-

Posts

145 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Steve Osbourne

-

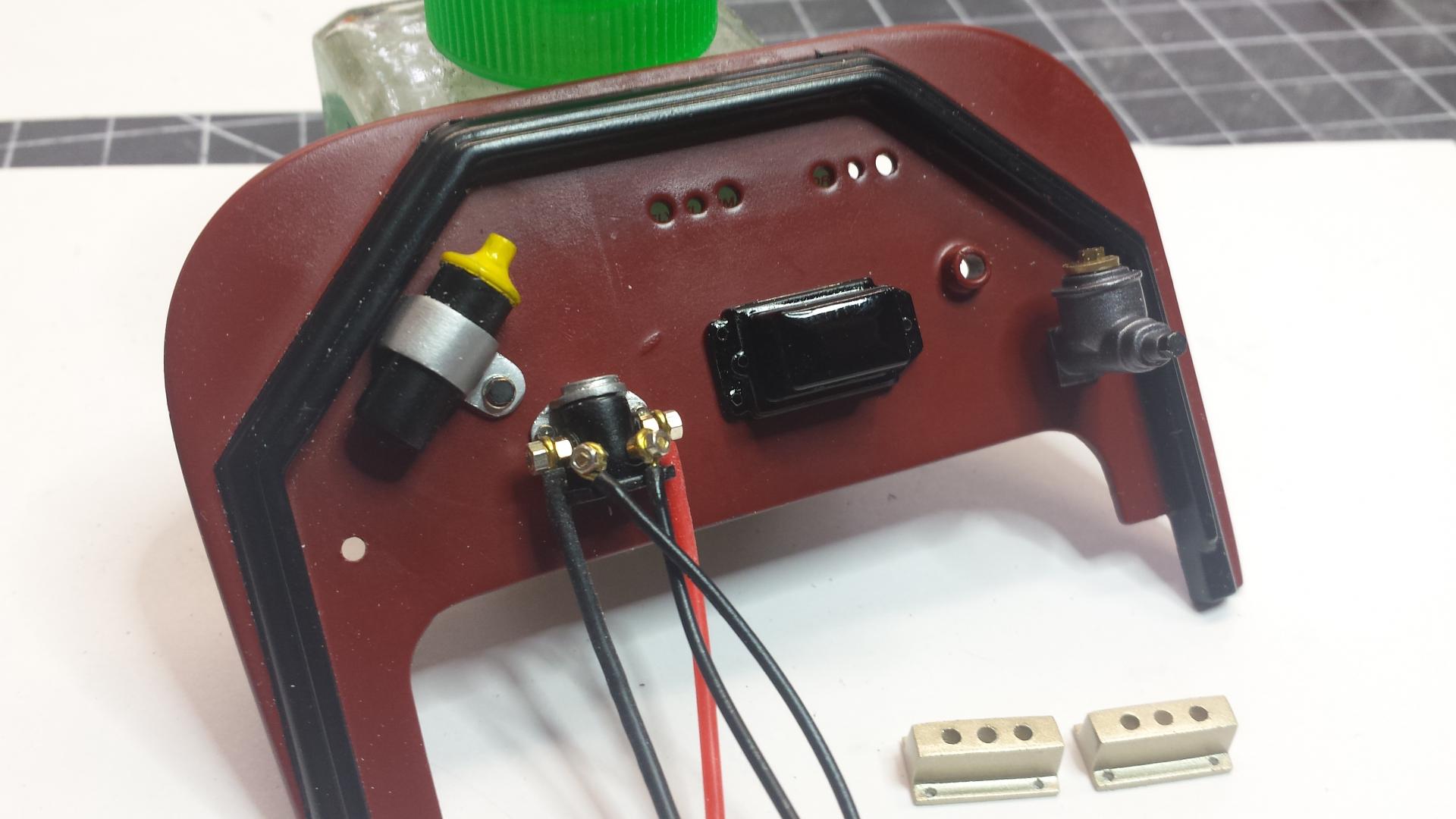

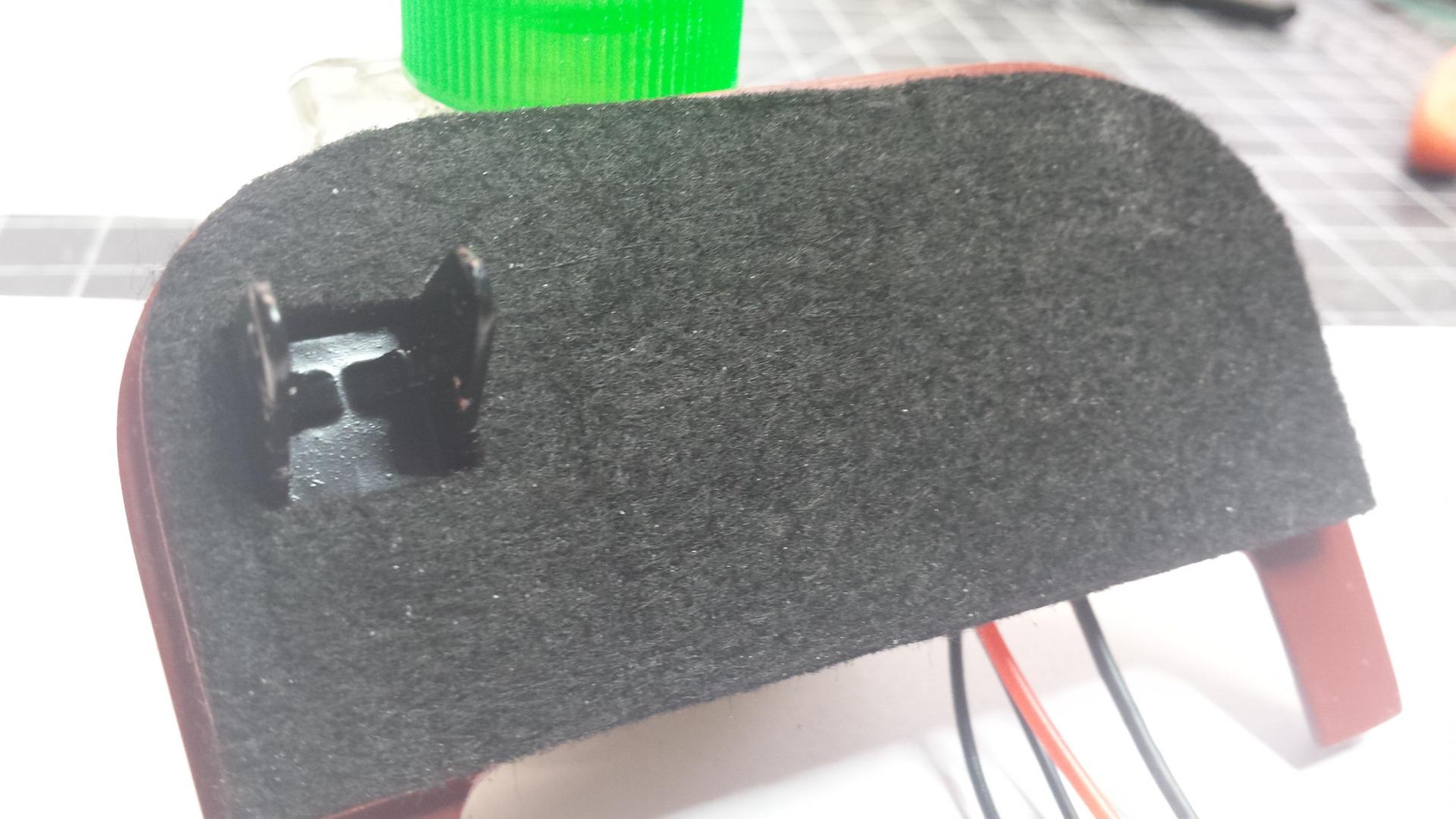

this is as far as I've gotten with the firewall. I moved the coil and master cylinder down from where the kit wants them installed. I need to add hardware to the voltage regulator and run wires. All wires entering the firewall will be hidden from the rear (interior side) by a panel covered with the black felt carpet. Also note that the pedals are mounted using a piece of threaded rod which allows me to adjust their location slightly. The clutch pedal in the previous photos will be moved a little to the left during final assembly. It was too close to the steering column.

-

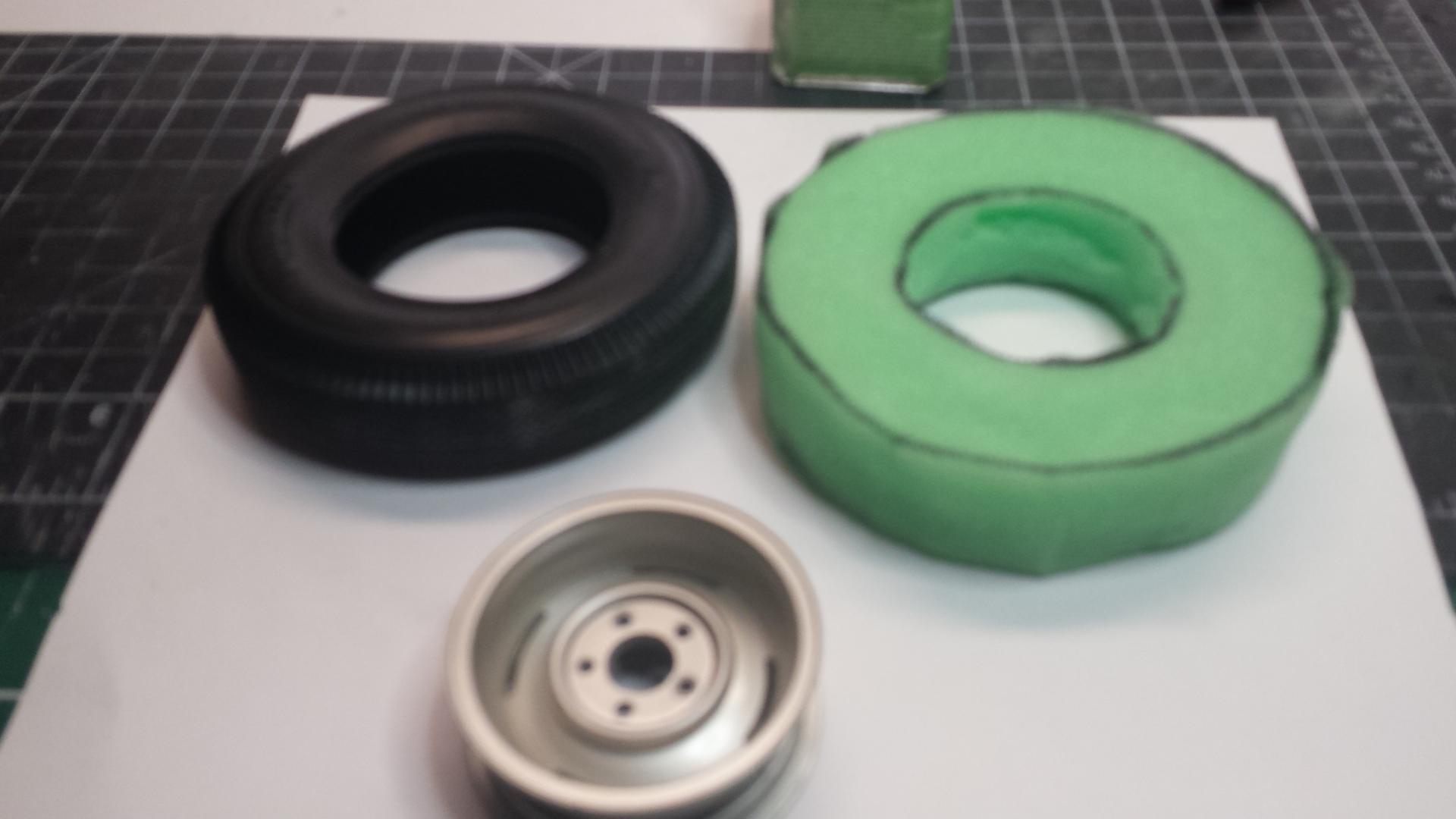

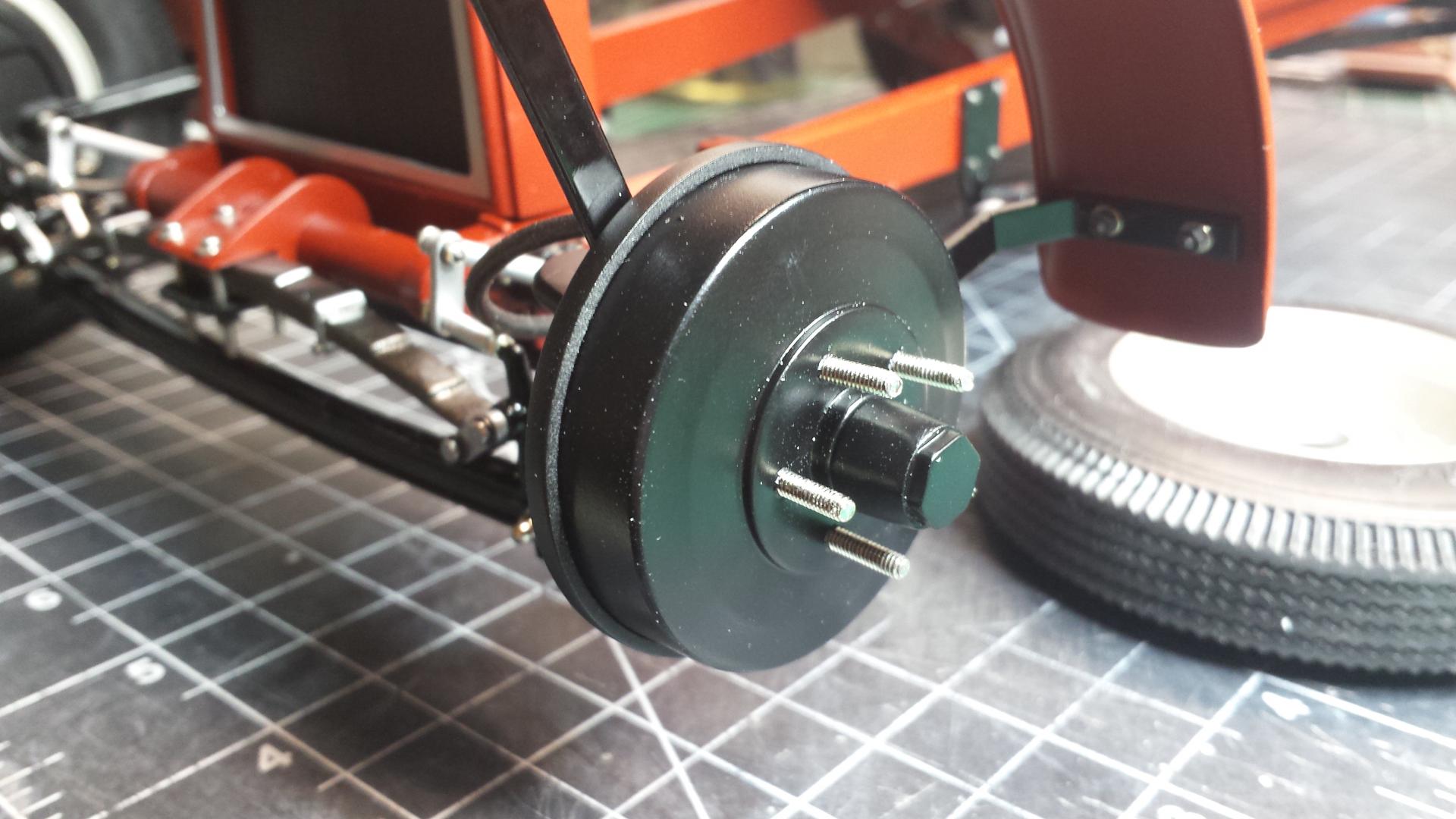

I had to modify the wheels since the kit wheels didn't fit the Firestone tires. So I used the inner part of the kit wheels, drilled out for lugs, and the outer wheel from the Big T kit. Anyone that has used these tires probably know that they are a bit flimsy. This is easily fixed by making a "donut" from 1" thick foam rubber from the craft store. The wheels were sprayed with Tamiya Titanium Silver.

-

Thanks Bill!

-

more subs. Right now I'm working on the firewall and wiring. I'm doing only basic wiring - starter solenoid, voltage regulator, generator, ignition, starter, etc. Also working on the intake manifold with six Stromberg 97's.

-

more sub-assemblies. License plate is from MINIPL8S. License rim is made from Evergreen sheet. Taillights are from the Big Deuce.

-

Thanks Mike. I've used this kit for parts on other builds before but never did a build up until now. I think it's under-rated. Note that I used very little chrome. The gas cap is most notable. It's a knock-off hub cap from the parts box.

-

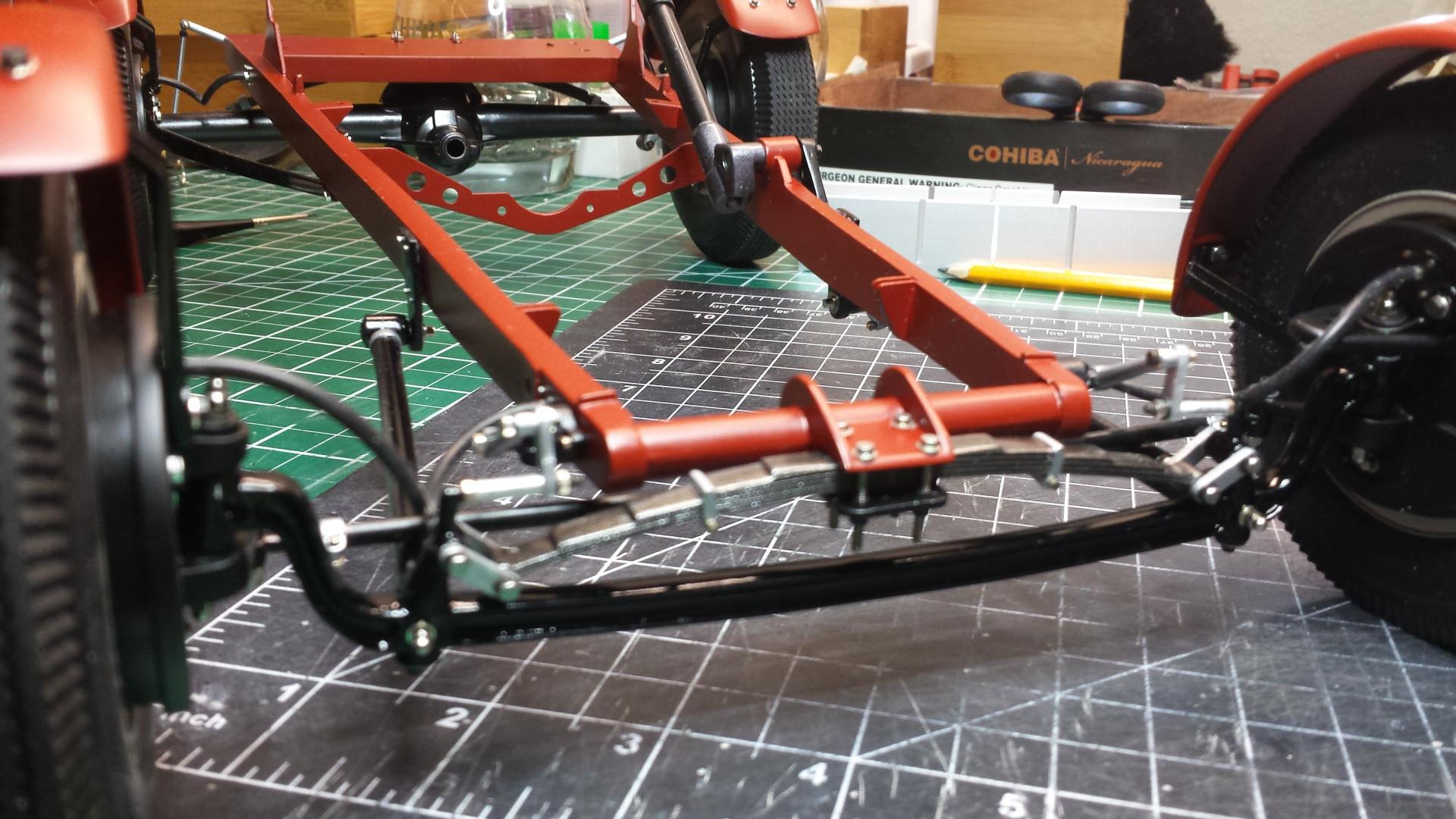

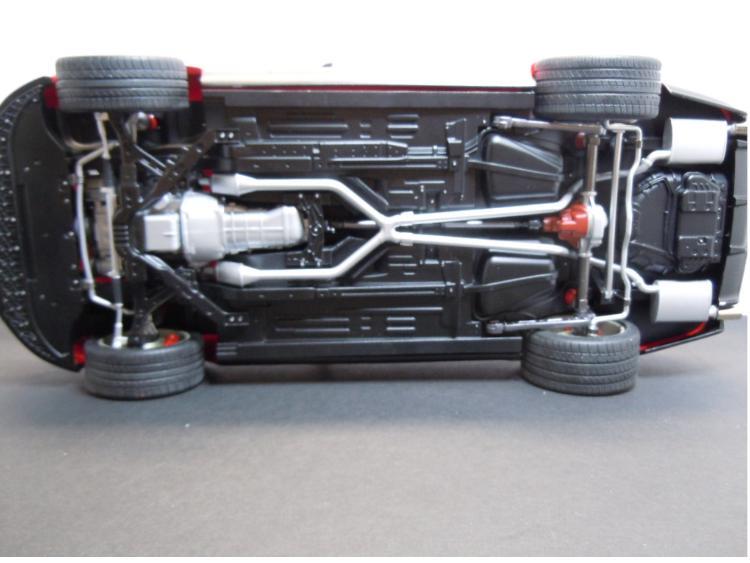

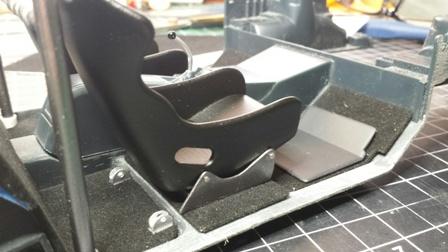

I added a bracket to the frame (made from Evergreen square tubing) so I can mount the interior bucket easier during final assembly. It will mount with screws that will be hidden under a false floor covered with felt. Transmission is from the kit. Pinion yoke and driveshaft use 3-D parts from TDR specialties.

-

Interior panels are velour Contac paper. Carpet is adhesive-backed felt. Steering wheel is made from Model T outer rim (due to its smaller size) and the center spoke part from the kit's custom steering wheel. Moon gas pedal (trimmed down) is from Big Deuce. Steering wheel drop is scratch built. Kit pedal pads were made from pipe screens. Gear shift lever is 1/16" aluminum tube. Knob is a sewing (dress?) pin. Seats are from the Lindberg Tall T. Console between the seats was made to represent where the battery is (no battery in there though). Engine is kit Ford Y-block with a few additions from the spare parts box.

-

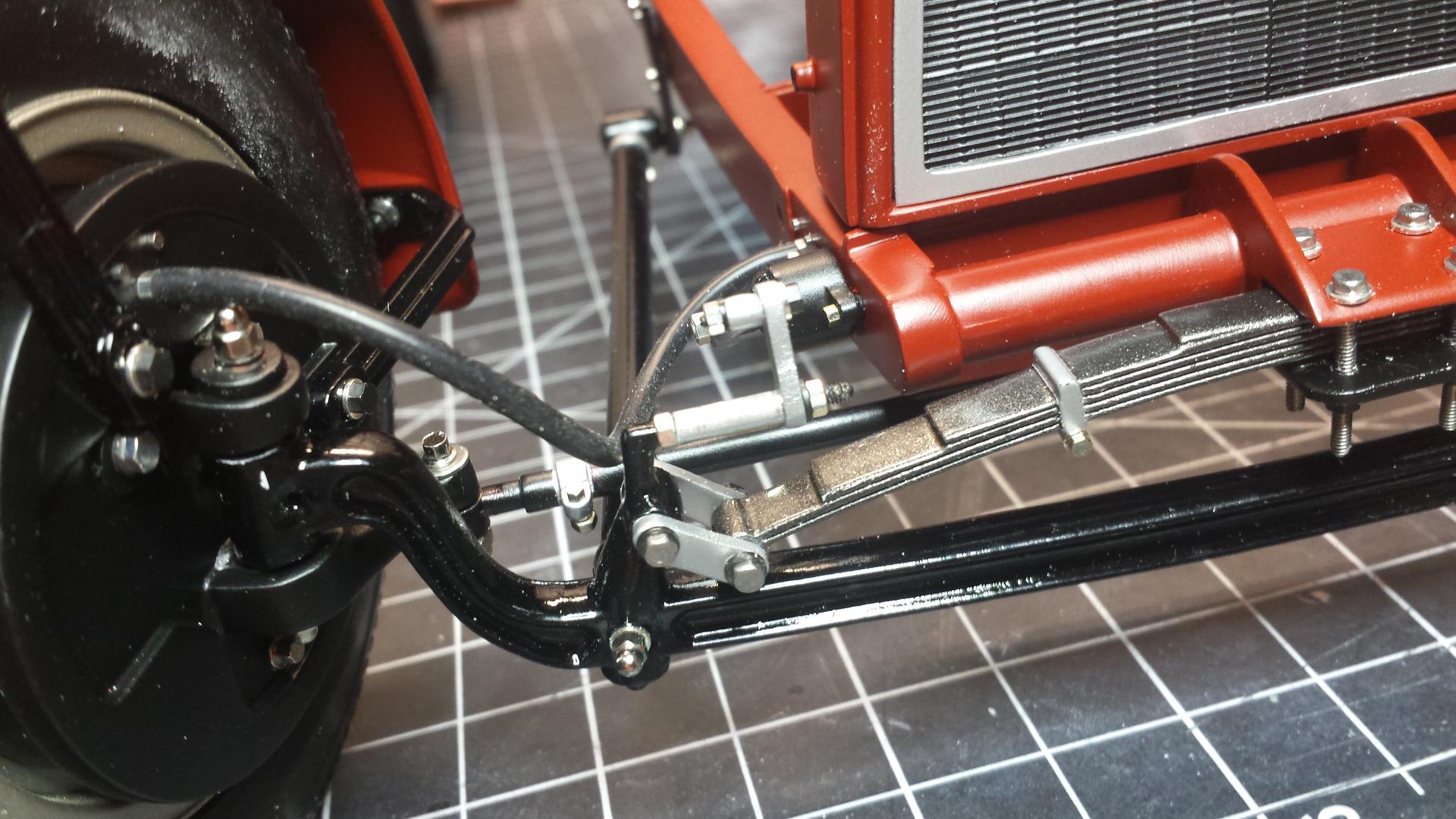

I'm getting close to completing this build. Here are a few photos of the sub-assemblies. Frame rails were boxed and cross-members were reinforced. Firestone bigs & littles are from Big Deuce kit. Fender brackets had to be modified to allow for the larger tires. Chopped windshield is scratch built. Moon tank was made from PVC tubing. Roll bar is made from Plastruct tubing and fittings. I ruined the kit banjo rear end so I used a Pontiac Trans Am unit from the spare parts box. Dash is wood veneer that has been decopauged and drilled out. Gauge bezels are aluminum tube.

-

-

-

Here we go. Finished 2010 Shelby GT500 Custom. The first 3 pictures were taken just after sunrise and it was very humid. My camera lens fogged up as well as the windows on the model. The other pictures (next post) were taken late morning and the sun was very bright. Not exactly optimum conditions. Still, I was ablt to get a few good pictures. This was a fun build and I already want to do another one. There are so many different ways you can go with it. Although at first it seemed that I was doing too many modifications the end result was sort of a sleeper. You don't really notice the flared fenders unless you are looking for them and the smoothed body, minus door handles and other items seemed to work. I'm going to spend the afternoon taking some indoor pictures and I will post them later. Those will include interior, engine, chassis, etc. Thanks for looking.

-

Objects in mirror may appear closer than they are...I've pretty much finished the assembly so I waxed the body with some Meguiar's #7 Show Car Wax. It's supposed to be a nice day today so I'm going to take it out for a spin and get some outdoor photos which I'd like to post first before posting the indoor photos later.

-

-

Window glass was taped off on the inside and the edges blackened with a wide-tipped black Sharpie. I would recommend taping off the entire outer (opposite) side also to prevent scratching while doing the Sharpie thing. The kit glass is very thin so be careful. I painted the windshield wipers – which are molded into the body – by hand before installing the glass. Also installed the sub visors/overhead console/rearview mirroe assembly to the body. Now you can see the painted headliner.

-

I made a license frame from 2 layers of Evergreen plastic sheet. First by tracing around the scale license plate from MINIPL8S.com and the using a standard 1/4" paper punch to punch out the center and then clean up the edges by filing. Then took that piece and glued it onto the 2nd piece of Evergreen plastic and then cut away the outside of both pieces until it was the right size. I drilled out the plate, frame and car body to accept 1mm screws which I used to mount it to the body.

-

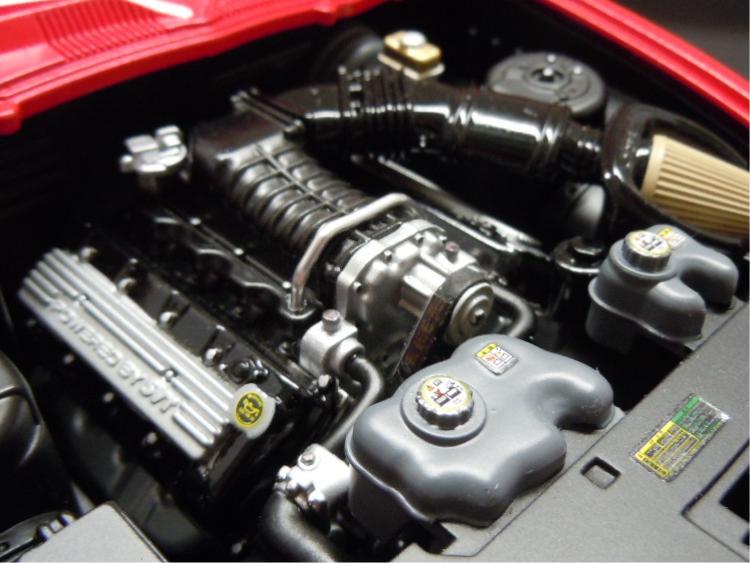

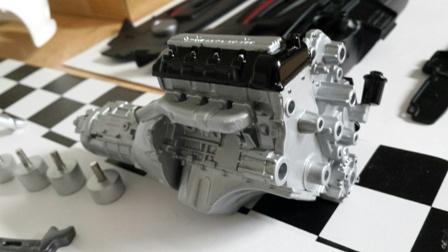

I finished the engine and assembled the frame parts. Also finished the dash and installed the '65 Shelby steering wheel.

-

I masked off the body and painted the rocker panels and bumpers matt black. You can't tell from these photos but I also painted the headliner matt black as well.

-

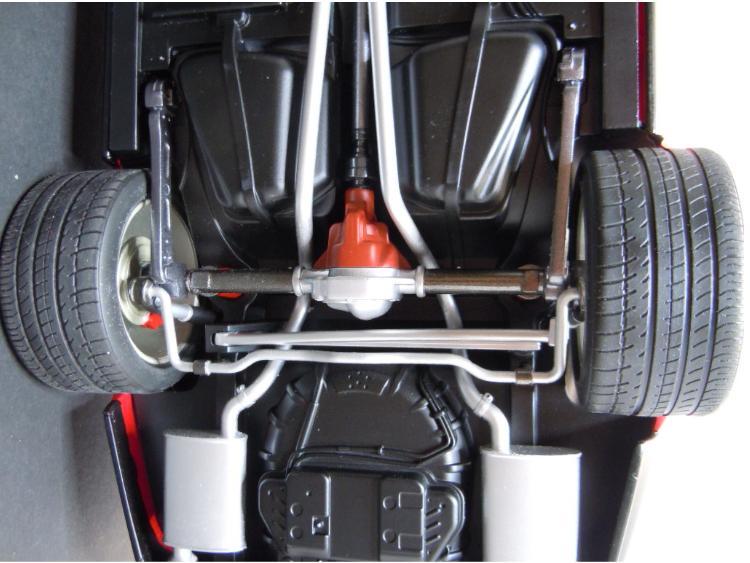

The wheel hubs shown next to the engine are scratch-built to adapt the wider Porsche wheels to the Shelby kit.

-

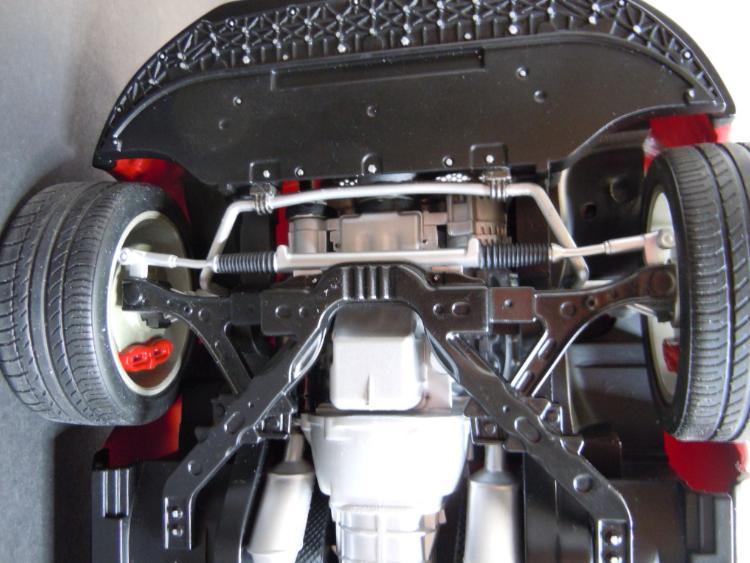

While the paint has been drying between coats I've had a chance to work on the chassis, engine an other sub-assemblies. These parts are being kept mostly stock with a few exceptions. The yellow Dhelby wheel caps are from the 1:8 1967 Shelby GT500. Steering wheel is from the '65 Shelby GT350 (with black rim - not wood). I thought It might look nice to add a little accent color to the matt black interior panels. Since y\the body color I’ve chosen is Tamiya Italian Red so that’s what I used here. You can also see that I’ve removed the part of the rear panels above the belt line where the kit rear quarter windows were. They would have interfered with the ‘new’ ’65 Shelby vents.

-

In between working on the interior I've had a chance to start applying the Tamiya Italian Red to the body. The temperatures here in Florida have been in the low 90's and my garage (where I paint) is a little warmer. The result is that I'm moving along quicker than expected. Here is the body in red...

-

I should mention the oversized shift lever is a piece of 1/16" aluminum tube with a black ball-end dress pin inserted on the end. The little neck pads on the Recaro seats are adhesive-backed felt from a craft store.

-

-

This is where the fun really begins. The Recaro racing seats are from 3D Specialties and made by Shapeways. You need to build your own seat brackets which I did from Evergreen sheet. The 4-point roll-bar is made from Plastruct tubing and fittings. I painted it Tamiya Gun Metal. The rear deck is made from sheet plastic after making 4 individual templates from card stock. The plastic sheets are held together from the rear by masking tape. After being satisfied with the individual panels I covered them with black velour Con-Tac paper, wrapping the velour under so there is no frayed edges. It’s best if you add masking tape on the backside to prevent the Con-Tac paper from coming unstuck. You can see that I also made seat belt brackets from Evergreen rectangular tube that are mounted to the rear floor panels. The seat belts will mount here with miniature hardware (00-90).

-

I found some cheap 1:1 Shelby valve stem caps on Amazon hoping that I would find a use for them someday. Here I cut a hole in the trunk and added a piece of sheet styrene underneath to simulate or replicate a "frenched in" look. I sawed off the end of one of the valve stem caps and filed the bottom flat and now I have a frenched in custom Shelby gas cap.