-

Posts

3,791 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by customline

-

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Thanks, Jason, "fantastic" might be a bit strong but I do appreciate your interest. -

‘55 El Camino

customline replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

You can see Buick portholes on a lot of cars in downtown Newport News ?- 141 replies

-

‘55 El Camino

customline replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Save it for a '55 'Vette ?.- 141 replies

-

‘55 El Camino

customline replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Vent windows were a necessity in the summer months if you didn't have A/C (or it didn't work ?) They were a deluxe feature in the early days that became a standard thing eventually. I think the manufacturers eliminated them to sell more A/C equipped vehicles. Can you still buy a vehicle without A/C? Greg, it looks like the it's a no-go on the T-Bird roof. I kinda liked it . ?- 141 replies

-

- 1

-

-

Monogram's 1955 Lincoln Futura Concept Car: WIP

customline replied to David G.'s topic in WIP: Model Cars

Yeah, ditto that. I spent a few ebay sessions trying to find one at a decent price but I'm glad I gave up ( I'm happy with my Edsel ?.) It takes a very methodical, patient, experienced....any way, that's why I gave up on it, the truth be known. I like the idea of adding filler to CA; I need to try that. Nice work, David! -

Yessiree, this is shaping up to be a right proper worm can! ? (a cracked windshield is always nice, Rob. ?)

-

Wow, man, you have my attention! Let's see what else you've got going! ..... Now what did you do with the rest of that Fury? ?

-

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

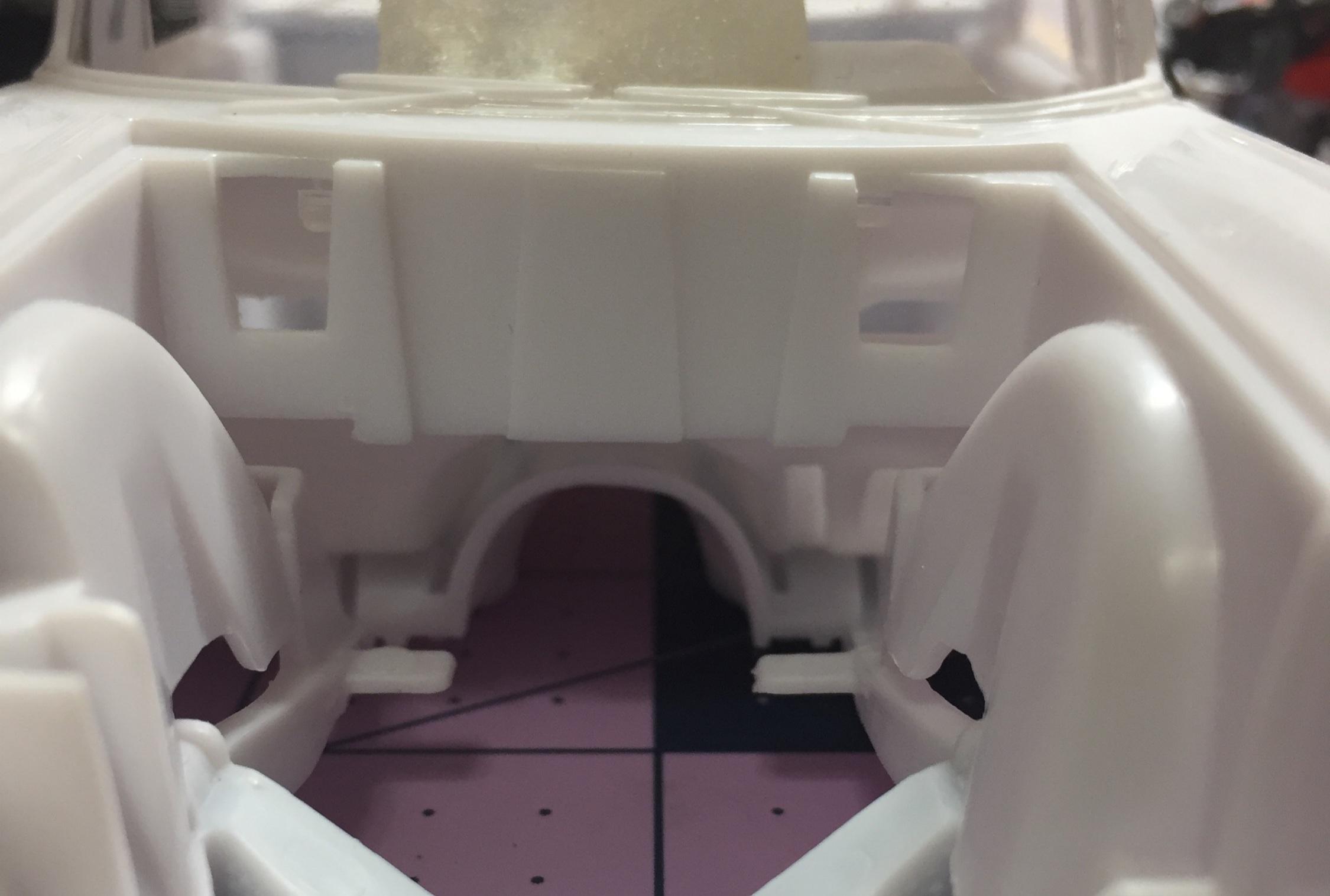

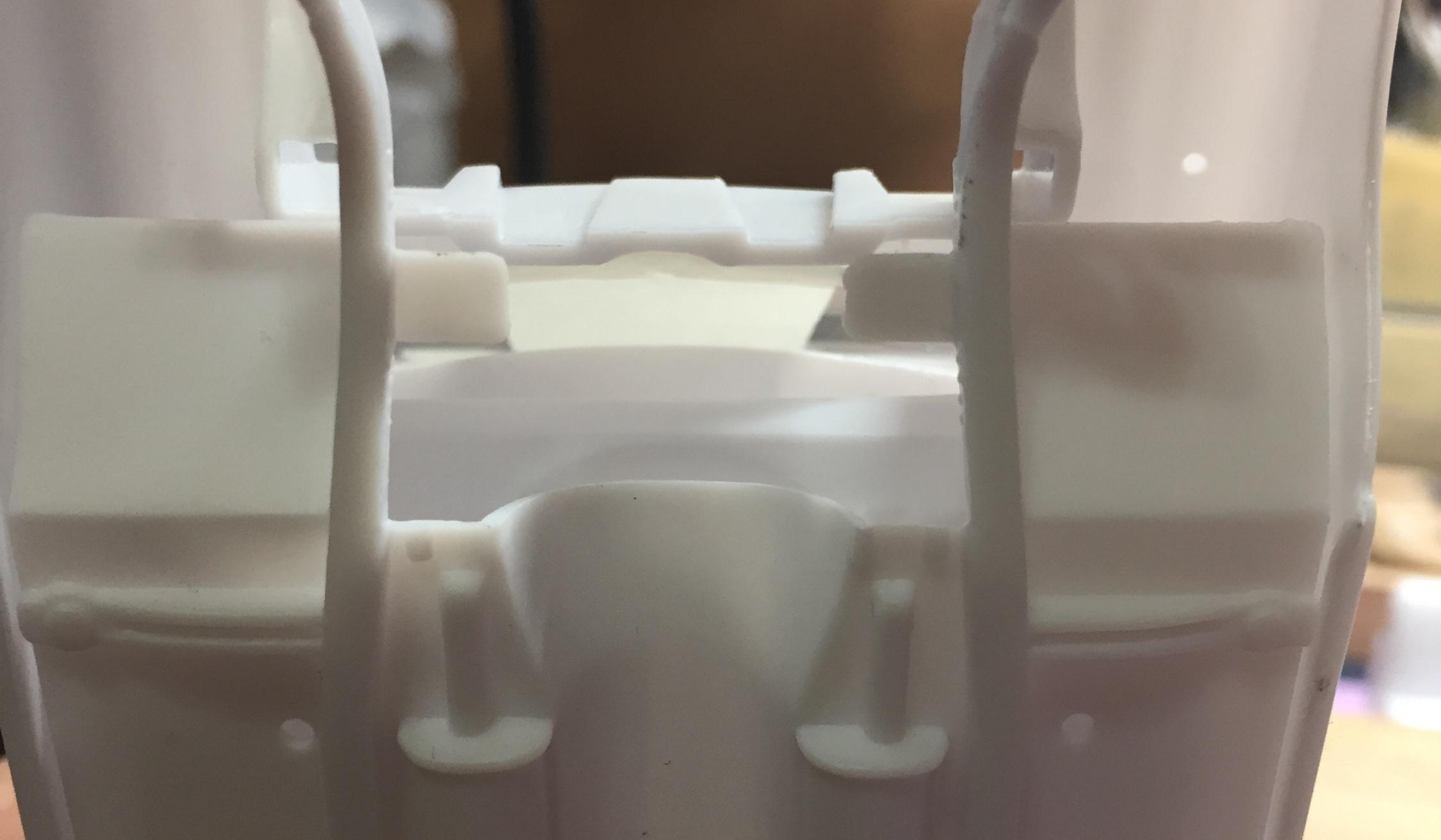

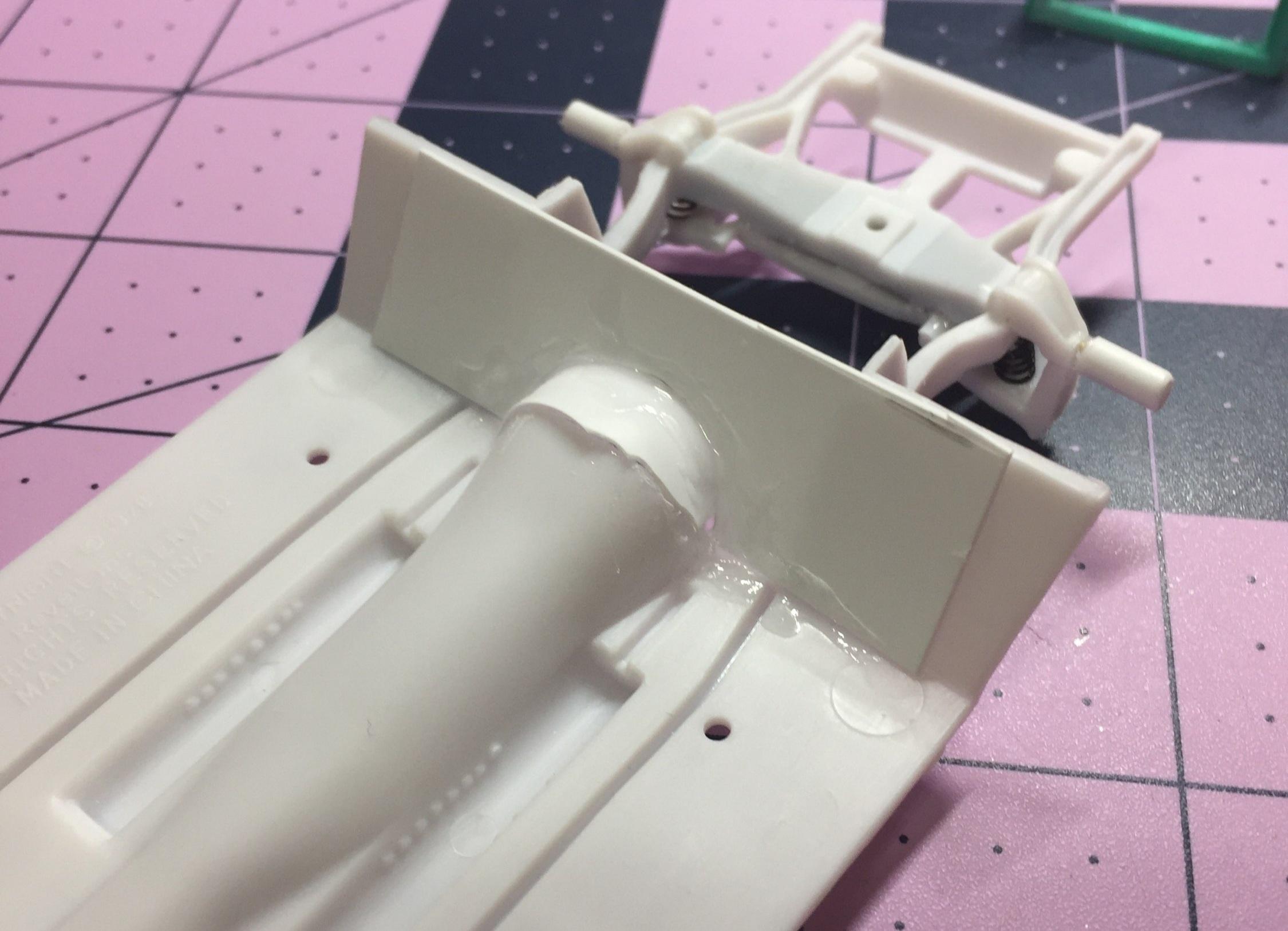

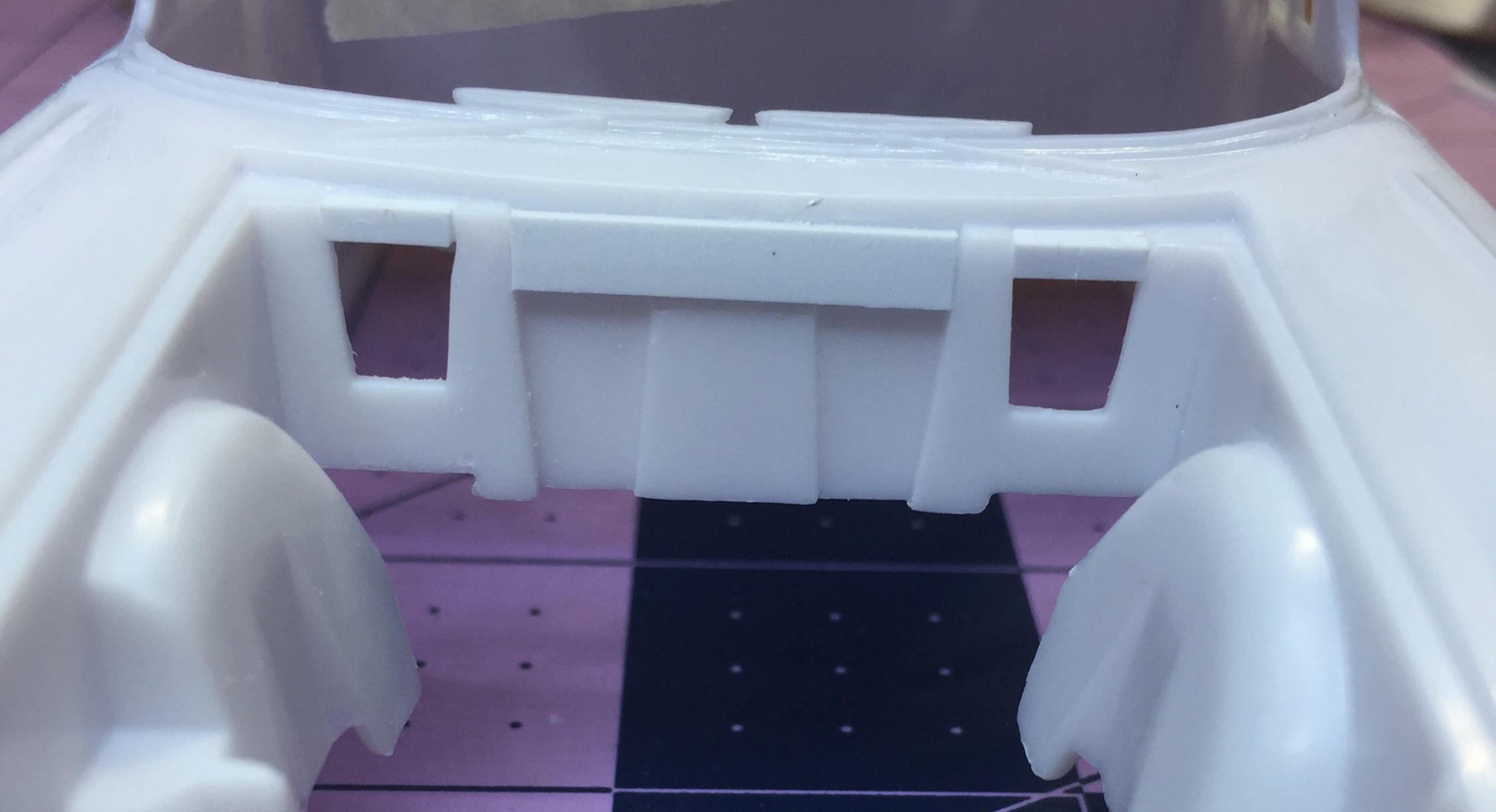

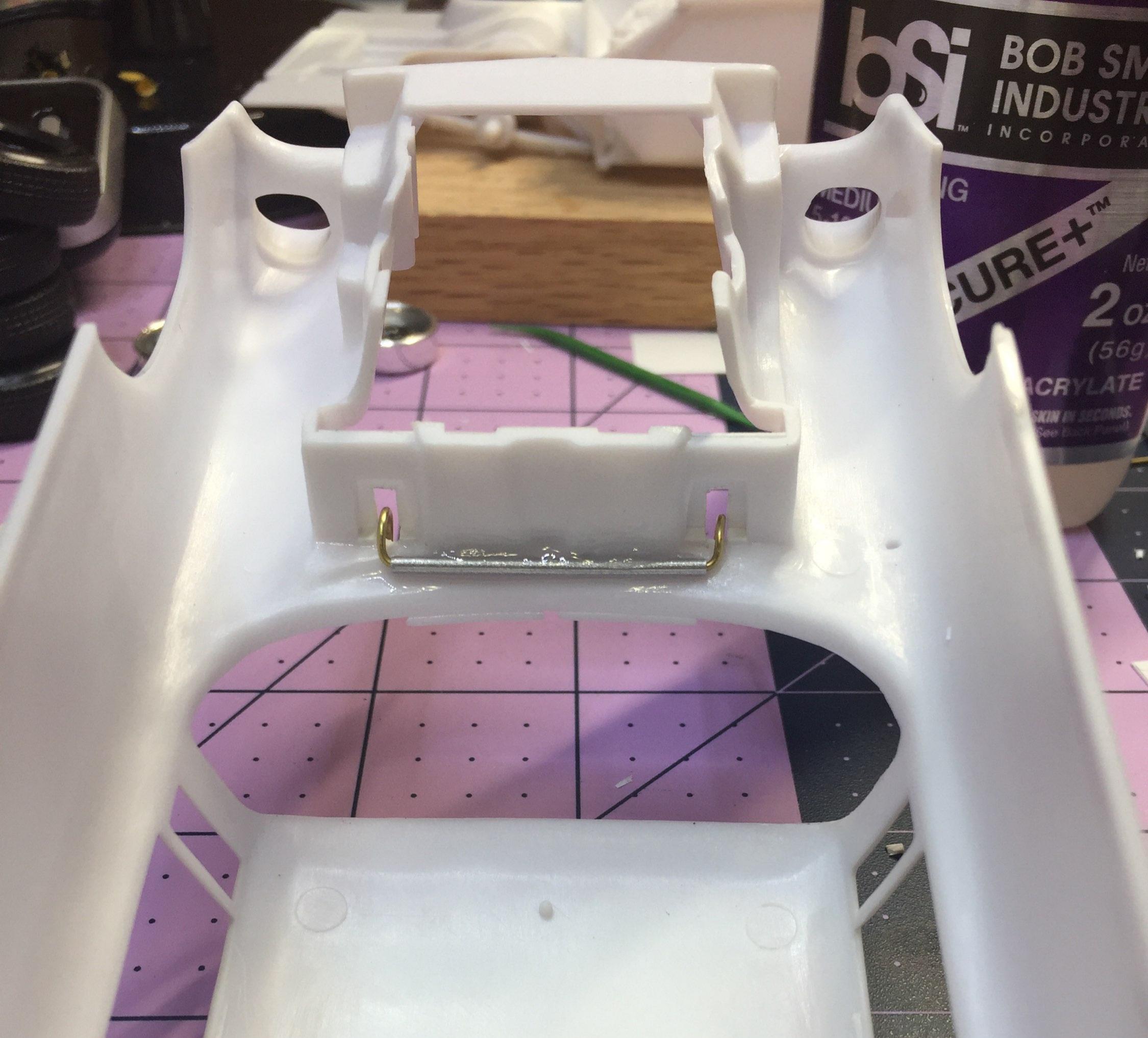

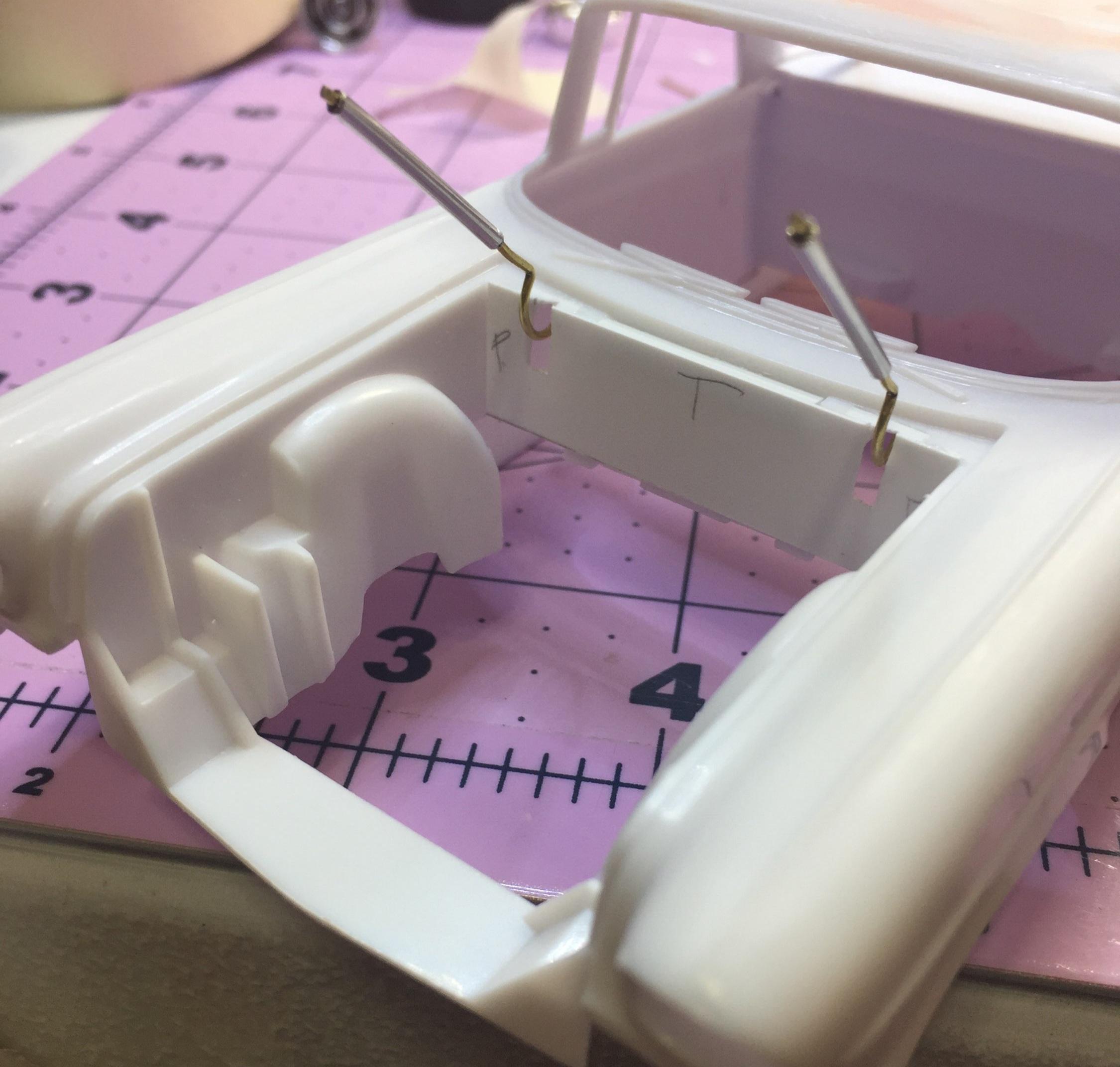

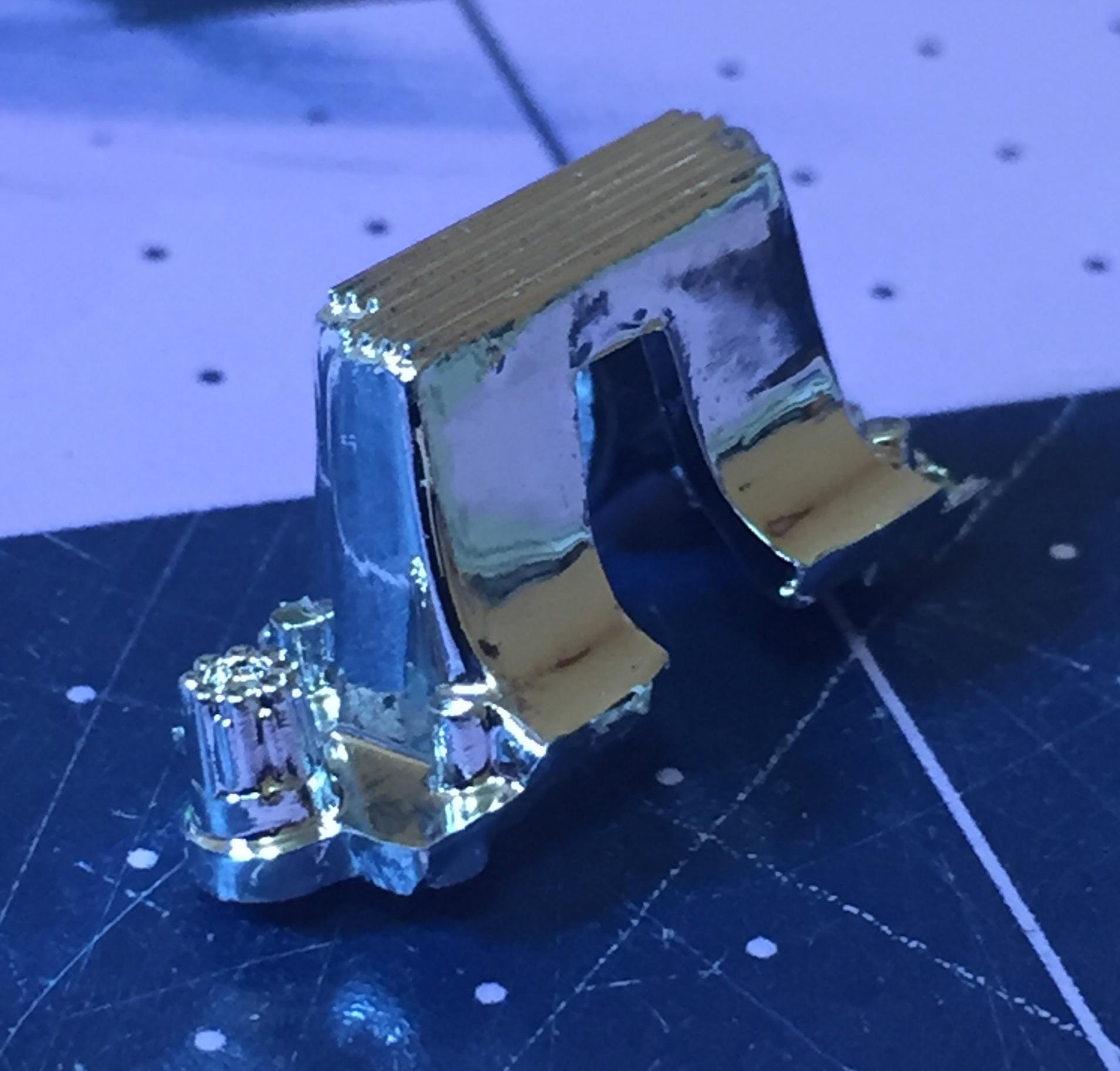

One thing that reeeeeeeeeeeeeealy bothers me about this kit (and all of it's siblings) is the idiotic firewall which is no firewall at all. They put the emphasis on hinging the hood but that rendered the firewall as...well...observe? And it looks unfinished; there's a void between the thing that serves as a firewall and the interior tub. ? the bell housing and transmission, I guess, is supposed to hide the emptiness. Not to worry. I have plenty of Evergreen in my drawer. The floor/ toeboard/transmission tunnel is easy enough to close up with some sheet and CA. The firewall is a bit more complicated. I had decided to just go with the kit hinge and maybe try to cover the weird thing and to try closing the hinge openings....nah. It was time to make a wire hinge. That allowed much smaller slots and a smooth "custom" firewall. I added pieces of strip to build out the low sections and cut slots in some .015 sheet for a veneer. It's not perfect by any means but I can add a few details to a flat wall now and still have an opening, hinged hood. I cannot imagine building this kit straight out of the box. That's it for now, thanks for stopping by ? -

‘55 El Camino

customline replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I was looking to see if Buick had a version of the Nomad and I ran across this. https://www.barrett-jackson.com/Events/Event/Details/1957-BUICK-CENTURY-CUSTOM-WAGON-138984 Pretty cool, huh? ?- 141 replies

-

- 3

-

-

Is There Room For Another 41 Plymouth or Two?

customline replied to LennyB's topic in WIP: Model Cars

Oh how true ? -

‘55 El Camino

customline replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I say add some Buick portholes (Roadmaster portholes ?) and keep the 'Bird lid. Then see if you can find a '57 Desoto front bumper and some '58 Edsel tail lights. Awesome! ?- 141 replies

-

- 1

-

-

Is There Room For Another 41 Plymouth or Two?

customline replied to LennyB's topic in WIP: Model Cars

Don't sweat the running boards, Len. They take a beating. The rubber dries out from sun exposure and cracks and then the salty winter roads rust the metal away and...well then you have a nicely weathered running board. ?. -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Thanks, Len, but that ain't sayin' much. It was pretty bad. The body mods are the important thing with this one (for me at least) but I just can't put the rest of it together as is. Let's face it, the kit is pretty poor quality. I'm sure that's common knowledge. ? Not worried. Wifey is busy spending the grocery money on paper craft equipment and couldn't care less what I do. It a symbiotic relationship ?. -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

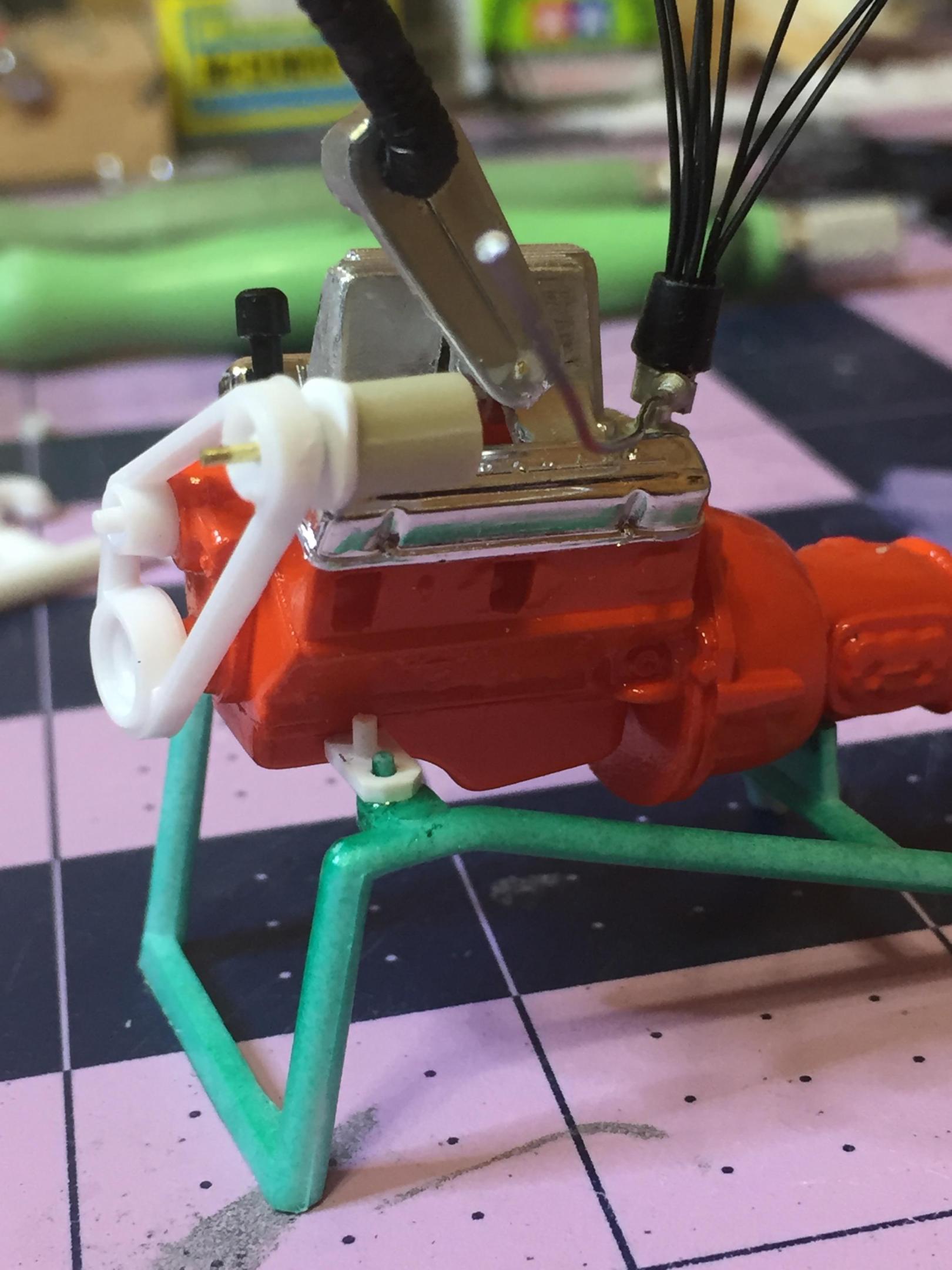

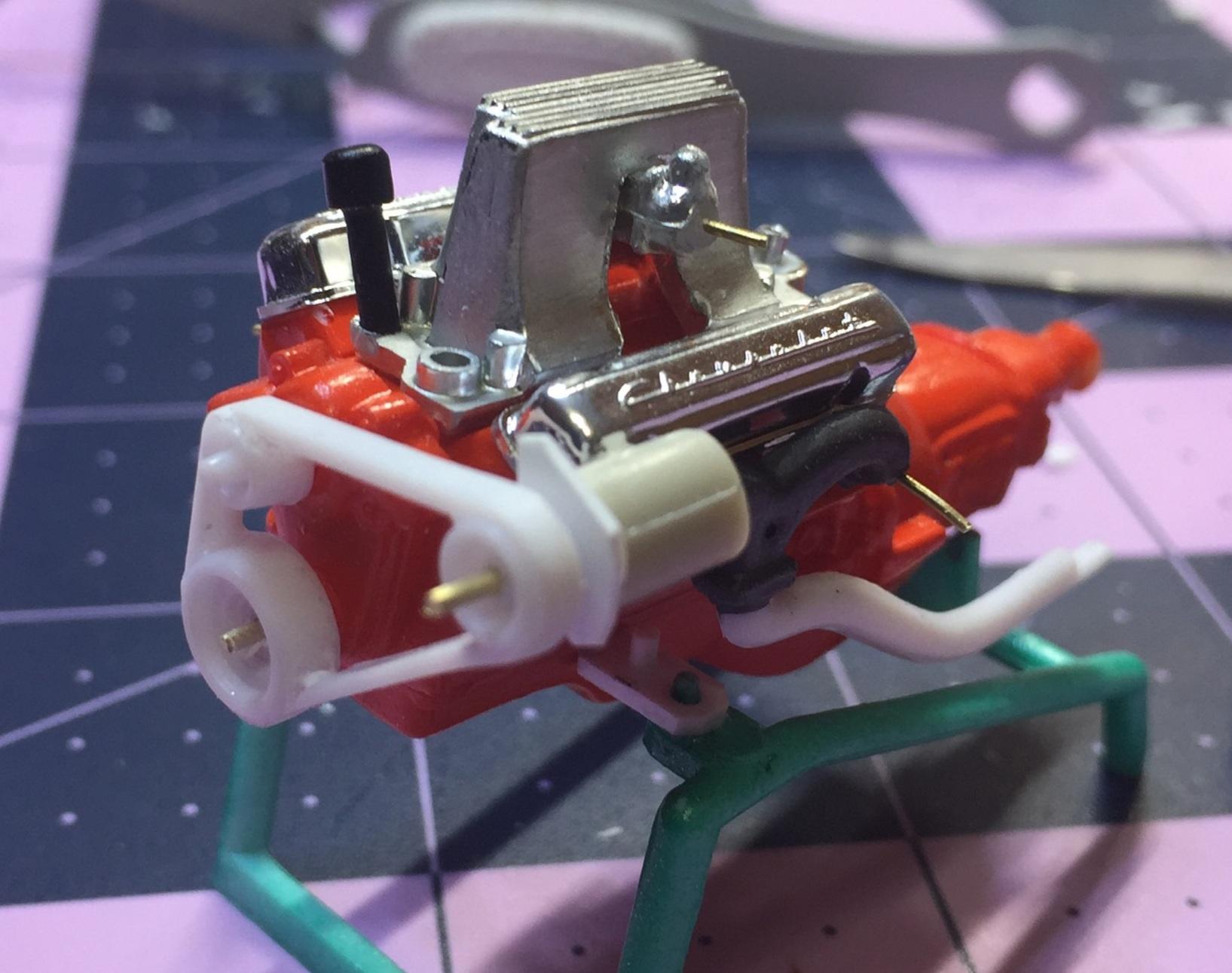

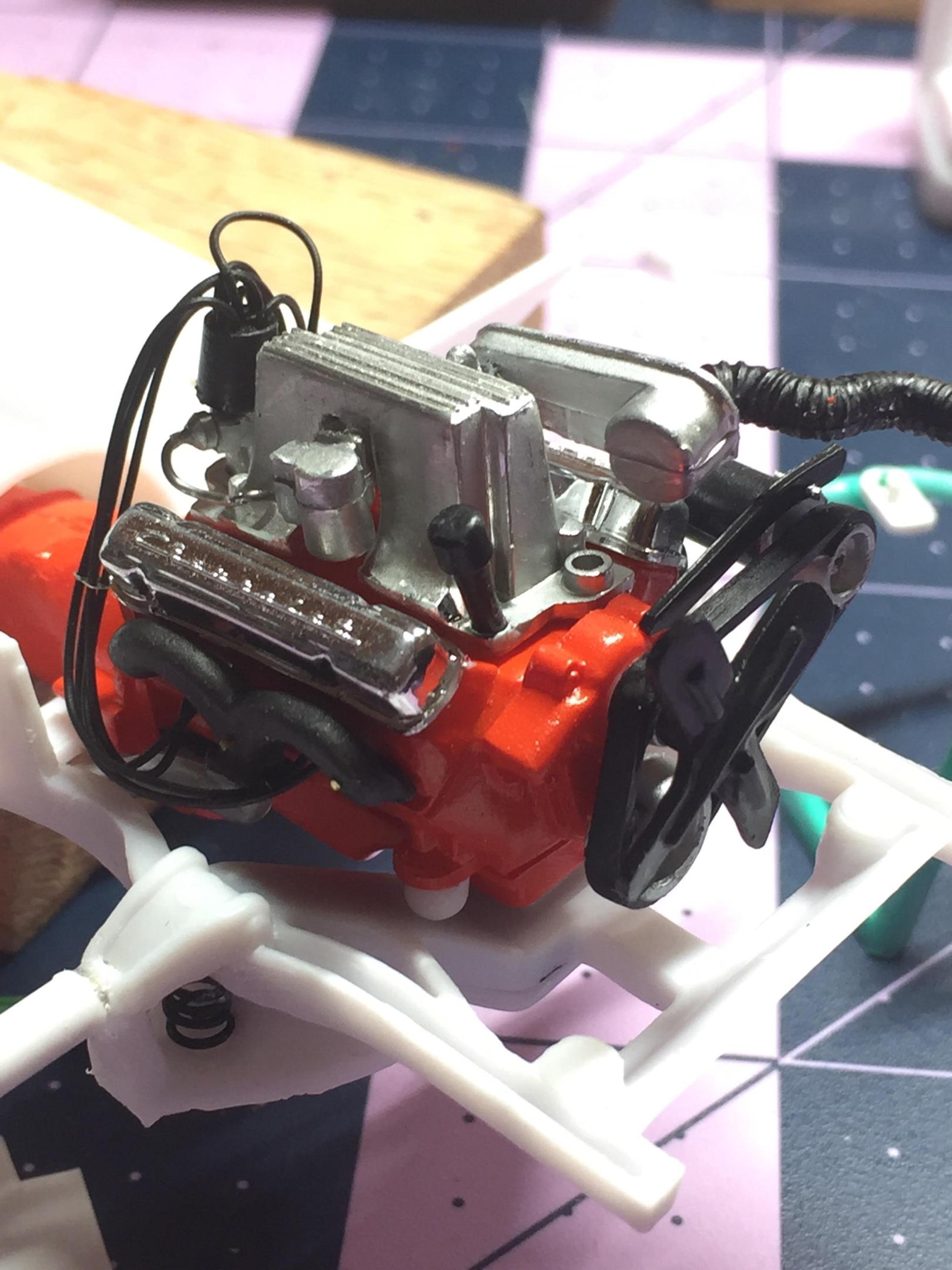

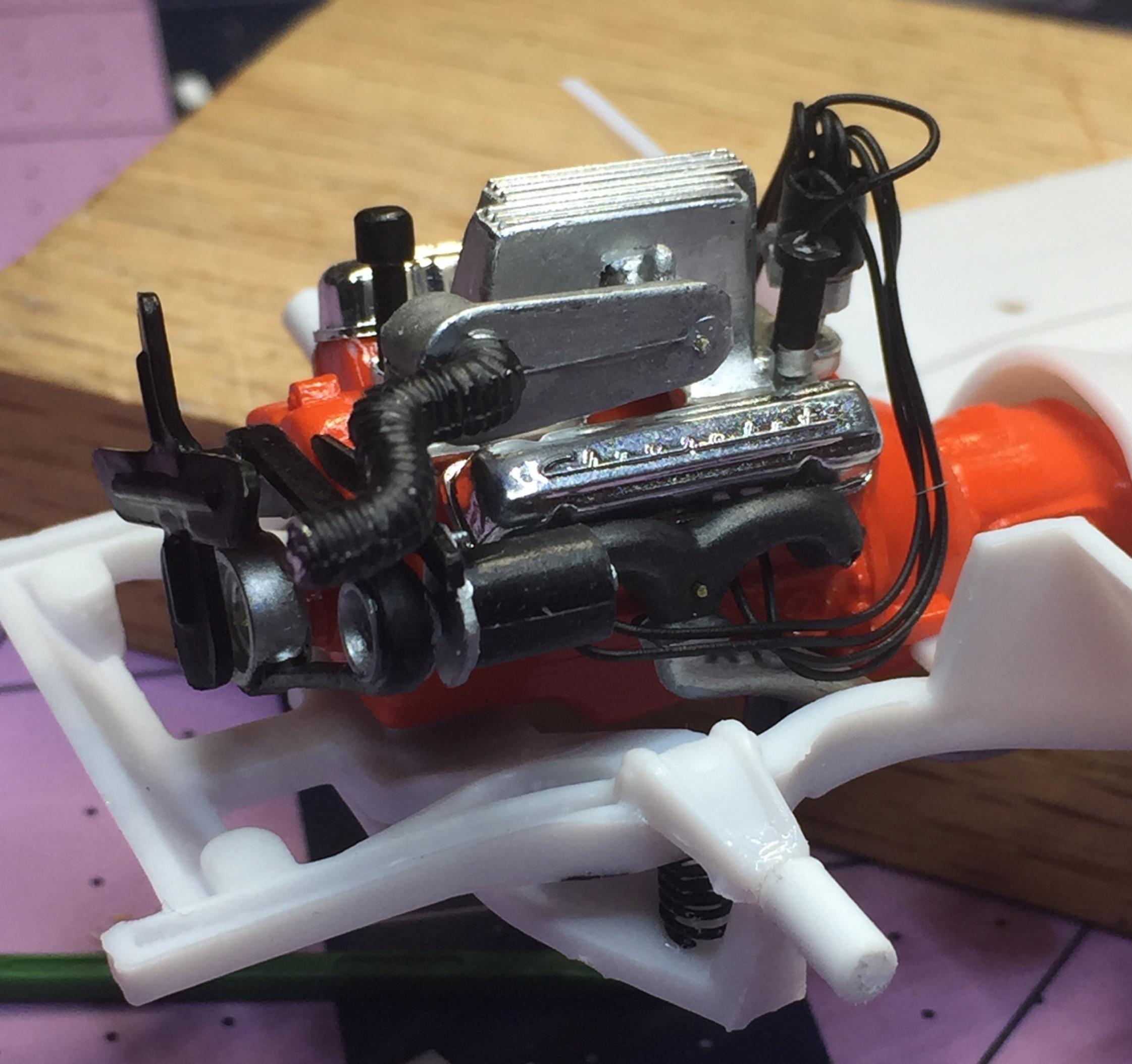

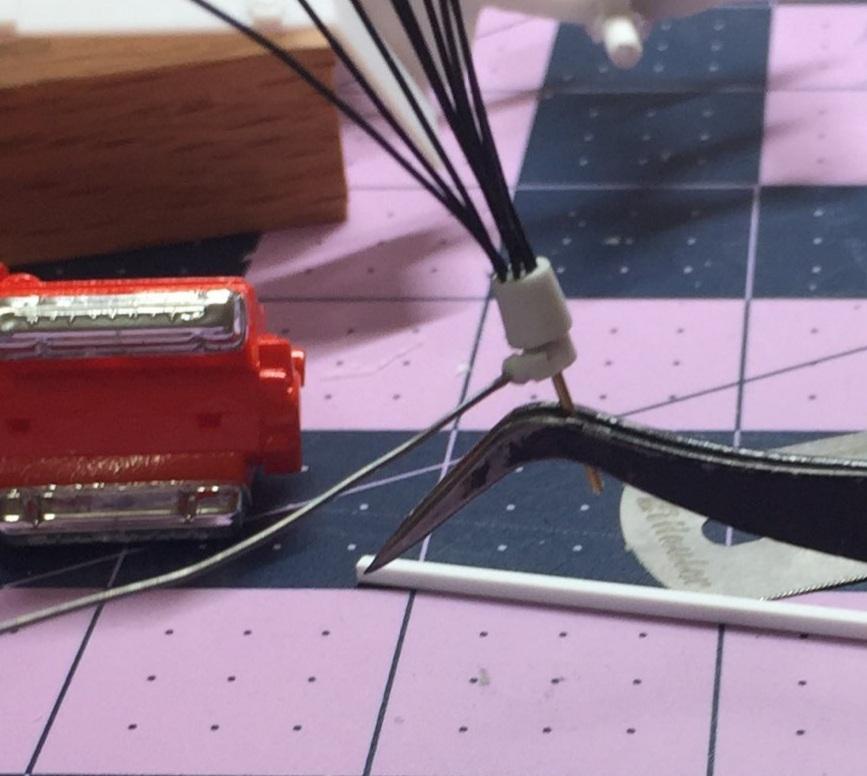

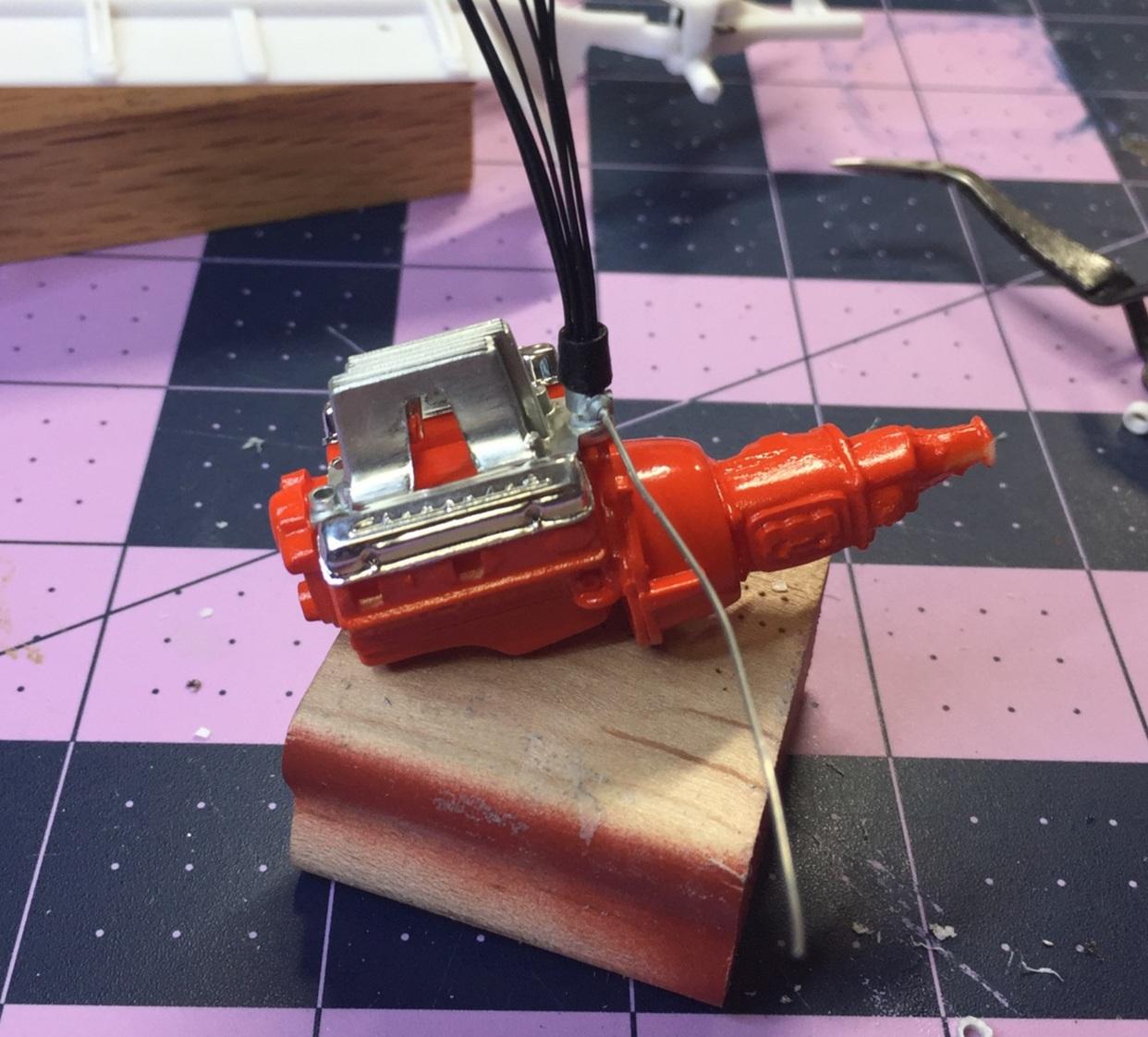

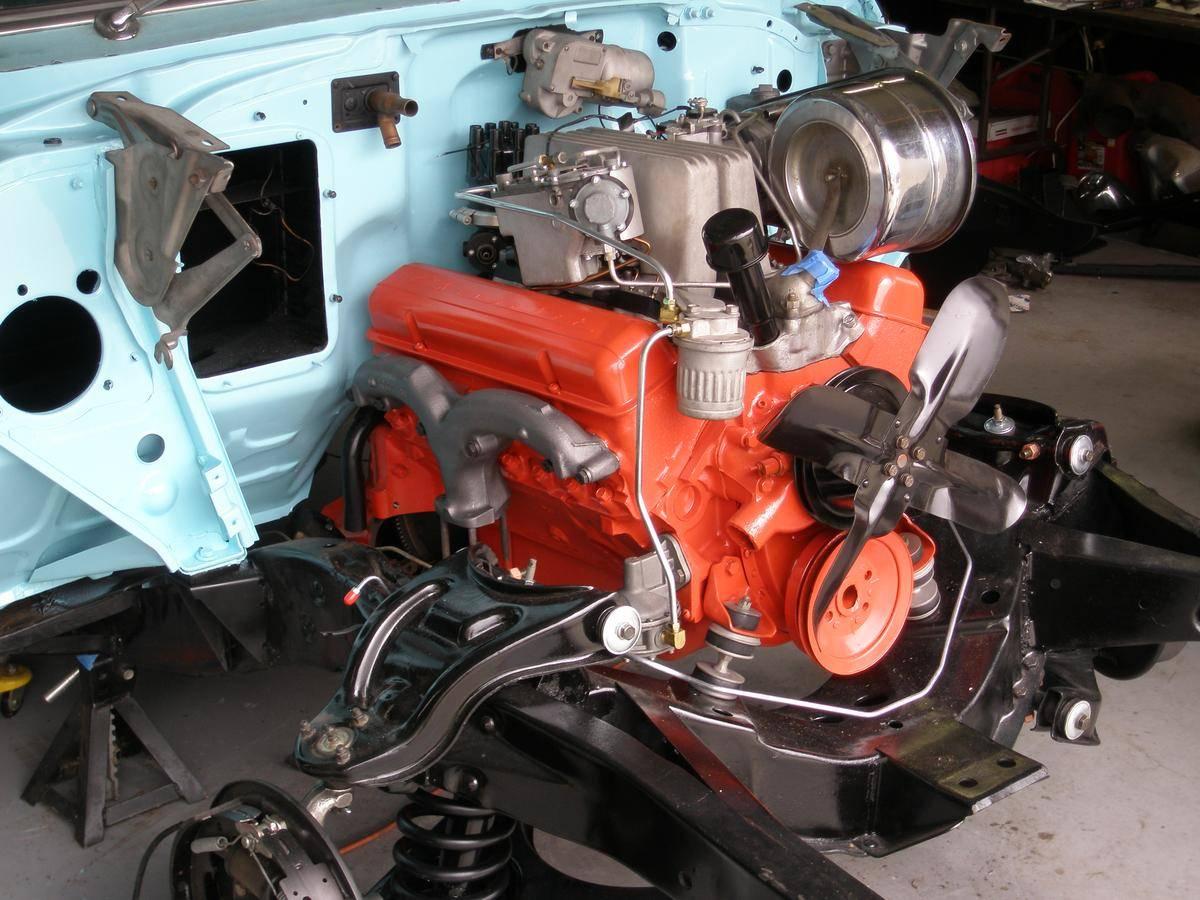

I spent some time on the engine today, mostly tedious, neck-ache stuff like re-locating the "new" generator and ignition wiring. Threading the wires through PE looms...you know the drill. Anyway... One thing that hits you as odd is the way the heads locate the exhaust manifolds so that they may end up lining up the molded in pipes on the "chassis". I drilled holes and pinned them. Easy ?. Next I noticed the generator was not in the right place. In fact it looked like it would interfere with the air cleaner/intake duct so I decided the prudent thing would be to locate it where all my reference pics show. I continued to add an oil filter cannister of my own design, and a coil, and a oil filler. Then the dis..... well you know. there's a few more little things I want to add but my neck is killing me ? -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Ah ha. If you only use one pair you got your money's worth. ? . Thanks Dave! -

Hubcap theft was a popular practice back in those days. ?

-

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I am. I'm a traditionalist and I won't apologize for it. I still have my little hex key on a flex handle to adjust my points with a dwell meter ?. -

Monogram's 1955 Lincoln Futura Concept Car: WIP

customline replied to David G.'s topic in WIP: Model Cars

Uh....mmmm.....no. but in my defense, I have "CRS" . That was good thinking, David! Your planning paid off ....uh.....as planned! ? -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

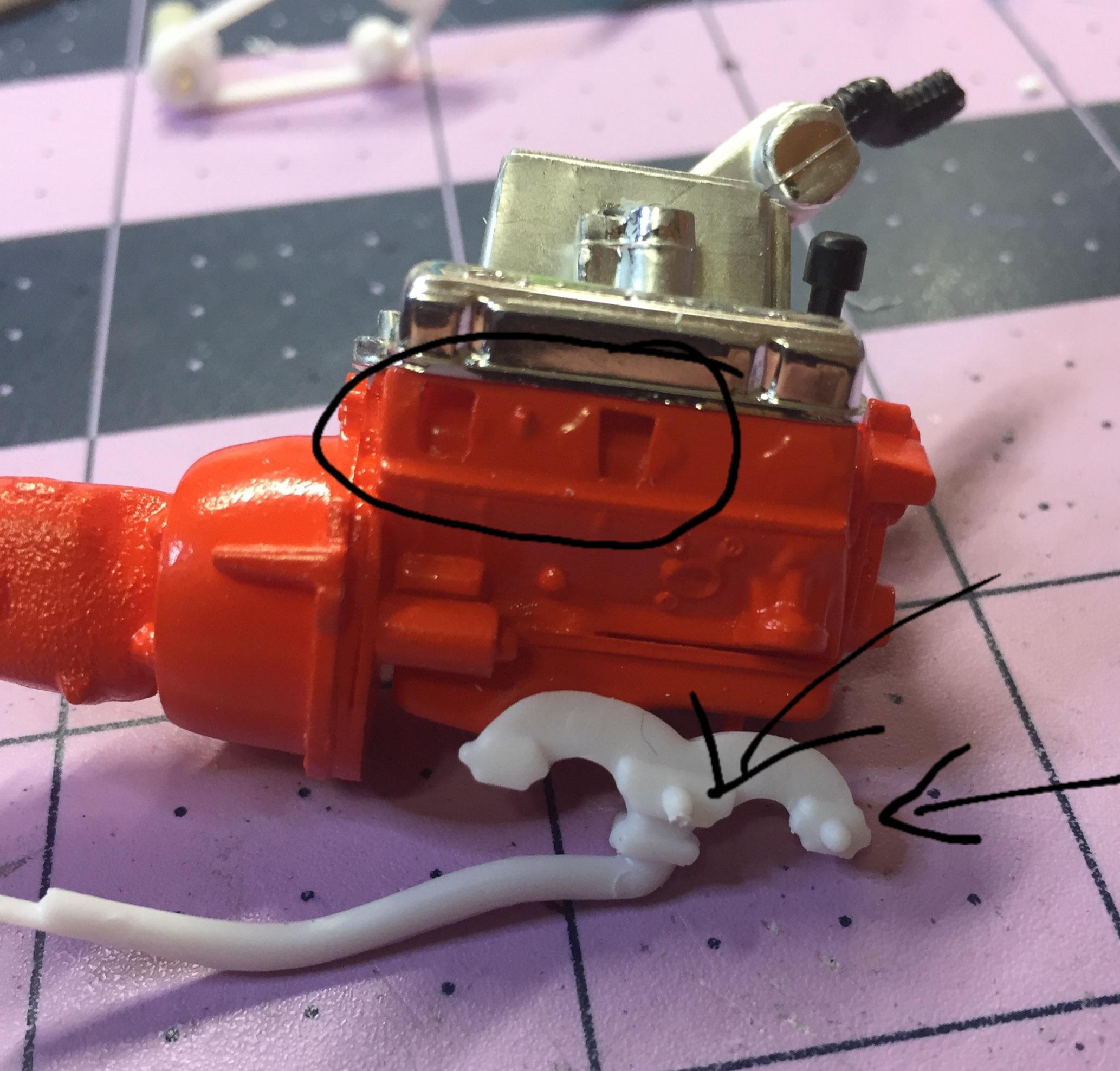

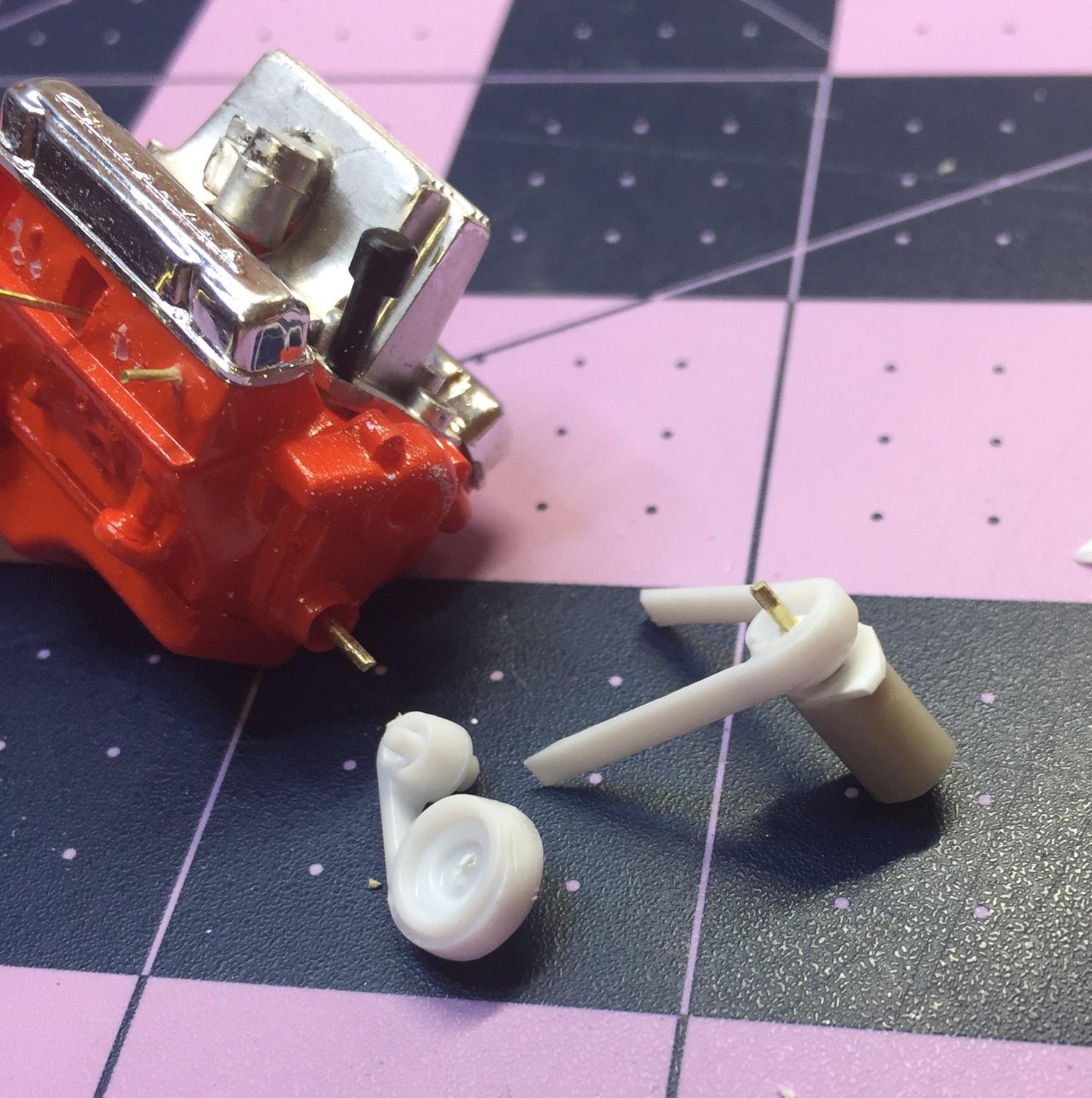

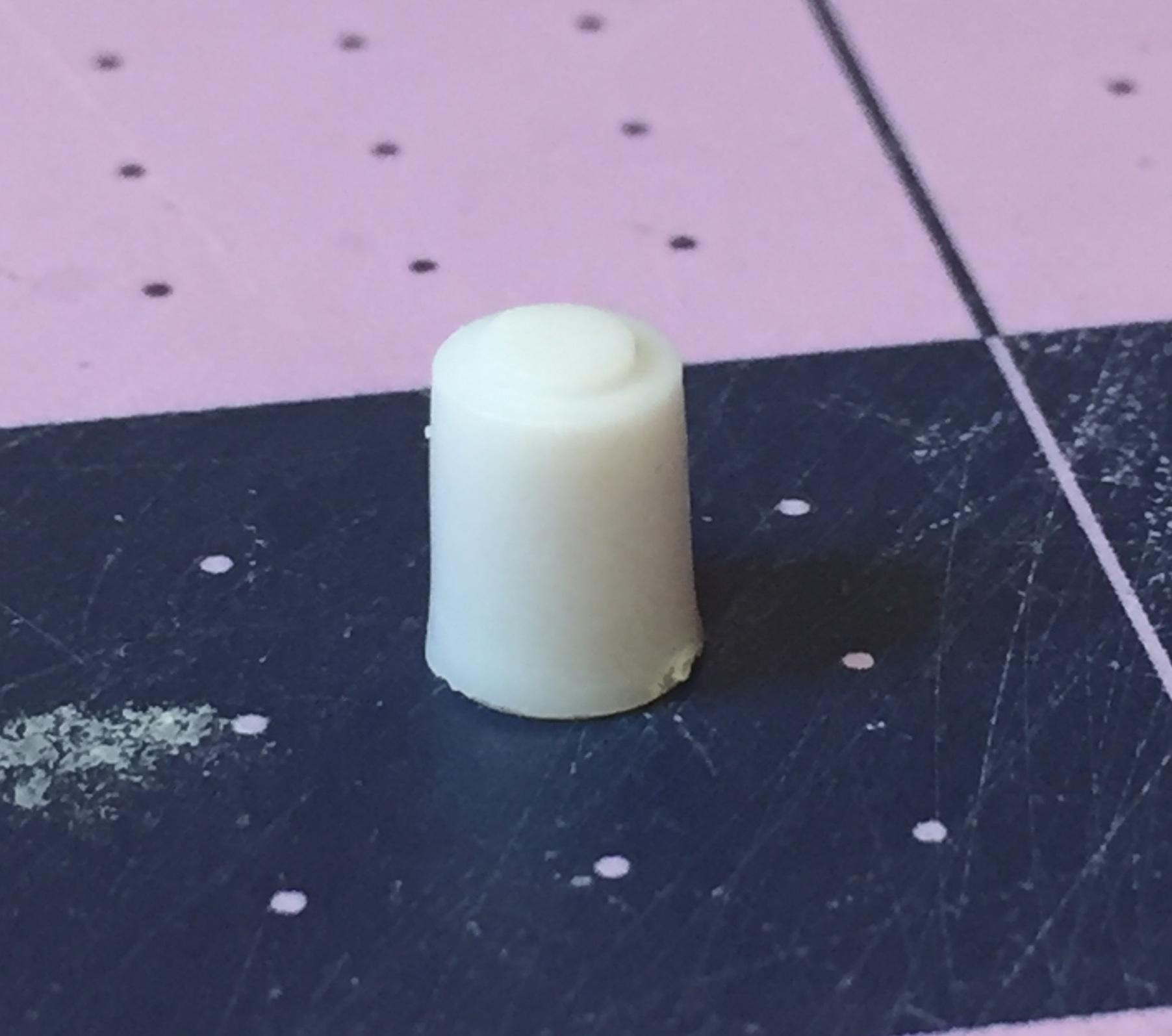

Something that irks me (and probably you too) is that the small cylindrical items like oil filters and generators are conical. I get it though, they do that so it will exit the mold. But it bothers me enough to want to fix it. Its easily done so i won't bore you with the obvious. I recently discovered those cone shaped generators are ideal to serve as distributor caps! ?....well at least this time anyway. You even have a guide to drill eight holes around the raised center I inserted the wires through and, from the bottom, filled in with CA to form a solid unit. After it was cured I cut it to size and added a slice of styrene tube to act as the housing and drilled the bottom for a short length of .032 brass wire. Then I gaffed a vacuum advance, painted it like a stock item. I removed the molded in distributor and added an aluminum tube to act as a sleeve and look like the shaft housing. I messed up the angle when drilling the hole to accept the new distributor but don't worry, I feex. Later. Now the reason I had to fab a distributor: See the 1:1 ? See the teeny-weeny 1:24? That's why. ? I'm starting to like 1:24, it's easier to work with ? Next up: repositioning the generator- next for me, that is ? -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Thanks, Ken, i hope i can keep it that way. These things have a way of flat-spinning for me sometimes. -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Nope. No shame whatsoever, David. You are always here helping everybody on this forum and I know we all appreciate you. I think most everyone knows I don't take myself (or my building skills) very seriously. Especially those coils I made. ? (Mongram didn't provide the springs so they're better than nuthin' ☺️.) I am interested to see what you were talking about so post it here! -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

Dave, you didn't see my coils? I made some from black bead wire. I took a length of 1/8" tube and drilled a hole through it. Then I stuck a length of 26 GA. bead wire through the hole and wrapped it around till I had enough for a couple of springs. Cut 'em and used my tweezers as a spring compressor and inserted them between the lower A frames and the chassis with a drop of CA for good luck. Not exactly to scale but I had fun doing it and that's what counts, right? Scroll back and look. ?..... didn't even need to paint 'em. Feel free to put up a picture of those things so we can see what you're talking about, Dave. I'm always open to inexpensive off-label items being somewhat of a cheapskate myself ? -

'57 El Nomado

customline replied to customline's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

I've got the rear as low as I can get it anyway; the shaft change isn't a factor unless I can lower it more. That would mean removing the glued-in unit and cutting off the badly molded springs and adding blocks ...then I would need to raise the top of the tunnel...ya think it's worth it? ? I appreciate your input, but put this one on the list right under "AMT '41 Plymouth" ..maybe if I had a 1/24 IRS setup....a 'Vette or Jag . Next time. -

‘55 El Camino

customline replied to NOBLNG's topic in WIP: Model Trucks: Pickups, Vans, SUVs, Light Commercial

My feeling about the roof is that, as a full-blown show custom its a cool identifiable element. I think it depends on what else you do to make the picture complete like, say, monochrome treatment, rolled pans, a nice teak bed deck, slammed to the asphalt, billet rims, all that. Oh sorry....??- 141 replies

-

Oh yeah ?. Now we're cookin'!