lets try this.

The colourful exploits of the Silver Bullet has been told and retold countless times over the years. We know what the did- but why was the legendary car so successful? Let us return to yesteryear to find out how this Plymouth GTX became "king of the street".

As safety and responsible driving attitudes were of paramount concern in Detriot-especially on Woodward Ave.-between 1969 and 1973 (as they are here today at Mopar Action), folks were modifying their cars to give them more peace of mind when "passing on hills." Not that stock Detriot iron wasnt't up to the task, mind you (Chrysler Corp. built some of the safest), it's just that a few super safety-minded folks wanted a tad extra security for the wife and kiddies on their way to the Sunday after church family picnic (non-alcoholic beverages) in the park.

The silver GTX you see here was built with that idea in mind. The car began life as a Chrysler engineering test car for the A-134 440 Super Commando/Magnum drivetrain package. It was originally painted blue and was equipped with the standard 375 horse 440 and a column operated Torqueflite automatic.After serving at the Chrysler Proving Grounds as a durability mule, it was then used to test cam, carb, intake and header combinations for the RB wedge. The research data gathered during this testing helped to form the basis for the 1970 Hustle Stuff over-the-counter dealer installed speed equipment line. That program evolved later into the famout Direction Connection parts pipeline in 1972. Incidently, Tom Hoover tells us that 8mm film footage exists of this very car, in its original form, being put through its paces, during a Chrysler drag strip test session.

From its assembly date on February 1, 1967, up until some time in early 1969, the car was under the ownership of Chrysler Engineering. Then it was given to James "Jimmy" Addison. Jimmy was into performance and had excellent tuning skills. His personal car up to that point was a 1962 Dodge with a transplanted 426 cube Max Wedge.

Although it was originally wedge powered, that didnt stop Jim from equipping the GTX with a healthy dose of Hemi power. Initially a lightweight Hemi K-member was used to locate the engine. It is unclear today whether it was a special one-off piece made of stainless steel for a '66-up B-body application or if it was a '65 A/FX unit with reworking to fit the later B-body, but the fact is that it began to crack soon after installation and was replaced by a lightened standard issue B-body Hemi K-member. Vintage photos published in the Spring 1972 issue of 1001 Custom & Rod Ideas depict what appears to be a standard Hemi K-member, however it is notable because the Hemi-only steel skid plate has been ground away, most likely for the 4 pounds of weight it saved.

As anyone tooling along the right lane to a family picnic knows, you just can't trust fender emblems. Sure, they may say 383, but that doesnt mean the car has a 383. More likely its a 426! To deal with this situation, Addison substituted a CSC 4.25-inch stroker crank for the stocker to bring cubic inches up to 487. Stock Street Hemi rods and cut down TRW pistons were used to bring compression in at a true 12.0:1. Addison managed a Sunoco station so he had free access to plenty of Sunoco 260 high octane gasoline. A set of 1965 A-990 aluminium heads were used with porting and detail work by Bartley Kenyon. In true Race Hemi tradition, a '65-only magnesium crossram intake and dual Holley 780's were used. The result of it all was enough horsepower to push this 3200-pound B-body through the quarter mile in 10.40 seconds at over 135 miles per hour.

The rest of the car was just as trick as the motor. For isntance, Jimmy worked with B&M testing new transmission parts. He got a prototype high stall torque converter to try out in the car. It was a tiny (for the time) 8-inch unit and it made the car launch so hard that would always pull the front tires 6-inches off the ground. Just imagine seeing something like this happen on the street. Mind blowing! This very converter went on to become the famous B&M "J" converter, a mainstay of Mopar Stock and Super Stock racers everywhere.

Of course the body of this car came in for some serious lightening. With a stock curb weight of nearly 3700-pounds, Jimmy managed to slice out nearly 500-pounds before he was done! Of course, it all started with replacing all bolt-on body panels with fiberglass replicas. This included the hood, front fenders, doors and trunk lid. The bodyshell was stripped of all undercoating, but it was not acid dipped. Throughout the car, aluminium fasteners replaced steel, and in the most curious places, one can find dozens of tiny holes put there by Jimmy and his hole saw in an effort to shed even more pounds. Open the doors and pull the sill plates, you'll find holes. Open the glovebox door-more holes. But unlike some street rats that are cut up that they look ugly, Jimmy did it all so that it is invisible at first glance.

The hood scoop has mistakenly led many people to assume that this is an RO23 Super Stocker with GTX emblems added. This is not the case. The RO23 hood scoops where thin gauge steel in accordance with the NHRA's rules about such things. The one on Jimmy's car is an even lighter fiberglass replica. Of course a quick look at the leaf spring bulkheads will reveal the absence of Hemi-only torque box reinforcements, yet another tip-off that this is not a factory produced Hemi car, RO23 or otherwise. Back to the hood for a second: in late 1970 when Jimmy replaced the crossram with a Weiand tunnel ram and dual Dominators, a tall, Chrysler-designed Bauman boundary layer hood scoop was used, just like the ones which were then just beginning to appear on the most up-to-date Pro Stockers. Heck, Addison got one at the same time as Sox & Martin did. Talk about being factory connected!

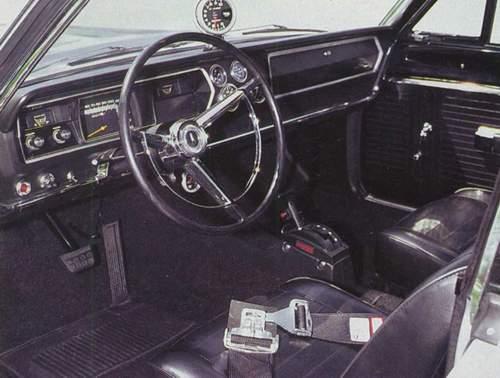

Inside the car, weight was eliminated by replacing the stock front bench seat with a pair of lightweight A-100 vans seats which sit on aluminium A-990 seat brackets. The rear seat was removed entirely and never at any time was this car equipped with a roll bar of any type. If you think that's brave, try this one on. Jimmy never used seatbelts and the car had none! Talk about attitude! But in over seven years of street thrashing the car from 1969 to the time he sold it in 1975, Jimmy never so much as scracthed a fender. Before we move on to the most interesting part of the car, the exhaust system, let's stop to discuss the brake pedal. In his never ending search for weight savings, Addison replaced the stock wide-pad brake pedal with one from a four-speed application. At less than half the width, the smaller pedal saved maybe a pound. Laugh if you want, but this car was never defeated in any matchup that it got into. Maybe all of those little things add up? Count on it.

Okay, now lets discuss the exhaust system. This is where the truly twisted genius of this car and Jimmy Addison shine through. A set of big tube Hooker headers feed into two pairs of 3-inch head pipes. These head pipes are spliced together and welded at an angle. Each of these four head pipes the travels rearward to a muffler. Two mufflers are mounted in the stock dual exhaust location while the other two are positioned under the driver and passenger seats. This four muffler system was created by Addison and Chrysler dyno operator Andy Thomas for minimum back pressure with a reasonable noise level on the street. The noise concern wasn’t so much for the benefit of nearby cops as it was to pre-vent scaring away would-be competi-tors. And for the ultimate surprise, the mufflers used were Cadillac items (p.n. 1492860). It seems that these muff lers were the best thing available from a noise vs. back pressure standpoint. Still available today, these units are speci-fied for 500 cube Caddy applications with single exhaust. Don’t rush out to buy a set, however, as modern muff lers such as those from Flowmaster and Hooker are much better. But back when this car was put together, Caddy muffs were the hot ticket.

The suspension setup relied on tried-and-true Mopar race car theory and practice. As such, lightweight 10-inch drums are found at all four corners, replacing the much heavier GTX 11-inch units originally fitted by the factory. Soft Slant Six torsion bars were cranked down and the lower control arm rebound rubbers were put on spac-ers to bring them closer to the frame to soften the ride over bumps and dips. The nose down attitude wreaked havoc with Jimmy’s custom deep oil pan, but it allowed unreal front end rise and excel-lent weight transfer. At the rear, a set of A-990 Super Stock leaf springs, long Imperial shocks and an adjustable pin-ion snubber were enough to do the job.

Because it was so light at 3200-pounds, Addison was able to get away with using an 8-3/4” rear axle. A stock clutch-style Sure Grip unit in a “742” housing was employed along with stan-dard production axle shafts, neither of which gave any trouble. The ring gear was another story. With huge M8 H 12 or 13-inch slicks, gear life was a little under one year. Jimmy considered going to a Dana but never got around to it. Gear ratios ranged from 4.30s to 4.56s. And to fit all that rubber under the extremely limited confines of the ’67 B-body wheelhouse, Jimmy simply cut vertical slices up the quarter panels, pulled out the area until adequate clear-ance existed, then welded the gaps shut. A bit of bodywork restored the fac-tory fresh appearance, a major point with Addison, who insisted on a factory look.

Within a year of completion, this car had earned a nasty reputation as being unbeatable. That kind of news travels fast and before long, national recogni-tion was being focused on Jimmy and his screamer by the likes of Car Craft Magazine, Hot Rod Magazine and the aforementioned 1001 Custom & Rod Ideas. But it was the article which appeared in the September, 1971 issue of Car Craft which was to have the most impact. In it, writer Ro McGonegal dubbed the car the “Silver Bullet” because of its color and its perfor-mance. To this day, the name has stuck º and car enthusiasts the world over are well aware of the legacy of Jimmy Addison and the Silver Bullet, one of the wildest family picnic and Sunday church cruisers of all time.

Today the Bullet is owned by Troy, Michigan, resident Harold Sullivan. Harold was a part of the Woodward Avenue scene back during the days when Addison and the Silver Bullet were in command. At the time, Harold was just out of high school and had his own ’67 GTX. Of course his was a 440 cube stocker. But many a night passed when Harold was lucky enough to wit-ness the thunderous roar of the stroked Hemi blowing through four muff lers as yet another ’Gammer, Rat, Goat or Boss got a good look at the Bullet’s tail lights. Harold kept telling himself...“some day”.

Now, nearly thirty years later, Harold is the lucky owner of the car he once admired from a distance. Over the years he was able to always keep tabs on who owned the car and where it was stored. Then finally after years of nego-tiating with a reluctant seller, he struck a deal. The owner of the somewhat neglected and now motor-less Bullet agreed to part with the car provided that Harold could come up with a pristine 1970 Super Bird. No cash, just a straight up trade. But that’s not all. The man stipulated that the ’Bird had to be Petty Blue with a white interior and it also had to be a four-speed Six Pack car. Undaunted, Harold ran ads in the national trade papers and put out feel-ers hoping to find such a car. A year later, he scored a mint original paint car in Kentucky and the deal was made.

The car that you see before you is the result of a complete, down-to-bare metal restoration that was performed by Jeff Reif. The objective was to return the Silver Bullet to its appearance in 1970, right down to the Cragar S/S mags, cross ram, small hoodscoop and steel front bumper. Some liberties were taken, however, and they include the use of a motor plate instead of factory Hemi engine mounts, Dart aluminum heads in place of the trouble-prone alu-minum A-990 items and a few well cho-sen internal engine mods such as Stage V roller rockers, and a slightly wilder camshaft grind than the .590 lift Racer Brown stick originally used. As a happy commentary on the availability of Hemi parts, once as scarce as hen’s teeth, the engine is based on a brand new Hemi block from Mopar Performance. Bore and stroke are just what they were when the best minds at Chrysler originally spec-ed this thing out in ’69, the result is a thumping 487 cubic inches.

Originally intended for nostalgia drag strip duty, the GTX was given a change of direction in mid-resto to a show car to preserve a significant piece of Chrysler lore and legend.

I received an email from a fairly unusual looking aol.com address which my spam software almost deleted, but in it were 3 super high res recent pics of Silver Bullet and the following text...