-

Posts

880 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Plastheniker

-

Thanks again! I doubt that they would be interested. But even if they were I would never have the heart to part with one of my favourite models.

- 44 replies

-

- scratchbuilt

- l 10000

-

(and 1 more)

Tagged with:

-

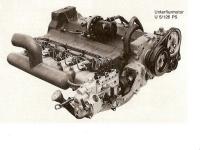

Thanks for your replies! I reviewed my old files and found this nice picture of the 12000 U13 chassis without engine cover. Unfortunately there are no elucidating pictures online showing the engine peripherals of Büssing's underfloor engines. I hope to find some usuable photos in my old truck brochures.

-

Thanks for your replies. Charlie, one could really suppose that this is a flat engine. Actually, however, all Büssing underfloor engines were straight six engines from the conventionals or COEs tilted by 90° to the passenger's side. Of course the engine peripherals had to be modified. Ben, I am sorry, but I built my model long after stopping writing magazine articles and long before starting posting in forums. This is why I didn't take any WIP pictures.

-

Joao, another immaculate model of yours - great job! BTW I can't tell the origin of the Fujimi kit but it is obviously not the Marui kit of the eighties.

-

Clean build, very convincing engine compartment.

-

Hi, Büssing was one of the oldest and most renowned German truck manufacturers. After WW II they resumed production with big conventionals very similar to their pre-war models. From time to time Revell of Germany re-releases an outstanding model of one of these conventionals, namely the 1952 Büssing 8000 S13. Today, however, Büssing is the synonyme for a completely different truck design. In 1951 Büssing presented the Büssing 12000 U13 as the world’s first production underfloor engine truck. By comparison almost any truck (nota bene mostly conventionals) of other manufacturers in these years appeared obsolete: The cab without doghouse offered incredible space. It was even high enough to stand upright in it. Its ultra-modern cubic design and its large windows gave excellent visibility. Far from the engine the driver enjoyed a riding comfort second to none: no noise, no heat, no vibrations, no fumes. Without the engine weight on the front axle the air-assisted steering gave outstanding manoeuvrability. Engine accessibility for service and for repairs was unique. The engine position improved traction and road holding of the unloaded vehicle considerably. Though the 12000 U13 was too expensive too be sold in really large numbers it became the ancestor of many heavy and medium-duty Büssing underfloor engine trucks. Technically ingenious the line of underfloor engine trucks, however, can be considered as the main reason why Büssing failed economically. The underfloor engine made it difficult to drive the front axle and the engine hanging under the chassis restricted ground clearance. Therefore this design was not usuable for the building trade. Thus Büssing was compelled to produce three different types of trucks to match all customers’ needs: underfloor engine trucks, conventionals and coes. For a smaller company this scattering was fatal. In 1971 MAN purchased Büssing and continued to produce underfloor trucks up to 1994. Two 12000 U have survived. They are the undisputed highlights of any vintage truck meeting in Germany. My scratch build shows the earliest version of the 12000 U13 as shown on this contemporary picture. For full visibility of the engine I “removed” the engine cover - as most owners and later on even Büssing did. The intricate chassis, the open platform body and the cab without existing drawings made the project rather time-consuming. Though I could use some identical or modifiable parts of the Revell kit I spent more than 1000 hours building my model. Among all approximately 250 models still in my hands (I really wonder how many models I have built during the past 55 years) this is my favourite model. If I were compelled to give all models away except one I would certainly keep this one. I hope you like it too. A similar topic of mine: 1937 Mercedes-Benz L 10000 Scratchbuilt 1/24 http://www.modelcarsmag.com/forums/index.php?showtopic=75830

-

Andreas, this is an immaculate model with one of the most beautiful colour schemes I have ever seen.

-

Super clean build. Colour combination violet/yellow sounds strange but looks really fantastic!

-

My version of the Freightliner FLC

Plastheniker replied to ghoodii's topic in Model Trucks: Big Rigs and Heavy Equipment

Looks fantastic, excellent colour choice! -

Thanks for your comments!

-

Thanks for your replies so far! Robert, I agree, but I just didn't dare to say. I experienced in another forum that some GTO enthusiasts are not to be trifled with.

-

Jacobus, I totally agree! Jaroslav, I am delighted to hear this from a modeler of such outstanding skills. Thanks a lot!

- 44 replies

-

- scratchbuilt

- l 10000

-

(and 1 more)

Tagged with:

-

Peterbilt 379 with D.T.U.

Plastheniker replied to truckabilly's topic in Model Trucks: Big Rigs and Heavy Equipment

Breathtaking detailing and scratch building, very subtle and thus convincing weathering. Perfect! -

KW W900 Aerodyne Snap tite 1:25

Plastheniker replied to Pavel A.'s topic in Model Trucks: Big Rigs and Heavy Equipment

Really outstanding job, Pavel! 1:25 Snap Tite? Another proof that it is the modeler and not the kit that makes or breaks the model. -

Hi, Though the Ferrari 250 LM was intended to be the successor of the 250 GTO there were only two kits of the Ferrari 250 LM produced by major kit manufacturers. The first was a terrible Esci kit. The second kit was made by Sunny/Academy/Minicraft. It was released more than 30 years ago and has been reissued several times. Only few modelers seem to be happy with the Sunny/Academy/Minicraft kit. I built my model maybe 15 years ago, and I found it not that bad. I remember the following major problems: The panel lines are not very deep and not clearly defined, i. e. the panel lines do not have sharp (90°) edges. Instead the edges are strikingly round. This makes the panel lines look very wide, and their width seems to vary. This would spoil any model. As a remedy I scribed all panel lines considerably deeper and sanded the body until all edges looked satisfactory. All grilles are molded plastic. The front grille is acceptable because it is recessed and because it is black on the 1:1 car. The 3 molded-in rear grilles, however, are flush and painted in body colour on the 1:1 car. Since I found no way to make them look realistic I replaced them by segments of a universal PE fret. The plastic “wire” wheels of the kit are really crude. Since the 1:1 car has strikingly different wheel sizes front and rear the model wheels attract the attention even more than usually. Using PE wire wheels will be a bad and expensive compromise if this specific feature of the car is not replicated. The web shows examples where wrong rim/tyre sizes make good models look strange. As always I made my own wires, so I didn‘t have to compromise. Provided that you tackle its shortcomings the kit makes a unique and at least acceptable model. For me it became one of my favourite Ferrari models. Similar topics of mine: 1962 Ferrari GTO http://www.modelcarsmag.com/forums/index.php?showtopic=78461 Making real wire wheels in all scales http://www.modelcarsmag.com/forums/index.php?showtopic=77554

-

Very clean build of an unusual and interesting car. As a former military modeler your paintwork impresses me most. This constant marginal shine on all parts is perfect and really hard to achieve.

-

Outstanding job as all your models I saw! But these modern wheels on such a classic - what would Ferrari say ... (I don't know either)

-

Oscar, this is simply perfect and really looks better than the original car! Hard to believe that the body is not painted.