Art Anderson

Members-

Posts

5,052 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Art Anderson

-

Max Wedge components could be gotten over the parts counter still, though. Art

-

Those neoprene rubber tires were a left-over from AMT's "Authentic Model Turnpike" slot racing cars and sets--I believe those got sent the model kit assembly line for the '58, just to clear them from inventory, as by the time AMT produced the '58 Chevy, the Turnpike had been discontinued (IIRC, that racing set was a pretty dismal failure, sales-wise) Art

-

Update 1/23/16: Moebius 1961 Ventura Hardtop

Art Anderson replied to Art Anderson's topic in WIP: Model Cars

Earl, Pontiac engines, from 1959 through 1965 were an aqua (or a light turquoise) color, which is what I replicated to the best of my ability, not having a paint chip to compare with--it can show up slightly different in artificial light, and on some computer monitors. Pontiac went to a light metallic blue for 1966-70, then a straight, non-metallic light blue after for a few years. Art -

The name of the alloy almost always used in diecast toys and models is Zamak, specifically Zamak-7, which is an alloy of zinc, aluminum and copper. When properly made, this alloy is actually very strong, and quite stable (witness the literally millions of automobile door handles that have been made from the stuff!). but if the manufacturer of the raw alloy isn't careful, impurities can get into it, and that is what causes the disintegration you're seeing, called "intergranular corrosion". The primary contaminants that can cause this corrosion are lead and iron, both of which can be found in say, scrap copper (solder used on copper plumbing used to contain a fair amount of lead, for example). Yet, even though decades ago, people turned up their noses at anything made from this so-called "pot metal", one of its early uses in automobiles was the casting of carburetor bodies, followed by door handles, window cranks and dashboard knobs Conscientious manufacturers who use this alloy for their products do insist on clean metals being used to make the Zamak they depend on, but occasionally (particularly overseas) contaminated scrap metals find their way into the making of Zamak ingots. But, when properly made, Zamak is quite stable, and has a pretty long life. With say, diecast toy cars made primarily for children to play with, those have to undergo random testing before being shipped, to ensure that there is no lead in them, but I suspect that high-end diecasts aren't necessarily subject to that kind of screening, given their "adult collectible" status and marketing. But, the long life of Zamak castings has put the lie to a statement made nearly 50 years ago by the then-President of the AACA, that nobody would ever try to preserve or restore post-1950 cars, due to all the "pot metal" components in them, most notably Zamak carburetors--he turned out to be badly mistaken! Art

-

Update 1/23/16: Moebius 1961 Ventura Hardtop

Art Anderson replied to Art Anderson's topic in WIP: Model Cars

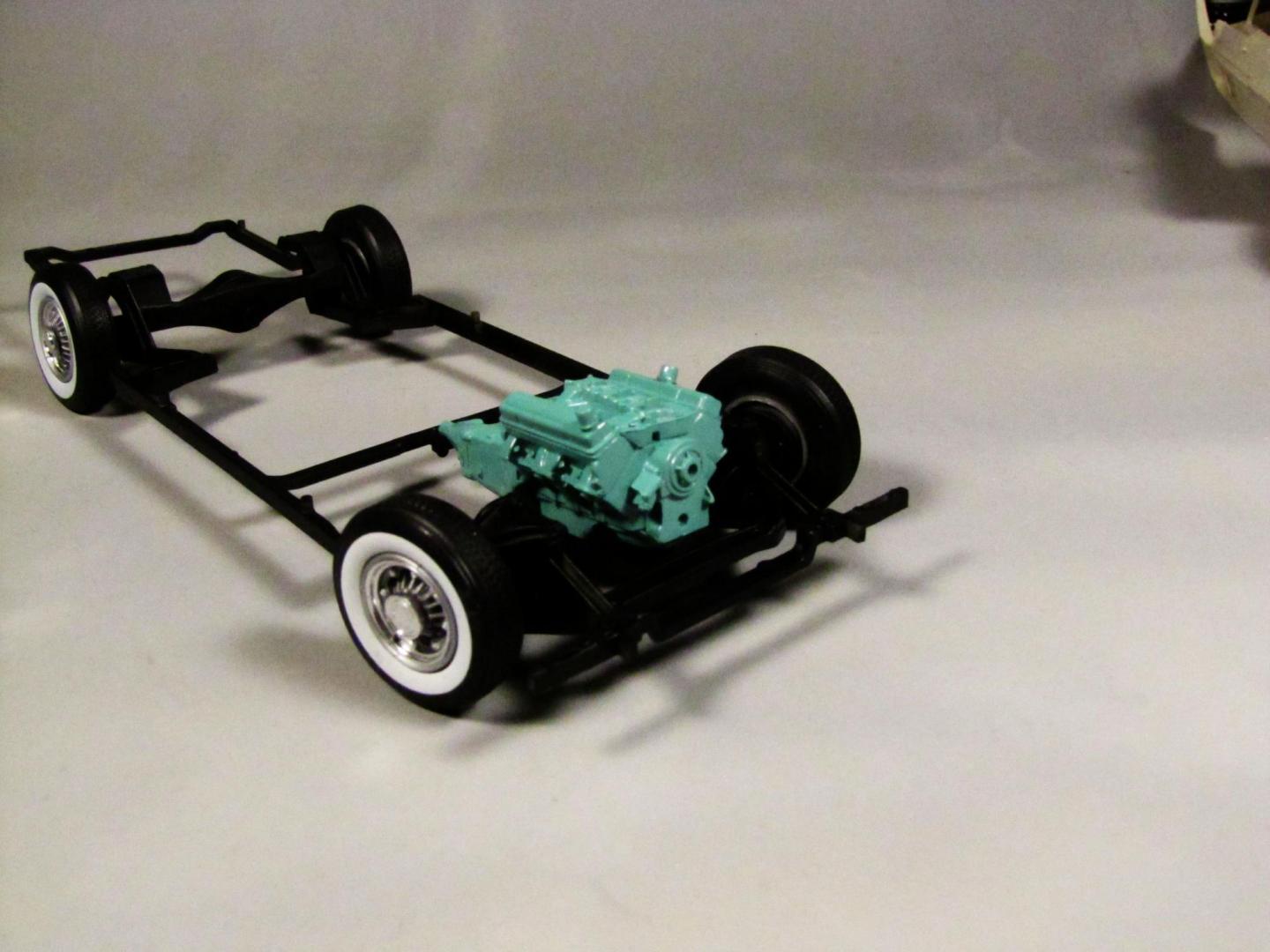

Engine is assembled, added a dip stick to it, mixed my own turquoise engine paint (turquoise was the color for Pontiac engines 1959-65) from several colors of Testors enamels). Test fitted into the rolling chassis. -

Not at all likely--seeing as Round2 owns the tooling for the IMC '48 Fords. In addition, the old IMC '48 Ford coupe was based on their convertible kit, and Ford convertibles then used a completely different winshield and frame than was found on coupes and sedans--very much the same way that GM and Chrysler were doing at the time. I'm going to suggest that this is an all-new body shell and interior made to fit on the Revell '48 Ford Convertible kit. Art

-

The least kitted brand....

Art Anderson replied to khier's topic in General Automotive Talk (Trucks and Cars)

In all this discussion, bear in mind that over 1,500 makes of automobiles have been produced in the US, and only a relative few have ever been done in model kit form, in any scale. Art -

The least kitted brand....

Art Anderson replied to khier's topic in General Automotive Talk (Trucks and Cars)

AMT Corporation made model kits of every model yearconventional Buick from 1958-66, several years in both hardtop and convertible versions, along with the 1961 Buick Special station wagon, and a 1966 Skylark. Riviera's were done by AMT 1963-65, along with front drive Riv's later on. Monogram did a 1970 Skylark in 1/24 scale, and there was a late 70's, Monza-based Skylark (US Airfix?). Monogram also did the 1976 Grand National. -

The least kitted brand....

Art Anderson replied to khier's topic in General Automotive Talk (Trucks and Cars)

Yatming did an excellent 1961 (which was updated to 1962 by Ford when making changes to the car) Lincoln Continental Convertible, as the X-100, the Kennedy Presidential Parade Limousine, in 1/24 scale (it's HUGE and HEAVY BTW). Art -

The least kitted brand....

Art Anderson replied to khier's topic in General Automotive Talk (Trucks and Cars)

in 1/24-1/25 scale, a fair number of Lincolns have been done as kits: 1927 Lincoln Roadster and 1928 Lincoln Sport Touring by MPC, 1941 Lincoln Continental Convertible by Monogram, 1948 Lincoln Continental Convertible by Pyro (later produced by both Life-Like and Lindberg), 1959-1969 Lincoln Continentals ('59-'65 were done both as convertibles and hardtops) from AMT. Of the 50's and 60's Lincoln Continental kits in this scale, the only one that has ever been reissued is the 1965 Convertible. in 1/32 scale, Revell did a very nice '56 Continental Mk II, and Ideal Toy Corporation did a larger scale full detail kit of that same year. Art -

Ford 4 cylinder speed parts source

Art Anderson replied to STYRENE-SURFER's topic in Model Building Questions and Answers

The long-running AMT '29 Model A Roadster has an OHV head in it, as an option also. Art -

Model Master Silver Paint

Art Anderson replied to TomZ's topic in Model Building Questions and Answers

I've never had a problem using any of the ones I've had or have time-after-time. One thing I do after each use is to GENTLY wipe off the excess paint from the tip (do not exert any "pull" on the tip, as that can pull it out irreparably!), then make sure I get the cap on completely. Also, be sure to shake up the pen before uncapping it for use each time. Art -

Model Master Silver Paint

Art Anderson replied to TomZ's topic in Model Building Questions and Answers

Pentel, Pilot, and PIGMA Micron all are lines of very fine-tipped artist's marking pens, which have a hard point, that transfers paint to whatever surface. They can be had with points (tips) as small as .25mm, although their metallic silver and gold pens smallest tips are .5mm, due to their using pigmented paint rather than inks. I love these, the come in a chrome silver, as well as a bright metallic gold, even a fairly bright metallic copper. I've had great luck finding them in the Calligraphy section at Hobby Lobby, sometimes find them at Michael's, even at a couple of art supply stores on occasion. Just follow the simple directions on the package! Art -

Think of an aircompressor as being a bit of a heater, simply because compressing air (or any other gas) does heat up the air at least a little bit. Now, think of that airbrush hose as a condenser, as it has air moving through it in which the temperature (at least to a little bit) will cool off as pressure is relieved. In addition, the hose itself can be at least few degrees cooler than the compressor cylinder (and the storage tank as well). This can allow moisture (from the humidity of the ambient air in your room or workshop (or outdoor air if you work in an area that is not otherwise climate controlled). A moisture trap mounted directly at the air outlet of a compressor or air tank can't collect condensed water from the hose, as the hose is "downstream" from the moisture trap. This is where an "in line" moisture trap does its best job--down the line from the tank or compressor, with a length of hose to allow water to condense out of the air that has had its pressure released. The condensed water droplets can flow down the inside of the first section of hose and be collected in the water trap, allowing drier air to flow beyond, to your airbrush. I got my first airbrush setup (Binks Wren, with diaphragm compressor and a length of hose, WAY back at Christmastime 1961. My bedroom (and my model building area) were in the basement of an old house (I live in mid-north Indiana, where it can be humid 24/7, 365 days a year--plus one more for a leap year), and I soon discovered that I was getting tiny droplets of water spitting intermittently out of that Binks airbrush. Fortunately, one of our neignbors was both a commercial artist (Mr. Nelson did advertising art for our local newspaper back then) and was a good customer on my paper route. As it was he who suggested I was ready for an airbrush, I asked him what I was doing wrong. His answer? Get a water (moisture) trap and a second length of hose to connect the water trap to my compressor--so I spent another $16 (a fair amount of change for a 17yr old in 1961-62!) hooked it up as Walter advised, END OF PROBLEM! The Binks Wren airbrush died about 35 yrs ago, and that Binks compressor went to Air Compressor Heaven a few years later, but I still use that solid brass Binks water trap to this very day--and no matter the humidity, no matter the season of the year (and I still live in the same city), I never get droplets of moisture in my paint. Art

-

Update 1/23/16: Moebius 1961 Ventura Hardtop

Art Anderson replied to Art Anderson's topic in WIP: Model Cars

I tried, but it wouldn't let me. -

I think for one very simple reason: AMT's designers and pattern makers were working off an actual car, owned by a private individual (Dave Wilder and his wife), probably without much assistance at all from Volkswagen. There is a considerable lead time in mastering and tooling up a model car kit, in addition to Lesney taking over control of AMT Corporation during that gestation period. Art

-

Update 1/23/16: Moebius 1961 Ventura Hardtop

Art Anderson replied to Art Anderson's topic in WIP: Model Cars

That mold parting line was inevitable, due to the shapes of the bumper. Without having the mold come open in that area, you'd NEVER get the bumper out of the mold--due to the severe undercut due to the "wrapped" curved bumper ends at the wheel arch. Such parting lines happen virtually every time a bumper with that shape to the ends of it has to be molded in a model kit. Art -

All I know is, depending on how the tooling is laid out, and depending on what all additional parts need to be tooled, given the nature of model kit tooling in the era when this particular kit was tooled, it can be difficult to almost impossible to just go in, add new parts to a hardened steel injection-molding tool. Art

-

I'll try and shed a little bit of light on this: AMT did two VW kits in the late 70's, shortly before their looming bankruptcy prompted Lesney to step in and buy the company. The VW Rabbit kit was first, coming out in 1978, done off an actual Rabbit (not photo's & drawings) owned by their then-Art Director, David Wilder (whom I got to know pretty well then, as I was doing a lot of box art models for AMT). Wilder followed up his Rabbit a year or so later with a Scirocco, which AMT also developed into a model kit, but IIRC, Wilder left the company before the Scirocco kit was released. Art

-

Got a decent start on this kit! It's one that was an almost unanimous recommendation from those of us who were asked, by Moebius, to come up with a short list of model car subjects for their consideration, way back in the spring of 2008. I started with the 8-lug wheels, and as Bill "Mr. Obsessive" Geary has shown, the wheel rims can benefit from having their inner flanges thinned down a bit, which I did using my Sherline mill and a 1/8" square-nosed carbide cutter. A word of caution here: Do not thin these down too much, as the styrene is a bit brittle, especially with a sharply definded "corner" between the inside of the rim and the flange--I broke a flange completely out of its rim due to my making it a bit too thin--fortunately I have a set of final round test shots, which provided a replacement). The finned center of these wheels is actually the finned, cast aluminum brake drum, which was not polished, just left as dull aluminum castings at the factory. I painted mine with Tamiya TS-30 Silver Leaf dulled down with just a tiny bit of TS-29 Semi Gloss Black from Tamiya (both decanted from spray cans, and airbrushed on). The rims are TS-30 Silver Leaf over red oxide primer, with the lug nuts detailed using a Pilot brand bright metallic sliver .5mm artist's pen. I drilled a .020" hole into each plated beauty ring, and inserted a short bit of .020" brass rod which is painted black, for the valve stems. I simply press-fitted the beauty rings into the rims, seating them in place with my fingernails, no glue needed as they are a rather snug fit. Again, due their somewhat tight fit, care is suggested here, as the beauty rings are a bit fragile; pushing them in carelessly will break them!. After gluing the brake drums into the rims (be sure that the small round raised "indicators" showing between every 2nd and 3rd fin align with a lug nut "tab" for correct fit and appearance here. In this pic, the wheel on the left nearest the camera is as the parts are molded, the wheel in the background has a modified lug nut flange: http://images34.fotki.com/v1633/fileisKX/e6d27/4/43743/3168549/Venturawheelfinished.jpg Assembled and finished rim: http://images34.fotki.com/v1633/fileisKX/e6d27/4/43743/3168549/Venturawheelfinished.jpg Assembled chassis with wheels installed. Note that you can set the front wheels in a turned pose, as the kingpins are round, very precise fit into the A-arms. http://images60.fotki.com/v662/fileafyv/e6d27/4/43743/3168549/61Venturachassisrightside.jpg Art

-

Hobby area flooring ideas?

Art Anderson replied to crazyjim's topic in General Automotive Talk (Trucks and Cars)

Living in an apartment that is mostly carpeted, I hit on the idea of using surplus carpet remnants to cover the floor in the spare bedroom where I do my building. I find those remnants in office supply and other stores here every August & September as university students are arriving back on campus here, setting up their residence hall rooms and apartments. They are fairly large (6' X 8' seems to be the most common size, are fully bound around their edges, and are close-weave, closed knap carpet). These protect the floor underneath from any minor spills, and as long as I keep my work area reasonably clean and straight, any dropped part can usually be found very quickly. I paid no more than $10-$12 for each of the 6 I put down in there, so it was an inexpensive solution. Art -

Further on Bill Geary's excellent tutorial: I just got done studying the glass here, and found that there is a mold parting line all the way around the edge (and on the edge) of the windshield, making for a very slight "pent-roof" shape there, when that edge itself should be flat in cross-section. I took a flat fine needle file, and gently filed this down all the way around the glass, and believe it or not,that took care of the problem. Total time elapsed? Less than 10 minutes! It's not necessary to even touch the visible surfaces of the glass when doing this, and the needle file works very well, as it's stiff (of course) and doesn't "wrap around" like sandpaper can. I'm now toying with the idea of gluing in the windshield and back glass before priming and painting,simply masking off the glass and it's molded on trim moldings prior to painting. Art