-

Posts

533 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Posts posted by Big John

-

-

Song Bird was Sky King's airplane's name.

-

Nah, that's the wood grain showing through. As Peter said, it was great to se how the 1:1 Sears Motor Buggy was designed and built. Something that most of us would never imagine, you captured so well. I especially like the tie down straps for when the top was down. If you don't mind, what CAD program are you using? Nice organic shapes to the top and the dimond tuck seat is deelightful .

Thanks again for a fun ride.

-

As memory serves, most all British cars, until recently, ran on 6V systems. So it would make sense for Bentley to use two 6's to get their 12V.

-

Disguise your 1500HP 917 mill in the back of a lowly VW Ghia.

-

6 volt no doubt.

-

Morning has broken is one song but do wa diddy was by Leon Redbone.

-

Love It! Knockoffs and hubs with threads and all.

-

7 hours ago, Scooter757 said:

My build is the Accurate Miniatures 1963 Grand Sport. I’ve had it in my stash for many years and with ACME show coming up in October with the Corvette theme wanted to start it up. Started to research the #4 Corvette that was driven by Jim Hall and Roger Penske. This kit looked somewhat basic for detail but is pretty nice.

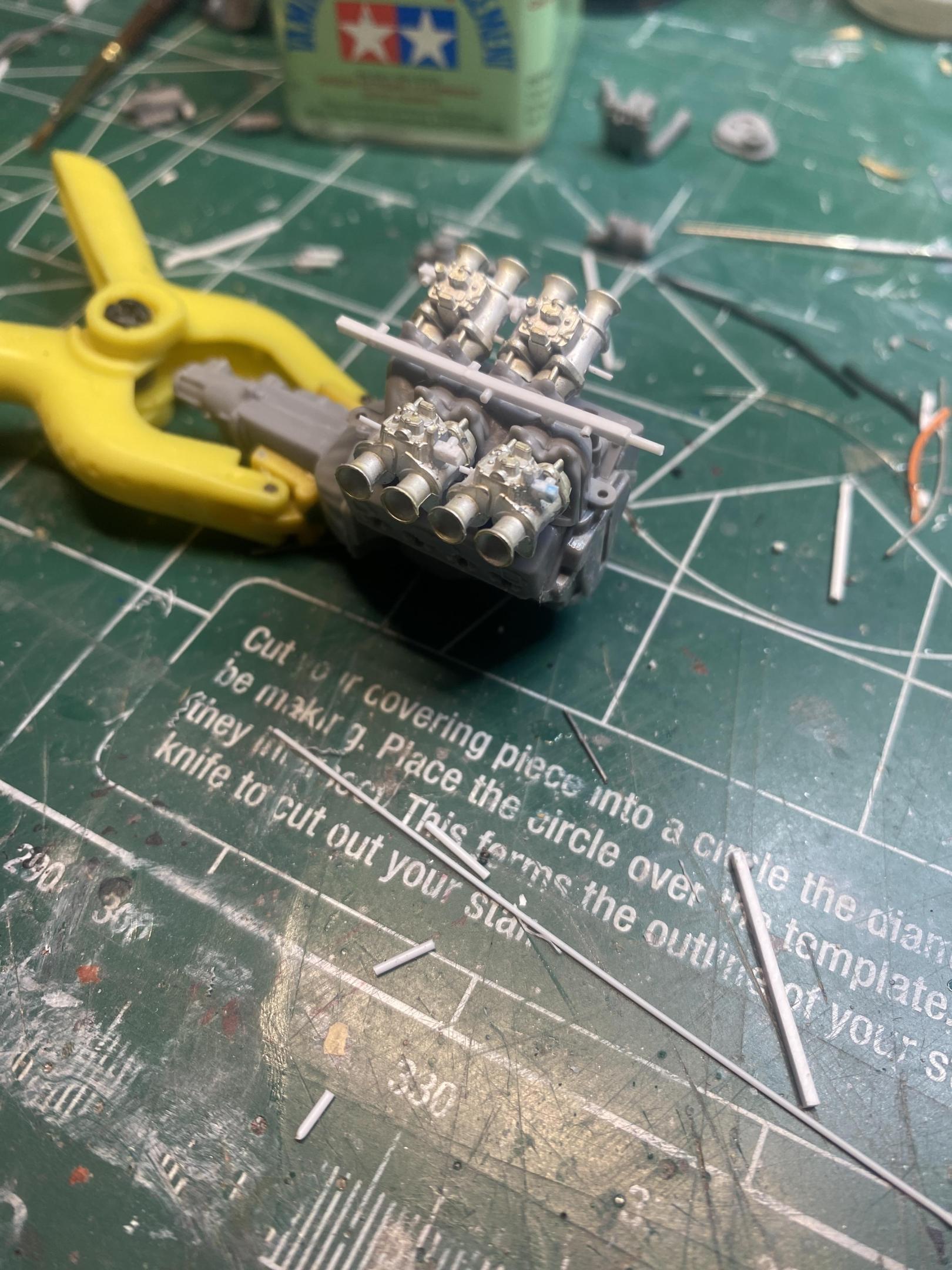

I started with the engine with plans to install throttle linkages and fuel lines.Are the Webers an linkage stock kit parts? The carbs look to be cast metal. ?

-

Fantasy is what modeling is all about, realizing your fondest dreams in scale.

-

Cool! Does it have any affect on the fragility (it's Italian you know) of the older decal sheets? +-?

-

interesting idea with the sun bleaching. Keep an eye on your reds they tend to bleach out faster than the other colors.

-

Thanks Ken, you confirmed my thoughts about the speed control and reverse action. If the center of the flywheel were dished a little you could achieve a true neutral with no additional wear on the friction wheel. Very cool, thanks again for taking us through this project.

-

Hi Ken, going back to your third reference pic I see now how the transmission of power gets transferred to the drive axle. It is the friction drive between the engine flywheel and the small spoked friction wheel. No gearbox required. Dash It All!

-

Outstanding, can't wait to see the transaxle/gearbox.

-

great work on the drive line and chains! Scale roller link chain can also be had at MFH and Micro-Mark railroad accessories. Not everyone wants to invest their time and big bucks in machining equipment just to join the "Real" world.

-

Fantastic eye for detail Ken, and skilled draftsmanship. Love the break mechanism, springs are bear in CAD.

Thanks for sharing your project with us, looking forward to getting color on this cutie.

-

Son, you're gon'a drive me to drink'n if you don't stop driving that Hot... Rod... Lincoln!

-

Hi François, Looking at the 1:1 green leather in the previous post I would suggest trying a reverse casting of a fine grit sand paper as a possibility. 380 or 400 grit coat liberally with mold release and spread a thin coating of urethane mold making RTV this should give you a dimpled surface more closely resembling the leather and be fairly flexible.

-

Cars was a song by "The Cars".

-

Solo he wasn't unless you don't count the Wookiee.

-

Section and Chop are two of the basic techniques used in custom car fabrication.

-

"Star Your Engines" usually signals the start of an exciting racing event.

-

Not to get too far off topic but Fernando does post the 251 fairly often on theebay auction site. Bellow is one that Curt Raitz had at NNL West22. I navee several of the FP models and am fascinated by Fernando's use of embedding wires for the suspension or in this case for the fender mounts!

Looking forward to the rest of this build.

-

2

2

-

-

Absence of anything good to say deserves silence.

3D Printing........Scratch Building or Not?

in General Automotive Talk (Trucks and Cars)

Posted

As I see it, the basis of our hobby is to create scale representations of our favorite, historic, or fantasy vehicles. To that end we use a vast variety of tools and materials to realize that vision. The selection is nearly limitless in scope, paper to plastics to metal. I think that most of us started off in our youth with commercial kits as a basis for our building and progressed to more sophisticated construction and detailing methods as our dedication to the hobby grew.

CAD drafting and its associated 3D printing are just a couple of the newest tools and materials to become available to us. To those who believe that CAD drawing is “Just putting parts together” really have no concept of the amount of work that goes into our drawings. The CAD detailer creates every nut, bolt, screw, and complex shapes as 3D solids and surfaces within the CAD program.

Just like any other discipline within the hobby, once the parts are shaped and ready for assembly we are all just putting together our kits be they machined metal, cast in resin, or printed in a plastic medium. Going beyond the basic assembly of our kits, all the detailing and finishing is Scratch building.

Model On