-

Posts

1,525 -

Joined

-

Last visited

About redneckrigger

- Currently Viewing Topic: Link-Belt HC-218 Truck Crane

- Birthday 09/18/1954

Previous Fields

-

Are You Human?

yes

-

Scale I Build

1/25, 1/35

Profile Information

-

Full Name

Tom Decker

Contact Methods

-

Facebook

Tom Decker

Recent Profile Visitors

8,183 profile views

redneckrigger's Achievements

MCM Ohana (6/6)

-

redneckrigger started following Do You Keep Pictures For Future Builds? , 1970 Winnebago D27 Chieftain , 1970 Ford C 600 and 1 other

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

1970 Ford C 600

redneckrigger replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That is a fantastic build, Jeff! Used to see those trucks all over the place, and still see one once in a while when our small town does an oil and stone job on some of our back roads. That 3D work is INCREDIBLE! I wish I was younger and I would try my hand at it, but it would be an all consuming project for me at my age and with my limited technical ability! But it sure would have sped up my crane build that is at more than five years, with no end in sight1 Only a few resin cast pieces from AITM and Moluminum on it and the rest is 100% scratch styrene etc. But, I am envious of those with the superpowers of 3D! Keep the updates coming! -

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Jamie Rahmoeller…..MOLUMINUM

redneckrigger replied to redneckrigger's topic in General Automotive Talk (Trucks and Cars)

Anyone who has used Jamie’s parts from his Moluminum site knows these parts are beyond compare. And you also know he is a gentleman. I just talked to him, he is recovering from bilateral below knee leg amputations. His hands will be next, one at a time as soon as he is mobile on his new legs. There is no time frame yet, but they will be taken. This is a craftsman who was a hot rod and street car builder, master craftsman, model builder and an incredible resin caster. If anyone can see fit to help him out, please go to the Facebook page referenced to make donations. I know everything will be highly appreciated. Thank you. -

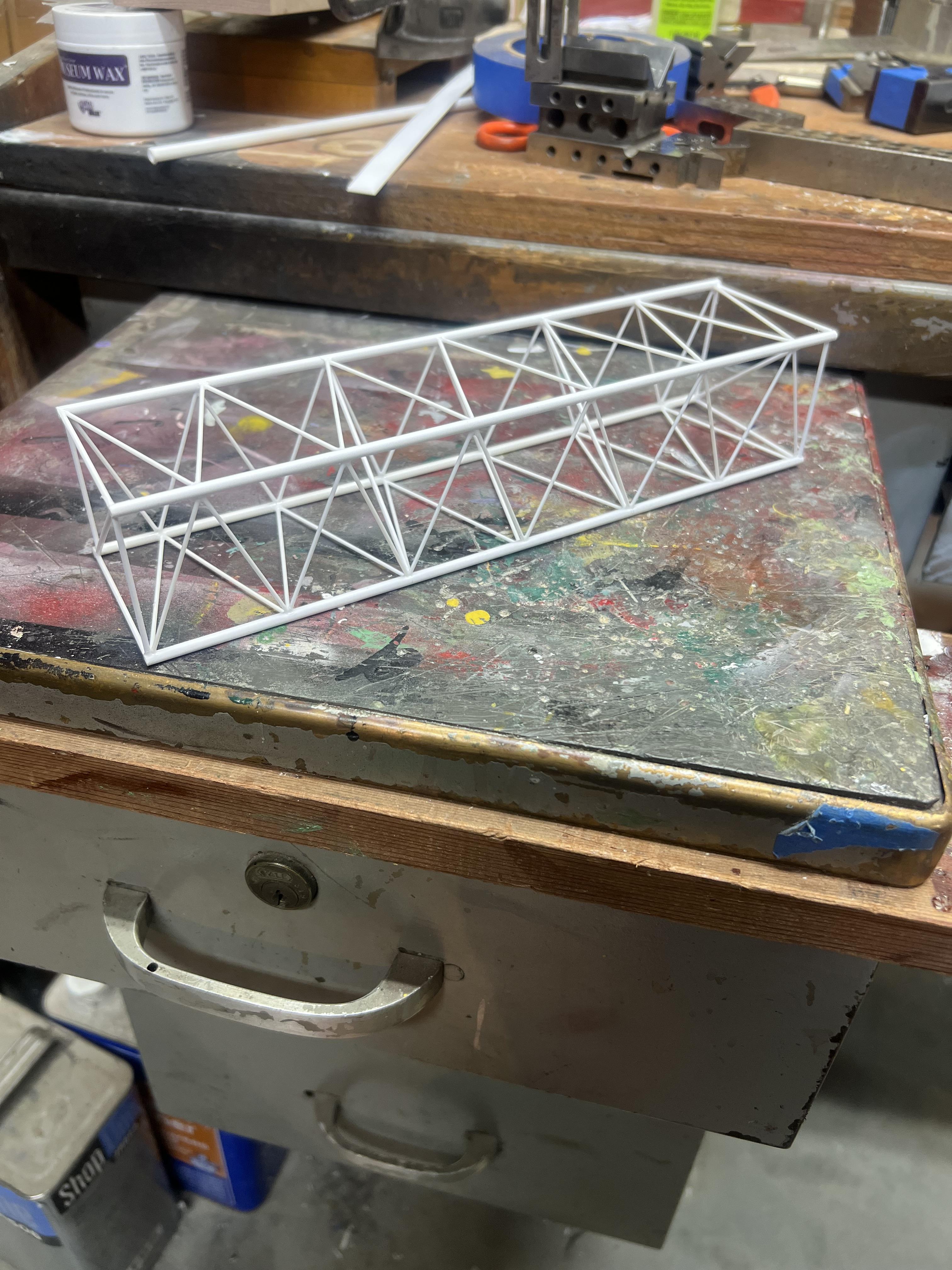

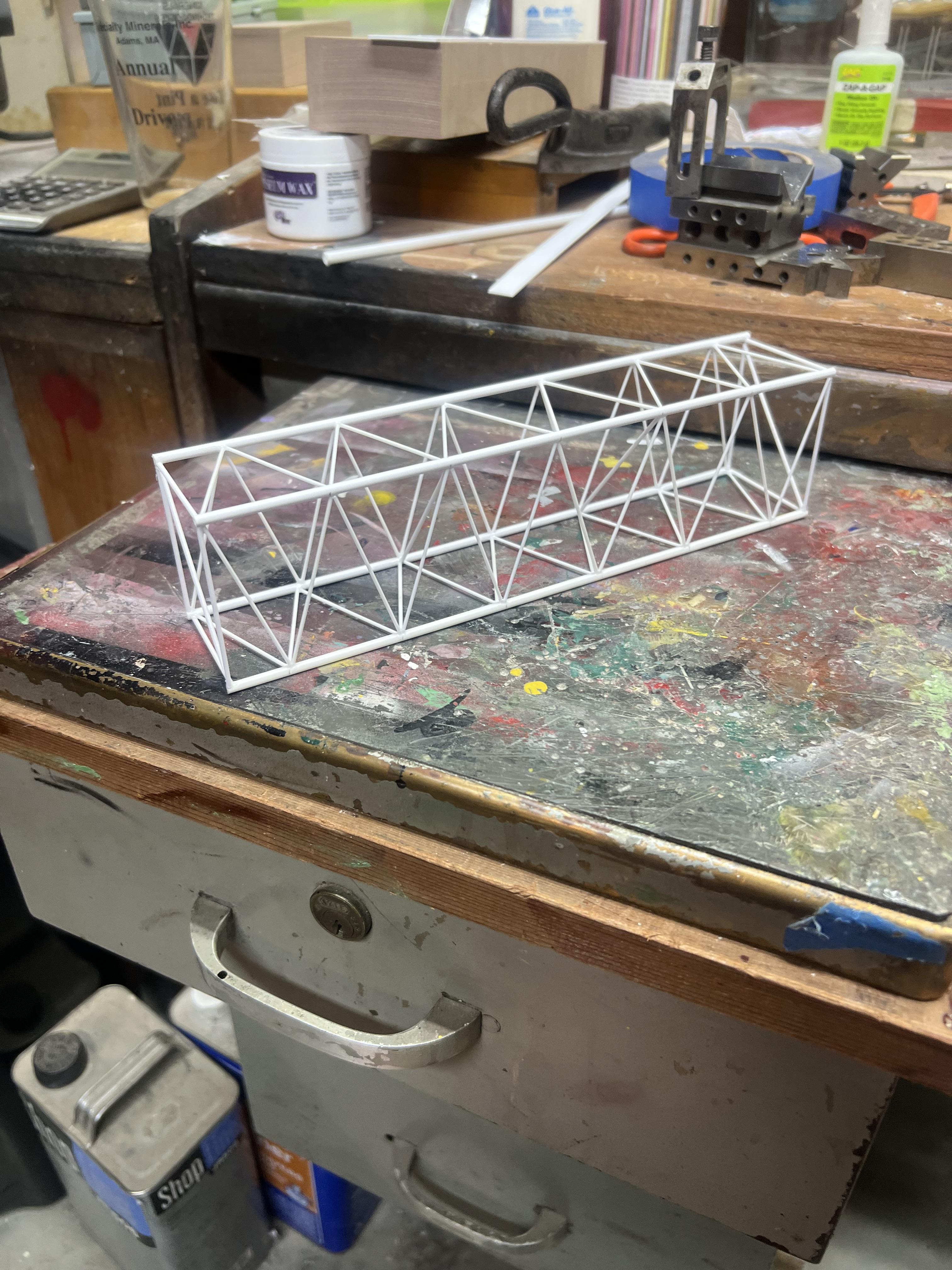

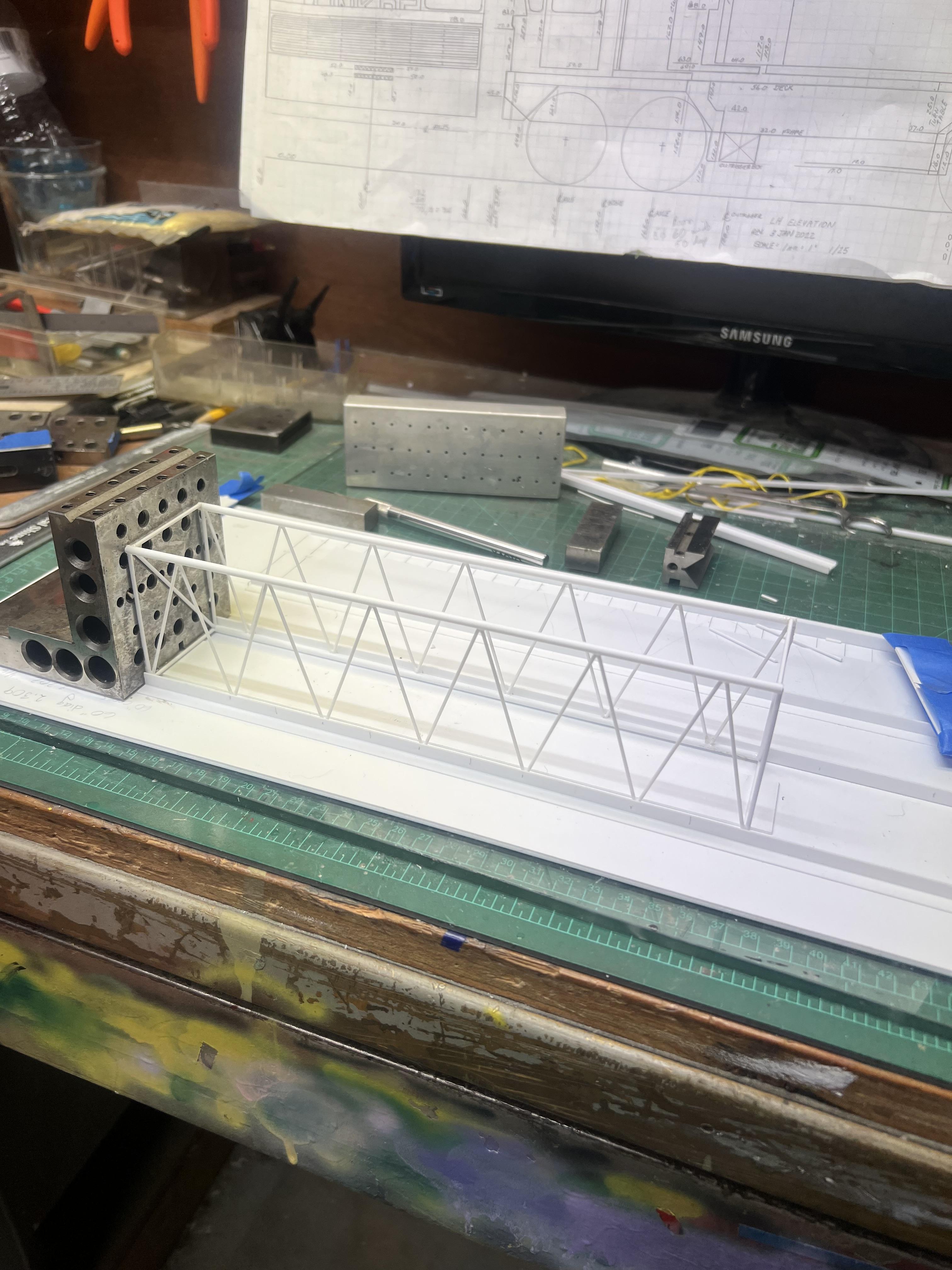

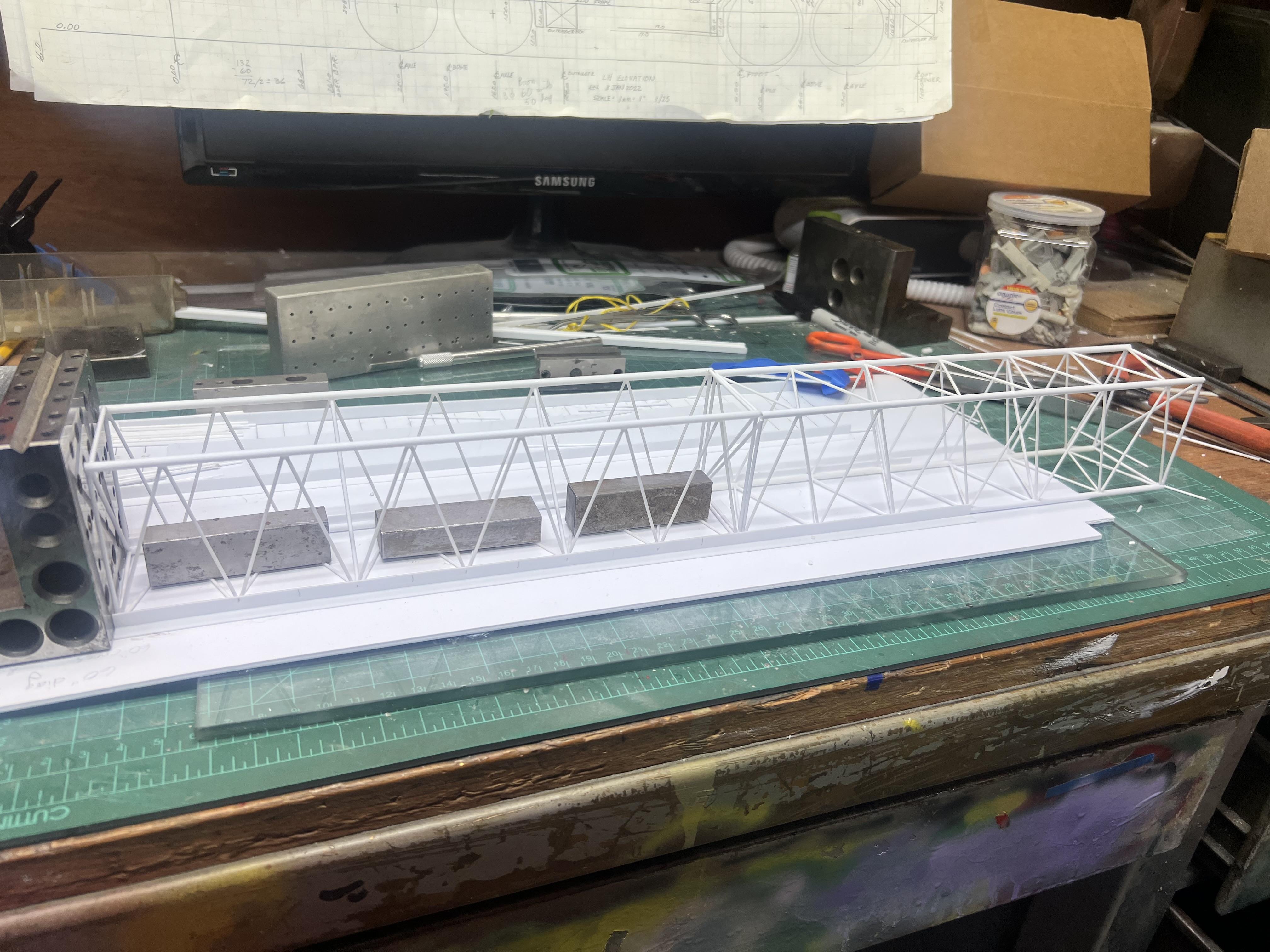

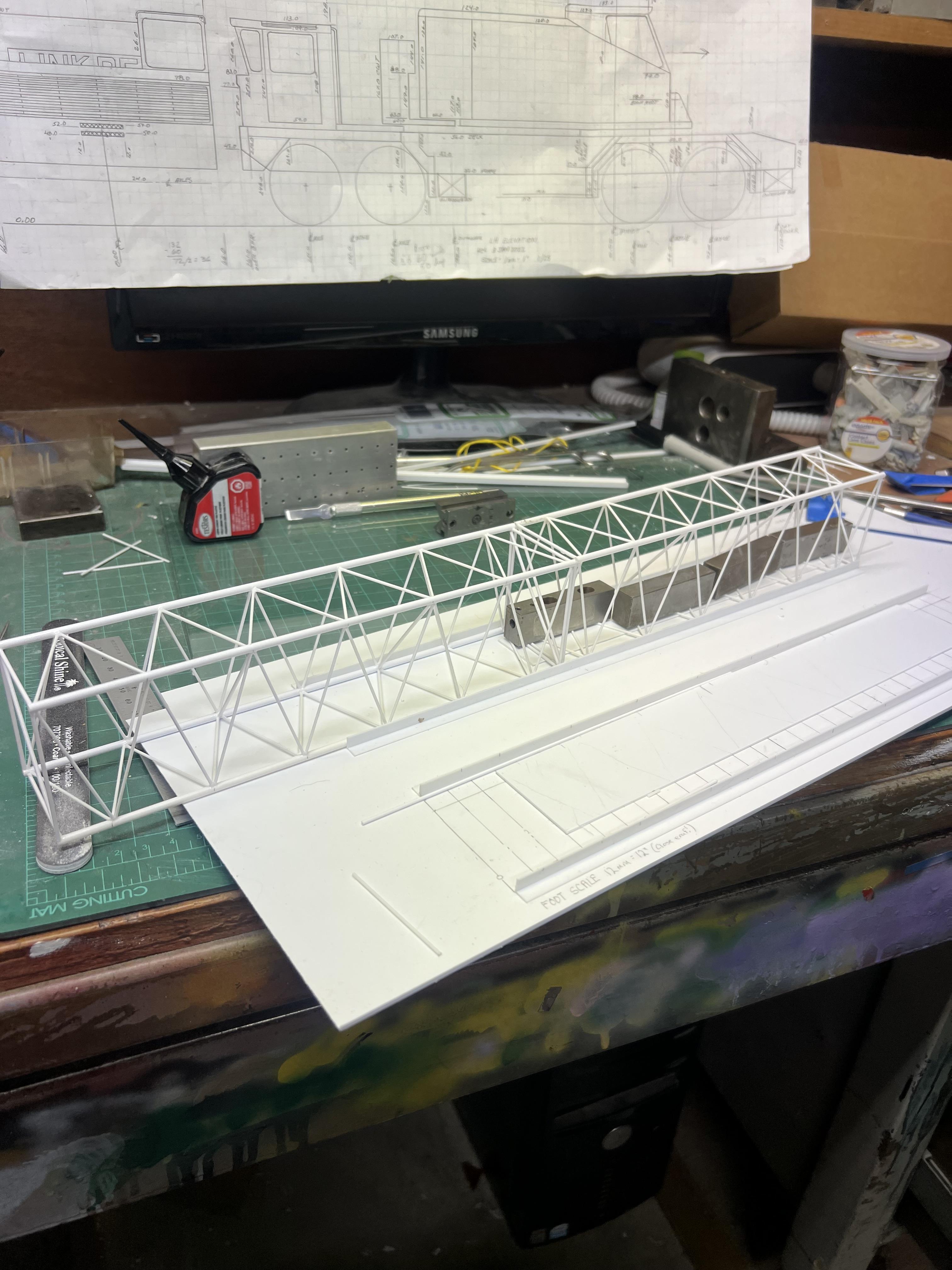

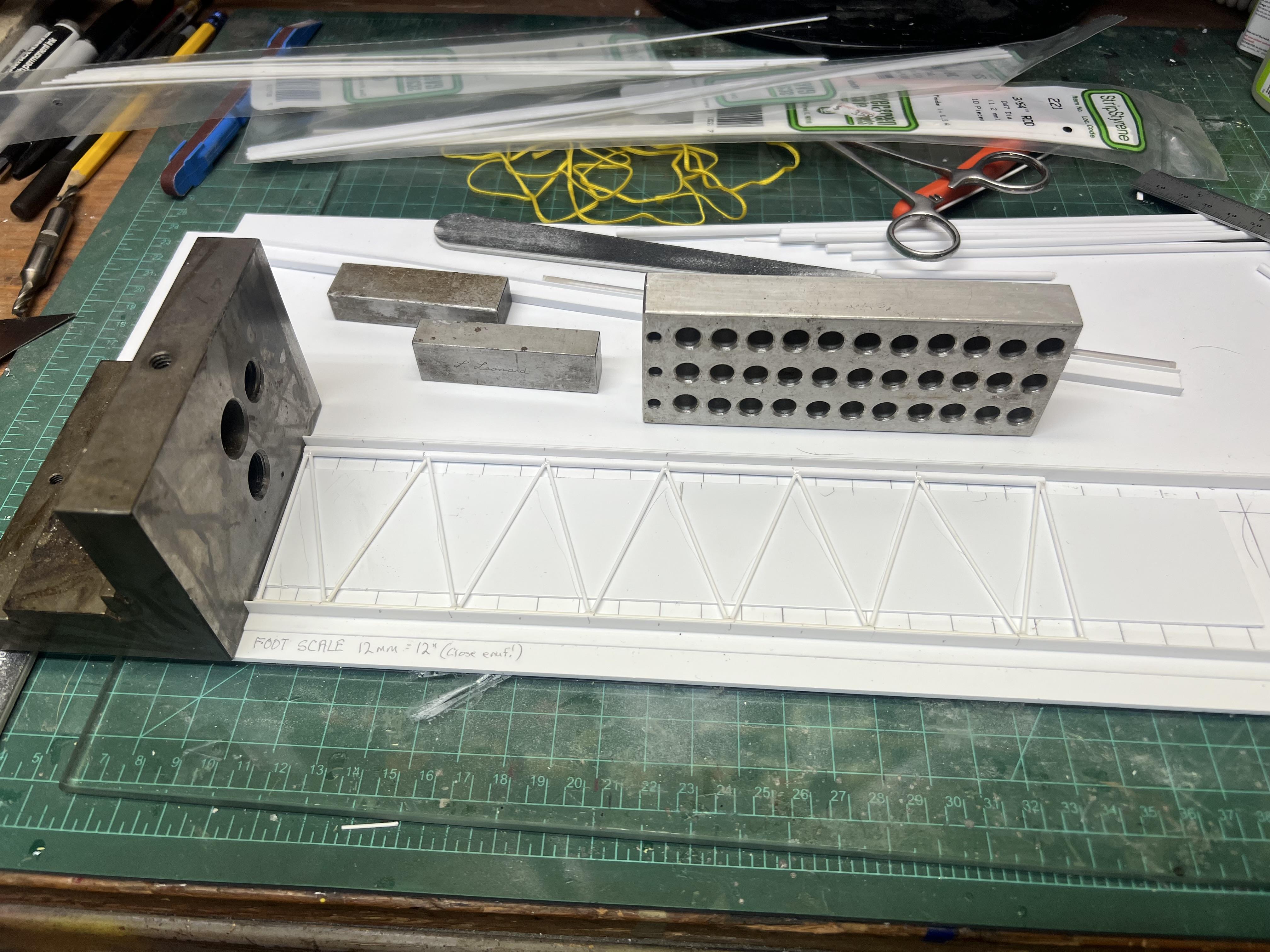

First 20’ section of boom is done, except for the pin connections etc. came out pretty well I think, and the second is about 1/2 done. Once the jigs were set up, and a procedure for cutting and such was perfected, it went WAY better and quicker than I expected. The first section is amazingly stiff. The size is 60” on centers of main tubes in width and 48” on centers in the vertical direction. Here is a scale 40’ of boom still needing the connection points, and the boom section on the left is drying before I add the diagonals on the top but it looks rather good! edit: just added last photo to show the second twenty foot section all together as well

-

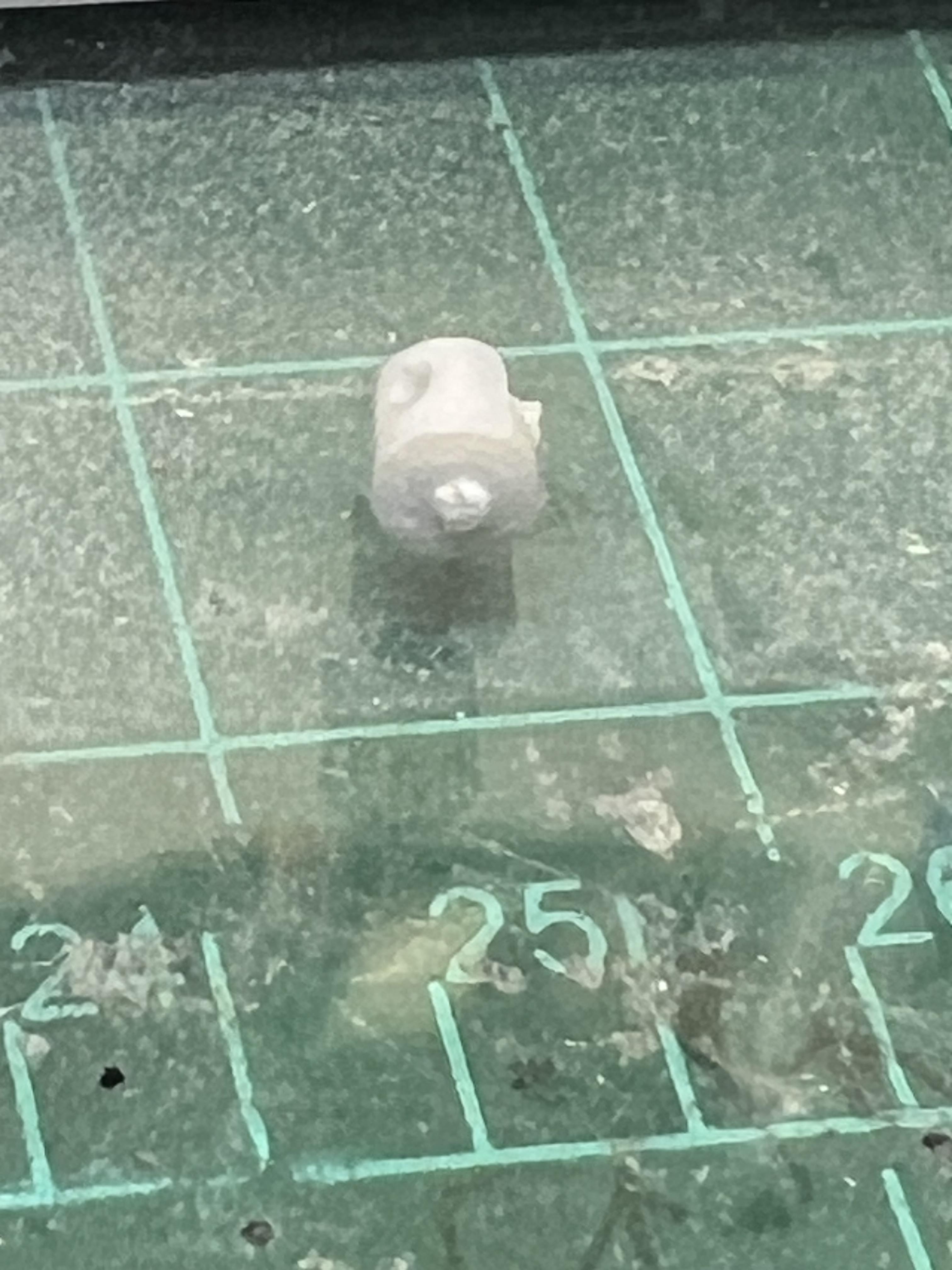

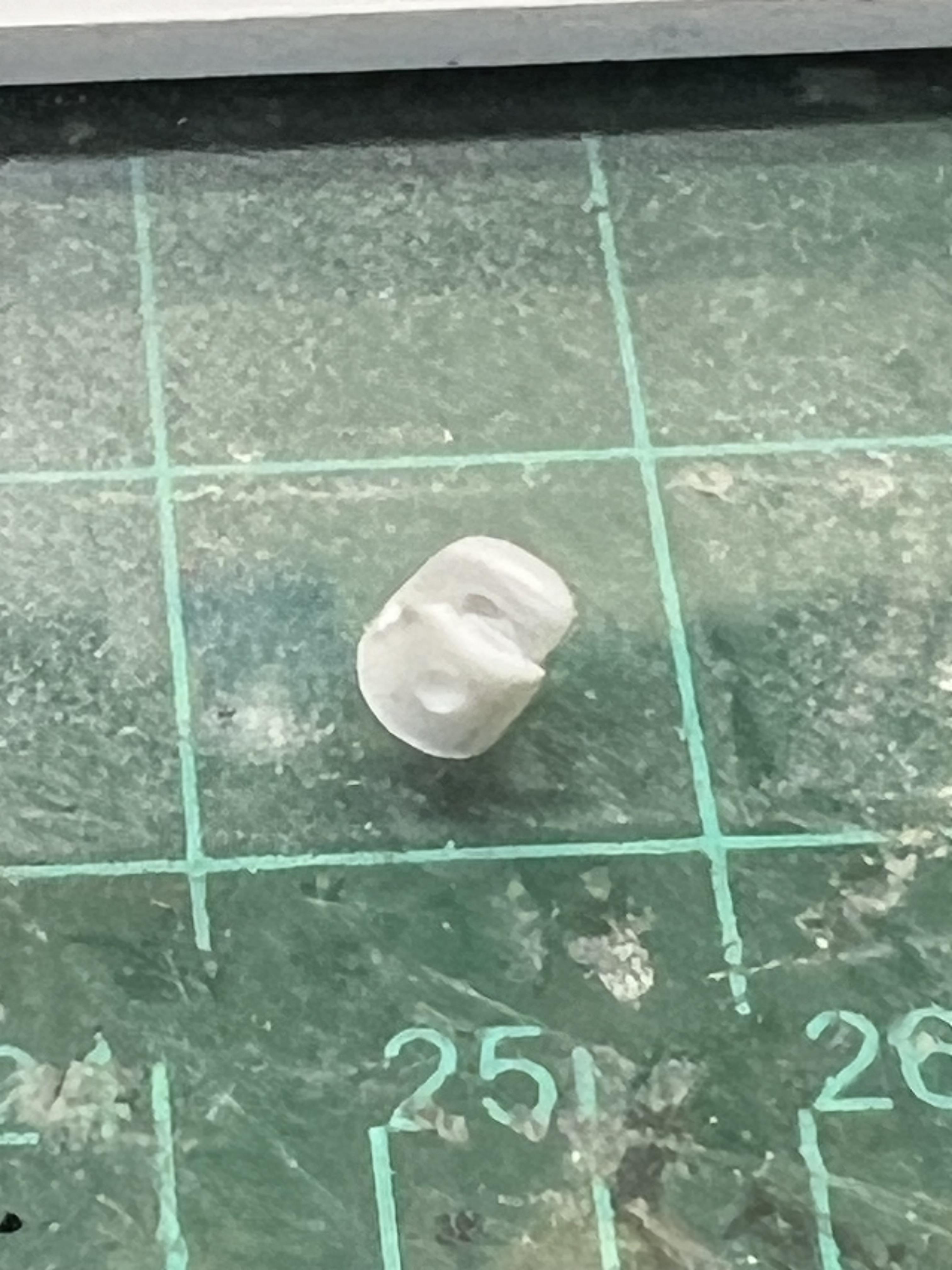

Sat down tonight and started fabricating the first 20’ section of boom. There will be two straight 20’s, two 10’s for the folding joint, a 20’ base and a 20’ tip. Each basic 20’ straight section will have 64 pieces of tube making it, not counting the mounting pieces and joining plate parts at each end. I also sat and figured out how to make the female joint piece for joining the booms. Males are next. These are the times I wish I was knowledgeable about 3D printing! Sometimes I think I enjoy the planning, problem solving and design of how to build these things more than the building!!!

-

I just sold a '91 Mustang GT that I had for 30 years. It was a hoot to drive and even though it had 185K on the clock, it was a VERY spirited ride with the 5 speed. When I first got her I had more than a few surprise rides around in a very tight little circle while driving in the rain, and it would do a great burnout. Only sold her because I bought a '95 Corvette and I simply could not drive both at the same time and found myself using the Mustang for rainy weather and good, instead of the Vette, (which was no fun at all), so I decided to sell the Mustang. At just about 3200 pounds she had plenty of power. I have driven several of the newer ones with the Coyote engine, and while heavier, the power was incredible, and it is easy to see why their drivers lose them so easily. My 'Vette with the 6 speed is faster, and quicker than my GT and far more fun to drive, but also more well mannered especially with the ASR engaged. With ASR off, it can be a handful. She does NOT get driven in the rain. A very good friend has a couple of McLarens, a Ferrari, three Porsches, a Lotus and a Jaguar. I have driven several of those as well, and BOY, it is easy to see how trouble can come along FAST. I cannot imagine the new 1000+ HP C8. But, as with all things, if you exercise caution, you won't make the front cover of Car Wrecks Weekly!

-

I injured my back by being stupid lifting heavy stuff 35 years ago. Have had all sorts of procedures including fusions. This stimulator has so far been incredible. As far as my next project, don't hold your breath! I have to live long enough to finish the crane I started 5 years ago! But it's getting closer every time I get to the bench!

-

Thank you. This was my ninth back surgery since a construction work accident in 1990. I had a spinal cord stimulator installed to send electrical signals into my spine for pain management. So far it has eased my chronic pain by about 85%. It feels kind of strange to have so little pain after 35 years!

-

Thank you sir. Actually, just got to the point where I can comfortably sit at my bench again today. Started cutting the first of hundreds of pieces of tubing and rod to make the scale 100 feet of boom. 1/8" tube for the main stringers, 3/64" rod for the side and top diagonals, and 1/16" tube for the end verticals, horizontals and internal diagonals. The whole thing will end up at 4 feet long. Got my work cut out for me!!! Made up a jig to cut them all uniformly as well as another jig to assemble it all together. Getting there!

.thumb.png.e64ca4fead948adbdf6a111229b6cf2f.png)