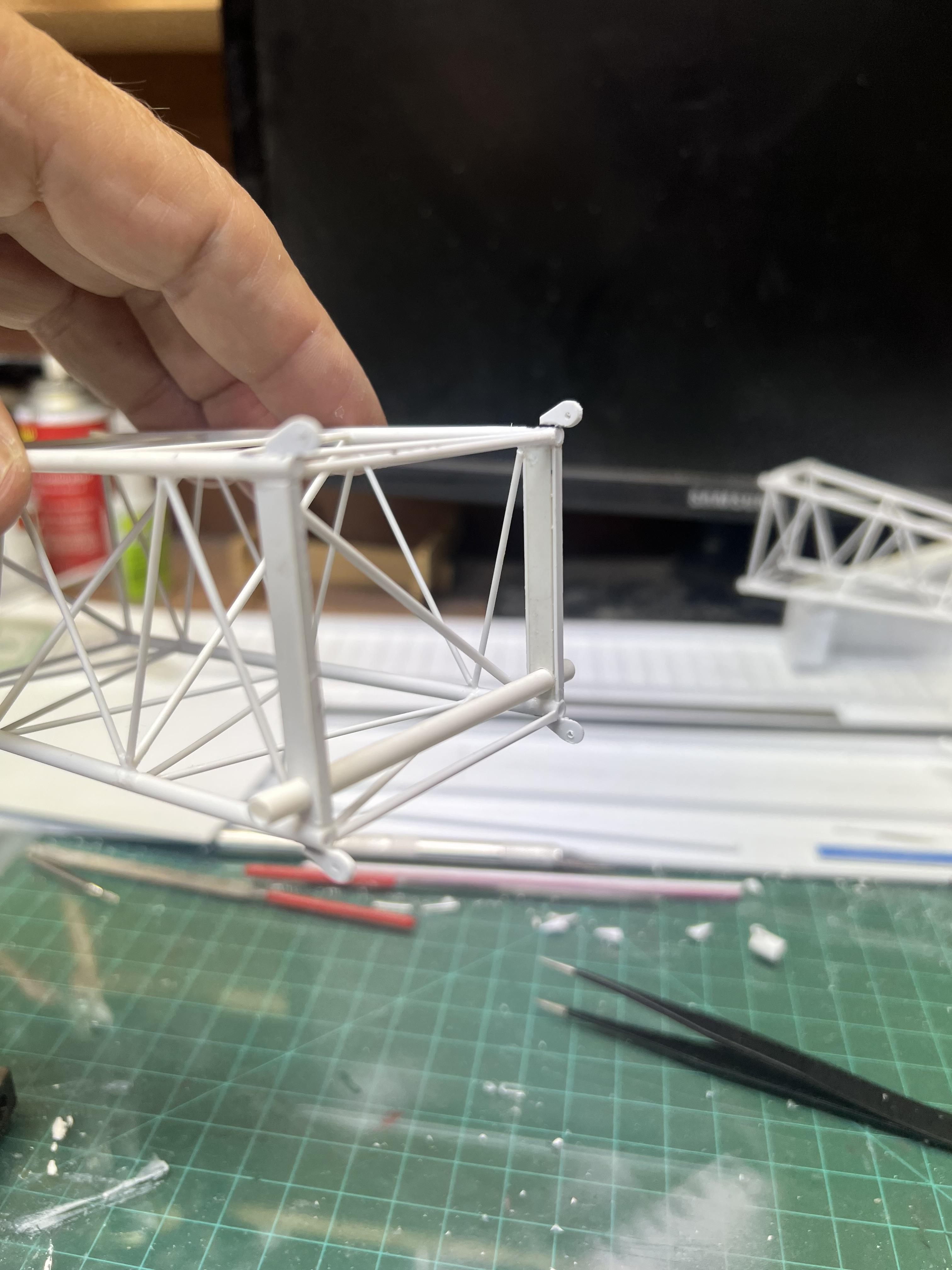

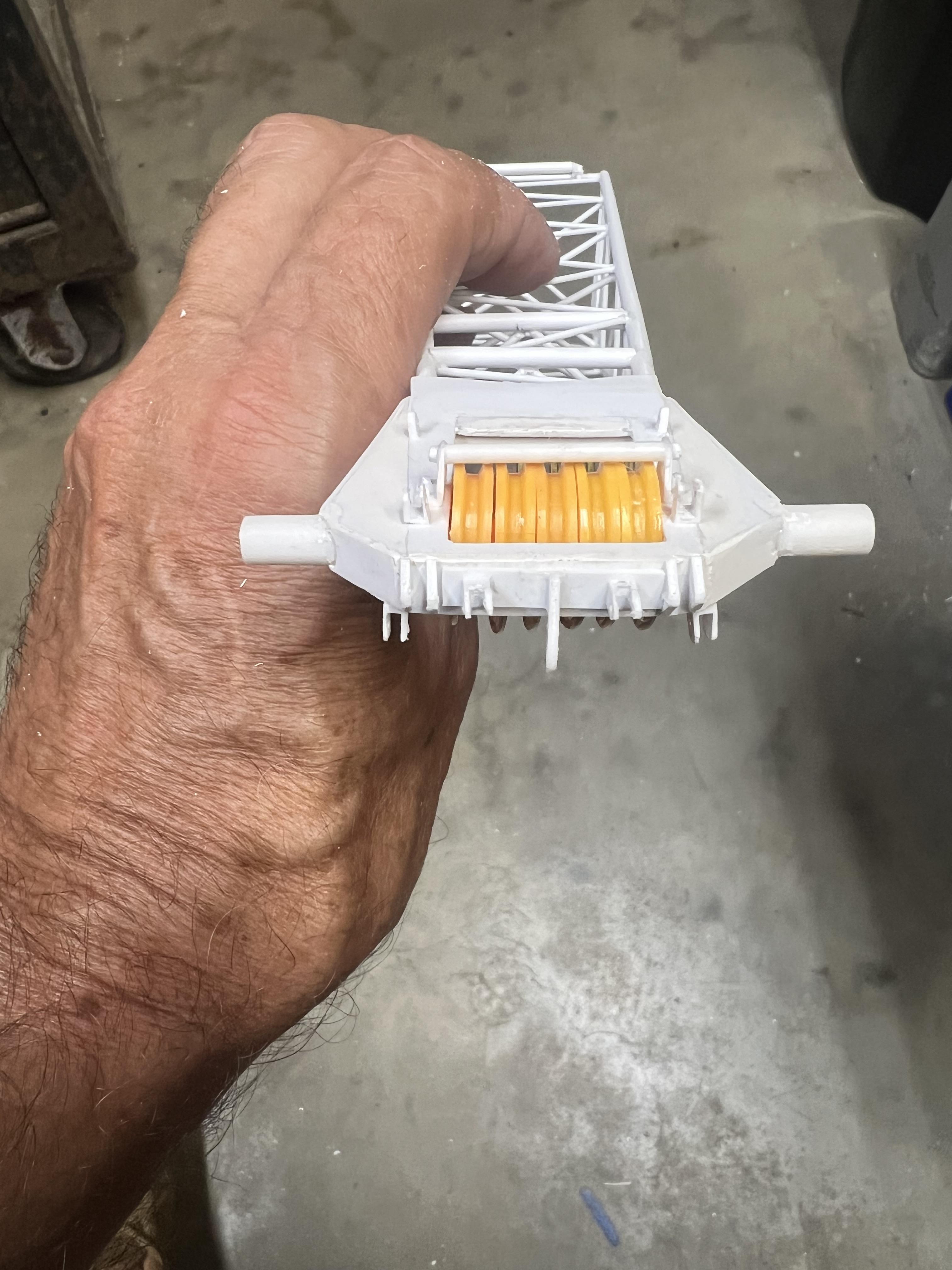

Just finished up the folding boom joint assemblies, the offset joint pieces on the 20’ section are removable so they can be put on any section. Added the offset male parts of the joint to the short folder section. Just gotta wait for all the glue to dry and will pin it all together and see how it looks and works. This is totally a static model, and the boom will be assembled and not folded, but what’s the fun in designing all the working parts into it if you can’t prove they work?!

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Western Star 4900 FA plow truck

redneckrigger replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Your build photos literally look you were taking them at the REAL factory that truck was built at. Absolutely stunning work. You have the finishes even looking in scale, incredibly done! -

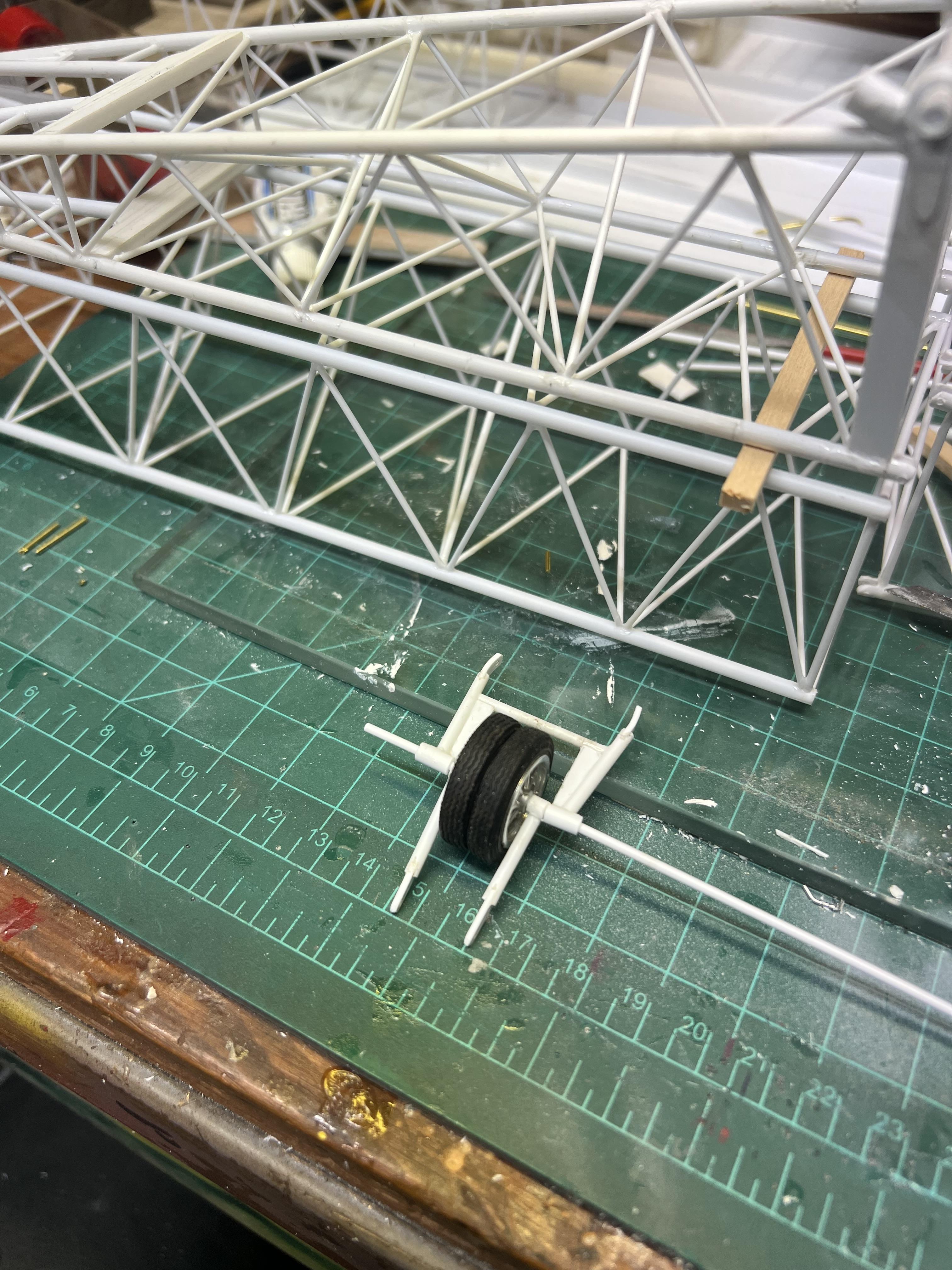

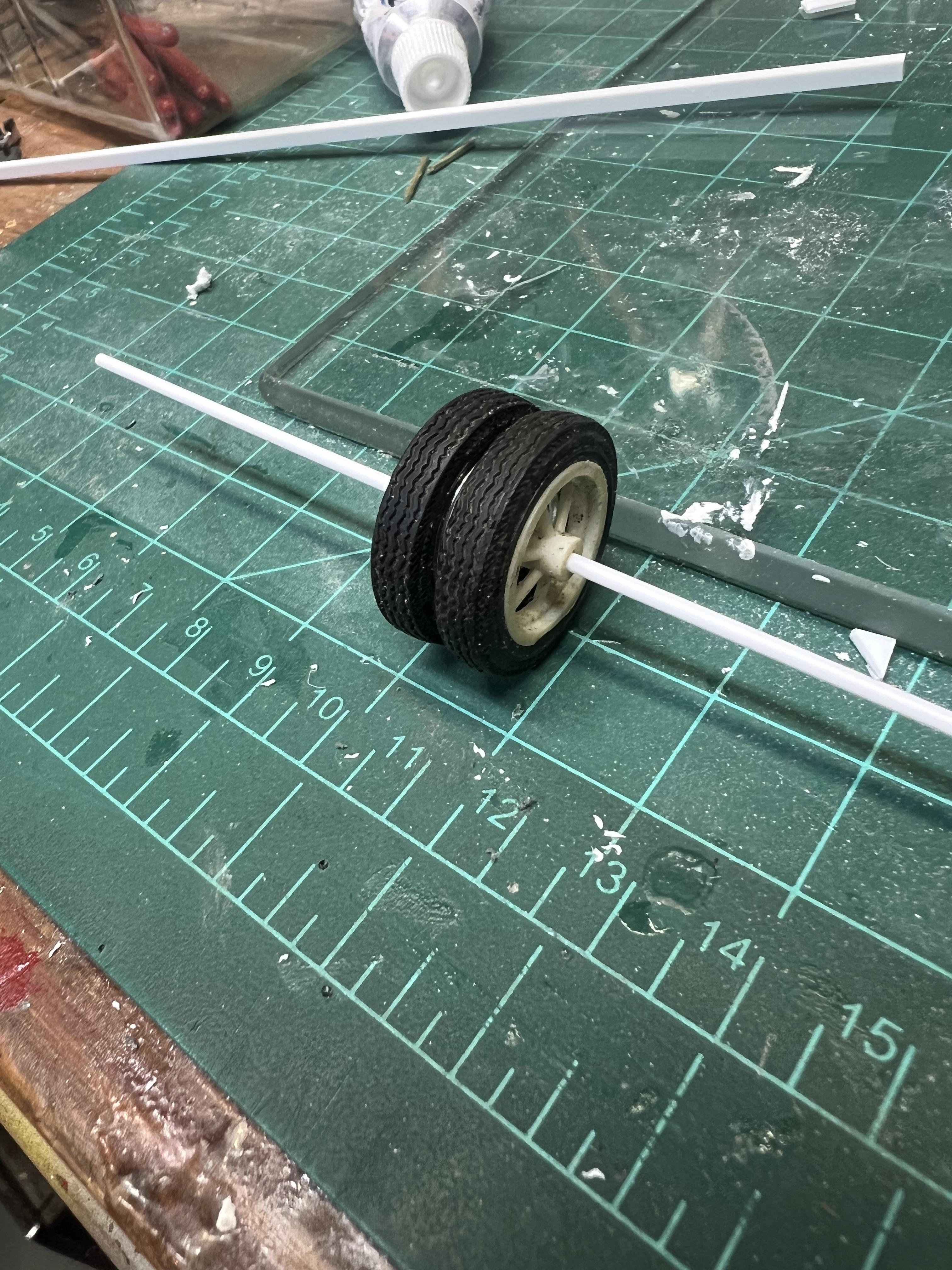

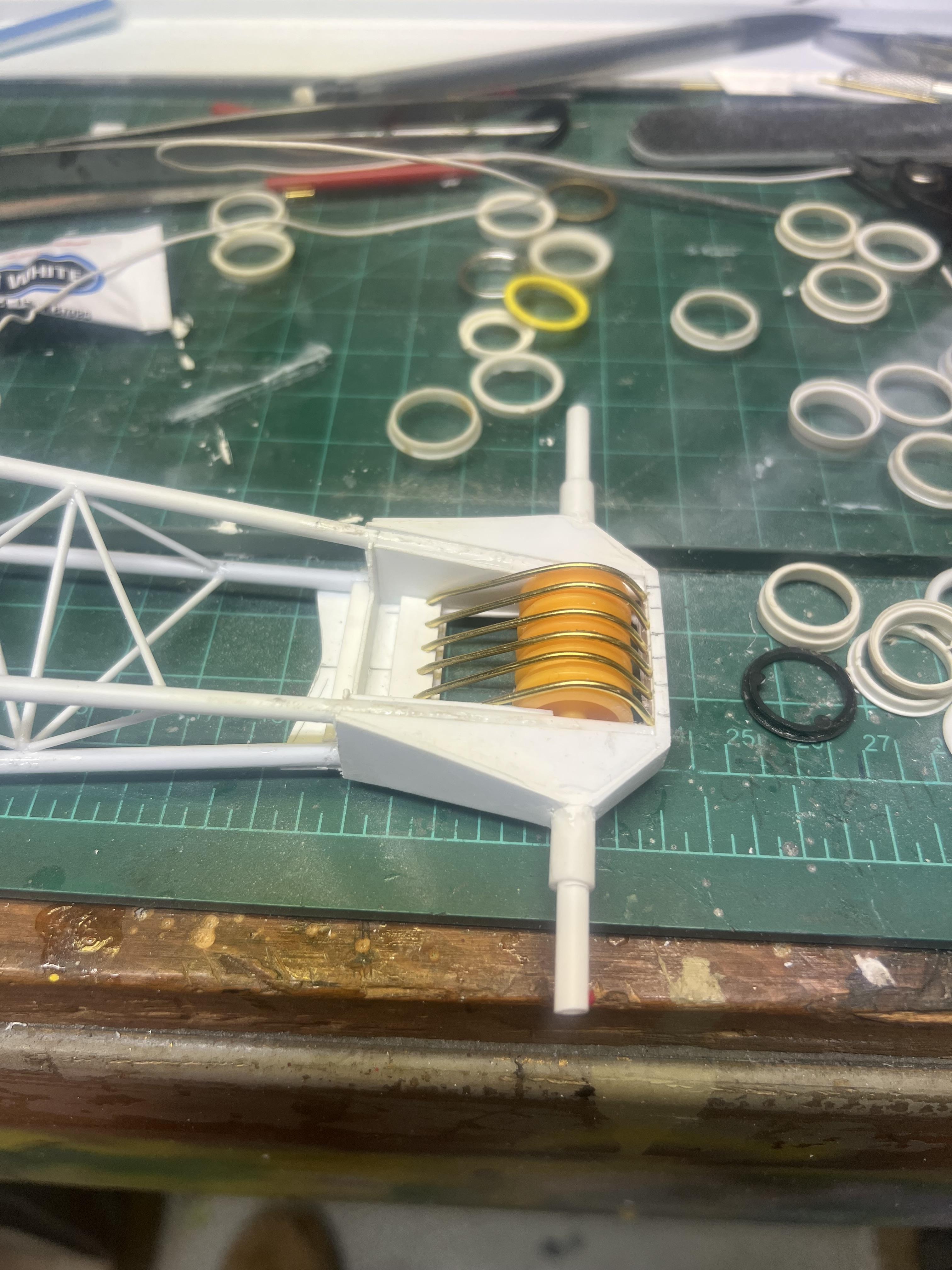

This is the boom folding tire assembly in place. It attaches to the very end as shown and when the boom is folded to where the folding end is vertical, the boom is lifted and the two wider attachment points are detached, rotated around the axle and reattached to the other side of the head gear, boom is then lowered and folding continues until it is folded, then a link is attached from the center point in the end to the main boom. The axle will be trimmed and finished after painting. I don’t intend to have this on the finished crane as the boom will be in working position, but it will be stowed on the carrier. Also shown is the actual crane I am trying to replicate, with the boom folded. This was taken last fall on a local job. It has 100’ of boom in place in this photo, as I am building this one to match. It is capable of 210’ of main boom and a 30’ jib totaling 240’.

-

Here is the complete boom, not yet pinned together but to give an idea of size. Finished all the lattice work on the boom head. Still many many more bits and pieces to add to just the boom sections, but it is definitely looking the part! Going to add the jib mounts and the boom folding tires next. Lost a day yesterday, went out into the woods bright and early to prepare for upcoming deer season. Walked smack dab into a tree branch and badly scratched my left eye, my good one of course. Thought I was gonna have to pick the eyeball up off the ground! Got to the eye doctor and spent from 10 AM yesterday until 8 this morning with both eyes shut and lying on my back. But, still better than working! Much better now!

-

Actually, all of the boom sections were stored right on 40’ flats and brought to the job site as needed. The butt section seldom gets removed and can be carried behind or out over the front on the rests over the grille. Sometimes it will be driven to the site with 60-80 feet of boom folded up behind it. Any boom 60- 180’ in length can be folded for carrying behind the crane. Wow! Makes a long load too, even when folded. And if necessary it can have the crane operator in the upper cab to slightly swing the boom for clearance while the carrier is being driven similar to a tiller fire truck. Simply very cool and interesting machines.