-

Posts

364 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by John Clutch

-

Than you DeeCee, Im working on the firewall atm, and I hope to have something for you guys to look at later tonight.

-

Thanks Mike. I'm enjoying working on it. I'm a b body fan as well, and the second gen Charger is by far my favorite body Chrysler ever put out. I wish they made a 1:12 version.

-

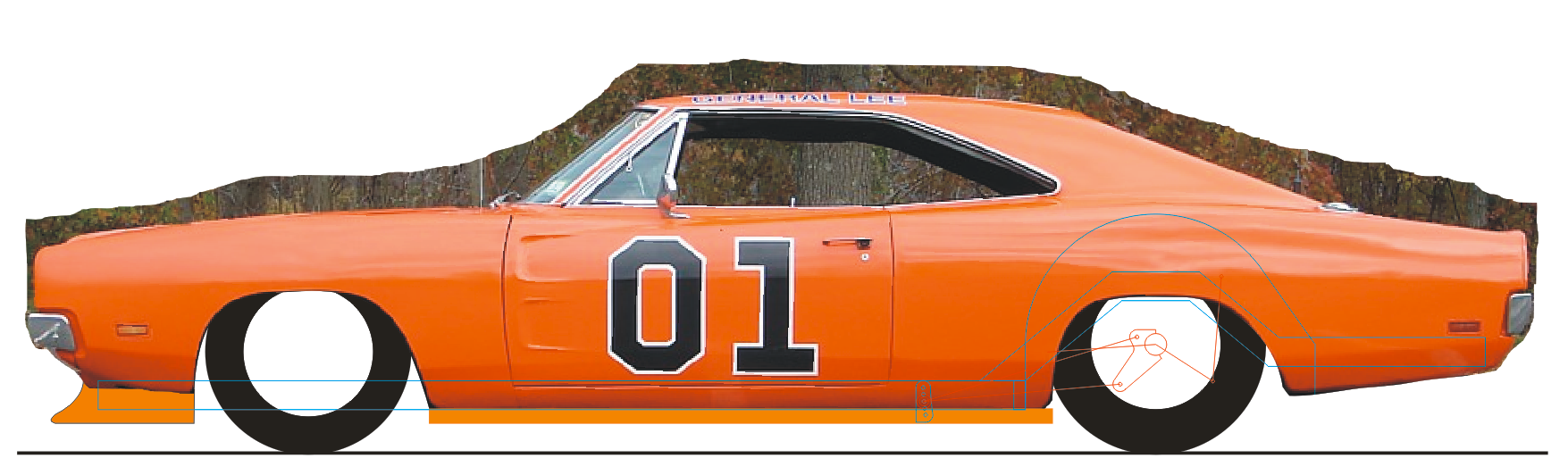

Just like most things in my life, plans change without notice lol. I think the car will be heading more towards a street/strip set up, as far as the suspension is concerned, but I do like the large rims on a Charger, so it looks like Im leaning towards 18" front and 18" rears for the time being. The chassis is laid out with 32" ladders and coil overs. What do you think would be a better system for locating the rear axle, a pan hard bar or wishbone? The space between the frame rails would be around 36" or so. Thanks for looking!

-

Ok cool, that would be a 1:1 section width of 12.9" and a tread width of 10.2". Thanks again !!!

-

beautiful Joe, my favorite car. you did a real fine job on it. I remember seeing a few runner and GTX's back in the day trolling the streets in a$$ end up stance and those beautiful cragars reflecting the street lights. John they r good year blue streak tires.i think they r from older mpc kits. I have a lot of them. Pm me if you need a set.. Thank you Joe, but Im building a 1/16 pro touring/ pro street charger with a 30" tall tire. The 30" is for certain, the width I wasnt sure on. Was hoping to see a B body with a nice tire on it, and I sure did !!! Thanks!

-

Joe, very nice build! And that rear tire width is perfect for the B bodies. Im building a Charger and if you dont mind, I would like to know what the tire width is on this model. Thanks

-

Thanks Ace!!!

-

I would like to add more detail to the engine block but some mods will require cutting through the wall. Is there some sort of filler that I can back fill the block, that's strong and paintable? Thanks Clutch

-

Looks great. I always wanted to build a willy pick up!

-

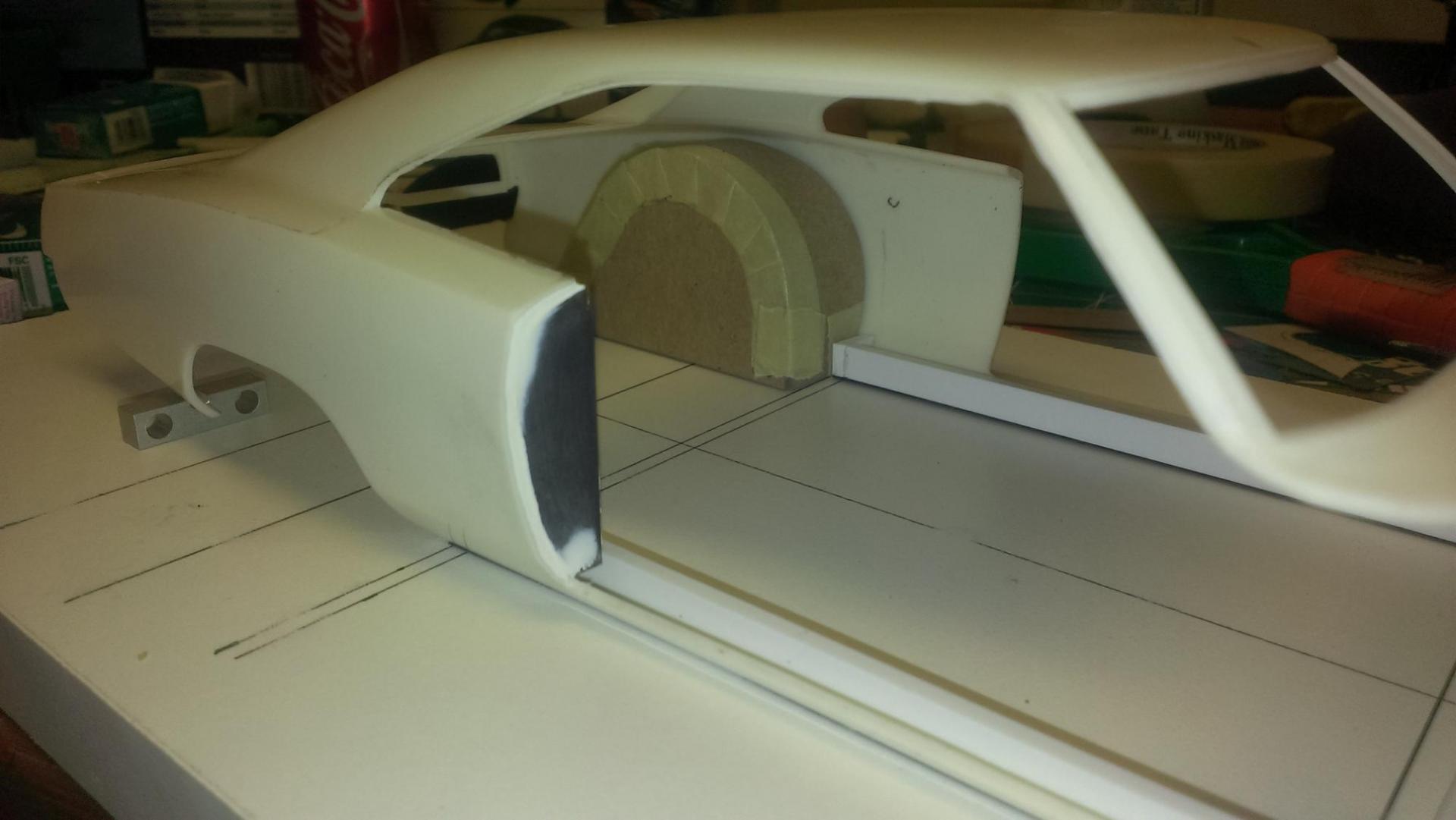

Also, I made the mistake of working on the door jam before boxing out the rockers first. Don't do that lol. I know better to work from the ground up, but I couldn't come up with a solid plan for the rockers, and figured it wouldn't get in the way. Well, it did lol

-

My first issue with the body was it didn't sit flat. It had a bit of rock to it. The second issue was that the contour of the cowl area didn't match the back of the hood. The cowl has a much bigger arch. I was planning section off the fenders and doors from day one, but I thought doing so would relieve a bit of tension in the body and the cowl would spring out a bit. That didn't happen. And because the firewall that came with the kit was wrong (the Richard Petty 71 Charger firewall came with it. I don't know why. Too wide by .160 and the arch wasn't going to help) I decided to make my own. Here I'm boxing up the rocker panels. The body now sits flat and true. To keep the body and door contours the same, and to build a square chassis, I had to add .062 to the backside of the each rocker. I used .100x.250 rod and .020 sheet to box the inside and bottom. Not sure how I'm going to close the top side yet, but I'm happy with how it sirs now. The plan is to have the chassis/floor pans sit inside the boxed sections. This pieces will represent the outer frame rails, and the roll cage will mount on the top side. The frame, body and roll cage will be separate. The roll cage will have pins in the bottom of the main hoop and the A pillar bars that located to the top side of the frame rails. I'm doing it this way because I want to paint the floor and cage separately, to get a nicer finish. I also started making the rear door jams and tried using Tamiya Putty white for the first time. I don't like it. It shrinks too much and I have no patience for the dry time. PLEASE tell me that Bondo works good with plastic models. I also made templates for the wheel tubs. I need to make templates for both sides because they are noticeably different surfaces. BTW, I like using the do-it-yourself hone depot cabinet panels. They are cheap, very flat and superglue bonds to it nicely for making jigs. Strong enough to hold the jig is place, and weak enough that I can wack it off with a hammer if need be.

-

Yes sir, I did mention wheel openings in the OP And thank you for the diecast tip. I havent nailed down the exact tire/rim combination yet, but I havent seen anything that says "THATS IT !!!" either. I do have the ability to make my own rim/tire, but Ill be looking into the diecast world before that. Thank you Ken !!! And now that Im thinking about it, this is more modifications than what a restomod would have, considering Im changing alot of the exterior appearance, I think Ill change the title to Pro Touring, as it does seem more appropiate.

-

Concerning the NHRA TV lineup

John Clutch replied to Nytrozilla's topic in General Automotive Talk (Trucks and Cars)

I agree. The lack of manufacture involvement absolutely kills the class. For YEARS, teams have been giving the big three credit and FREE advertisement with little to no influence on drag racing, except for two factory drag cars. And thats the only involvement in decades. -

World Record Semi Truck Jump

John Clutch replied to Custom Hearse's topic in General Automotive Talk (Trucks and Cars)

That was awesome ! -

Thanks Mike. Again, nothing is set yet, chances are I will do and redo a thousand times before I settle on something. Im also planning on adding 2" of ground effects to the rocker panels. The issue Im having is that the car itself is massive, with wide wheel wells, so trying to get a big tire on the car, and have it sit low without the wheel tubs resting on the tires.

-

Concerning the NHRA TV lineup

John Clutch replied to Nytrozilla's topic in General Automotive Talk (Trucks and Cars)

Being a fabricator/mechanic, the driving itself is the last thing Im interested in when it comes to drag racing, regardless of the class. Drag racing has always been a mechanic's sport. The action has always been in the pits and garages for me. When I see someone reset a record, the congratulations are never for the driver's seat. Its for the 36 hour days, weeks without sleep, blood, sweat and tears that is required to run at the front of the pack or to improve personal bests. Its very hard to go fast and its even harder to stay in front of the pack. People who complain about teams like Force, Schumacher, KB Racing, etc. dont understand what it takes to be in front and maintain it. "oh, well if I had the money they had, I would win races and lead the pack for the next three decades"........ Your chances are quite slim, if not down right impossible. It takes years of R&D to do what these teams do, and no money in the world can buy you that. Schumacher has proven time and time again that building a team, with the best equipment, the best talent with the "do or die" mentality does not, and will not give you a winning team. Some people just dont work well together no matter how much you pay them. -

Looks great!

-

9 out of 11 !!! truth be told, I cheated on 6 of them

-

-

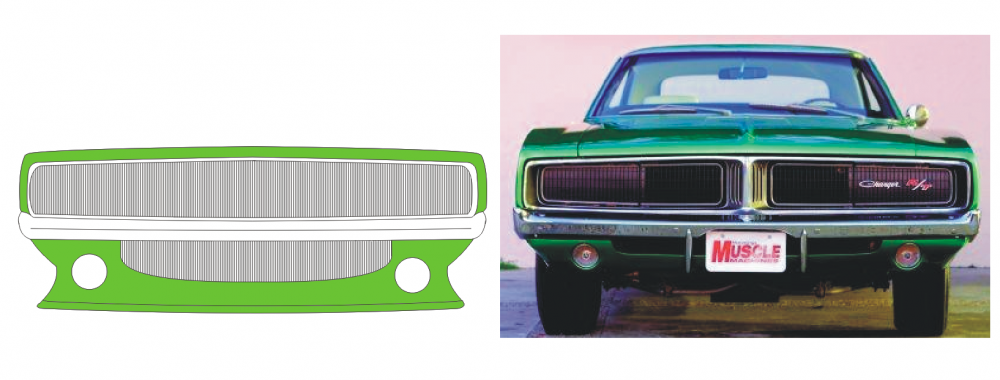

Custom Mike, here is the concept for the grill. Not the actual finish dimensions but just a rough idea.

-

Concerning the NHRA TV lineup

John Clutch replied to Nytrozilla's topic in General Automotive Talk (Trucks and Cars)

I'm.happy about the new Pro Stock rules. The throttle body will add power and the lack of that hood scoop, which requires 60hp to push through the air, will help on top end. I'm willing to bet a 3 mph increase. I'm sure they will run some sort of cowl induction. -

Looks good!