-

Posts

227 -

Joined

-

Last visited

krassandbernie's Achievements

MCM Friend (4/6)

-

AMT 1934 Ford 3W conversion

krassandbernie replied to Chris V's topic in Model Building Questions and Answers

https://www.modelcarsmag.com/forums/topic/144491-1934-ford-3-window-coupe-not-chopped/ -

Drag City Casting FB Post

krassandbernie replied to Sledsel's topic in Car Aftermarket / Resin / 3D Printed

Cameron, I agree with many of the points you made here, but not all of them are entirely accurate or as black and white as you make them out to be. I was actually against being on FB for years until I was pressured by friends and family to give it a try. In 2018 I created the Drag City Casting business page on FB and was extremely busy with sales for quite some time. For a couple of years the average waiting time for me to process an order was 2-3 months due to the volume of sales. Fast forward to the past year or so and I finally came to the conclusion that FB is no longer sharing my product posts with all of my 19k followers like it once did.......like it was originally set up to do. I also learned that FB is actively pushing out businesses who do not wish to pay for their advertising. I was told by others who have paid for it that it did not work for them at all........as in no sales from it. Why throw money down the drain then? So giving people notice of the current standing of my business and telling anyone reading to "get it now while you still can before I shut down this FB page and get a regular job" now equates to guilt tripping? That seems to be a very liberal way of trying to shame or slam someone on social media these days and I'm tired of it. Those who want to bash me are quick to say things like this without putting themselves in another person's shoes. I have seen many cottage industries close up shop over the years and it never fails that everyone states (after the fact) how they wished they would have known it was going to happen so that they could have helped keep them in business longer or stocked up on stuff before it was too late. Since it is largely hit and miss with my posts on FB I've made more than one post over the past year or so letting my customers know that this was where I was headed (closing down) if things didn't change. In between those posts things might have improved temporarily and I kept plugging away until noting a huge decline in the average monthly sales again......thanks each time to FB NOT sharing my posts with my followers. I didn't know for certain that this was the main issue and had to "fish" to find out if it was FB screwing things up or if people were no longer interested in what I was offering. Many of my followers would see my posts questioning if anyone is seeing my product posts and realize that they were not seeing them much or at all up until that point........but that they once did before. They would subsequently place an order for something they would have purchased sooner had FB showed my product posts to everyone following my page. I had a web site and an eBay store many years ago. Both cost more money to maintain than they brought in at the time so I shut them down. My FB business page is basically the same thing as a web site but without a shopping cart, and it gave people direct access to easily communicate with me through messenger. If they had a question they didn't have to wait days or a week for a response through e-mail like you do with so many web sites. Again, this was doing quite well until recently. My product has been featured in quite a few YouTube videos over the past 6-7 years, as well as a number of model magazine articles over the past 20+ years too. Spotlight Hobbies has also been selling my product for the past couple of years for those who are not on FB.......or wish to check out with a shopping cart or pay with a credit card. Modelhaus (Tires) has a web site but absolutely no way of communicating with them, and Norm Vebber is still kicking it old school with no on-line presence at all on his own accord. He is still strictly mail order for decades now in an age when everyone is shopping on-line. There will always be people who complain you don't have a web site, aren't on Instagram, YouTube, eBay, or etsy, don't take cash app, or Venmo because they hate PayPal, or they won't purchase anything unless they can use a credit card. There are just way too many options and venues these days and everyone feels you should offer every conceivable option to them.....to suite the customer. I feel like you have to be all over the place all the time and it doesn't leave you any time to create the actual product you are selling. I am still making new molds......just this past spring I stopped casting long enough to do so, and I am about to again. Not everything is worth the amount of work it takes to re-mold, especially due the rising cost of materials and demand falling off for certain cast items. The days of keeping everything you ever offered in your catalog on-line for years are long gone. It simply doesn't make sense to do that.....at least not for me. If the demand drops off I quit molding it. Molds deteriorate with time even if you are not using them. That forces you to use up your valuable time and materials producing all of the product you can out of a mold and leaving the castings sit on a shelf hoping it will sell at some point down the road.........waiting to get a return on your time and money while you scramble to make ends meet producing something else.......and you might not sell it all off. I don't have that kind of time or money for a "maybe". You are right in that I now have a very limited/small list of items to offer at this time. I had to phase out all of the small parts and items that were eating up my time and only bringing in peanuts. I realized that by producing bodies over parts I could (in layman's terms) produce a product valued at 3 times as much money in half as much time using the exact same amount of resin. What wise businessman would not cut out the items eating up labor and materials and not being as profitable? At the same time I started phasing out the less profitable items (which 3D printing has already been gobbling up) the help I had with master work (being created by someone other than myself) dried up. I am simply spread too thin now trying to create a whole new catalog of masters, make molds, cast/fill orders, and network on-line. Had the masters kept rolling in every so often things would likely be quite different now. I'm not blaming others here. This is simply what has taken place. I have had a few others offer up some masters but I had to respectfully turn them down since the quality was not up to par with what I offer, and what my customers have come to expect. As you can see there was a valid reason for me to respectfully turn down each of those marketing suggestions you listed off above that others have mentioned. What may work for others doesn't always work for everyone else. I think for me being a one-man operation is my biggest set back at this time. There simply is not enough time or energy in a day to do it all. You do have me re-thinking a web site again so that I might possibly funnel everyone to one location that I have more control over, so thank you for that! Ed -

I don't recall saying that. I suggest (with my resin) that you simply wash it in regular Dawn dish washing liquid and luke warm water prior to primer. My resin does not need to be soaked in anything to remove the mold release agent because it is a paint-able release agent. When I have mentioned lacquer thinner it was in regards to stripping paint off of the resin, and even then it was not suggested that you soak the resin in lacquer thinner but rather wipe the primer or paint off with a dampened rag or paper towels followed by a wash with Dawn again before starting over............just don't want anyone reading this info to think otherwise.

-

Drag City Casting Hot Rod Bodies

krassandbernie replied to Dennis Lacy's topic in Car Aftermarket / Resin / 3D Printed

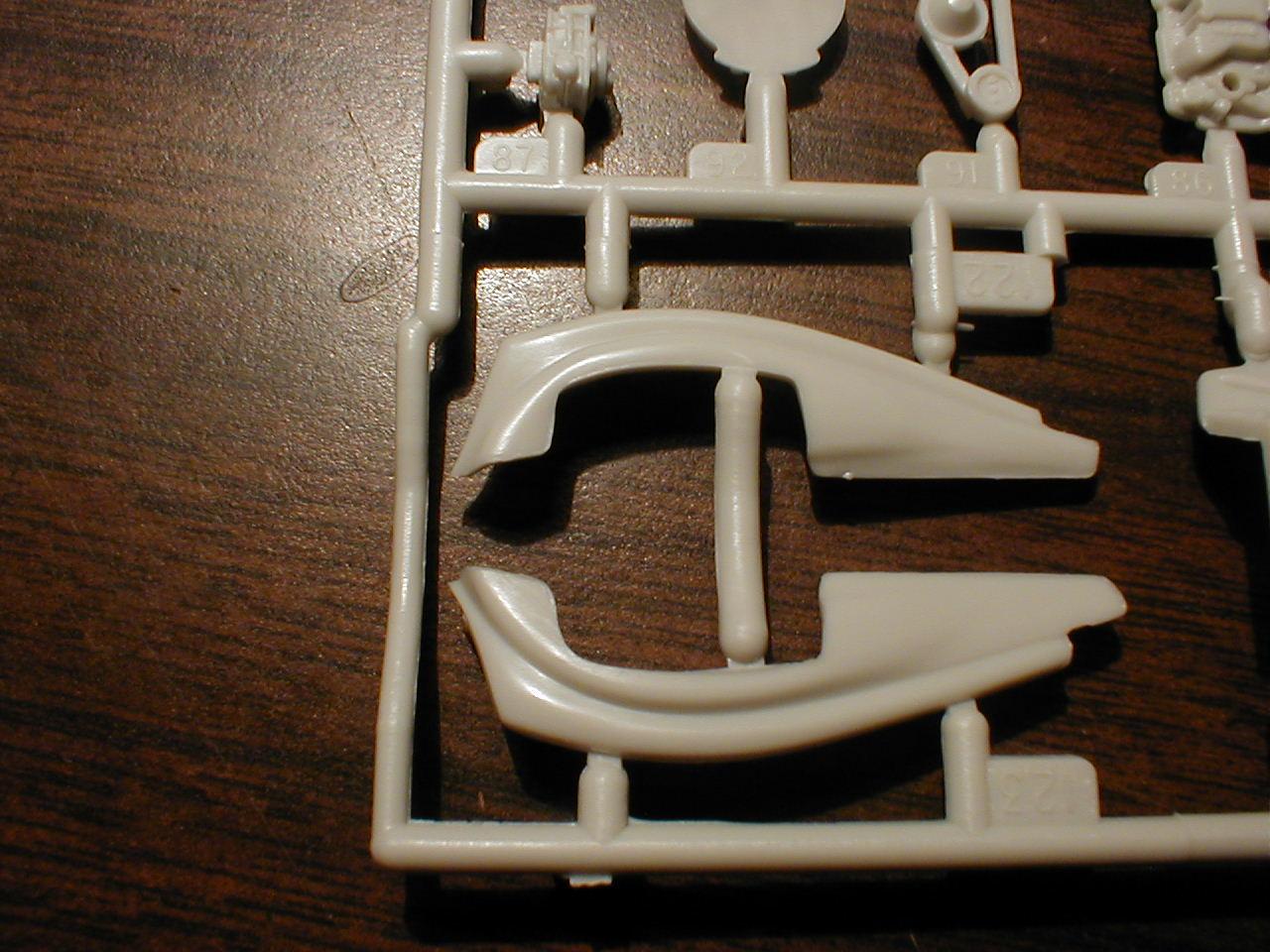

Thanks for the post (Dennis), and the kind words! The chopped '34 Ford 5 window coupe body is just about off-line for good. It will be discontinued indefinitely since the master did not hold up this last time from previous repairs and re-chopping the roof.....after making 3 new molds in a row. I now have less than 20 of these bodies in stock and will likely only get a few more out of the molds if that. The front splash aprons for it have not been available in over 15 years now and are not included with the body. The splash aprons in the kit have a huge notch cut out of the center so I molded these. Craig Turner mastered them and offered them to me a long time ago. They can be ordered along with the coupe body (or if you order something else they can be added to an order). I have gotten away from offering small parts since they eat up too much time for too little profit being a one-man operation. So, I will not ship a set of splash aprons alone I am sorry to say. -

Silvercreeker started following krassandbernie

-

Calb56 started following krassandbernie

-

Tarkmucker started following krassandbernie

-

This is shaping up to be a fantastic build! I don't know why so many modelers these days gripe about this particular kit (the AMT kit, not my resin body). They keep comparing it to the Revell '32 Ford kits as one is naturally comparing apples to apples here. I think the AMT '34 Ford 5 window coupe kit is a pretty decent kit out of the box and you don't get all that many more options with half of the Revell '32 Ford kits either. This leads the average hot rod model car builder having to scratch build, kit, bash, or modify a few parts here and there to suit their project..............exactly what you have done here.........EXACTLY what you see most builders of the Revell '32 Ford kits (take your pick) doing. I am still left scratching my head at the absurd comments I receive regarding my resin body.........."I'd buy it if it were based on a Revell kit"...........which none exist currently by the way if you are referring to a standard 1/25th scale (non-snap tite) '34 Ford. At any rate, I am very excited to see this one completed! Great work!

-

Tom was an excellent resin caster. I was just telling someone about him this evening in a conversation regarding resin casters from 20+ years go. I have not kept up with him over the years........the same goes for Shawn Carpenter. Shawn didn't have a large catalog but his resin conversions were very high quality. I always thought both of these guys put out a product as good (even nicer quite frankly) than the average stuff Modelhaus churned out..........having ordered from all three back in the day.

-

57 Ford Wagon Gasser Street Freak

krassandbernie replied to Silvercreeker's topic in WIP: Model Cars

And here I was thinking you got one of the last teardrop hoods FOR the Revell kits that I offered! LOL! Great job! Where did the wheels come from? Were they from this kit? -

toyotech started following krassandbernie

-

I know you weren't.........and I certainly did not take it that way. I was just clarifying for anyone else reading because we both know someone would take your remark to mean that most resin is prone to be thicker than styrene parts and cause fitment issues like being discussed here. Then I would possibly lose out on sales because of that assumption.

-

I find it extremely difficult to believe that my resin body was the culprit here. Dennis received one of the first couple castings out of the mold, which would be more exact and on-point then the casting I compared here to Dennis' master. This casting is somewhere around the 50th one out of the mold and it is darn near spot on. If it is a hair thicker (on the sides) it would barely be noticed and certainly not cause any fitment issues since the body can easily be spread out or pinched in to fit a chassis.......and any amount of play needed here would not even equate to the wall thickness of the casting either. I am one of the few resin casters who pays strict attention to things of this nature. I am constantly comparing wall thickness of the castings to the original master throughout the life of a mold and try to correct any casting procedures (if needed/or possible)....again, if something were to crop up. I also design my molds in such a way as to prevent this from occurring in the first place. While I can completely understand how one would quickly come to your (possible) conclusion based on the history of castings in the automotive hobby over the past 20+ years I would still like to make it known that this is not likely the case here! LOL!