-

Posts

2,504 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Gary Chastain

-

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I am speechless, I am so glad to be in this group. Brian, thank you very much for the offer. So many people in this group have offered to help with this silly idea of a build from printing parts, sending parts to just bouncing ideas around. Thank you, I thought I was just kinda out of luck so I marched on with the eight bag KW air suspension. Post up progress in a while. -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Agreed, probably no issues -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Agreed, most hot rods from my youth were built from whatever you could find/ accumulate. This is my idea of a Resto Rod, a 1:1 truck I built in 92 and 93. this is a 1960 Chevy pickup, all I got from the seller was the sheet metal and frame ( unfinished project that I bought for 200 bucks) Engine is a 402 big block from a camper special Chevy truck) Turbo 400 short shaft from a pile of transmissions, rear axle from a 70s Transam with 4:10 gears and posit track, front suspension from a 72 Chevy half ton truck, redrilled rotors, driveshaft from an Elcamino, steering column from a GM car, wheels from a Corvette (rear) and from a Mote Carlo (front) and so on. I retained the mostly original body just updating the running gear -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

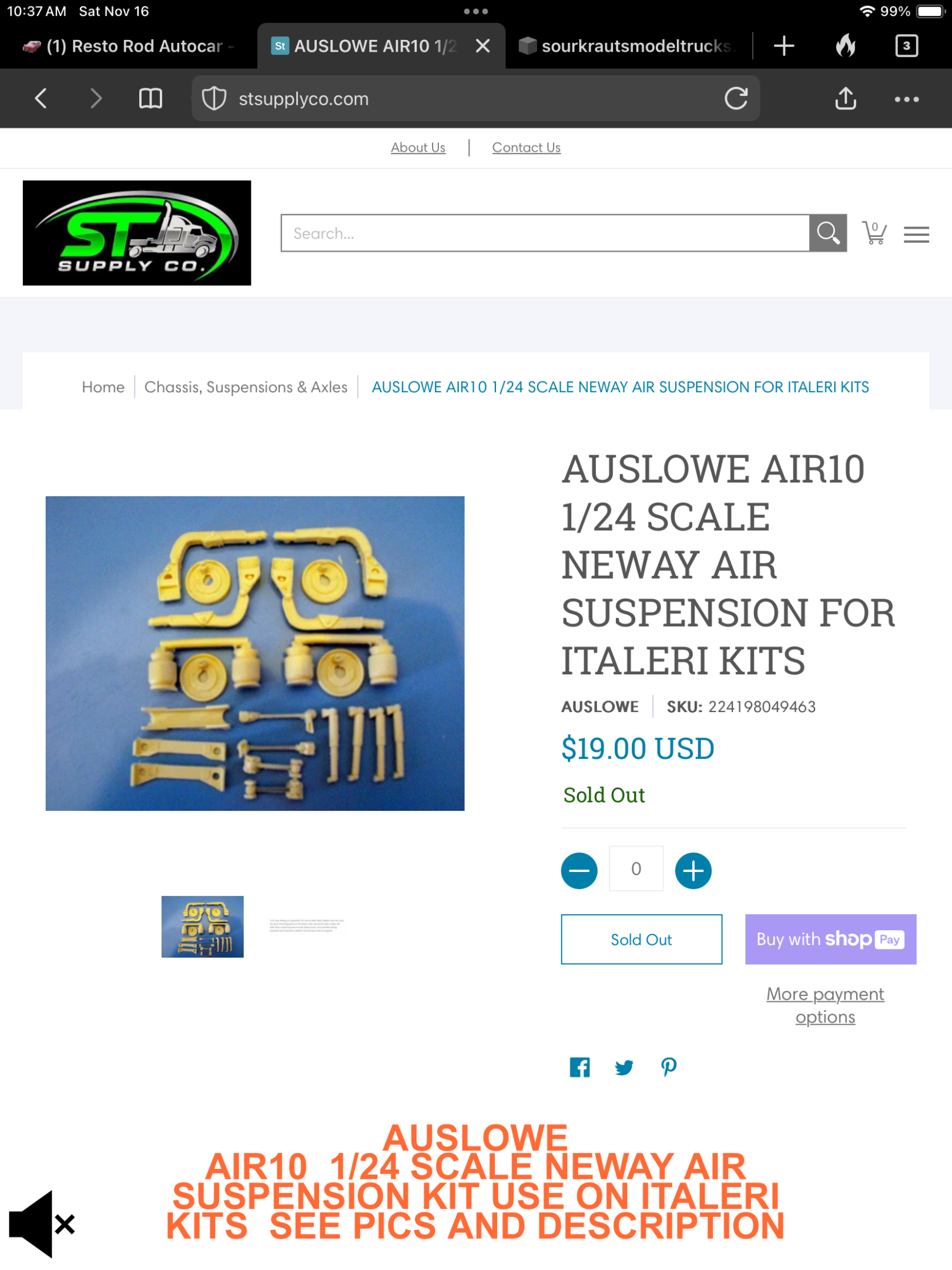

Checked again at ST , only in 1:24 scale ( although May work as I have mixed these scales before) but sold out. Checked a couple other sites and no go, looks like an opportunity for a printer person. -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Jürgen, that’s the problem with being retired, I have too much time to think about really cool builds and then…….squirrel….started another build. Need to stop and finish some, got three going now. -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Going to go look again at what’s in stock. -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Agree with you Hakan, but I spent a whole evening trying to find something in 1:25 scale air ride and could not find anything. I did order an air glide from a 3d printer but can’t get confirmation of the order or delivery date. I will check ST again in case something just came in. Even thought about hacking apart a 900 KW which I may still do (parts molded to frame). Just happened to run across that Cabover KW for cheap and I thought, well that will work. So for the moment it’s still up in the air. -

Western Star 4900 FA plow truck

Gary Chastain replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Really nice work, great detail as usual -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

Mid 60s Peterbilt Unilite COE

Gary Chastain replied to RoninUtah's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Well done sir -

Resto Rod Autocar

Gary Chastain replied to Gary Chastain's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

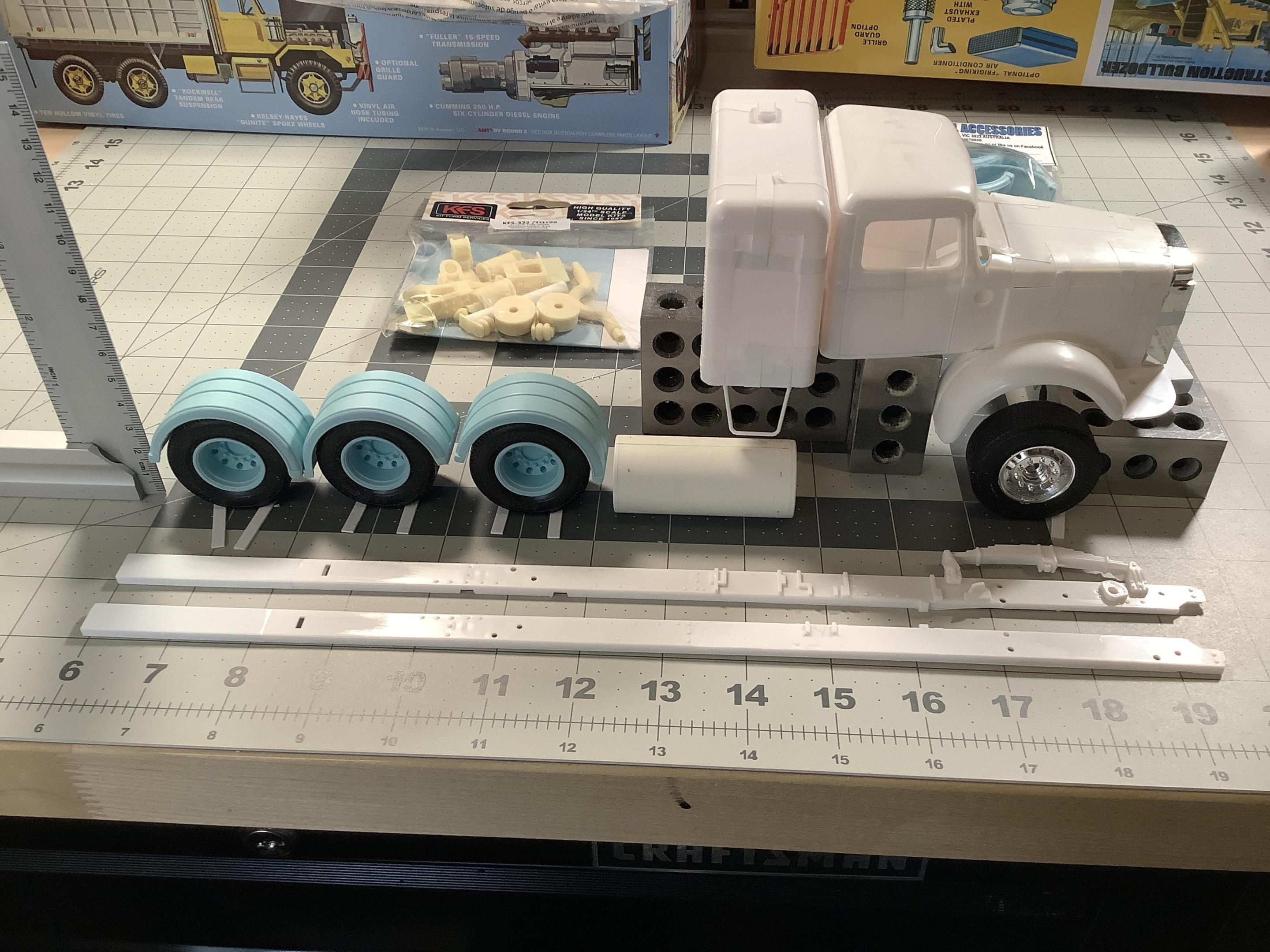

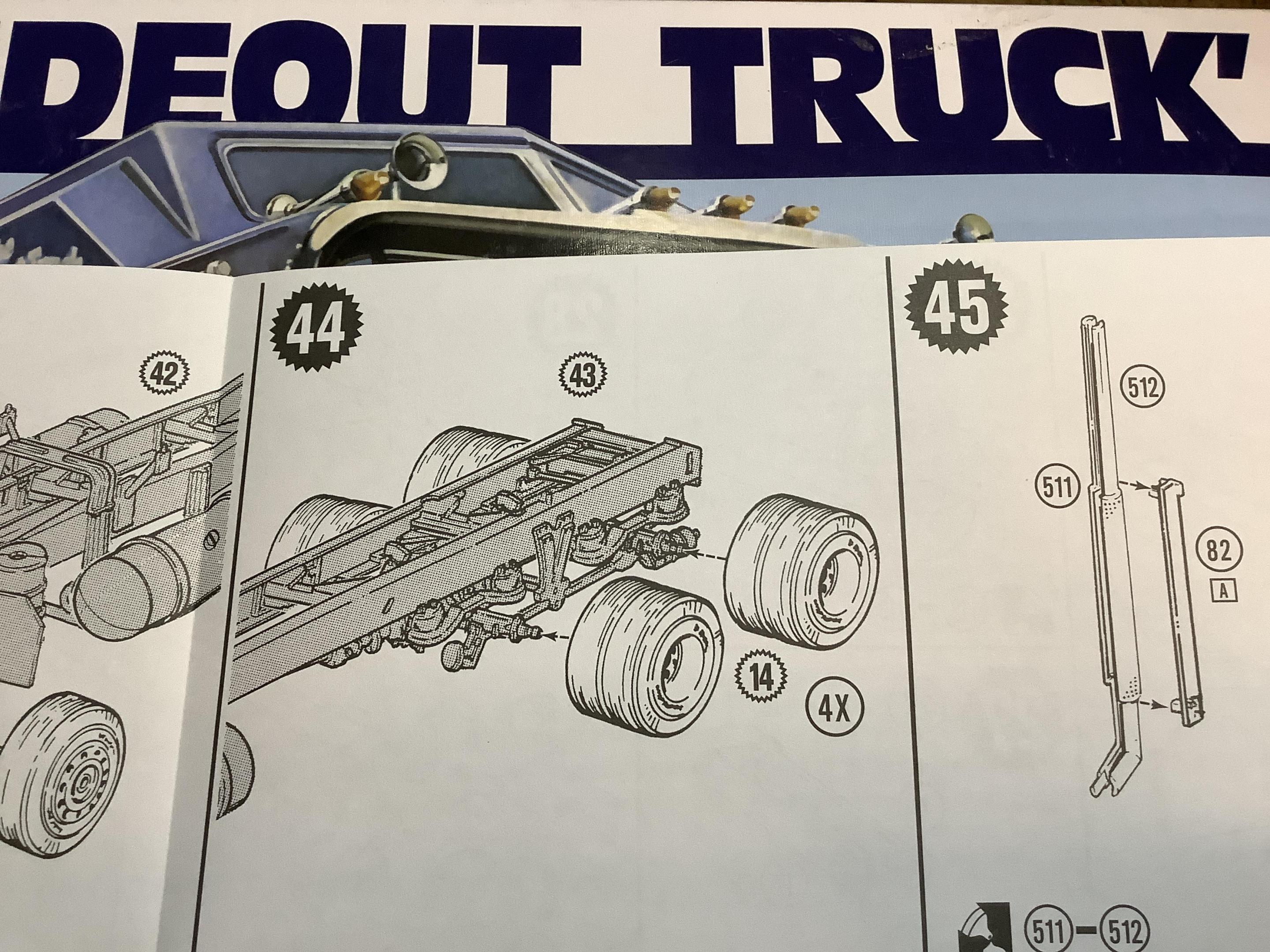

Maybe going off the deep end on this build. Went to Hobby Lobby today and picked up the Malone KW Aerodyne (40% off as a donor kit), it has a good air ride suspension that I could use. a mock-up as a three axle heavy hauler (maybe) with air lift third axle still working out engine but looking at the V-12 from the Malone KW drag truck, not sure if it will fit under the hood, but starting there. If not , of to a straight six. And yes, I am working on two builds at the same time…….. squirrel -

Tigercat 880E longer 1/48 scale

Gary Chastain replied to François's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Outstanding build, curious to your next build. -

Pete 359 tanker with trailer

Gary Chastain replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That’s impressive -

Western Star 4900 FA plow truck

Gary Chastain replied to BK9300's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Hoooooly cow, the details just keep coming. Can’t wait to see that finished. -

Mid 60s Peterbilt Unilite COE

Gary Chastain replied to RoninUtah's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

It happens to all of us, multi color paint jobs always stress me out. You got this, be watching. -

The Same but “ a little “ Different

Gary Chastain replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I had heard of guys polishing their paint with tooth paste, but first time I seen someone use a Q-tip to control removal, great tip. Looking good. -

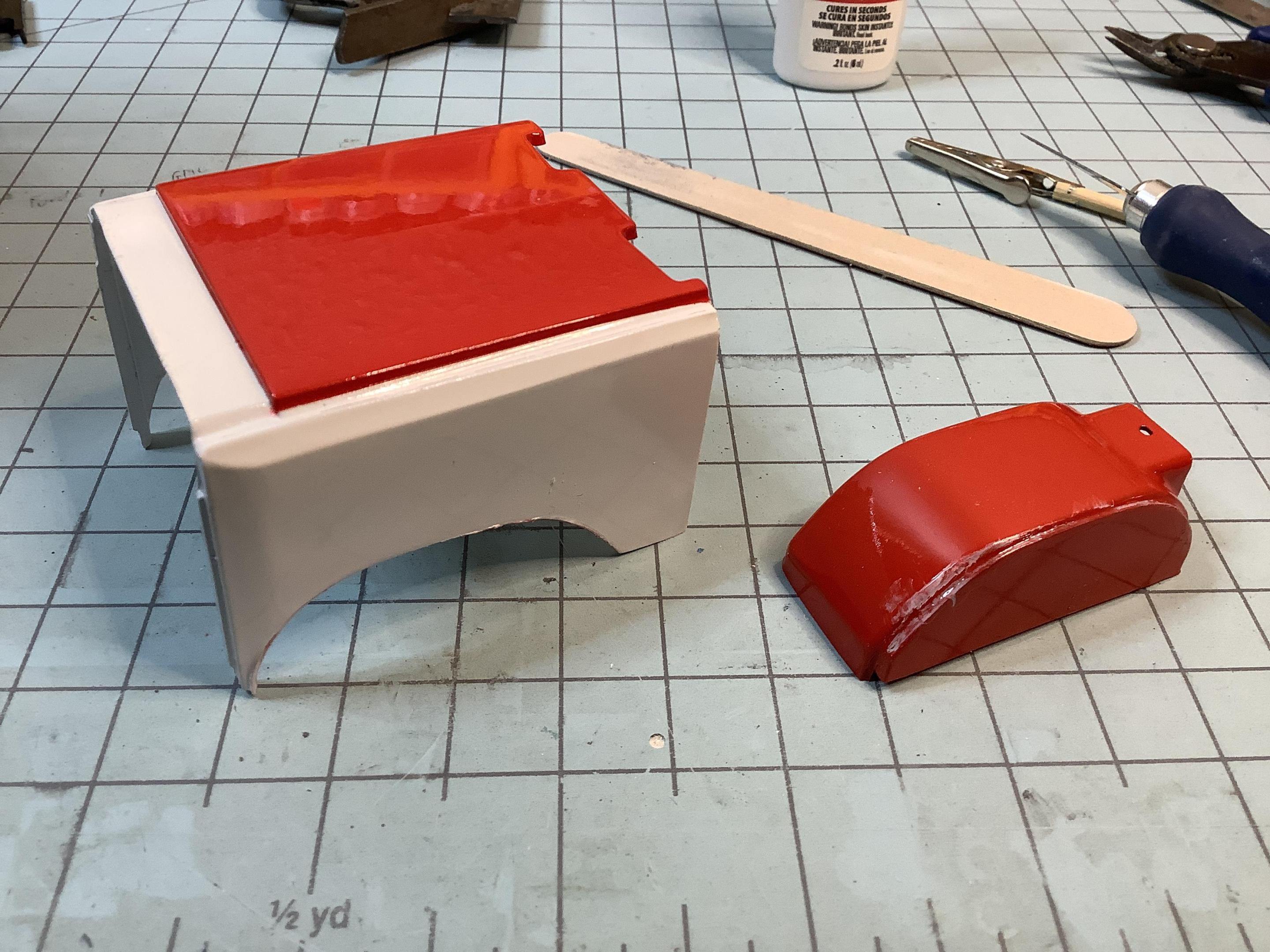

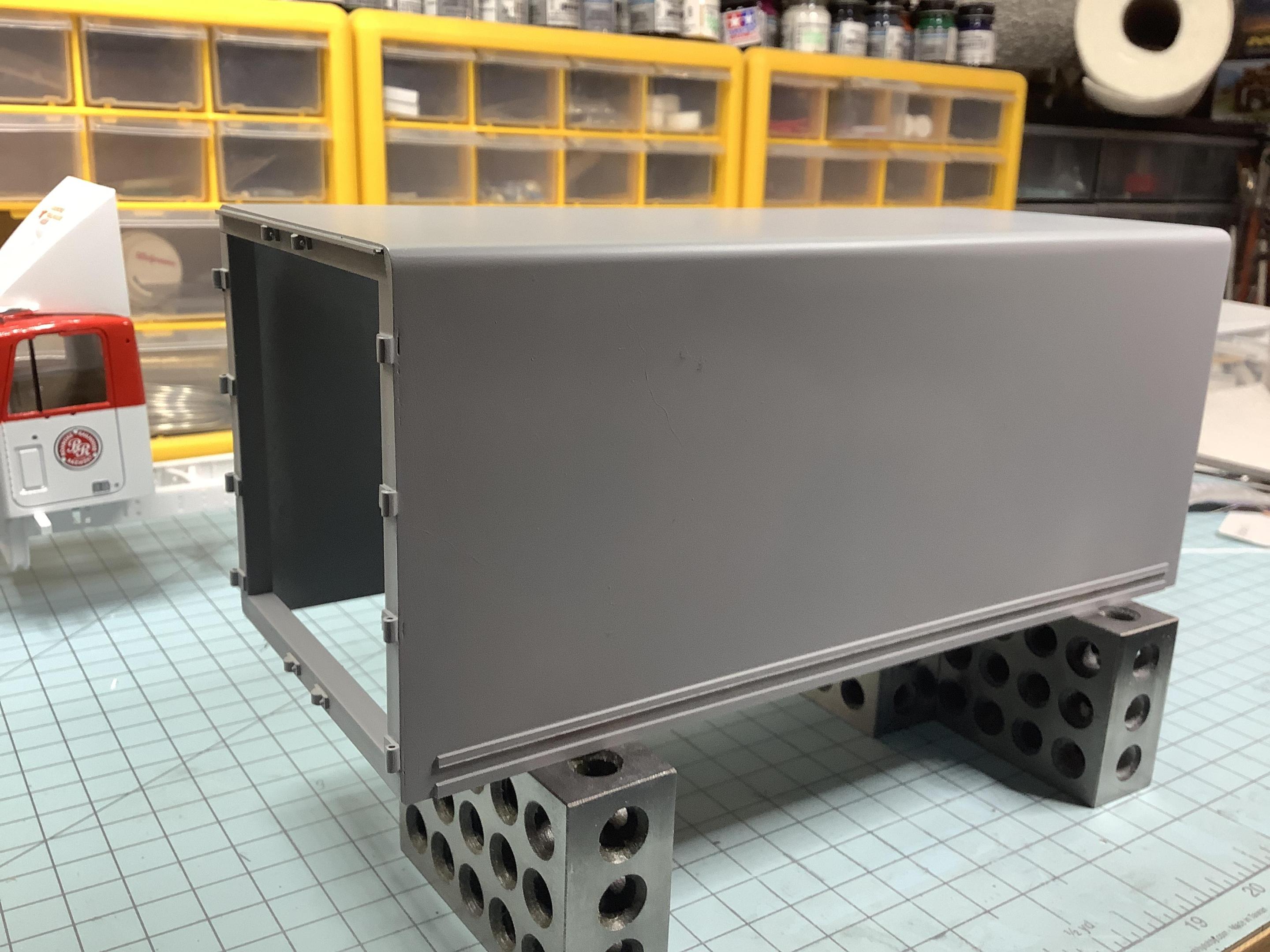

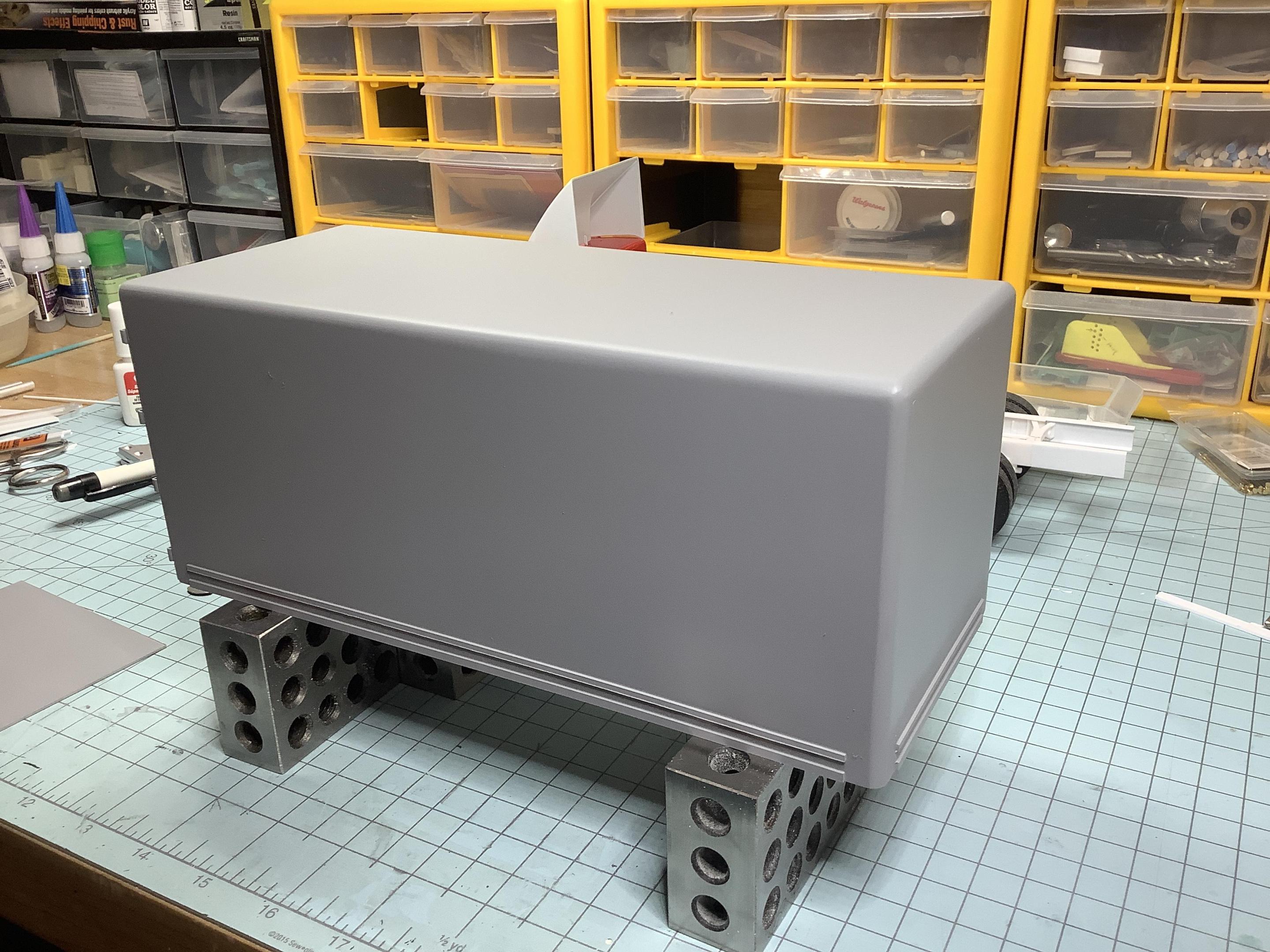

The totally fabricated delivery box is ready for rows and rows of rivets then paint. Paint will be typical white with the radius painted aluminum color. I am already having anxiety over getting those rows (about 35 rows) of rivets straight. Made up a test plaque to experiment With laying down straight rows of rivets and check adhesion. Got wait until these old hands are steady enough.

-

JM, this is the recipe that was given to me by a very old woodworker. This finish works best with open grain wood (such as oak) or soft wood like balsa or pine, this finish will not work well with closed grain wood (such as maple). Makes one gallon 16ounces Tung oil 16ounces Boiled Linseed oil 16ounces Polyurethane Gloss 16ounces Special Walnut Stain, Minwax 224 i use a lot of balsa and wood from pop sickle sticks, this finish works well, looks worn.