-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Steve Osbourne

-

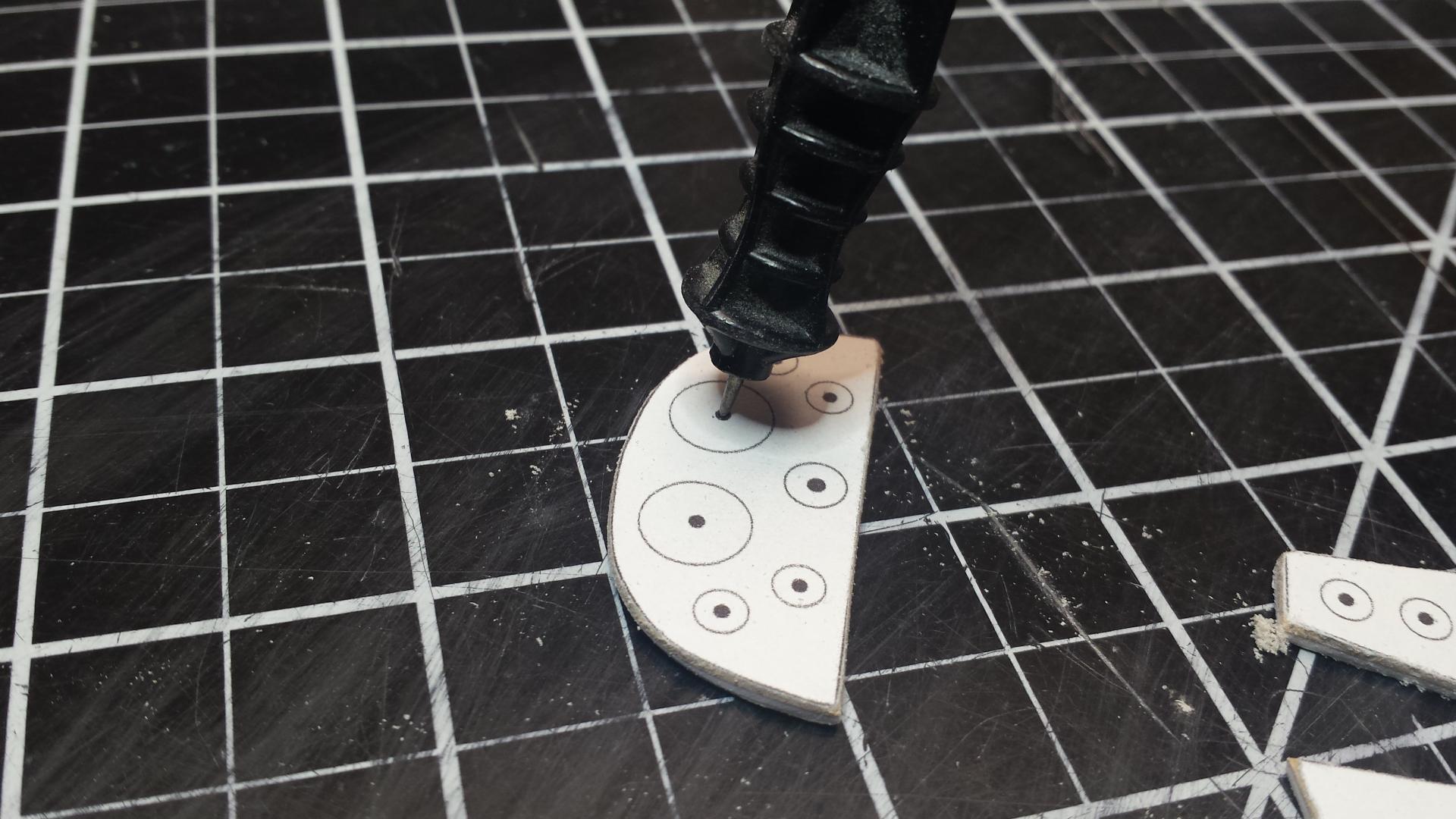

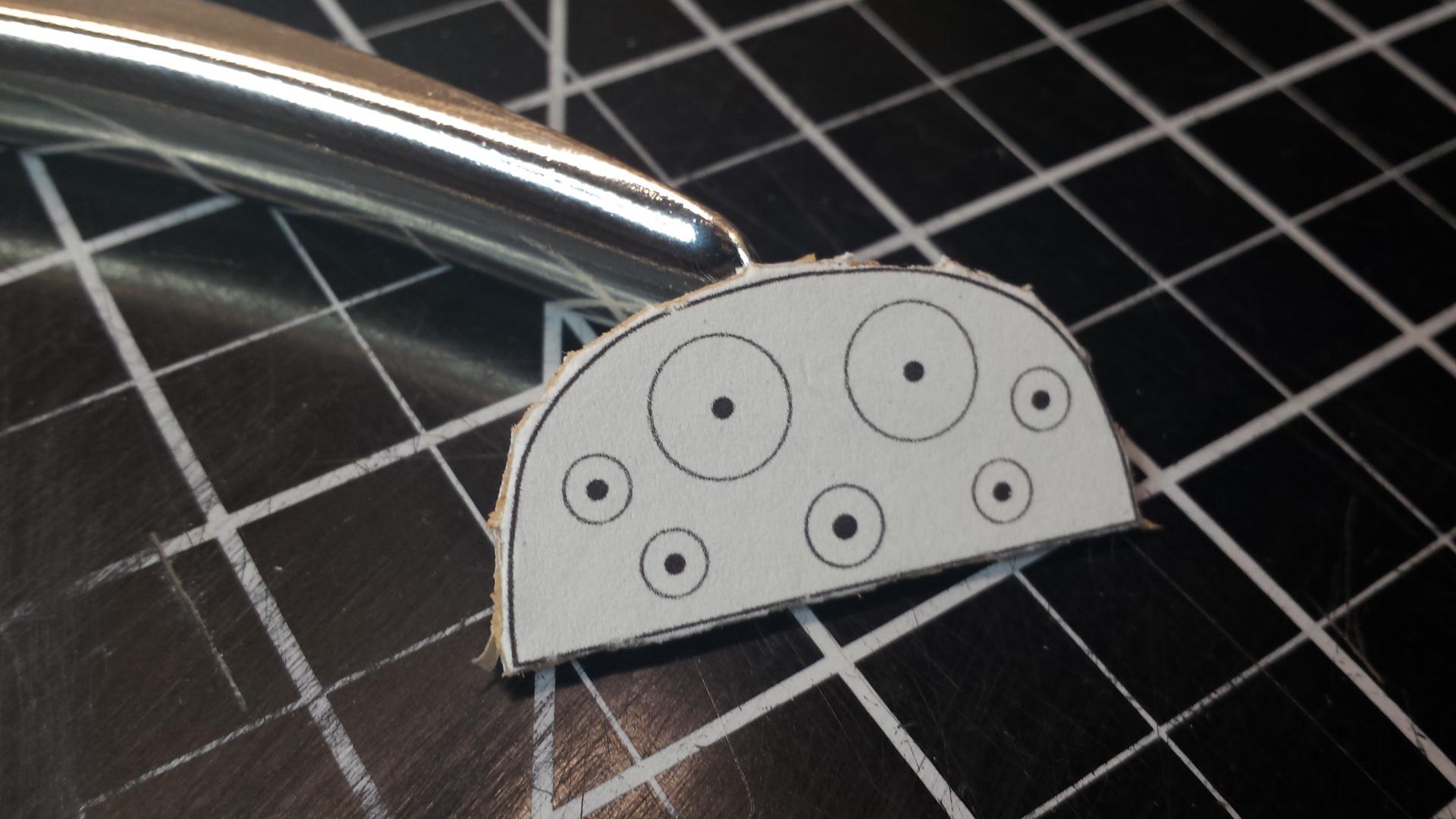

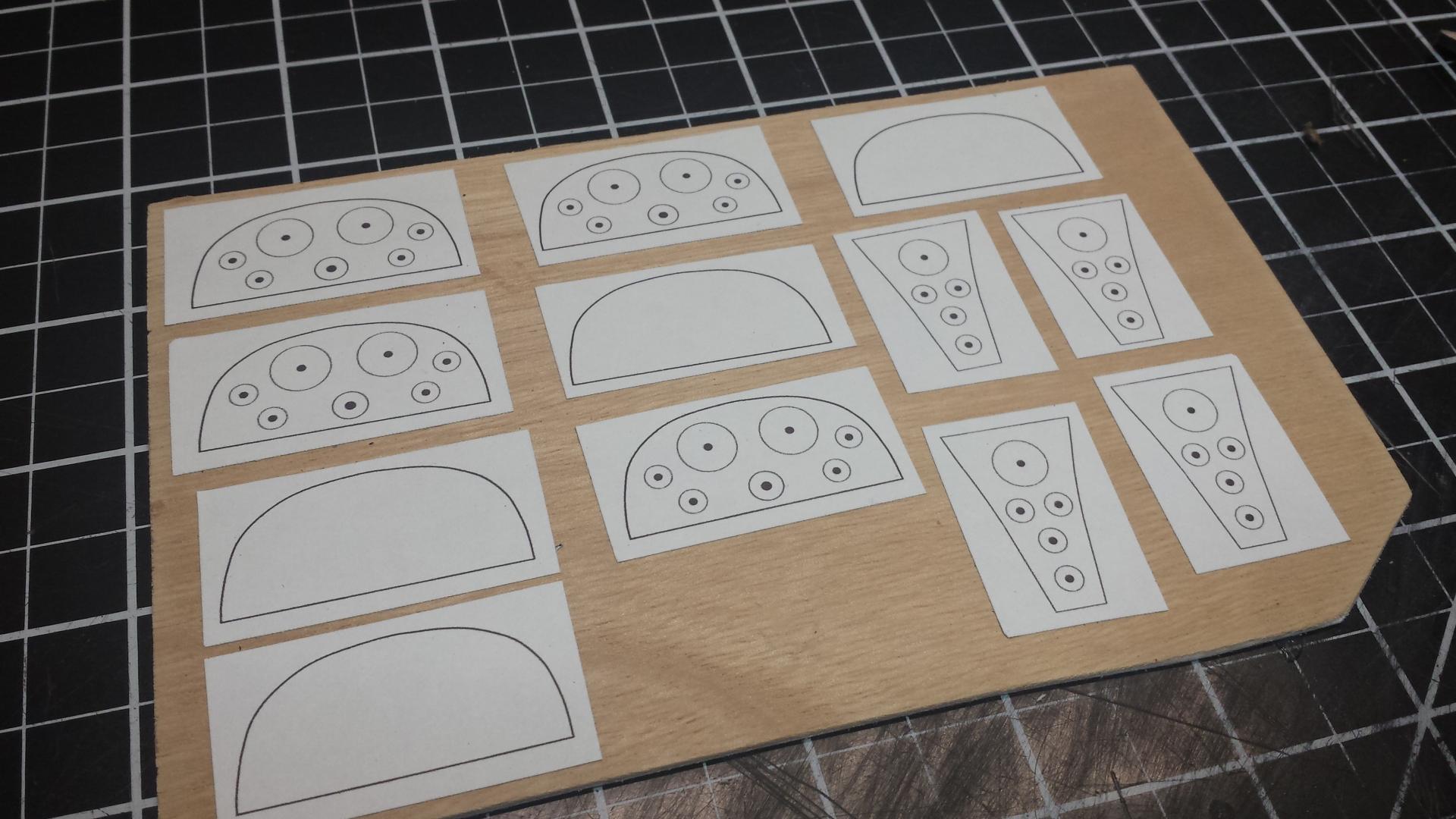

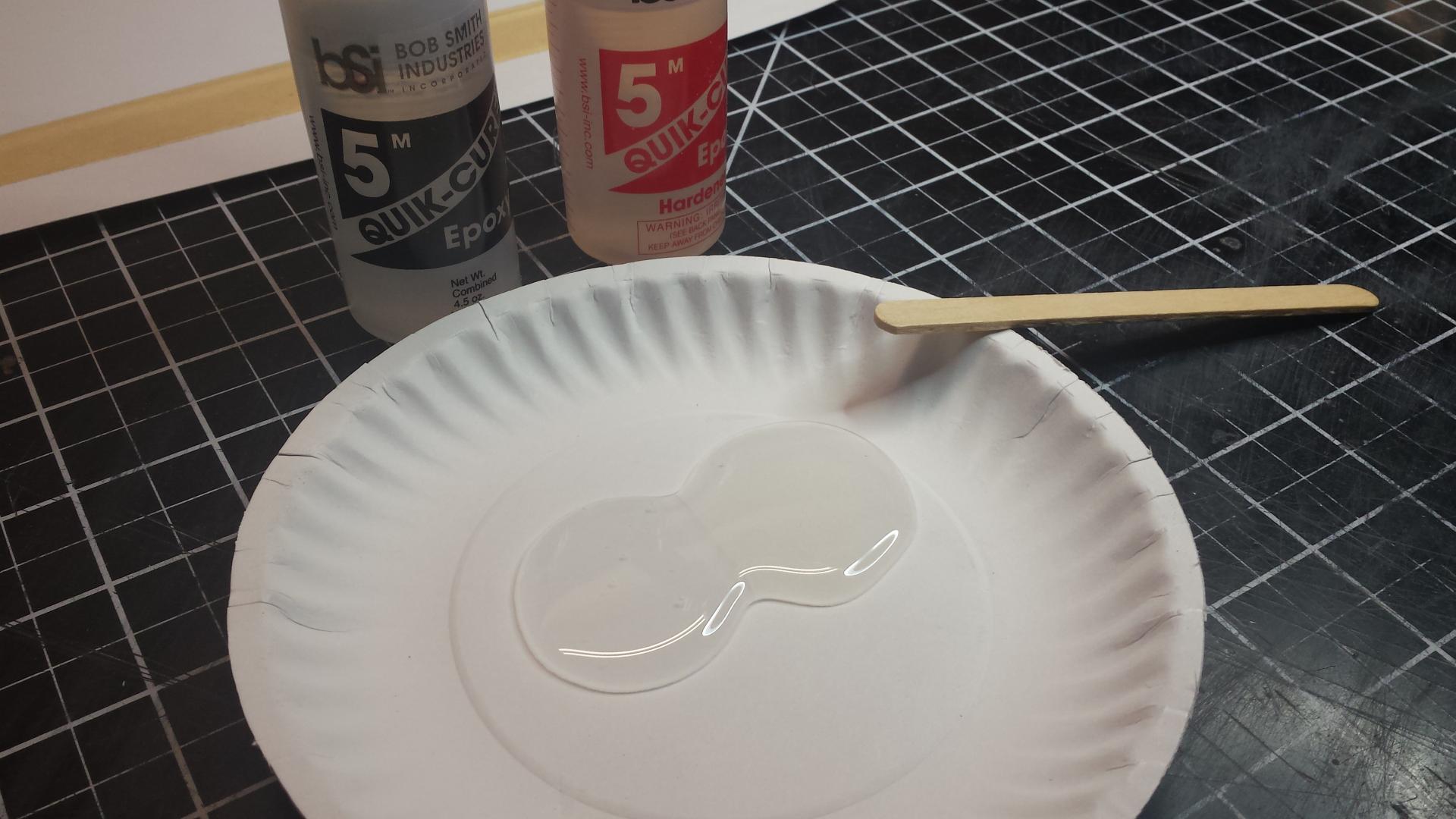

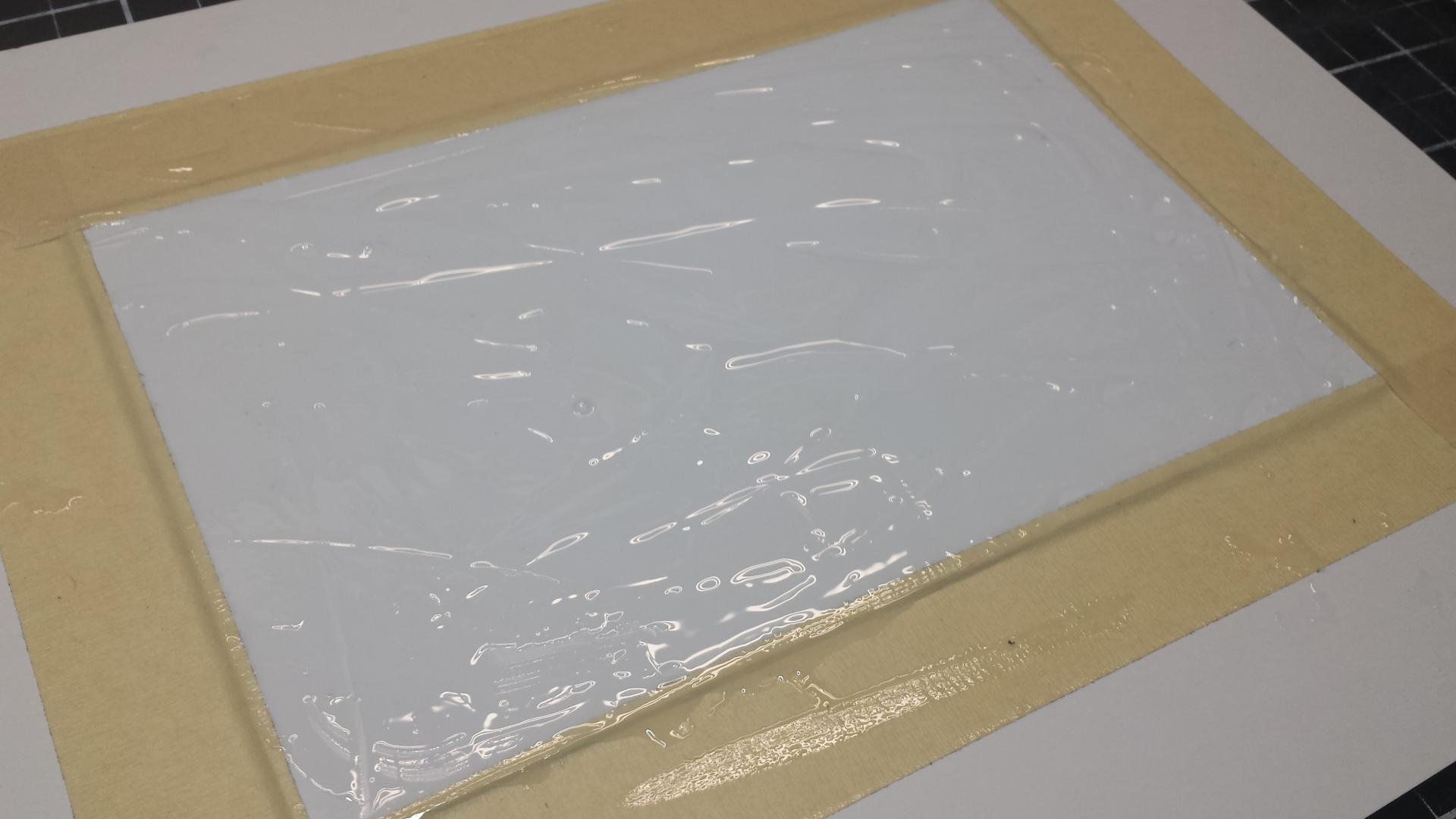

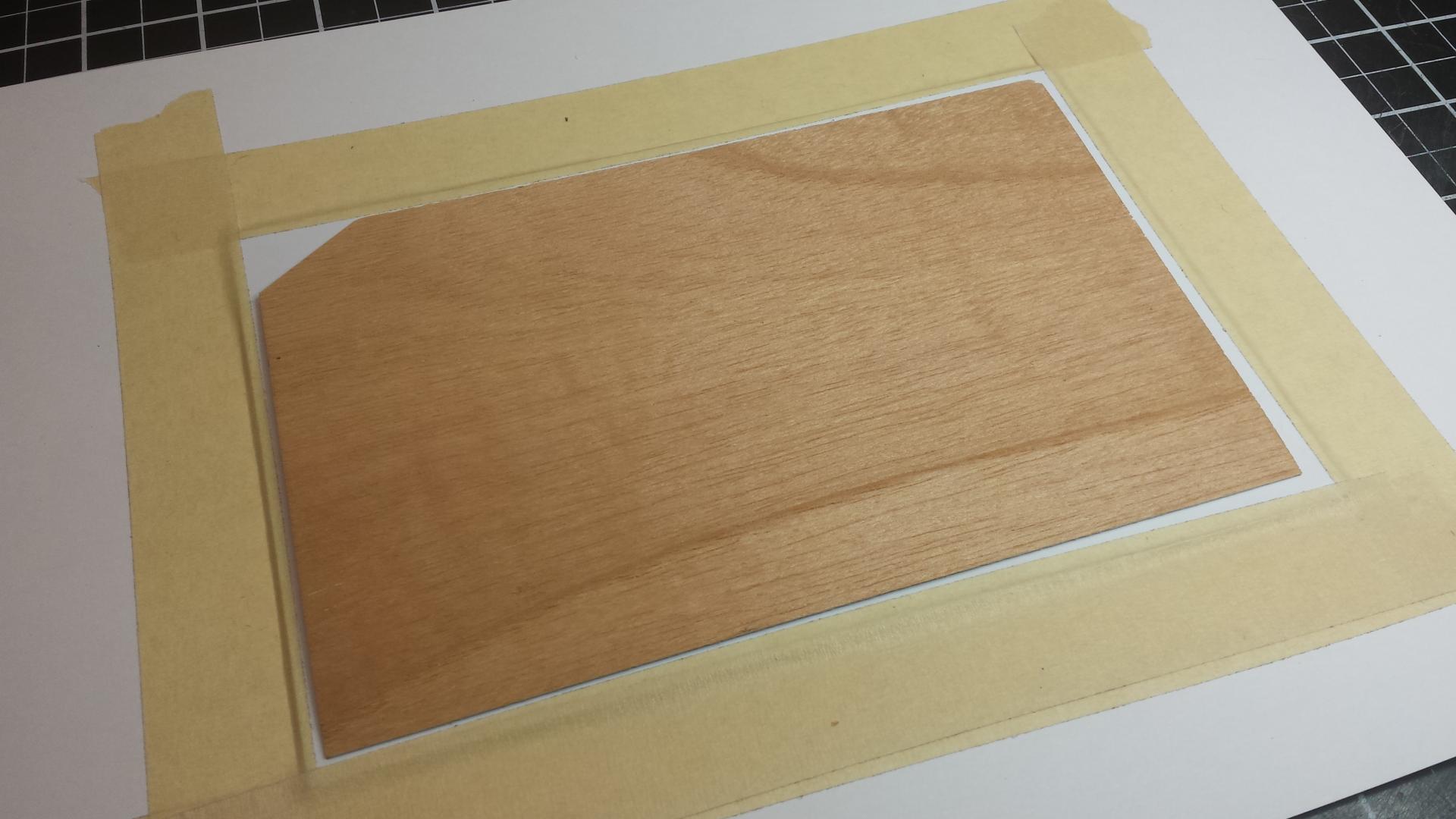

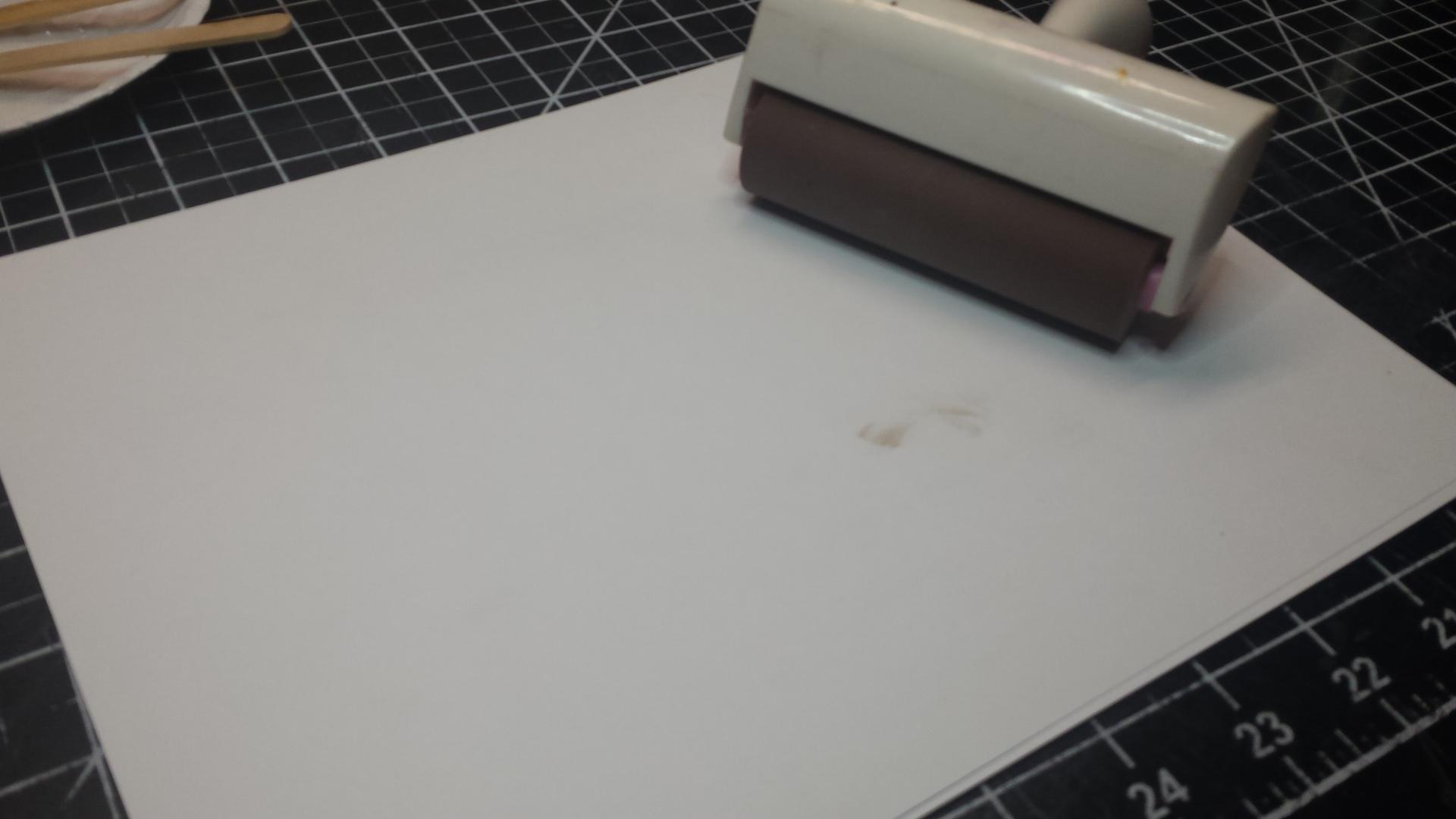

Cover the back of the plastic with masking tape. This will prevent the decopauge from sticking to the plastic. Turn the plastic over and tape it as close to the edges to a piece of cardboard or card stock. Mix 2-part epoxy and spread evenly over the plastic and then lay the wood down. I then cover everything with another piece of card stock and use a veneer roller to smooth things out and get a good bond. You can just use a rolled up rag.

-

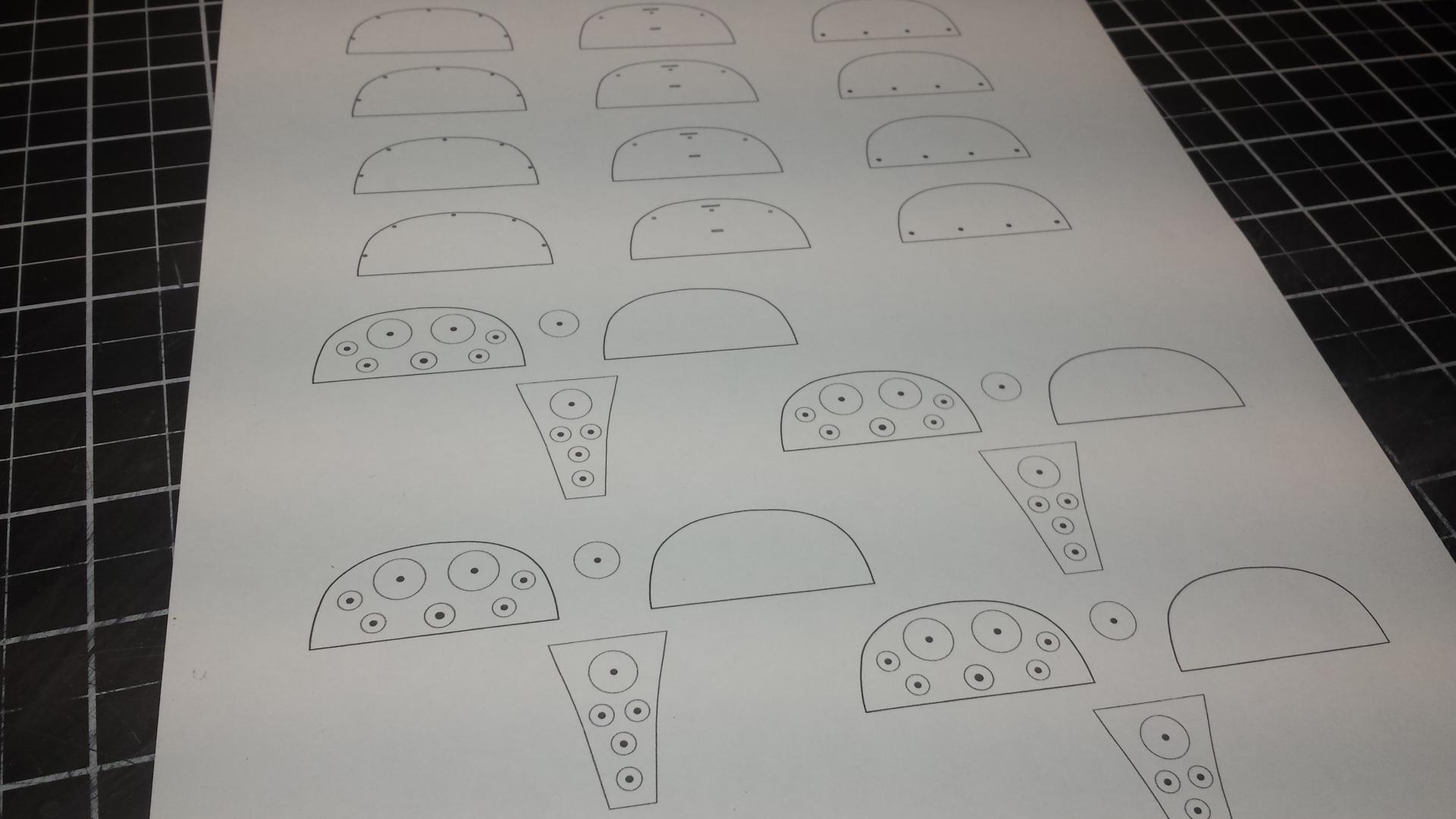

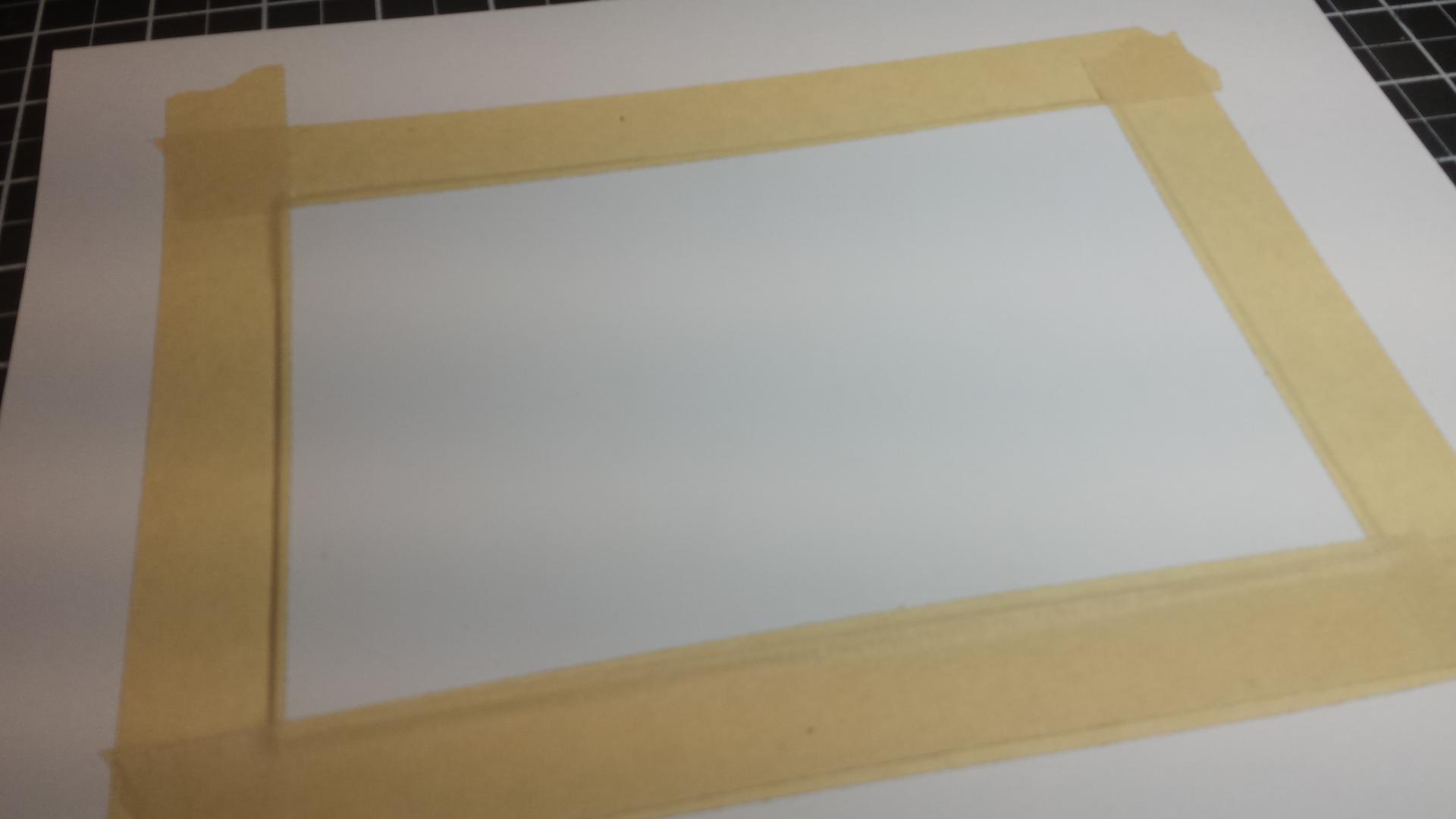

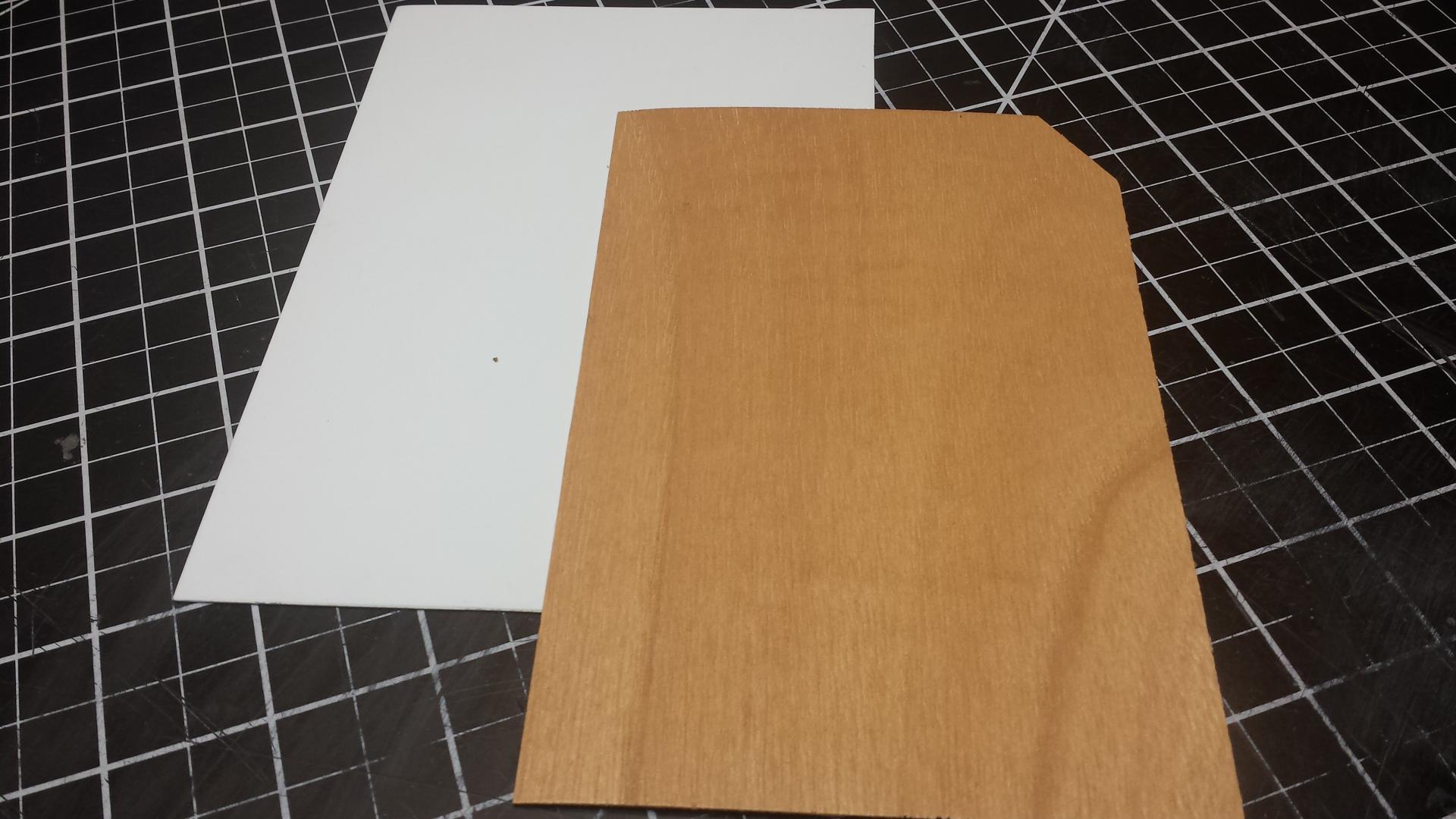

Here is how I do my custom wood dashes in large scale. I won't do a wood dash unless I use actual wood. I also cover the wood with EnviroTex (decopauge) as I feel it closely replicates an "automotive finish" as opposed to varnish. I'll explain things and answer any questions as I proceed. I started with a piece of .030 Evergree sheet cut slightly larger than the cigar box wood (about 5 x 6" here).

-

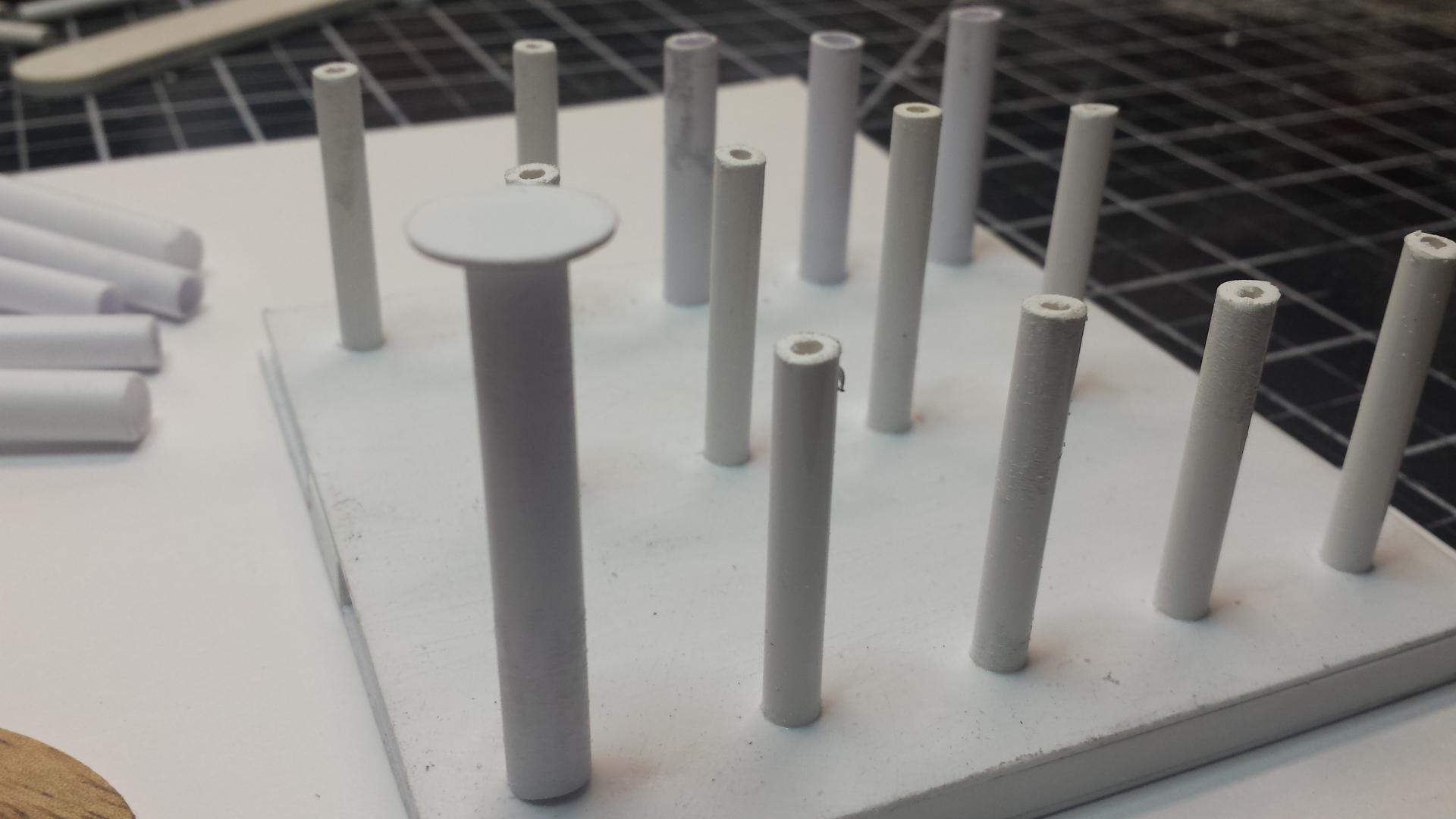

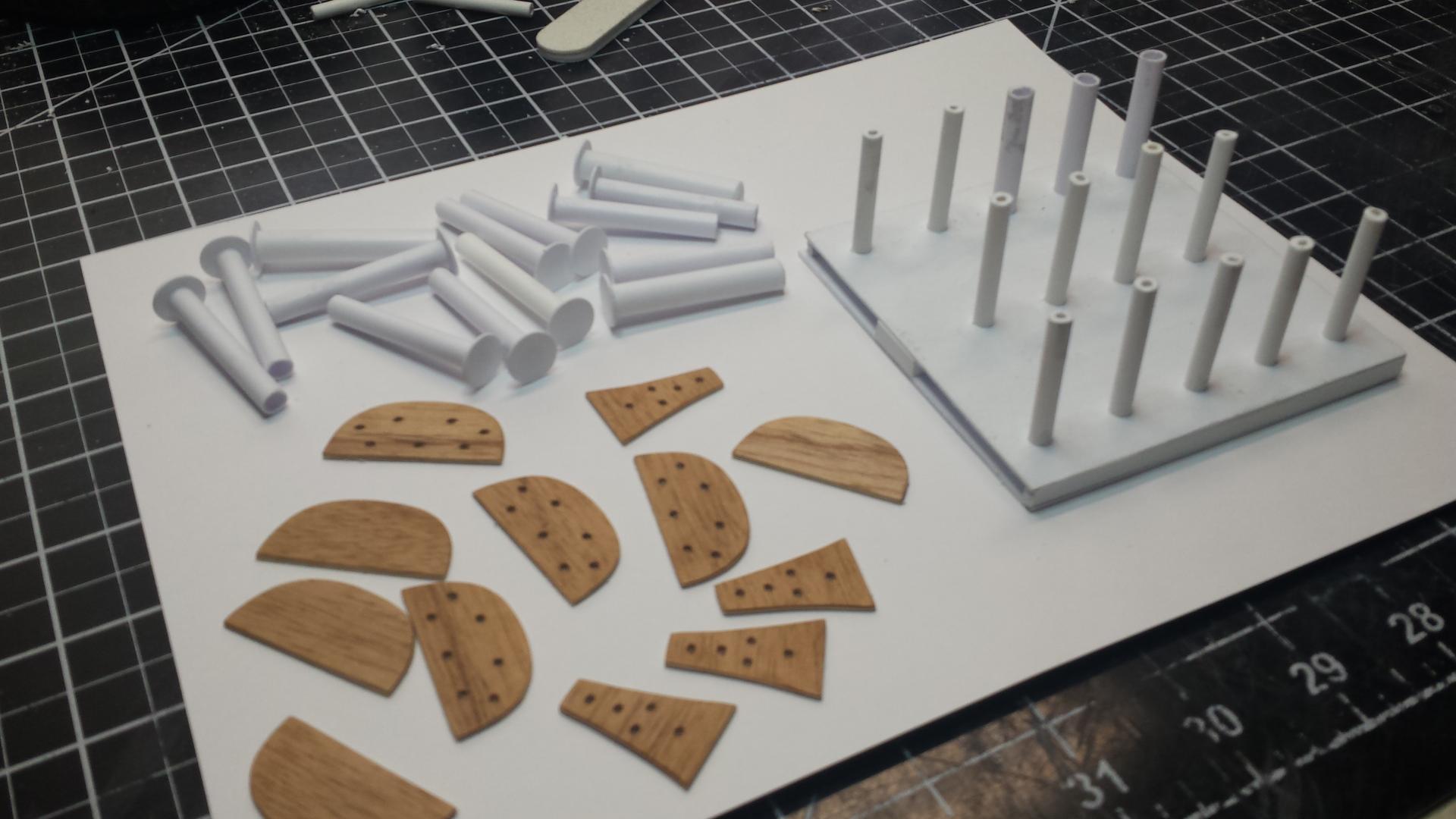

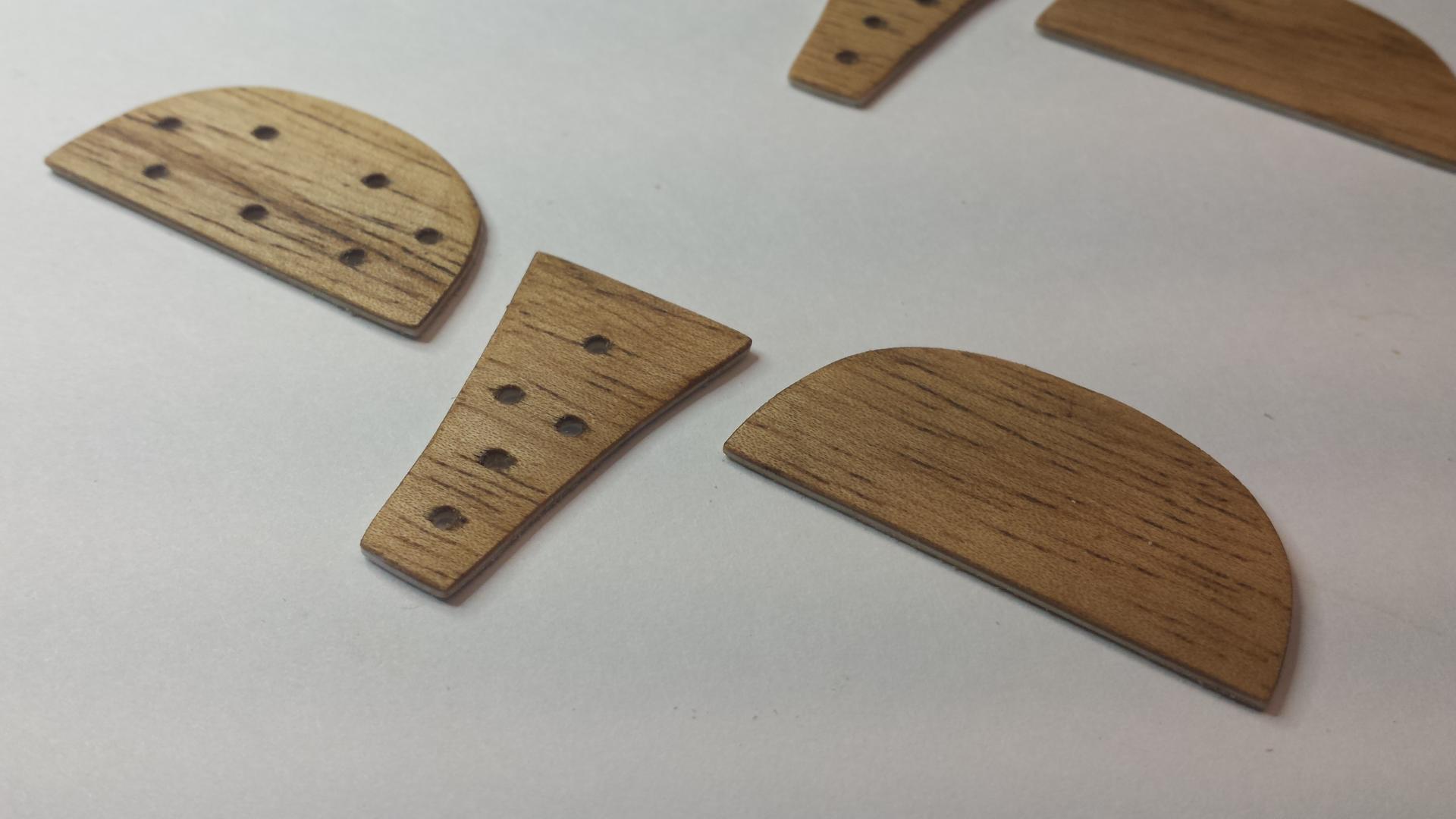

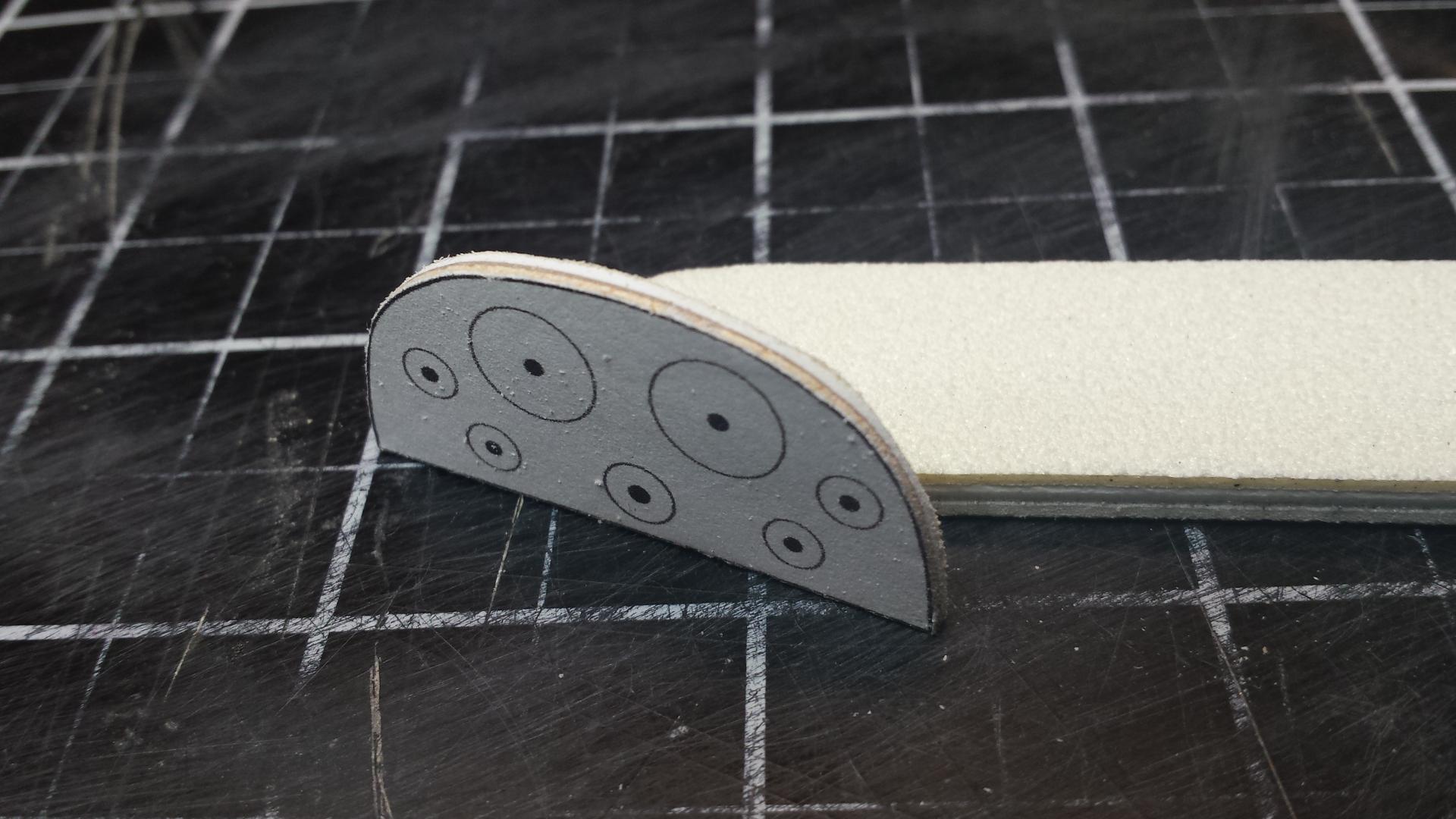

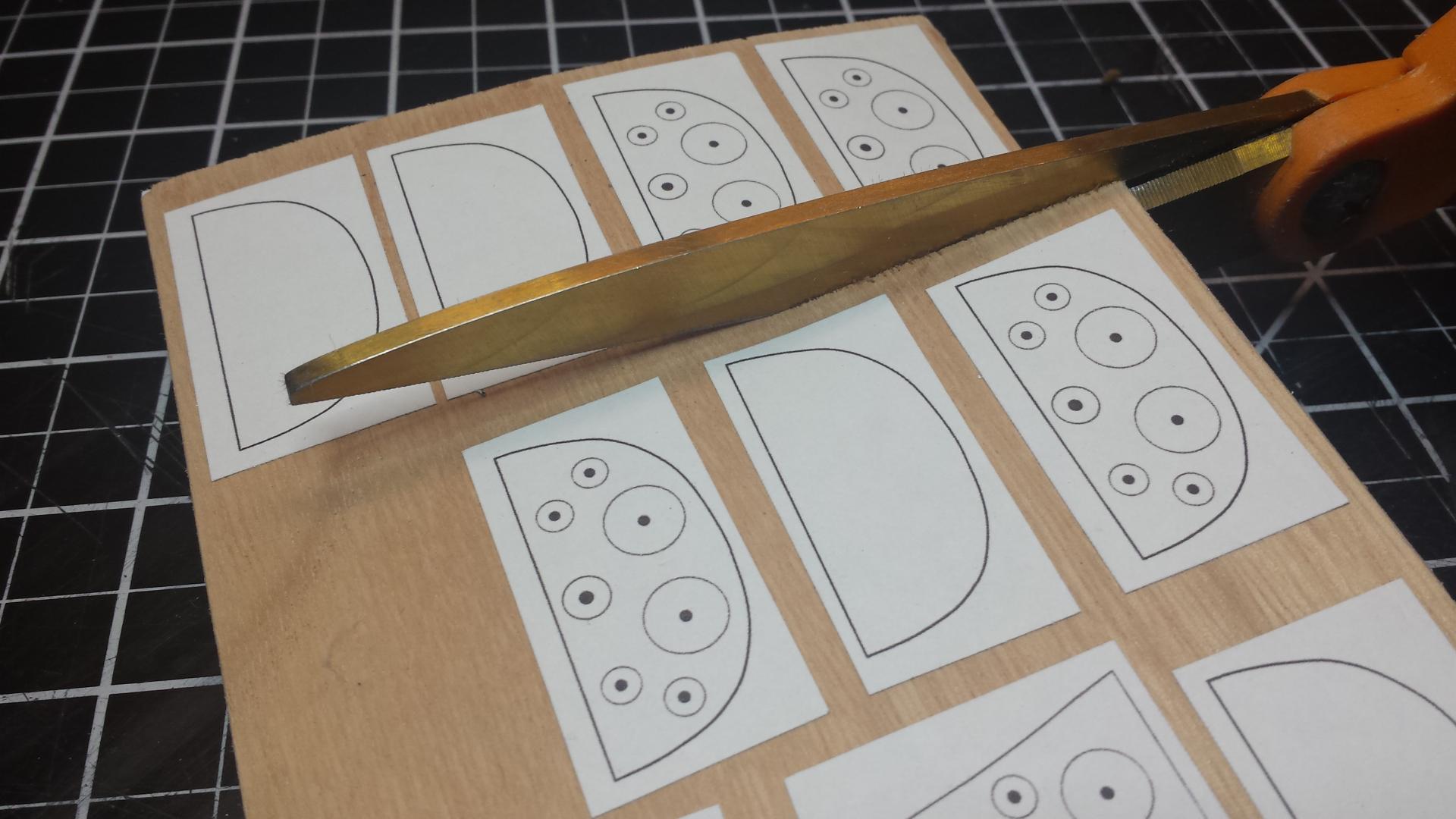

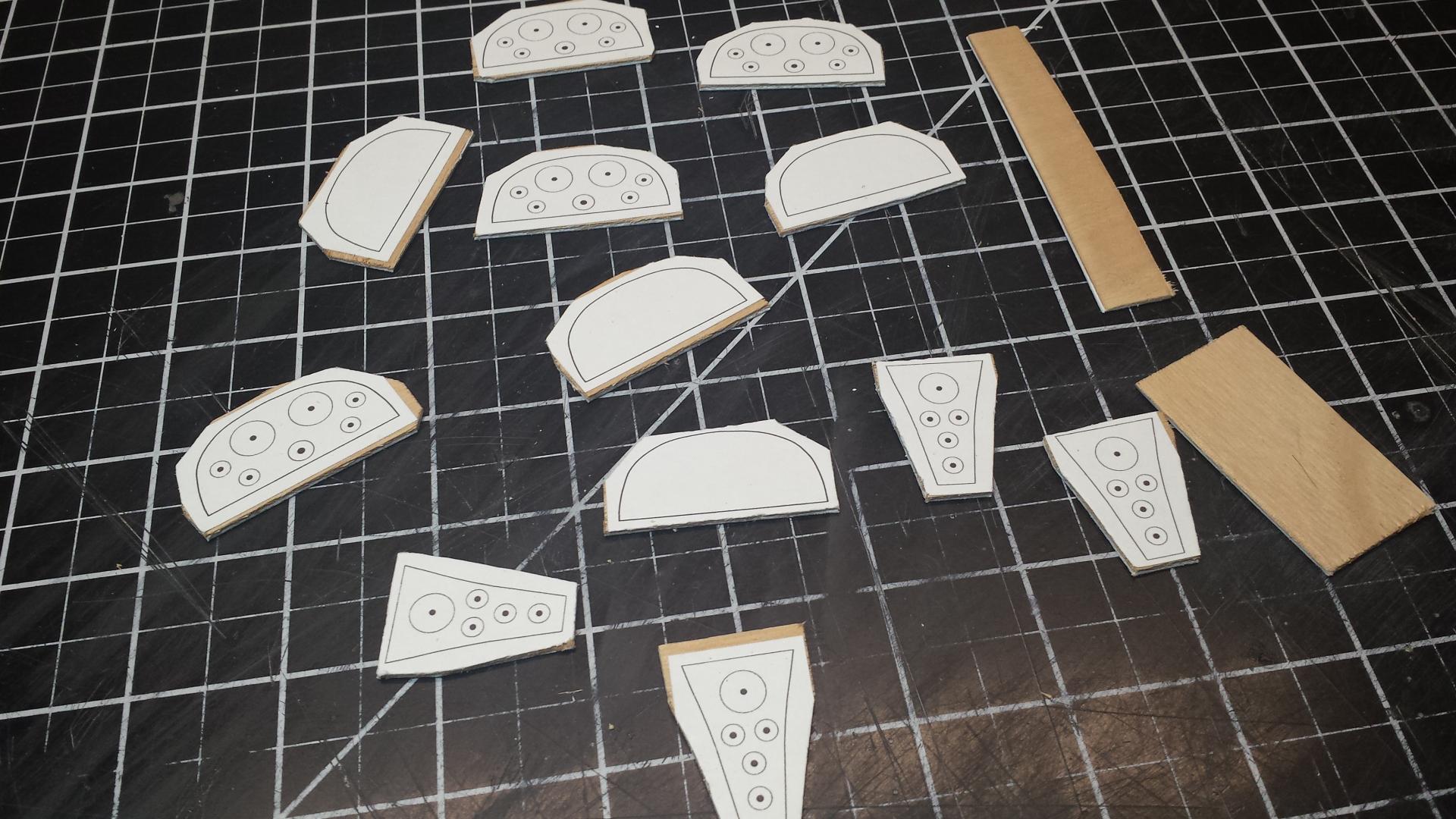

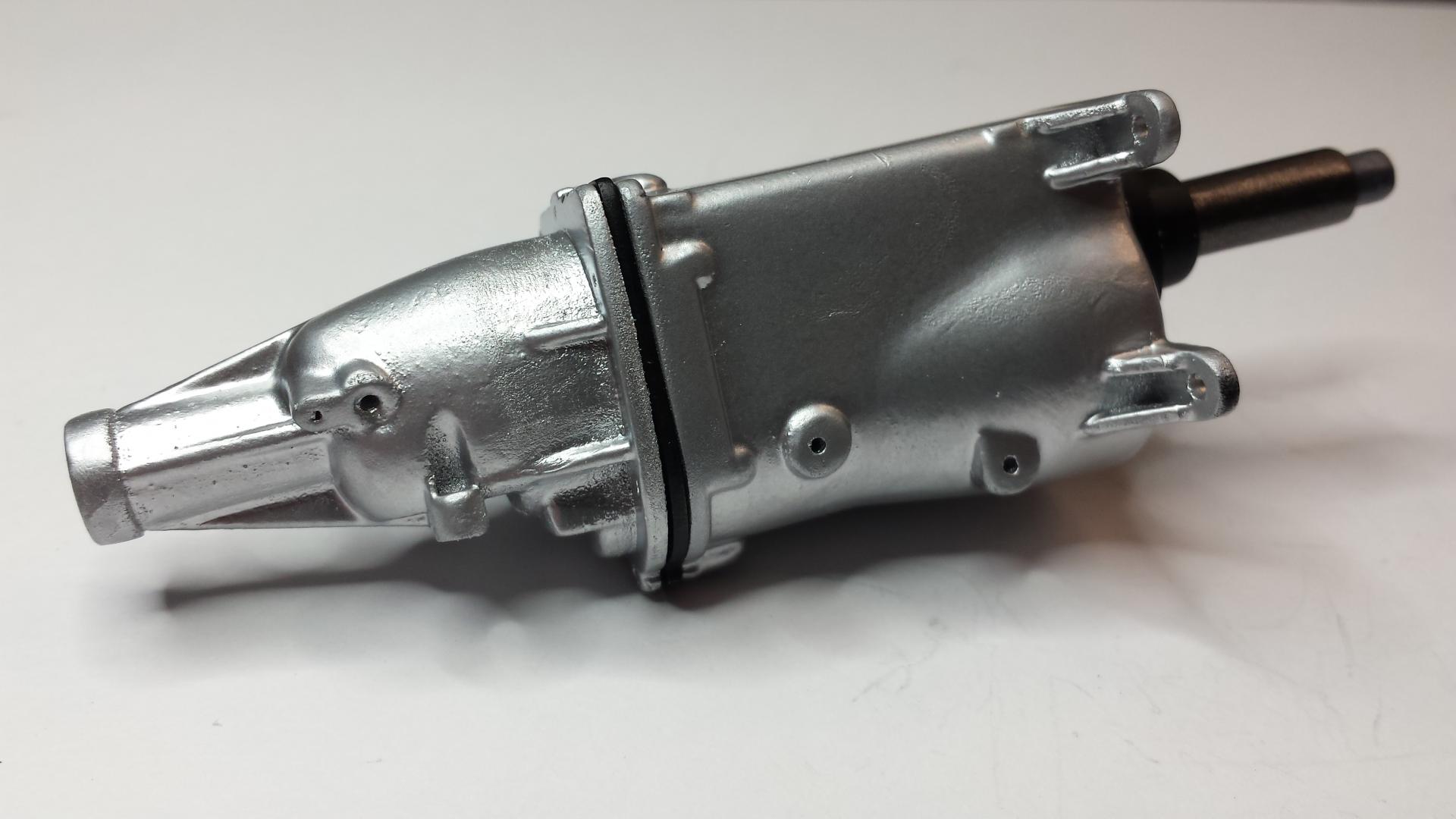

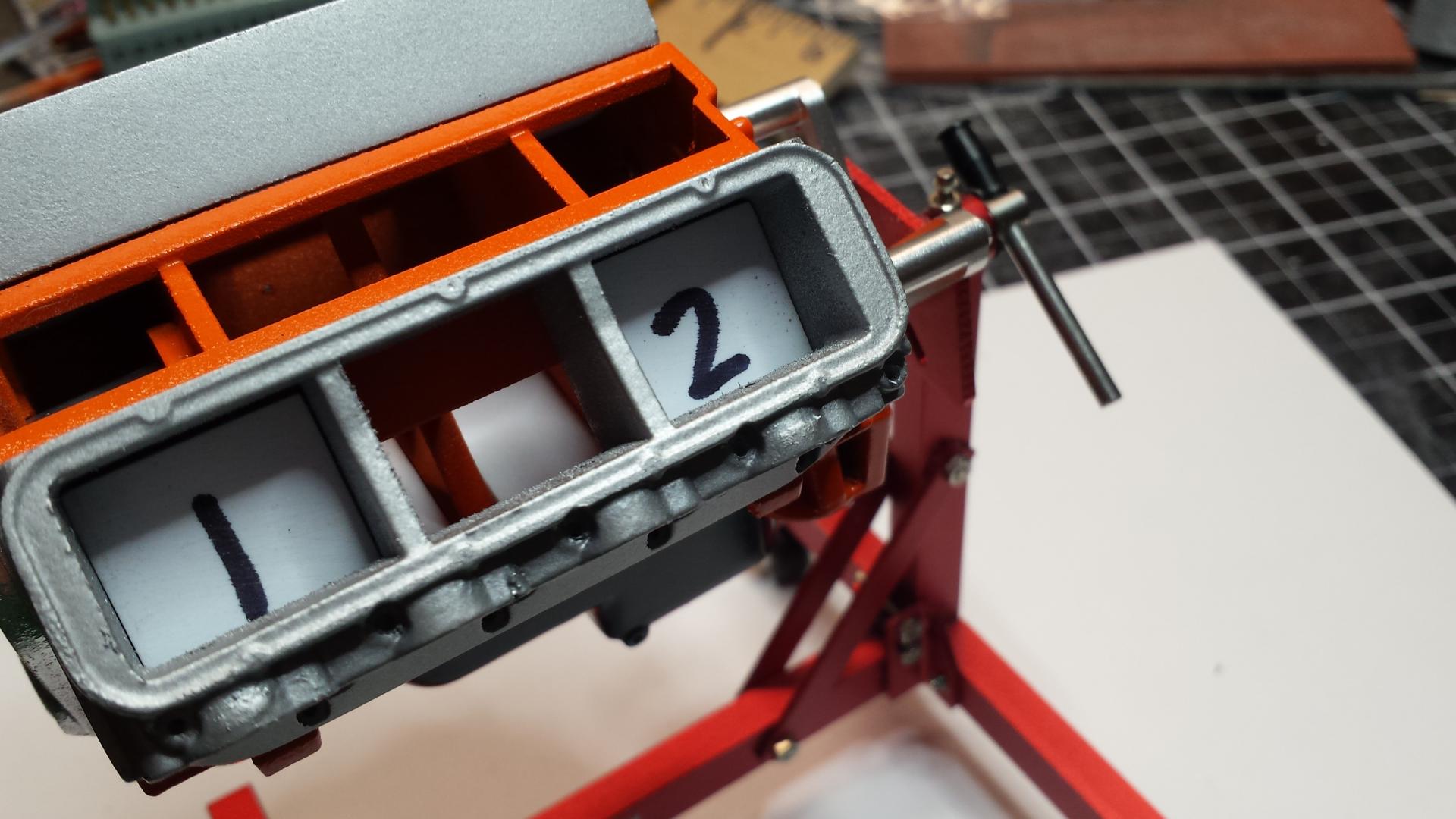

I spent some time working on the TDR Muncie 4-speed transmission with Hurst shifter. I made the rod adjusting buttons from 3/32" dia. aluminum tube with a slightly longer piece of 1/16" aluminum rod inserted. I then drilled out both pieces together to accept the rods. The pivot arms are made from 2 levels of .030 Evergreen sheet with quarter-round strip added to both sides where the 2 pieces transition. I made extras. I'm using 0-80 hardware for the pivot bolts. They will attach to the side cover and extension using 0-80 threaded inserts. The fake mainshaft is an assembly aid only. It will attach to a corresponding tube I'll build into the engine block.

-

I forgot to point out one small detail on this photo. Note the air vent on the dashboard has been opened up and the radio speakers are gone. I was going to try and replace the speakers with metal mesh or similar but made a mess of it so now we'll just call it radio delete.

-

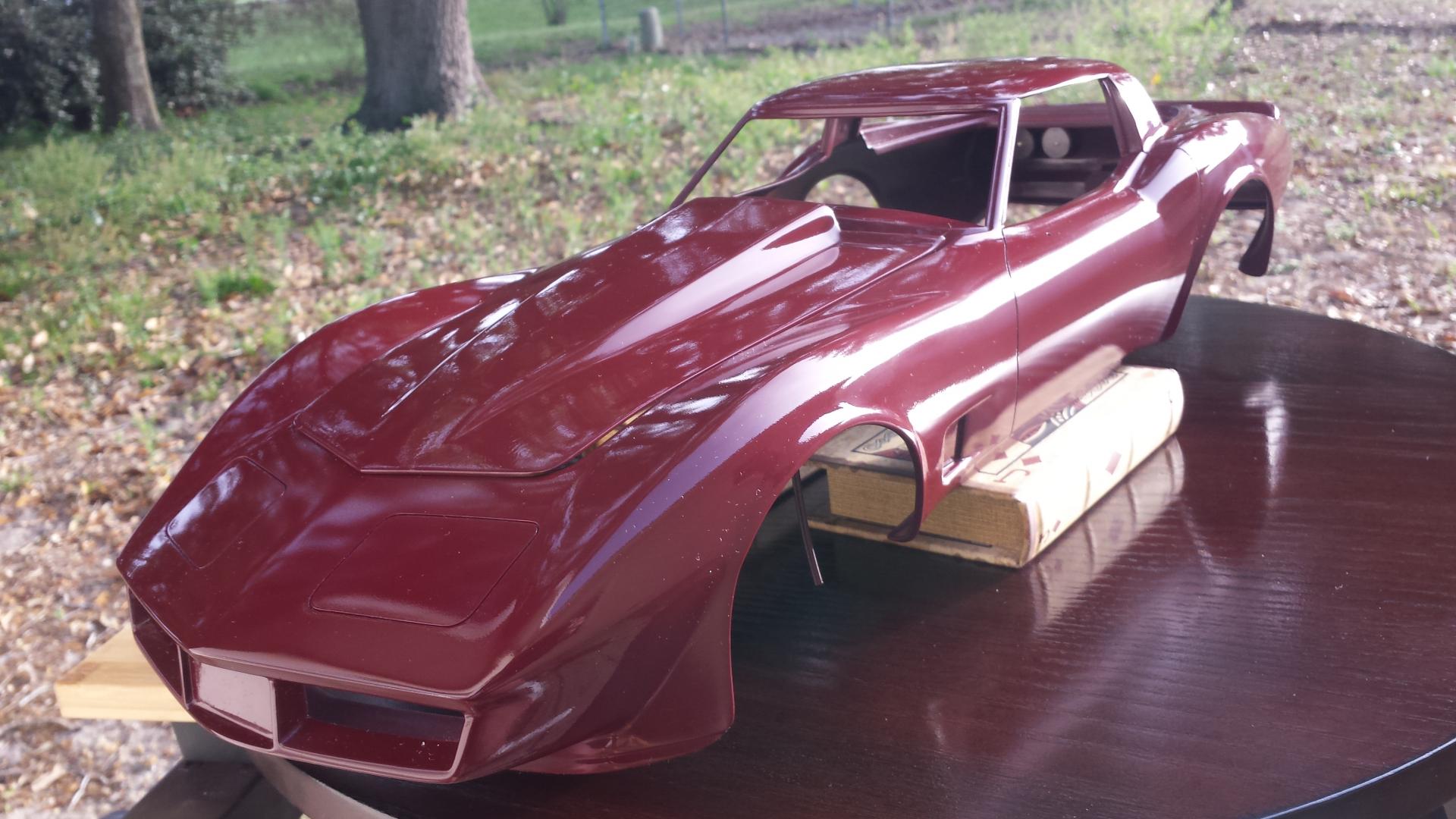

And here is the result. I'm now going to let it sit for a week or so and then go back and mask off the areas that will get painted matt black. After all that is done I'll go back and wax the entire body with Meguiars Show Car Wax #7. I'm not sure if I mentioned earlier but the big block is going in the next Corvette (78, also C3). This one will still get the original kit small block 350 with upgrades to headers, Holley carb, manifold and air cleaner.

-

Paint update...I shouldn't have rushed things and done a better job wet sanding last time as there were numerous trouble spots that had to be addressed. On a model this large, imperfections in the paint become increasingly more apparent. I've tried to take this project a step further by removing all the body chrome so I could focus on highlighting the smooth and flowing lines of the C3 Corvette. Noticeable flaws would be bad. But the next paint session went real good as the weather was very good for painting able to lay down multiple light coats followed by several heavier wet coats. I'll post a couple of outdoor shots in my next post.

-

-

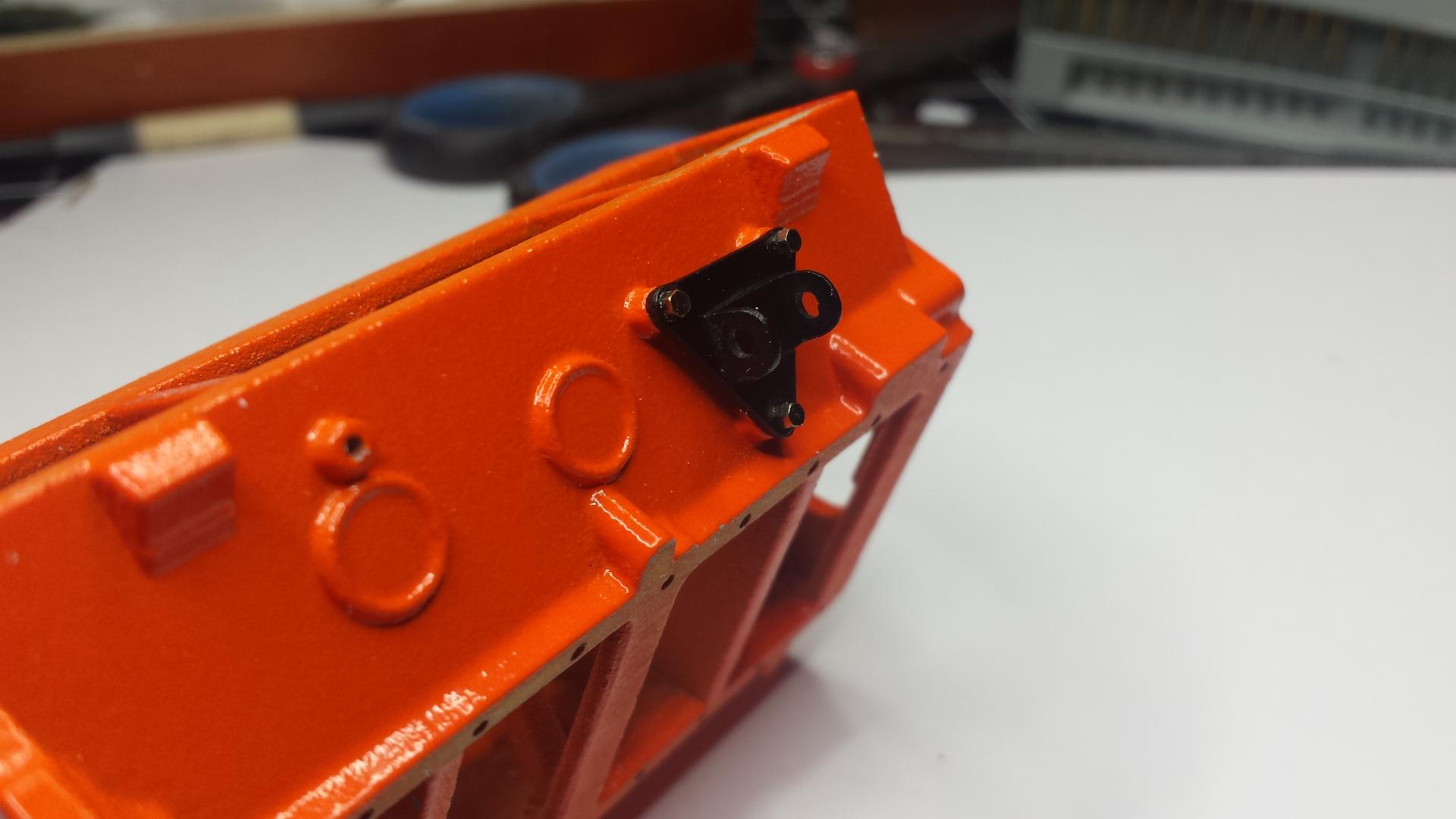

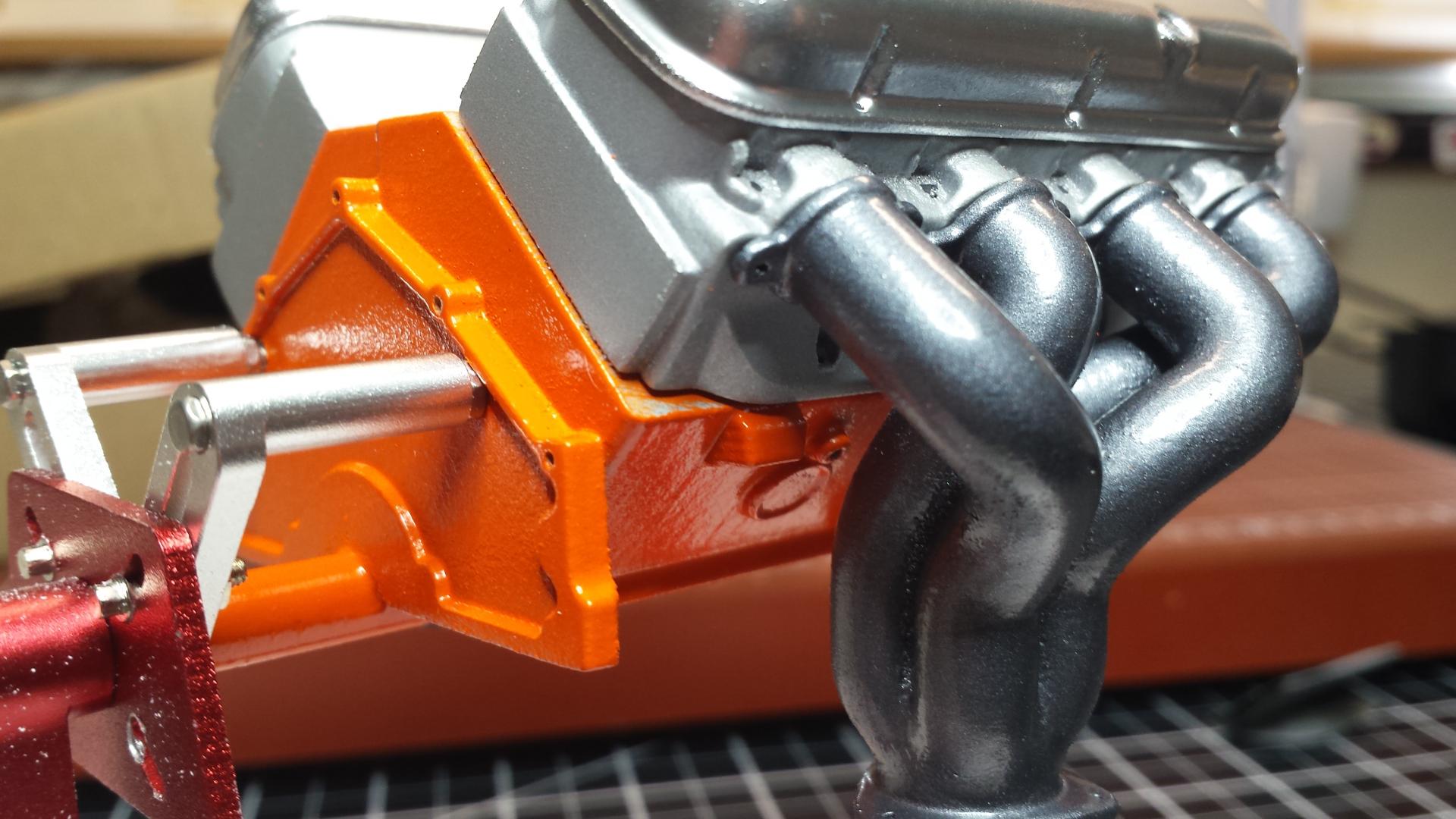

Thanks Todd. I made these motor mounts from Evergreen sheet and rectangular tube. They mount to the block with 1mm screws.

-

1/12 Super Street '69 Camaro

Steve Osbourne replied to camarobuilder's topic in WIP: Drag Racing Models

Hey Frank...I am so looking forward to your build. I've built this kit once before - basically stock and pre-3D printing & pre-Foose and am a big fan of 3D Model Specialties and TDR Innovations as far as they are offering to the big scale modelling community. -

-

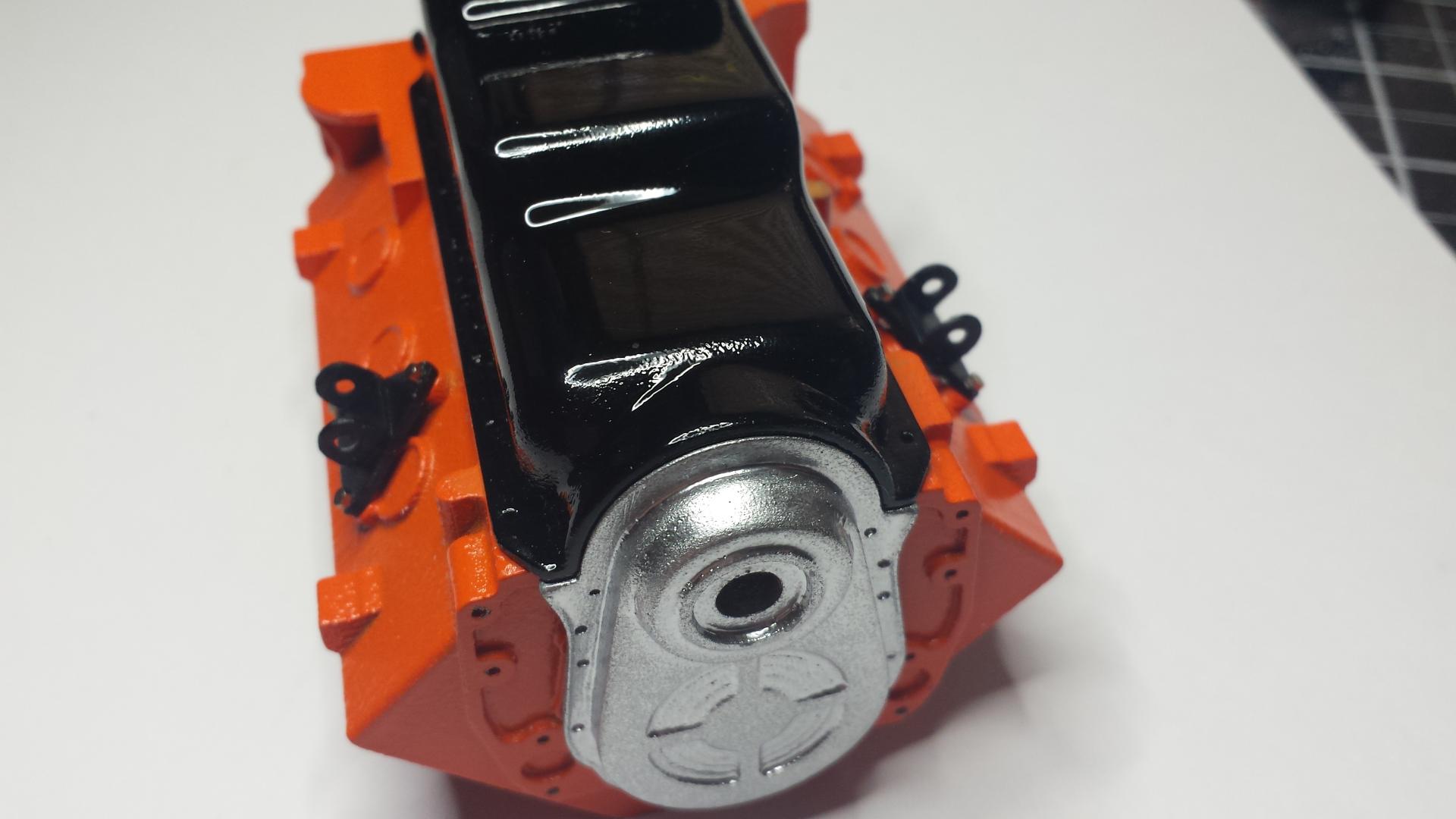

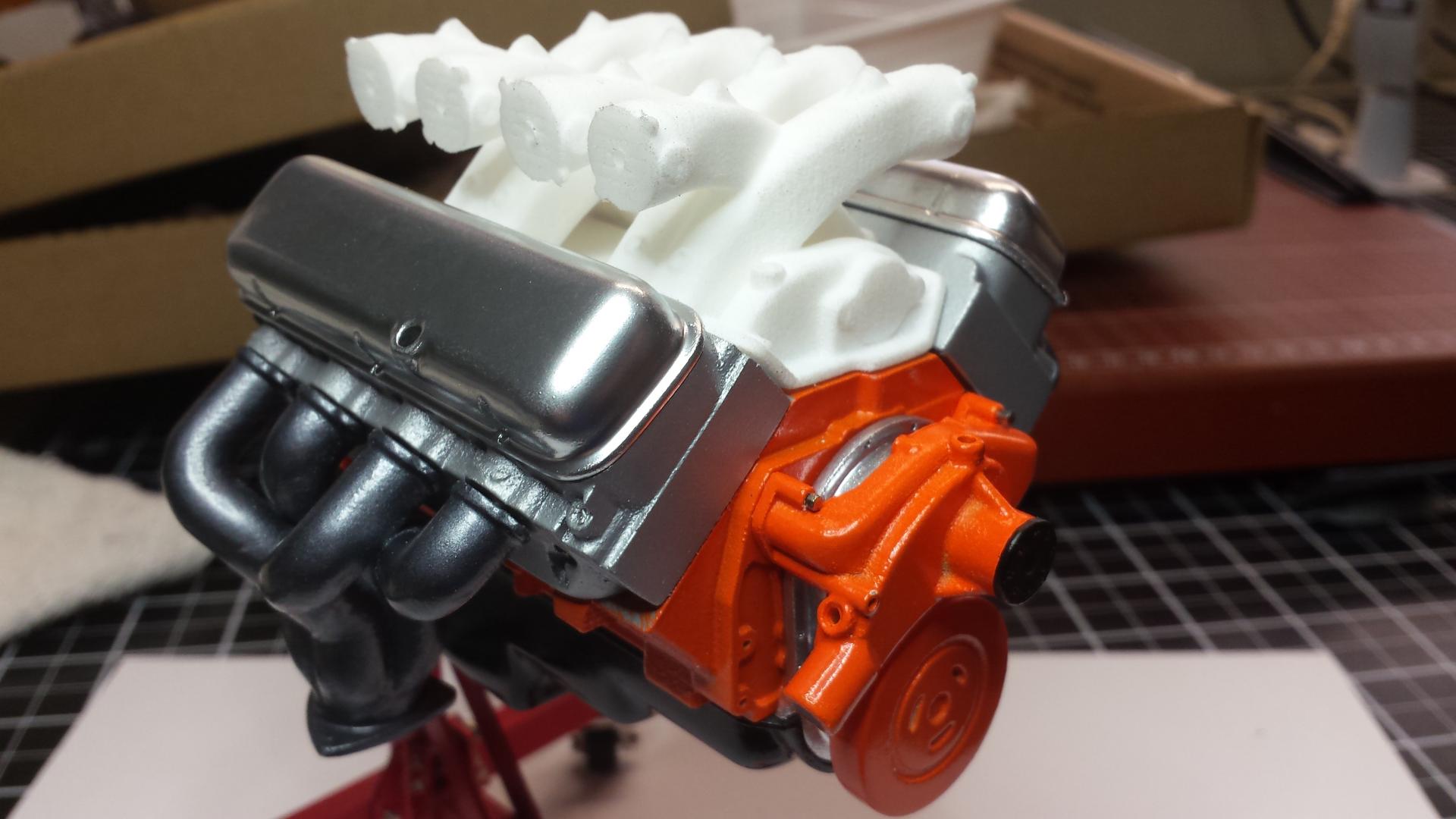

And here I've got the oil pan & water pump test fit as well as the cross ram fuel injection which has a piece of plastic glued to the bottom that fits into the opening on top of the block.

-

-

-

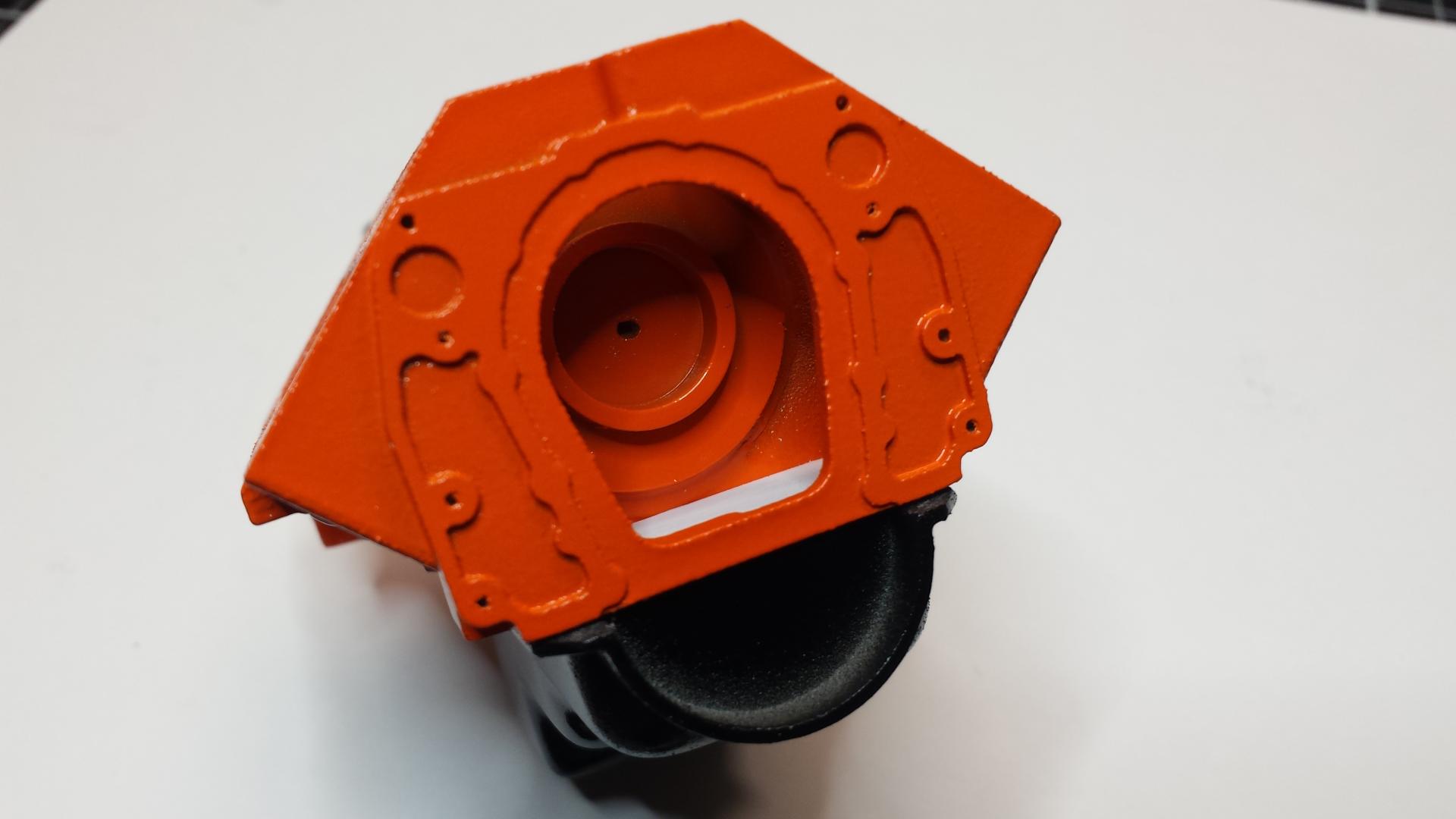

Timing cover, I attached a small piece of 5/8" PVC tubing to the back which attaches to a larger (3/4" I think) piece attached to the forward internal bulkhead inside the engine block.

-

-

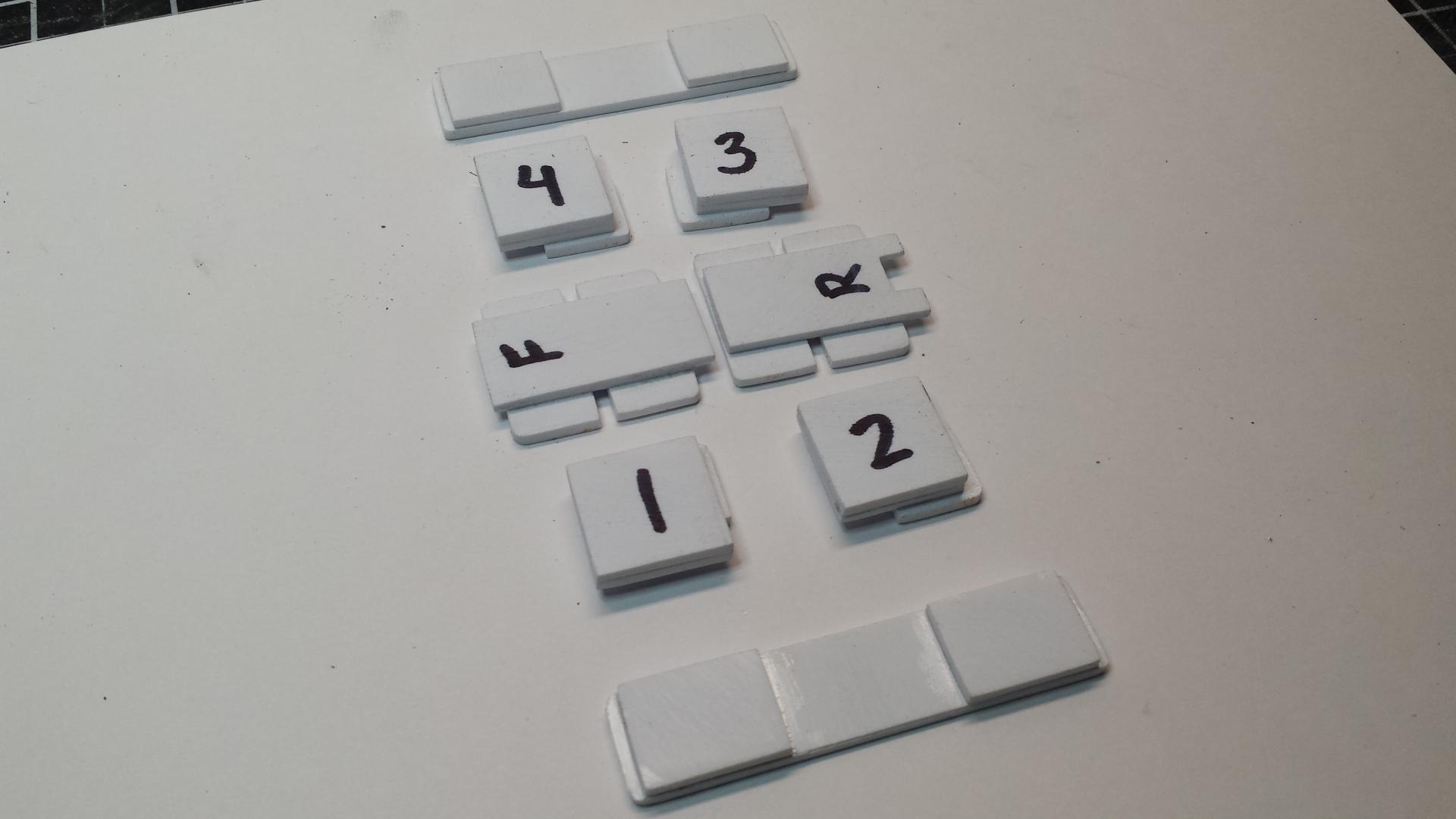

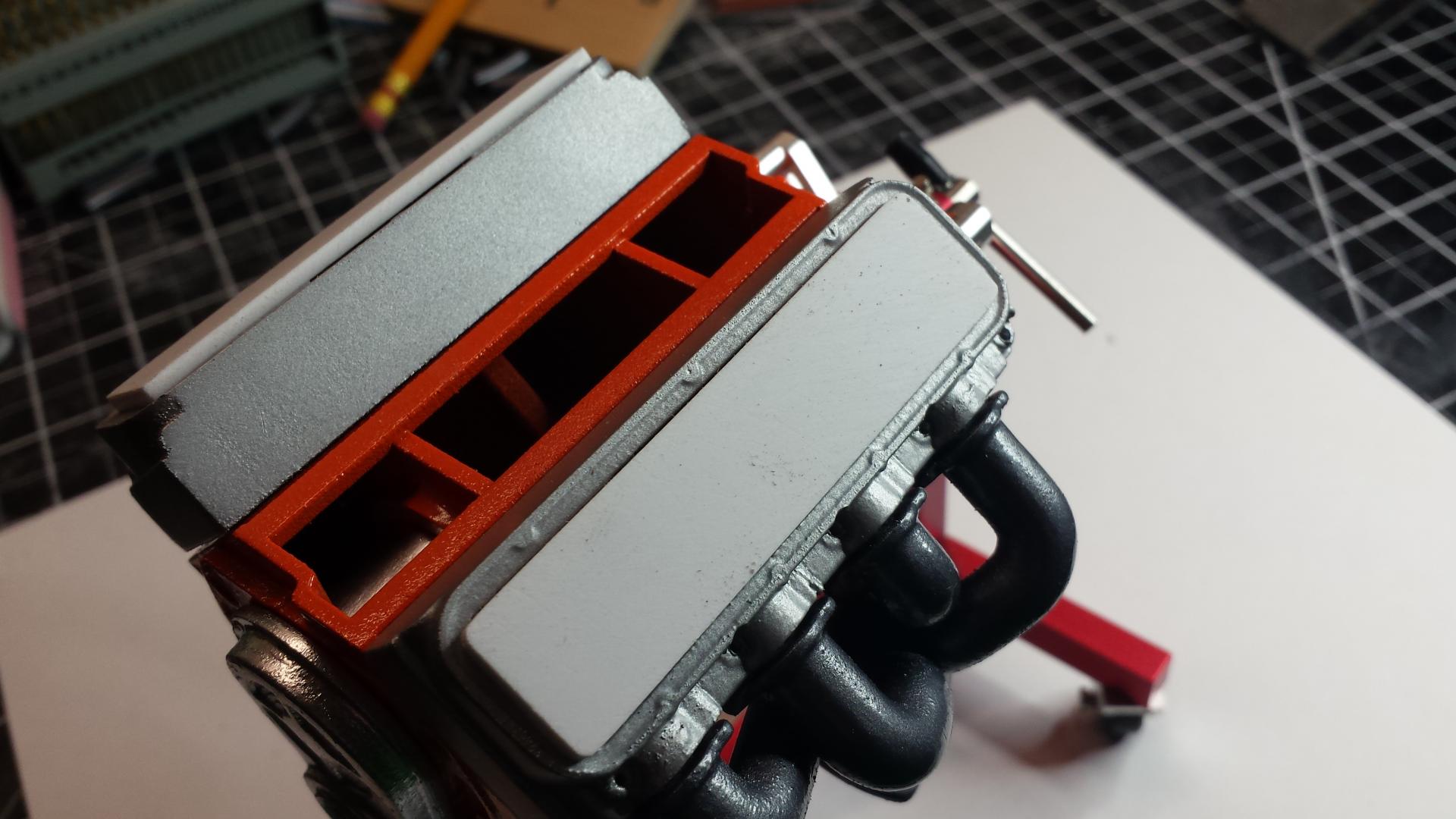

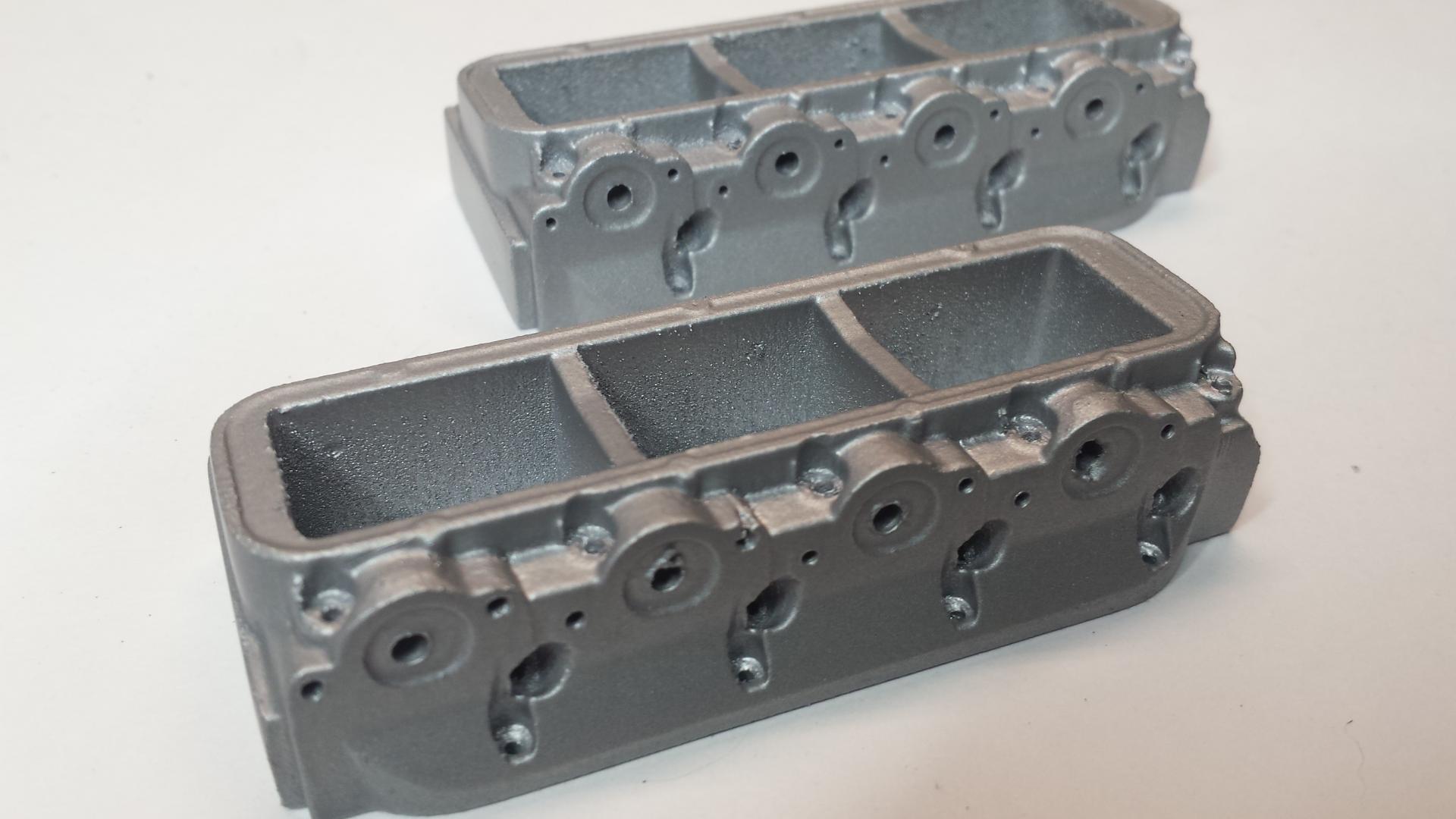

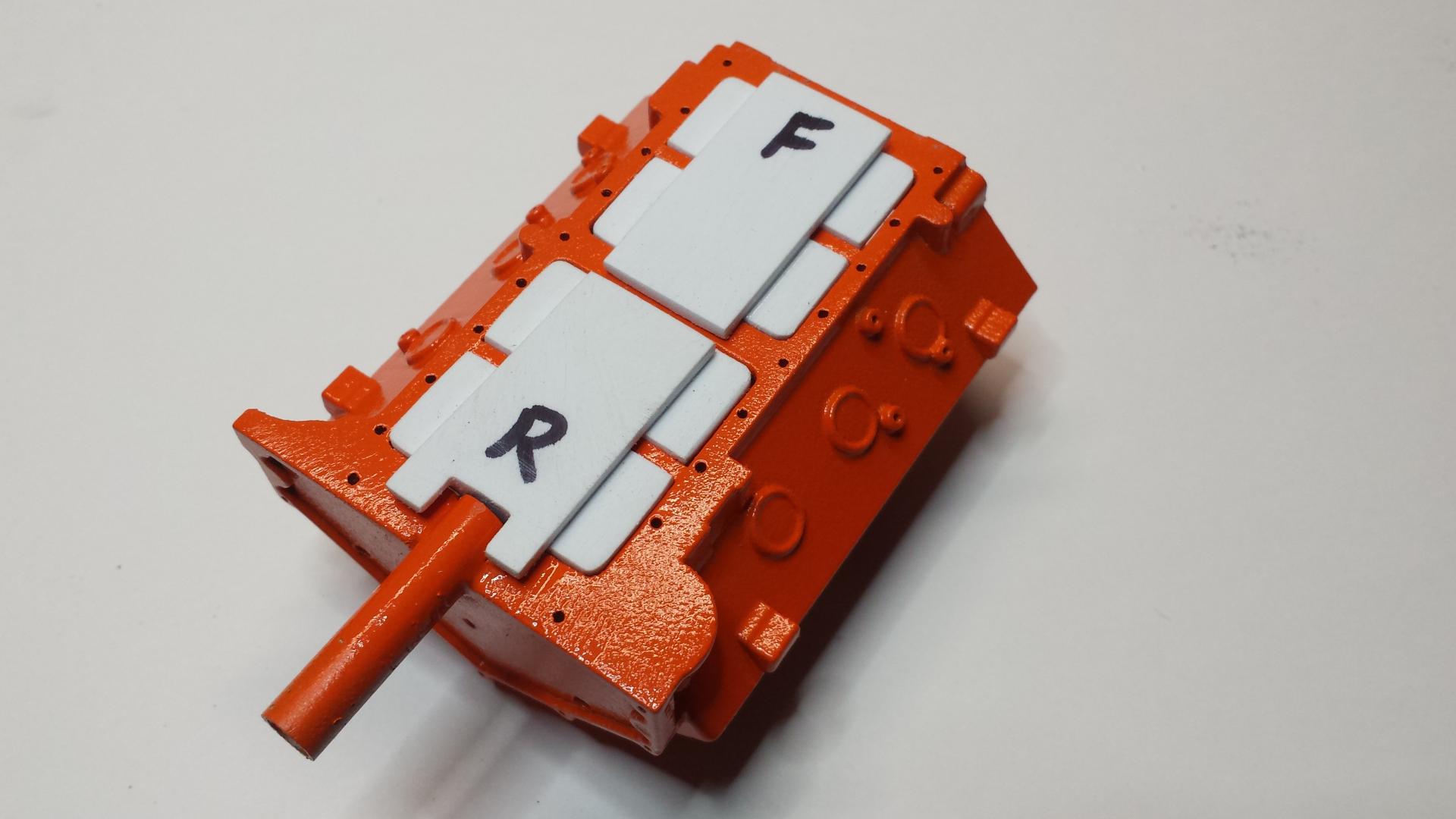

I thought I'd share my methods for assembling t he 3-D parts. I make little plastic locating pieces together - like the heads & valve covers, heads & engine block, oil pan & engine block, etc. Nothing shown here is permanently installed but rather held in by compression. First, the oil pan...

-

Having received the Chevy big block from Shapeways and after doing a few test fits I'm thinking seriously about using it here. I have both the cross ram fuel injection and the single quad Holley for induction choices. Both appear to fit under the modified hood. The TDR stuff is first quality all the way.

-

Model Motorcars took over Scale Hardware. Here is their site: https://model-motorcars.myshopify.com They have threaded and simulated hardware in sizes from .5mm - 2.5mm in lengths up to 12mm in brass, stainless steel and nickel plated brass.. They feature hex, domed, slot and allen head and also have rivets, carriage bolts, wing nuts, acorn nuts (7 sizes) and cool little threaded clevis' . Many other items. They also have threaded rod.