-

Posts

20 -

Joined

-

Last visited

Deuces WiId's Achievements

MCM Member (2/6)

-

midlineqb started following Deuces WiId

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with:

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

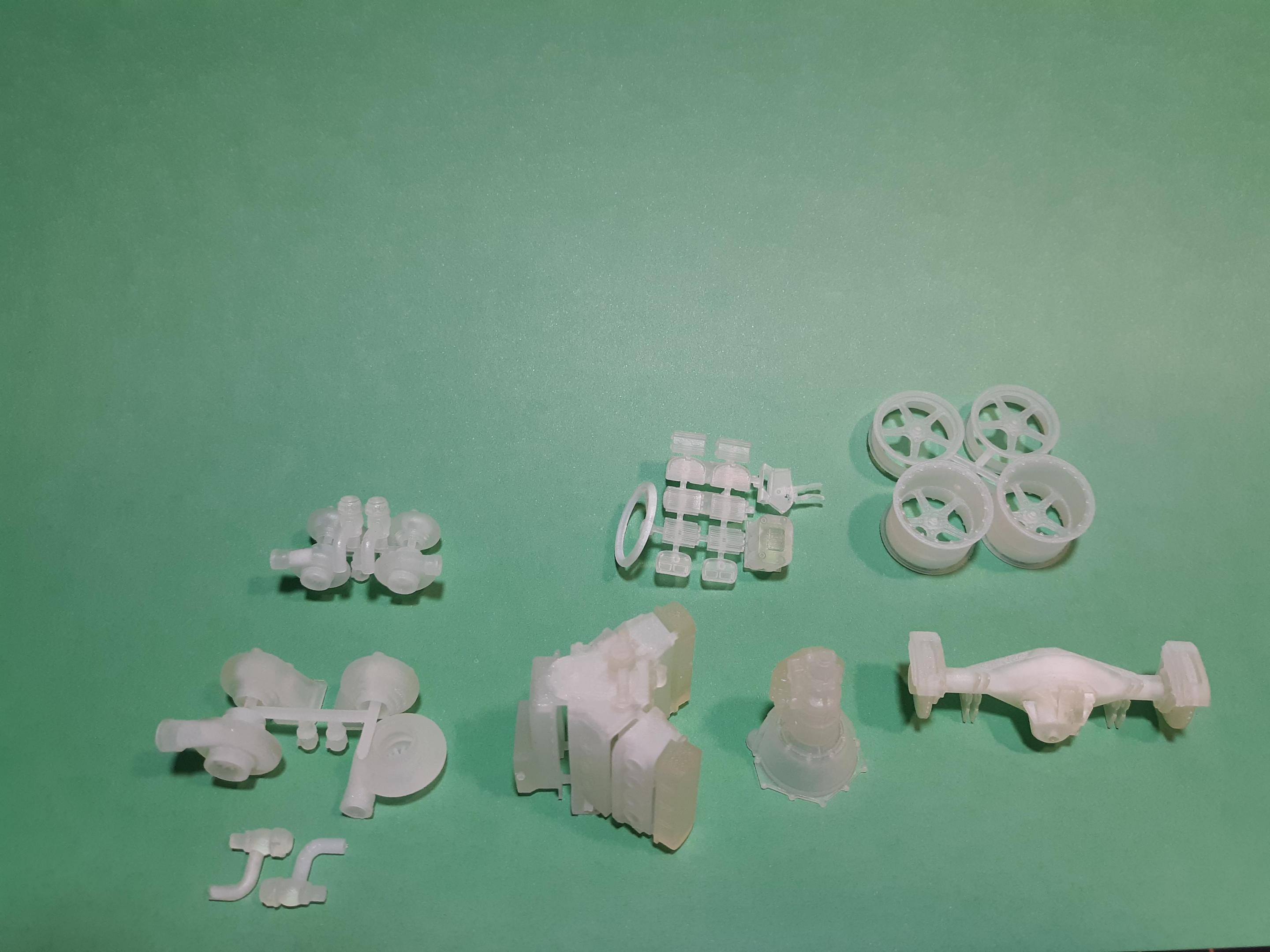

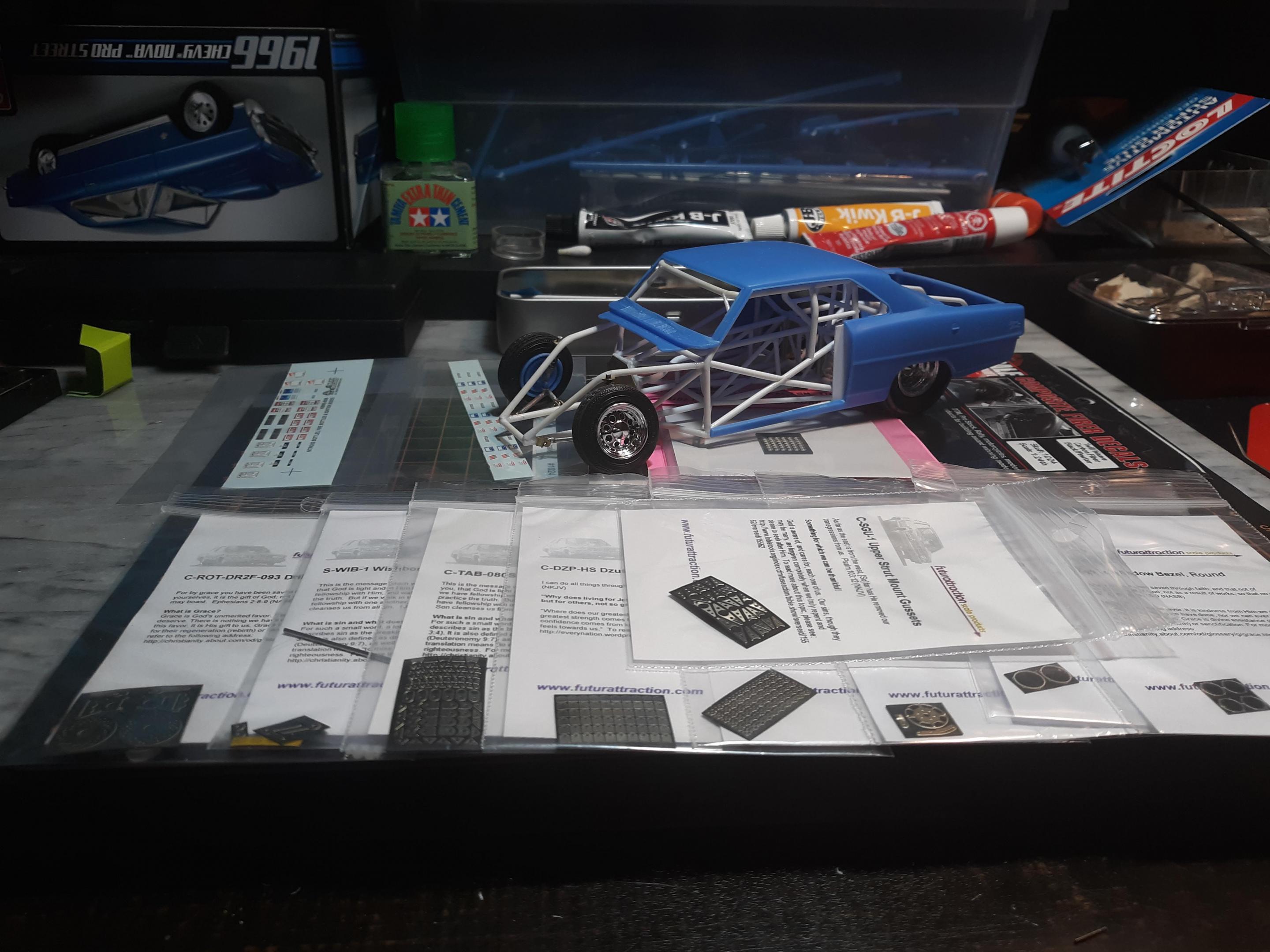

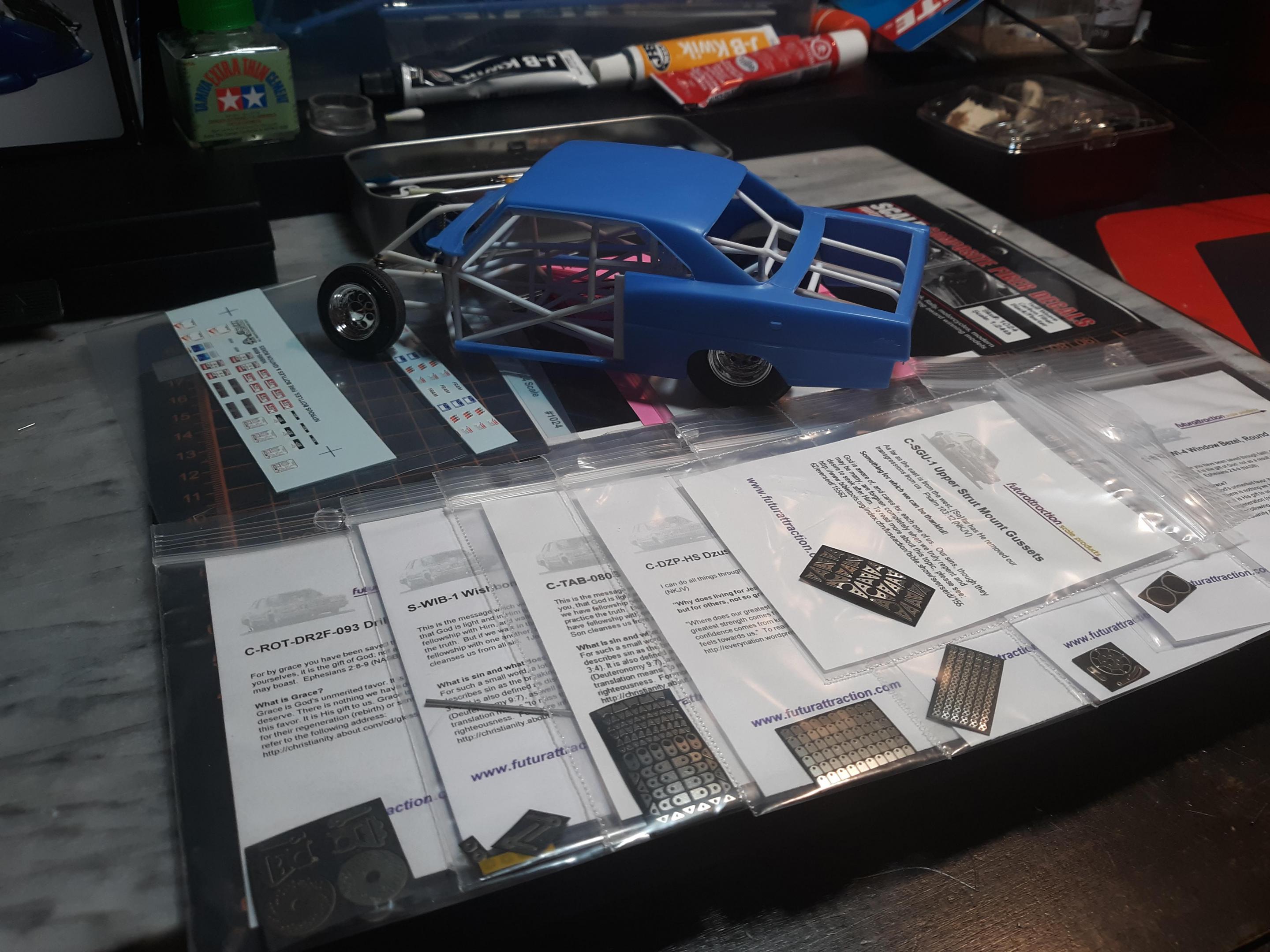

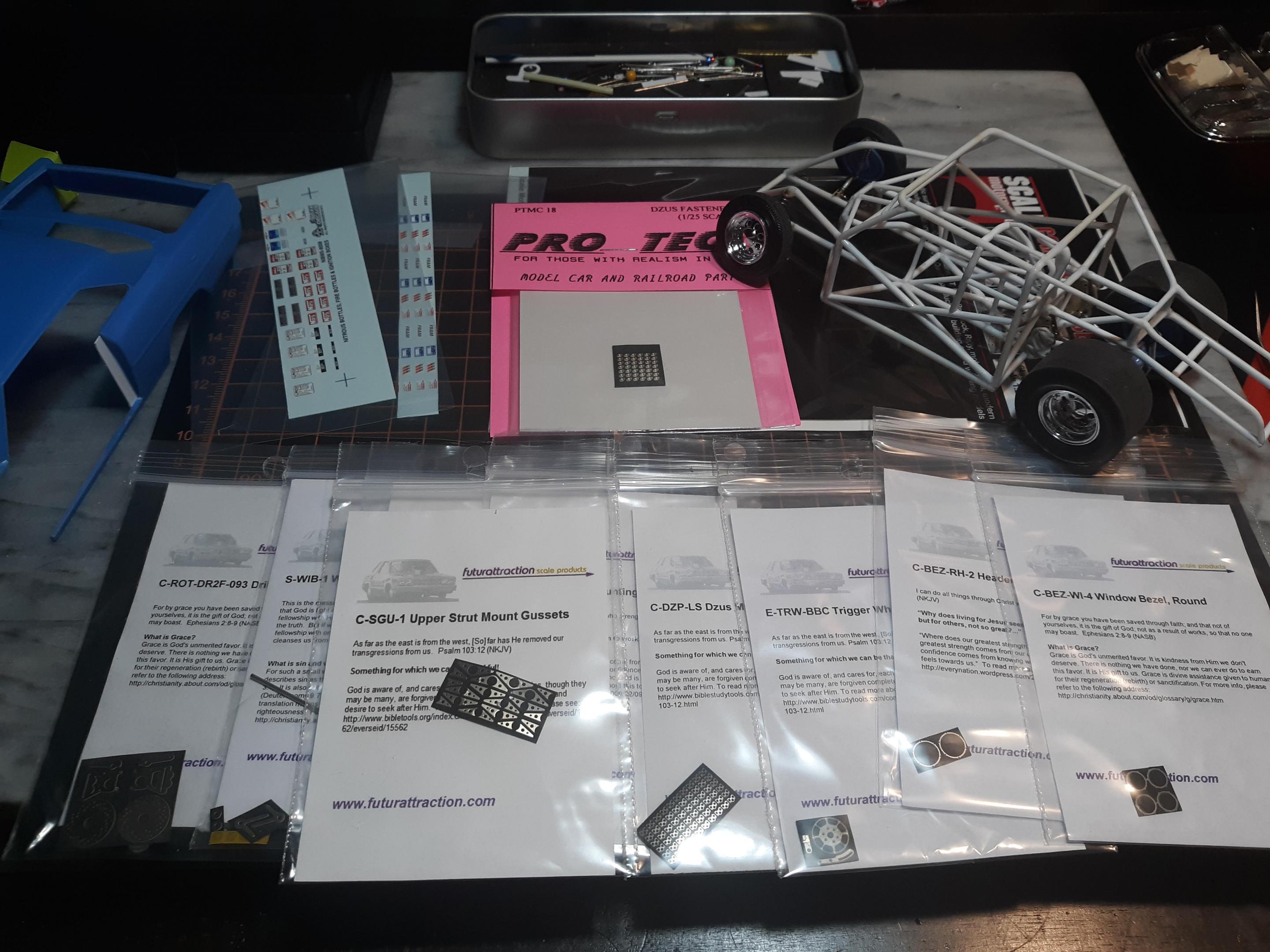

Got a bunch of stuff from the brown suit Santa Claus today. I got in touch with Scott and he fixed my Strut Supports and I ordered some Dzus Fasteners from him. The new parts look great and dealing with Scott has been a pleasure. I also got my 3D printed parts and 3D printer.- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with:

-

66 Nova Pro Street - My Return to Model Building

Deuces WiId replied to GeeDub's topic in WIP: Drag Racing Models

I start keeping a close eye on my radials after 20 passes, I'm happy if I get 35 passes on them. That's a Mickey Thompson 275 Pro Radial, I've never drove them on the street. I use Nitto drag radials on the vette and get around 20k miles out of them most of the time, all street miles. I've never worn out a pair of bias slick. I've put a few on the Nova due to the tires leaking out all the air and rim sits on the sidewalls for an extended period of time and cutting the sidewalls, or dry rot. It's probably been over 15 years since I've made a pass on a drag strip with big tires. I drive the nova around with 33x14r15 and it shakes so bad on the street that I normally have to turn around and pick up pieces of trim out of ditch after some spirited driving. I would hate to see what it would do at the track, but I also have a manual in it and its not doing much to help the problem. -

Jo-Han Maverick-Dyno Don's Ride

Deuces WiId replied to mustang1989's topic in WIP: Drag Racing Models

Looking pretty good. I'm a Chevy guy but I've always had a thing for these old Mavericks and for some odd reason Pintos. That Liberty shifter is trick. Well worth all the trouble you went through to get in the car. -

66 Nova Pro Street - My Return to Model Building

Deuces WiId replied to GeeDub's topic in WIP: Drag Racing Models

Most of these old engines aren't exactly air tight. They have stamped oil pans and even stamped valve covers for the most part. They build up a good amount of crank case pressure when you rev these engines out, especially if they have a PVC system or a little breather pushed into a valve cover. They're going to push a little oil out and road grime is going to stick to it. Every little place where you can't wipe with a rag is going to be pretty dirty. Good places where dirt likes to hide is on the engine block under the headers, around the timing cover behind the water pump, china rails always leak a little, around the base of the distributor and oil sending unit, starters are a good catchall, the transmission tunnel is impossible to keep clean, and inside the frame rails and floor boards can get pretty nasty. There's always 10 pounds of rubber built up in the rear wheel wells when I scrape them out no matter how much I try to keep them clean in between tire changes. Basically everything you can easily touch and see is spotless, everything else is surprisingly disgusting. -

I bought some cheap ones on Amazon and broke most of them the day they got here like I was getting paid to do it. The flutes on these seemed excessive, like they were designed to hog out a lot of material quickly. I know they don't like plunge cuts or drilling at all in styrene. I think they are designed for PCB cutting. I was fixing to start ordering parts for a CNC 3 axis mill until my wife turned me on to the 3d printer. I really enjoyed turning and milling perfectly good metal into completely useless chips with my old worn out Bridgeport and wobbly three legged lathe with a broken feed screw. I love manual machining, but it doesn't love me. I want to give mini machinery a go when I get into a place where I have more elbow room. I'm a glutton for punishment I guess. I have pretty good understanding of the tools, practices, and procedures that you are using to create these tiny marvels of engineering. I don't understand what the machinist is thinking as you go through mastering your craft. I'm in awe flipping through the pages wondering how you're doing it, and it has me wanting to figure it out. If I ask dumb questions it's because I'm trying to compare what you are doing with my experiences so I can learn a thing or two from you, I'm not criticizing your work at all. I want to join the ranks with all you manual machinists, if I ever sell my home. I'm stuck with digital machines in the meantime.

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

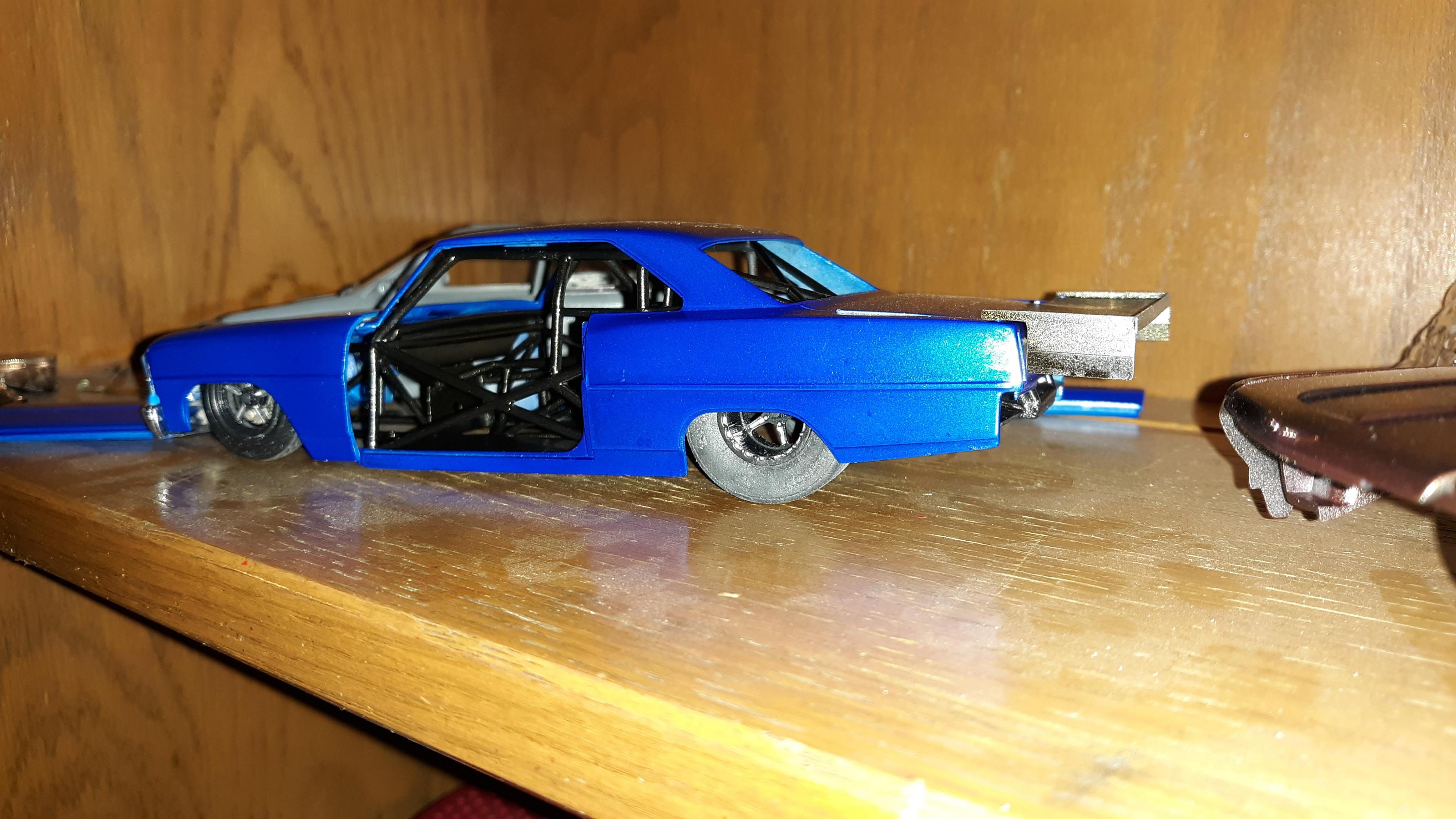

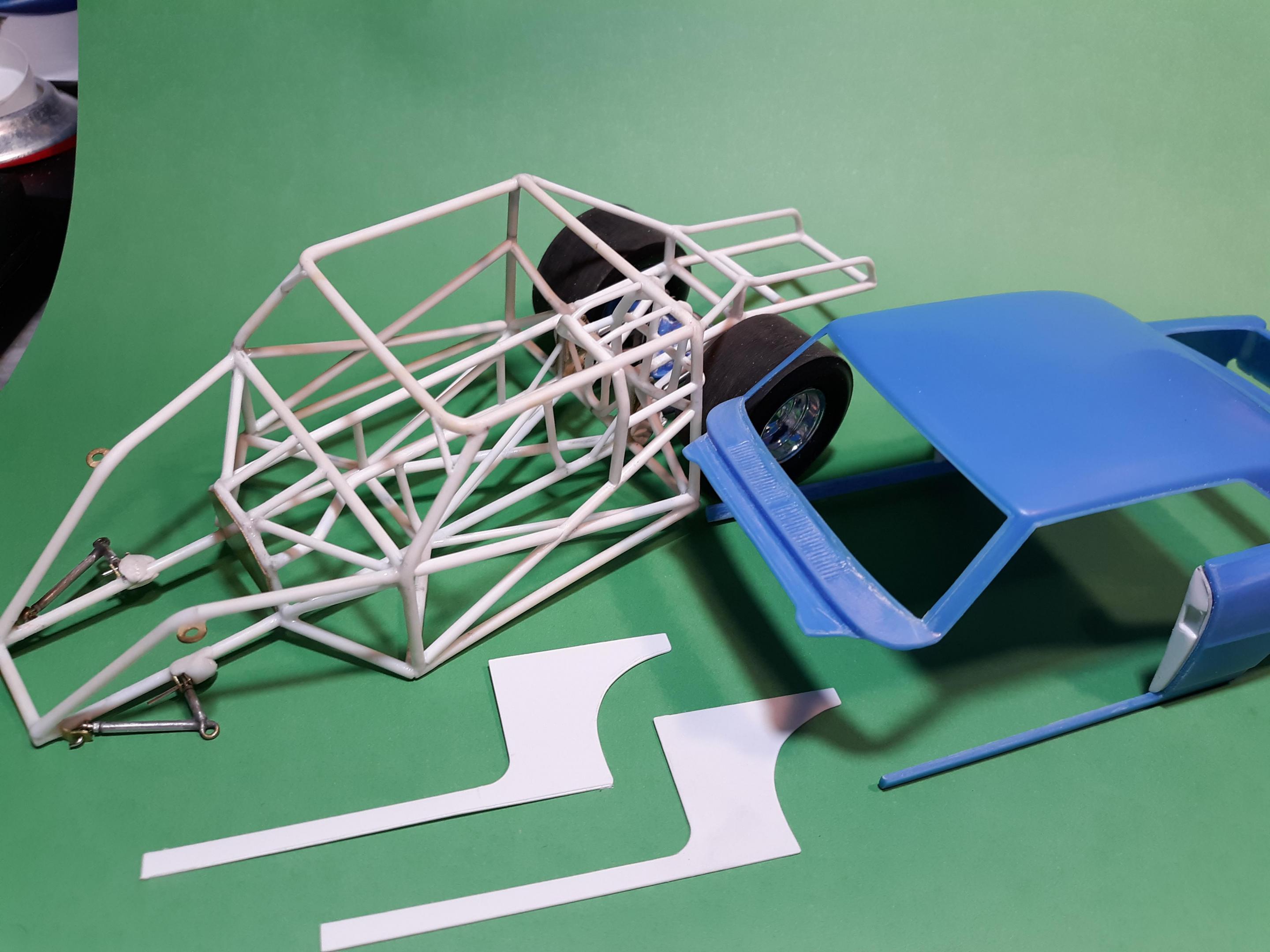

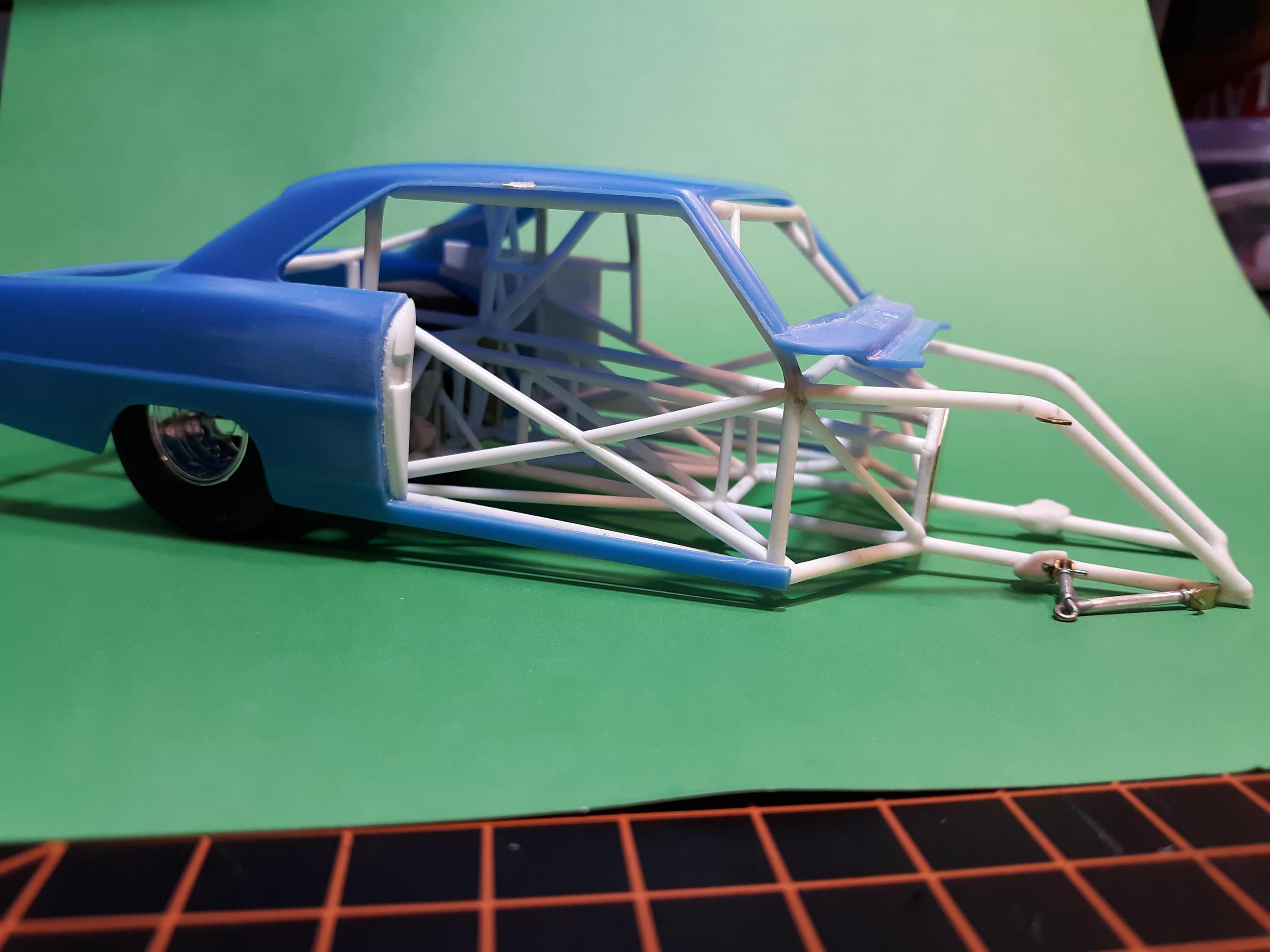

I got all the suspension pinned to the chassis and started skinning out the door jams. I've been spending more time building CAD parts in preparation for the 3D printer than working on the car. I got all my PE and decals in mail. Most of the parts look great, except for the front strut supports. Only half of them are useable, the rest are all eroded away. Is this a common problem with PE parts? Is there another company that produces these that are better, or do I just order more and hope I get lucky? I'll be printing out my own parts before my Shapeways order gets here. I've got my RCD wheels ready to go and I'm making good progress on the billet AJPE 481X.- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with:

-

Is there a reason why you couldn't mill the features further into your stock and part off both bases at once? Your attention to detail is insane and inspiring. I want to build a mini machine shop when I move. I'll probably just make washers and drill holes, wishing to build something half as cool as your work.

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

Things are going to get pretty crazy from this point forward. My wife was asking about the parts I ordered this evening and when I told her about the Shapeways 3D printed items, she said I was crazy. I have a lot of experience with 3D modeling parts for civilian nuclear reactors. She asked me why I didn't just buy a 3d printer, my response was that they used resin printers that cost a lot of money. She googled them and it turns out that they are a whole lot cheaper than I thought. I'm buying a new SLA resin 3D printer under the stipulation that I make her all the baby Yotas she wants!- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with:

-

Deuces WiId started following Duck, PRO 275, RVW, 66 Chevy II

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

All this stuff adds up fast. I'm a little over a grand so far. This is also my first model, so most of that is just tools, supplies, glues, cement, paint, brushes, sand paper, raw materials like rod and sheet styrene, brass, and aluminum. Most of the stuff that I just ordered will be used for future builds aswell. I don't like spending a bunch of money for the sake of being frivolous. I want my money to be used on items that can be used for multiple projects down the road. I really didn't want to buy the items that are going to be used in this build only and nothing else. I tried building a turbo and a transmission, but they weren't going to be acceptable. I could eventually make something acceptable, but I want to finish this thing up in 12~ weeks or so. I actually built most of the tabs for this car already, but my poor fingers need a break lol. Filing and sanding on a piece of brass that's 25% the size of a pencil eraser with my finger tips hurts. I don't have a way to hold these small parts without marring the surface. It's difficult to find these kinds of tips and tricks in the forums, and the good stuff that I can find has broken picture links. So I'm mostly learning the hard way, trial and error. Even a bad day of model building is pretty fun. Thanks, I'm following your Nova build aswell. Don't expect much actual progress from me as I wind up throwing away more parts than I glue lol. Building these things is very therapeutic. Focusing so much while I file to my scribe line on these tiny pieces makes me forget about pain. I feel like the oldest 40 year old boy on Earth sometimes. I have way more titanium in me than my car ever had, and it had a bunch. I won't mention the cadaver parts in me. Discovering this hobby has helped me out more than I ever could have thought. I was born into drag racing and building hot rods. I was directly involved in building, piloting, or advising some of the quickest and fastest door slammers on planet earth. Technology has been advancing so quickly in the sport that my knowledge became obsolete 2 years ago. Now I can't even talk about race car stuff with my friends anymore without getting lost in the jargon. I can't give anyone advice about chassis adjustments or tune up changes. I can't even change the oil in my car anymore without help. I stopped talking with pretty much everyone about a year ago and deleted my Facebook because everyone kept asking me one question that I couldn't answer "when are you going to build another car". I'm starting to believe that I'm never going to. All I can do is stay the course and wait. This hobby is breath of fresh air that I most certainly needed. Hopefully it helps you just as much as it's helping me.- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with:

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

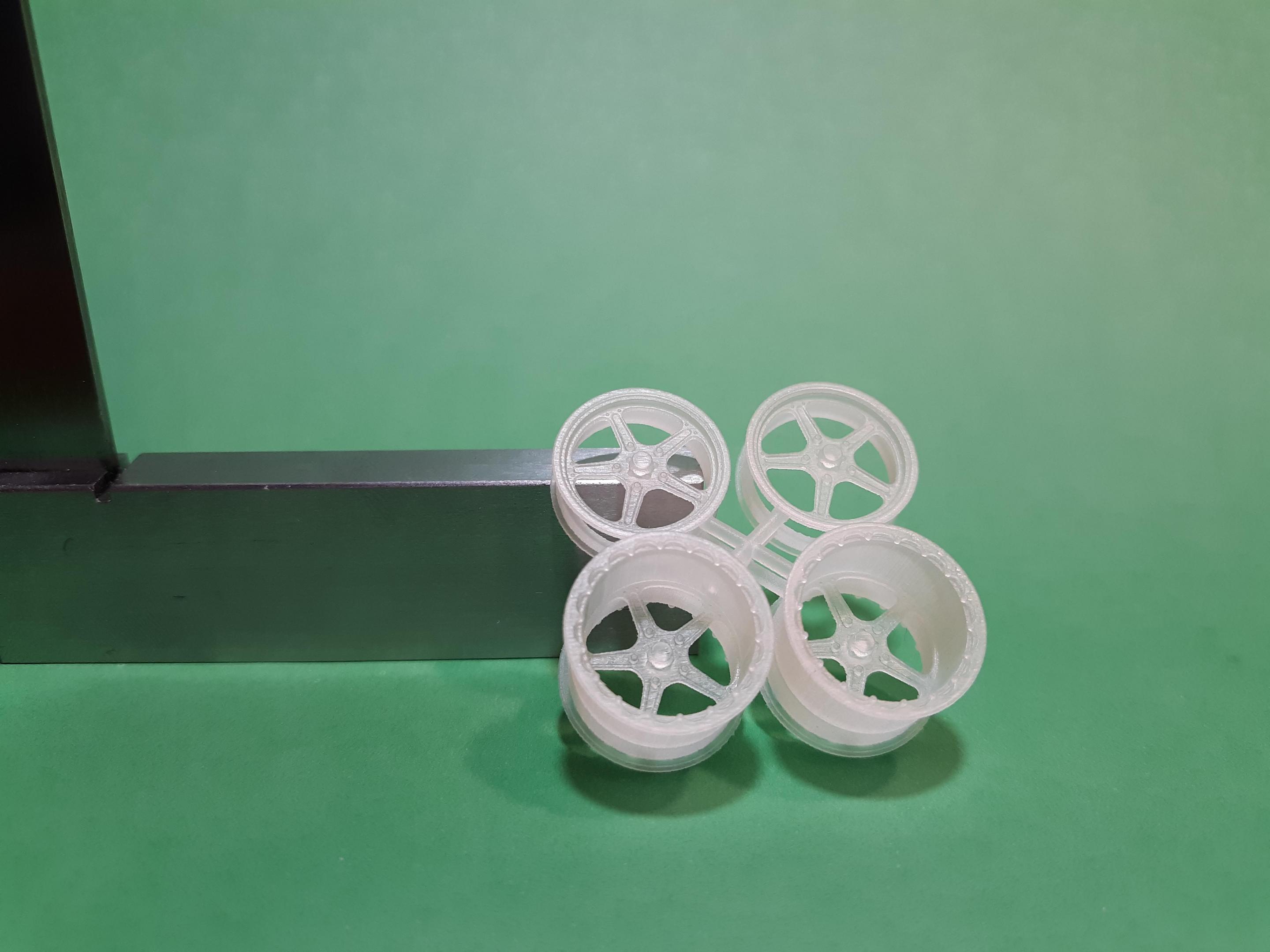

I haven't made much progress this week despite working on it every day. I lost a few chassis tabs that caused a rebuild of my work station. A friend dropped by to show off his new vette when I was in the middle of airbrushing my offsprings AT-ST. I dry sprayed the ever loving mess out of it. It was worth it, it's not everyday someone brings me a new vette to thrash. I ordered all of the parts needed to finish up today. My wife loves my new hobby after she found out what I spent. I told her to put some money into checking this morning because I needed some new radials, wheels, and some detail items. She rolled her eyes and shook her head because I failed to mention that it was for the model. Turns out that she still loves me after 15 years of marriage because she put 6 grand in there for me. I spent a few hundred between four vendors, I tried to spread it out as much as I could to help support these guys. I spent way more than I thought I was. My wife called me a few hours after ordering and asked how much I spent. I told her, and she sighed. I knew I was in trouble, but it was a sigh of relief. That's when she told me how much she put in the account. I missed an opportunity to get more Go Faster parts as I shouldn't push my luck. I got some brakes, tabs, levers, and dzeuse tabs from Futurattraction (tried to get a few more items but I couldn't get them into the order basket). I got all my decals, carbon fiber, and more tabs from Ted's Model Marketplace. I got a couple sets of radials from Cheetah. My biggest order was on Shapeways getting a handful of turbos in different sizes, BBC, AJPE Turbo HEMI, wheels, electronics, fire bottles, rear diff with brakes and tabs, and transmissions. Now I'm going to be looking out the window every time a truck drives by until they all get here. No pictures today as I only have the front suspension tabs mounted on the frame, one coil over finished and a box full of various brass and plastic "practice" parts that I messed up.- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with:

-

64 Dodge D100 Pickup Pro Street

Deuces WiId replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

I don't know how you can build with this much detail on such a small scale, mindblowing. I struggle putting u joints in a real car, and think it's the end of the world if I drop a cap and the needles fall out. You guys are making my own build so much more than I thought it would be. I'll be happy when I build something half as cool as y'alls. -

Deuces WiId changed their profile photo

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

I found that 3d specializes has a printed 275 pro. I'm not sure if they're going to work for me. The sidewalls are plain and the material might not stretch out on a 15x14 rim. There's also some of the 3d lines from the building process in the grooves of the tires that might be a chore and a half to clean out. But he does have some other items that look great. I need to get in touch with him and ask him about his Brodix BBC engines. I need a cast 5" Bore Space with a 9.8" Deck, but a 10.2" Deck will work if that's all he has. He has a gorgeous Reid TH400 case that I can use for my turbo glide. His shifter and interior components are pretty spot on as well. I also need a pair of AJPE billet heads and Precision 102mm turbos. Rules state that I can use a billet block or heads, but not both on the same engine. I'm a fan of the 481x style of engine because they're "affordable", easy to work on because it uses BBC architecture and parts are always less than 24 hours away from anywhere I've ever been. Thanks those tire look great! They're the street version of what I need, but beggars can't be choosers. They're a beautiful rendition of the MT Street Radials. The only visual difference between them and the MT Pro Radials are the tread pattern, but that's not going to be very visible when they're stuffed into the wheel wells. I need to stop drooling at all those speed parts and finish up the fabrication of my chassis.- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with:

-

Duck, PRO 275, RVW, 66 Chevy II

Deuces WiId replied to Deuces WiId's topic in WIP: Drag Racing Models

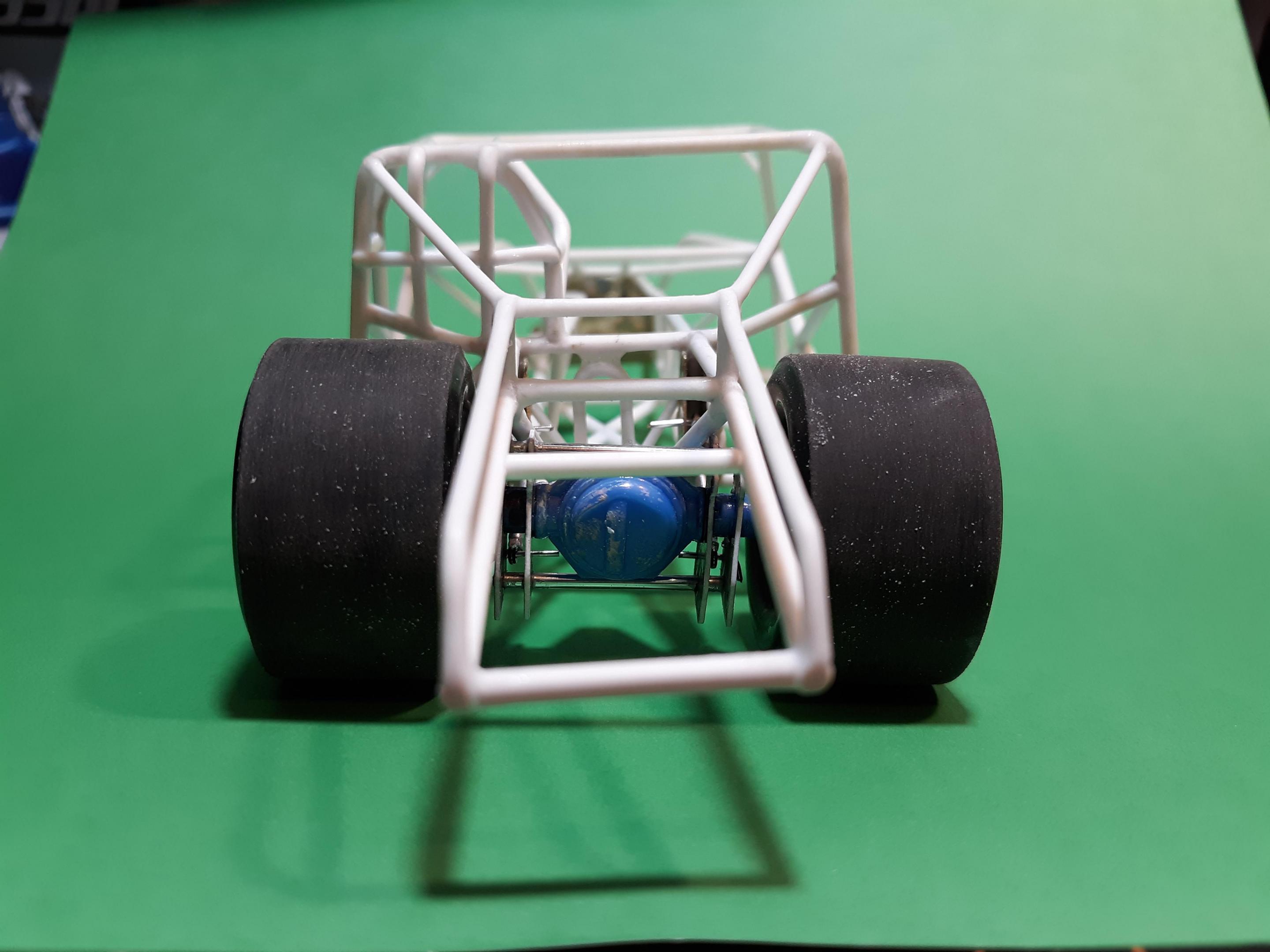

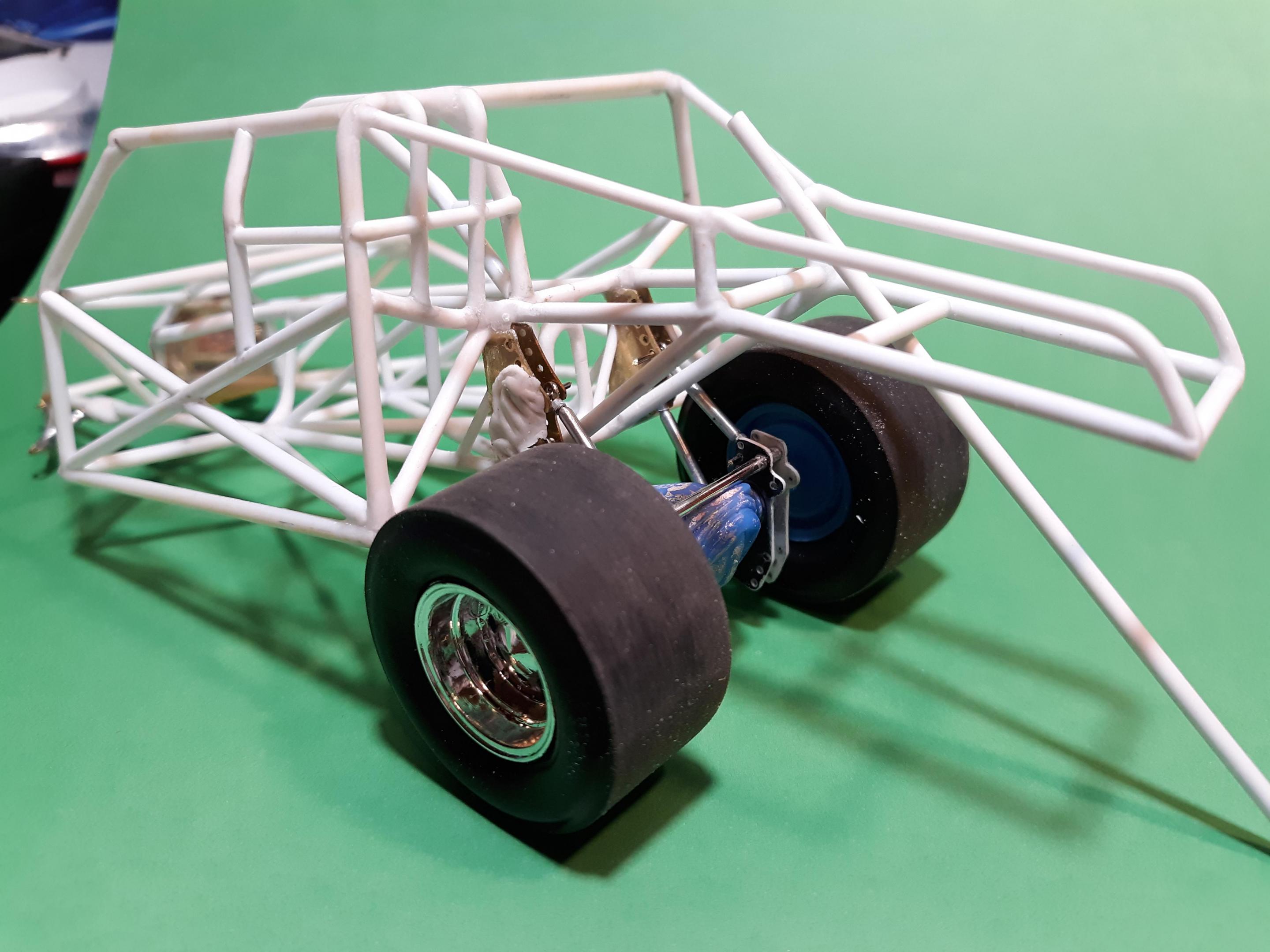

I need some help from you guys. I've searched the forum for my answers but there's little out there I'm finding. What I can find has broken links or pics with watermarks that make viewing impossible. First off I need to figure out how to make tires. I need a pair of 275 MT Pro Radials for the Pro 275, Limited Drag Radial, and No Time/Grudge racing. I also need a pair 315 MT Pro Radials for the Radial Vs the World class, and NT/Grudge racing. Secondly I need to know what kind of fluids I can safely use with Poly Styrene or just plastic in general. I need a thin light viscosity fluid that won't negatively affect plastic, aluminum, resin, and the stainless steel that are used in my rear shock bodies. Major kuddos if you know of something that doesn't evaporate like alchohol or turn nasty and evaporate like water. The shock bodies are polystyrene, the end caps are aluminum, the piston is resin, and shaft is either hardened stainless steel or high carbon hardened steel that are chrome plated, it's to tell. The shaft clearance with the end cap is very nice with no noticable play or drag. I filled the shock with some alcohol for testing and there was a little bit leaking during rebound with a solid piston, and no leaks with a small hole drilled in the piston for valving. I don't know the valves are going to like in the model when it's complete, I would like to use lead to get the center of gravity as close to a big car as possible. A good starting point for rear shock settings is 40/60. To make it happen on the tiny shocks I need two holes in the piston. One is unrestricted and the other needs to be much smaller with a check valve. I can make a reed valve very easily or a ball check valve with a little more effort.- 23 replies

-

- radial vs world

- pro 275

-

(and 1 more)

Tagged with: