-

Posts

533 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Big John

-

-

20 hours ago, bbowser said:

That would be awesome for a diorama!

Can you imagine 1/64 scale? Scaling digitally, at least in the CAD programs is pretty simple. I build my parts in 1:1 and scale them as (for example) 24=1 for 1/24th etc. We may take it for granted that the parts will print out the same size however we don't really know how that is translated in the printer. All the parts should be relative in scale to each other when printed on the same machine. To find out if the parts are to a specific size we would need to do some test parts and calibrate the printer by adjusting the scale factor of the artwork accordingly. 24.002=1 lets say. Remembering too that there are variables in resolution that may affect the final size. Vendor sourced parts will probably be hit or miss unless the vendor is meticulous in their scaling.

-

-

-

Amazing work on the wiring and close up details, as always François! Those chrome pens certainly work well even up close. Looking forward to seeing parts from the new printer, does it have an even higher resolution?

Thanks, J

-

This looks like pretty good reference http://www.cg-models.com/moteur50.en.html

Would the Pocher kit be helpful?

-

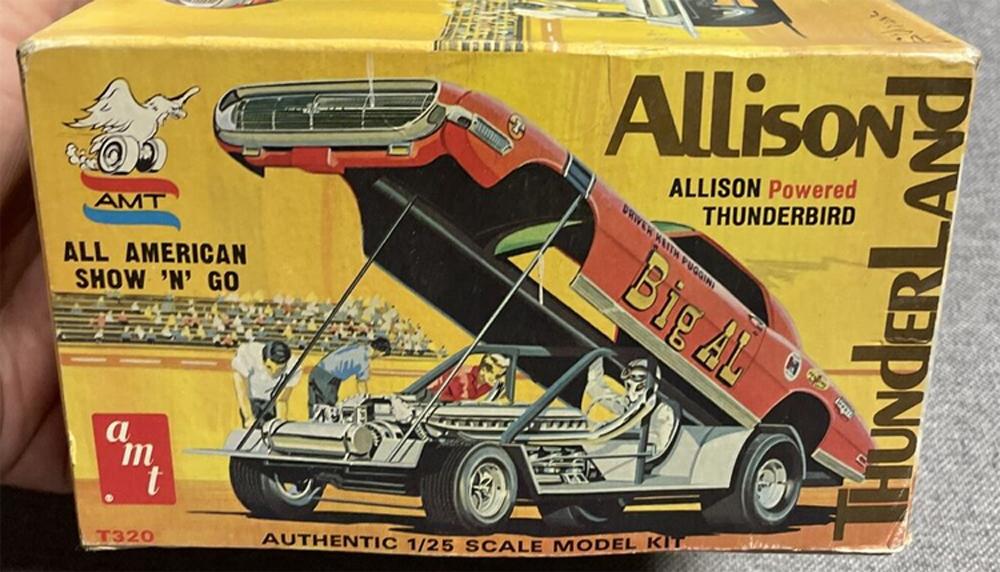

The one that seems to be missing is the 1967 or 70 Thunderland Thunderbird with the Allison engine. Mine is lost in the parts box somewhere in the shop.

-

1

1

-

-

Quest for perfection is what many of us aspire to.

-

On 11/4/2023 at 4:02 AM, WillyBilly said:

As much as I love old car styles, the reliability, performance and safety of newer vehicles is hard to overlook. This video should put things in perspective.

NOOOOOOO! Not the 59 Chevy!!!!!! I Can't Look!!!!

-

So, Pierre, what was your overall experience with this kit from FPP? I have several but have yet to build one, any hints?

Thanks again for sharing with us.

-

World is the second word in Auto World, a great model car catalog back in my youth, predating on-line sales.

-

She's a beauty...Excellent detailing and weathering, thanks for taking us along on your build.

-

-

Thought at first it was the gas cap but couldn't visualize how the hatchback opened. Ah the days of compacts. Hard to see from your pics but, does the gas cap have the details too? Really needs a hemi.. Hemi Gremi!

-

The RC car market has had some very nice contemporary tires however they tend to be in 1/8 scale and nothing vintage. Great for large scale hot rods.

-

On 10/10/2023 at 7:26 AM, landman said:

The car is gone too. Sold it about 4 years ago.

Nooooooooo! Nice touch the orange wheels matching the accent striping.

You even a Gremlin on the front fender, should be able to mold that for the back round thingie... can't be the gas cap, key hole cover?

-

Two Dapper Dudes! And the 34 Chevy is a beaut too. What color?

-

What a sleeper with the V8. Your cousin should be able to do a mirror image in photoshop st give you a template for the decals.

-

Hard to make up my mind... either Pink Floyd Dark Side of the Moon, Zeplin's first tour with Jethro Tull opening 69, but probably Crosby Stills and Nash with Joni Mitchel opening in 69.

-

1

1

-

-

Les' comment brings us back to the question expressed in another thread about "Why rubber tires and not cast resin." For me it is an esthetic choice going back to my youth and the models of the 60s. But this is another subject.

-

The one advantage that I see in the relm of 3D printing for the high end builders would be in the tooling of more accurate tires. Mr. Wingrove's process already requires several steps to tool the hard resin final mold and the level of detail will be much more accurate. I had considered scanning the old tire ash trays that were a marketing tool and abundant in many service stations here in the states back in the day. They appear to be 1:6 scale but have all the tread and sidewall details of full size tires.

Thank you Noel for another thought provoking discussion.

-

1

1

-

-

I stand corrected, and rightly so. I lost my focus on the title of this thread (My wife calls it ‘playing the Devils idiot’) and I did not mean to minimize the skills, abilities, and pure dedication involved in hand fabrication of models. I am also a great fan of Mr. Wingrove and am inspired by his books on model building, and deeply respect the work of those who are so gifted. I hope only to aspire to a fraction of that ideal.

So I grant you then that 3D printing is simply the act of producing kit parts from which we can build our models. I will however contend that the drafting aspect is still much more involved that just doing layout work. The 3D work we do in ‘Model Space’ and still contend are solid forms, can be used to provide dimensioned layout sheets as would be used for hand fabrication. However, we now have the technology available to have our models milled or print as a kit in any scale. 1:1500 through 1500:1 (as an example.)

To date my only 3D printed kit has been in collaboration with Mad Mike on the 1965 Indy DOHC Ford, and yes we did digitally drill every hole for the bolts and linkage. Mike even went as far as to create all the hose fittings, linkage, bolts, nuts, and hex socket cap screws, some with holes for safety wire. The dilemma is that in order for Mike to print the model in 1:24/25 or even 1:43 he had to go back and fill all the holes and fuse/union all the nuts and bolts, etc. to the larger units.

For the sake of argument then can we also say that any machine work which involves the digital programing of mills, lathes, and routers would take those operations out from under the heading of scratch building?

-

Thanks for your kind words. The miller is a Chris Etzel resin kit which had a assortment of metal castings and photo etched parts. He also used Top Queen/Willis Finecast wheels and tires for several of his kits. Yes, this is one of my favorite color schemes.

-

-

One sentence game

in The Off-Topic Lounge

Posted

Strangers can be unsettling.