-

Posts

1,510 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by redneckrigger

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Jamie Rahmoeller…..MOLUMINUM

redneckrigger replied to redneckrigger's topic in General Automotive Talk (Trucks and Cars)

News as of today: We just got the news that Jamie may be discharged on July 13 from Aultman Woodlawn. Big shoutout to the awesome care team at Aultman — they’ve been amazing every step of the way and we’re thankful for everything they’ve done for Jamie. Since starting therapy and getting adaptive devices, he’s made amazing progress! He can now wash almost his whole body, brush his teeth, put on a shirt, lie on his stomach, and feed himself. To us these may seem like small things, but with everything he’s going through — they’re HUGE wins! He’s fought every day to get here. He’s not just recovering — he’s THRIVING. 💙 Let’s keep cheering him on as he continues this journey. The support of his family & friends has made a world of difference!- 1 reply

-

- 1

-

-

Am kind of laid up right now.............got the pieces needed all sorted out and some cut, but had back surgery yesterday, (#9), and cannot get down the stairs to my workbench at the moment. Upside is that I have to lay low for 8 weeks so I am sure that I will get a bunch of that time at the bench as soon as I can navigate the stairs! Will post updates ASAP!

-

As many of you know, Jamie is going through a life altering event right now. He and his family need support. If anyone here can help this wonderful family out, it would be sincerely appreciated. If you want an address to donate to, contact me privately through this forum only. Or go to the Facebook page established for this specific purpose. Please do what you can! You will also find updates on his condition and status of his treatment plan on the Facebook page. I can assure you that what he is enduring would put most of us at our end. Jamie’s Journey-Healing and Hope.

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Mack B-61 Dump Body

redneckrigger replied to Scott Eriksen's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

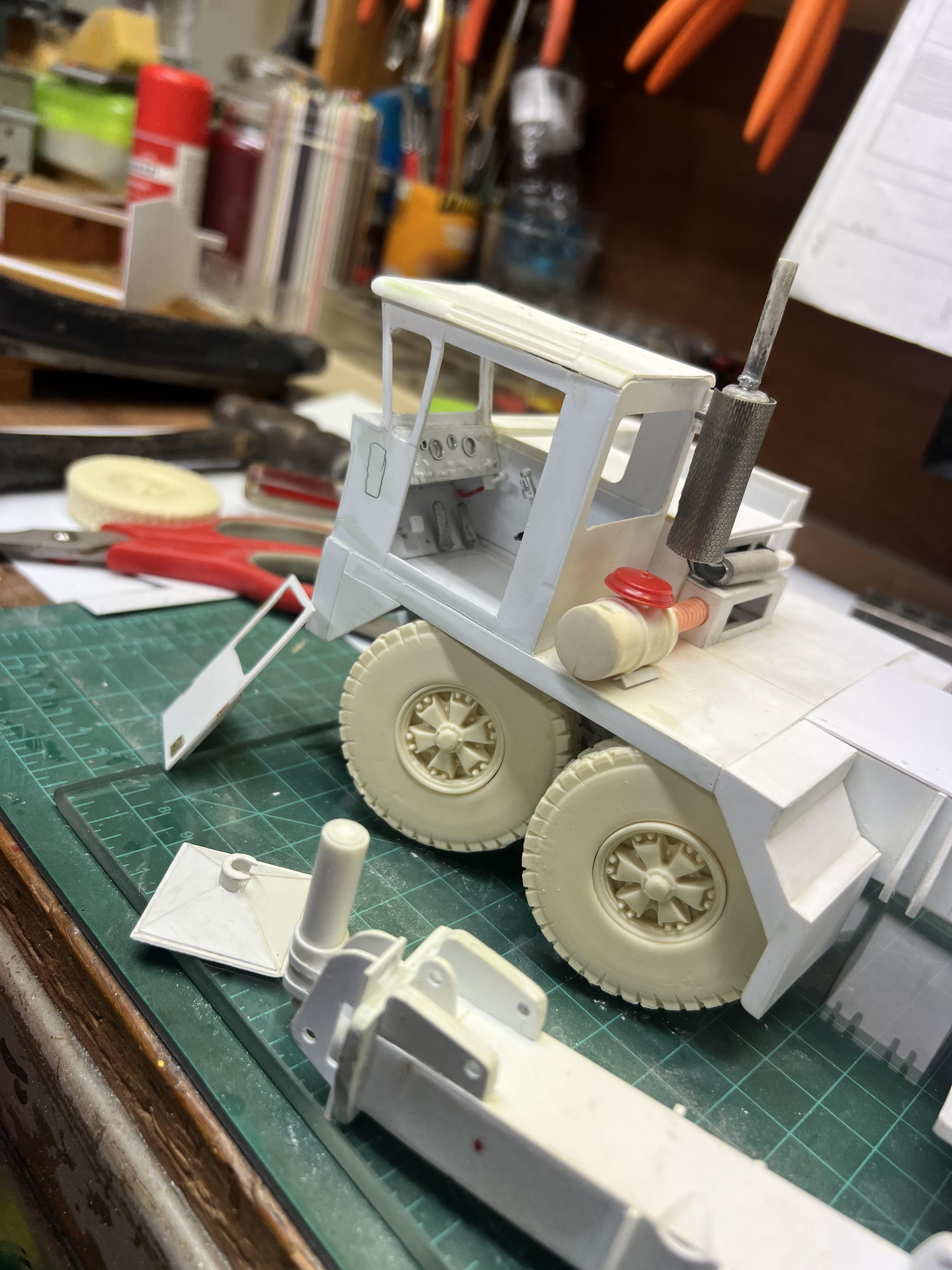

Global makes nice stuff, I got the same cab from them at NNL as well! When I was fire chief of our volunteer department, we had a Bermuda cab on a Thibault/ FWD pumper. But, being in the mountains, we got lots of snow, and the canvas top was long gone by the time we got her, so we took a cab roof and doors from a Dodge LCF truck I had for parts at my shop and made her cab weather tight. Was nicer to use for sure! -

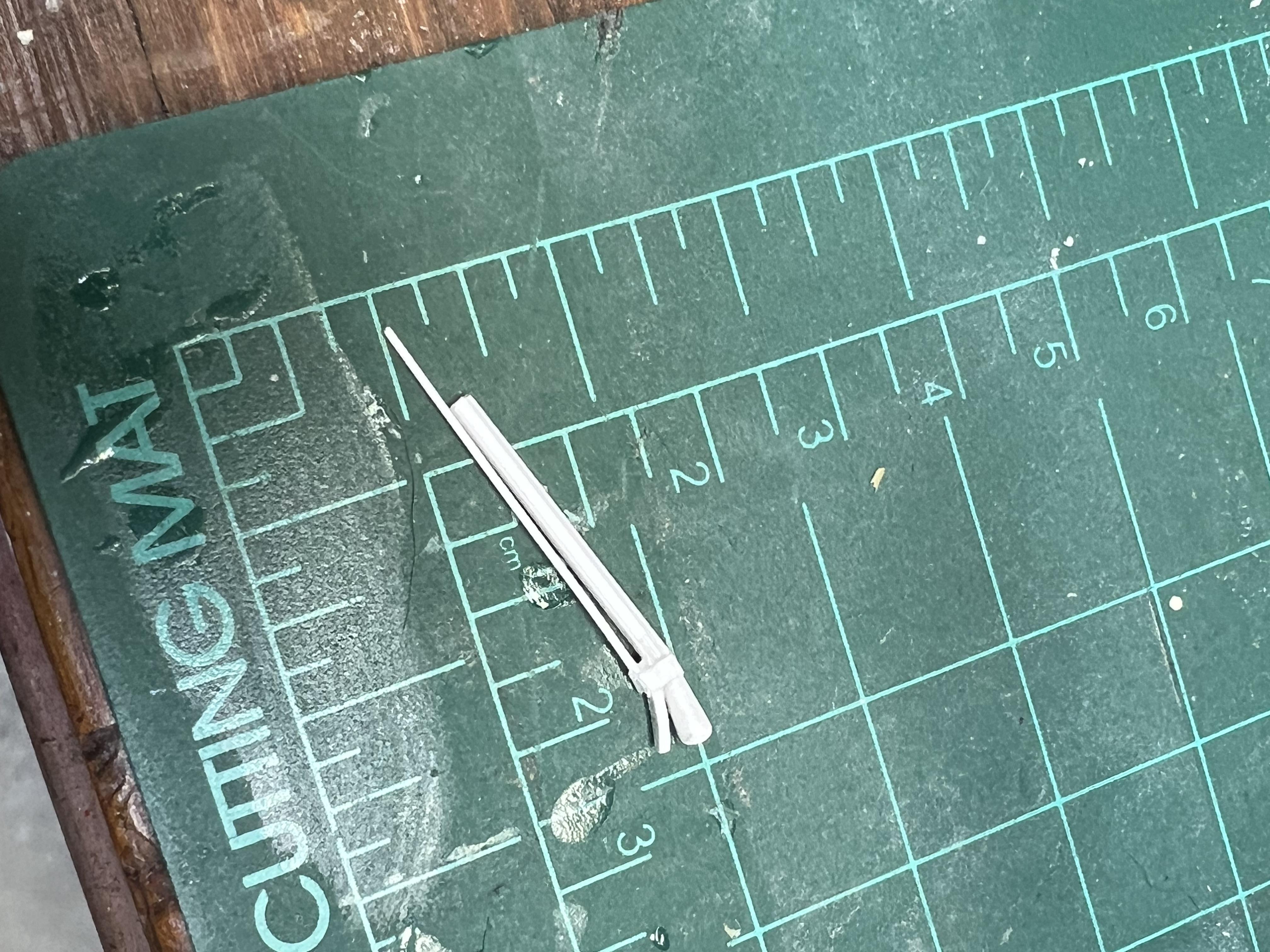

I tried a proof-of-concept with the styrene boom a little while ago and it worked pretty well. I built a jig to build it in and use a chopper with a cutting length guide to make repeatable cuts. Gonna find out real soon how it works with ten to twelve inch long sections that have to pin together! The good thing is that this boom will be a lot easier to handle than the one on the real crane. That one was 210 feet long with a 30 foot jib. THAT was a beast!

-

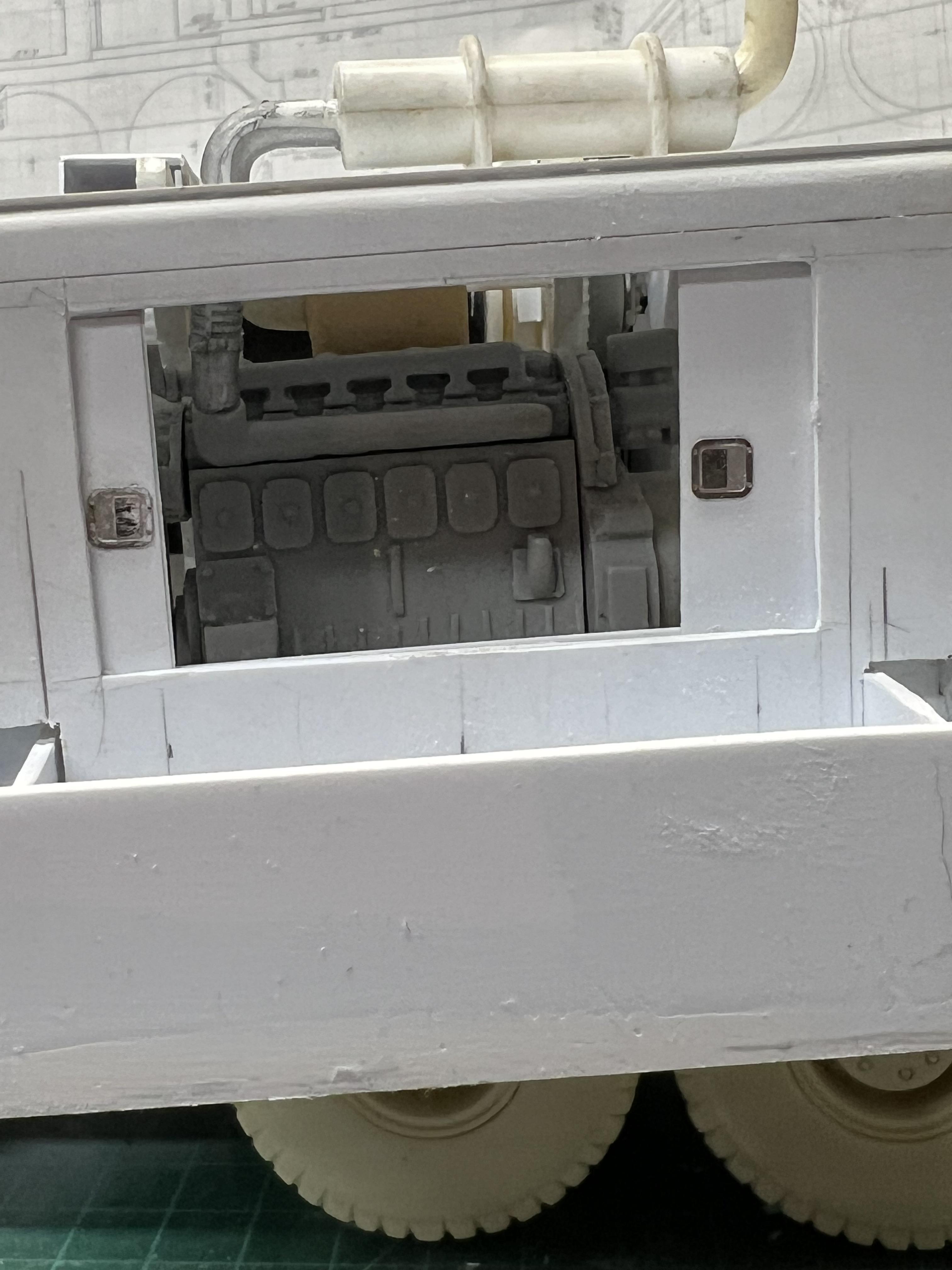

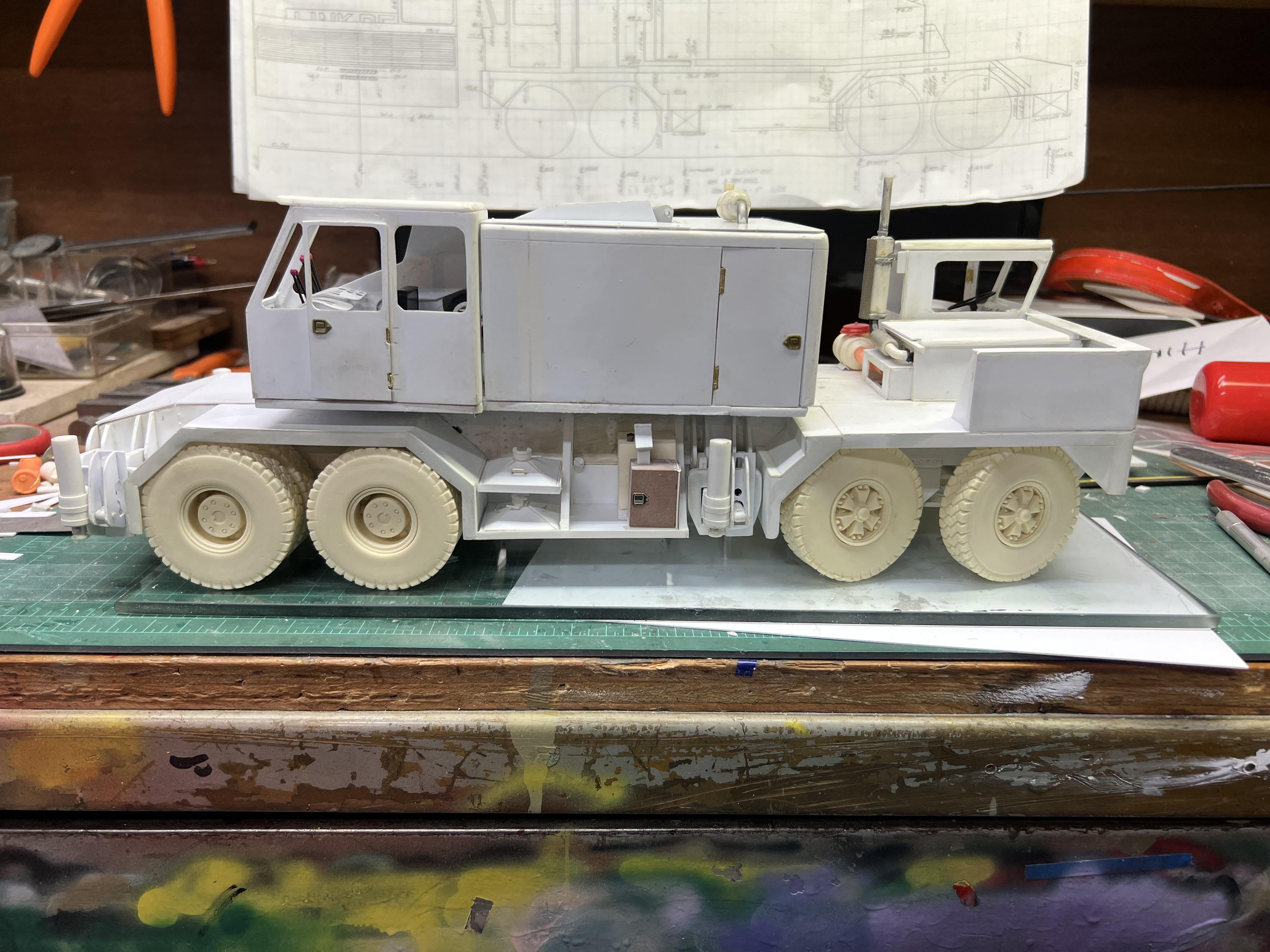

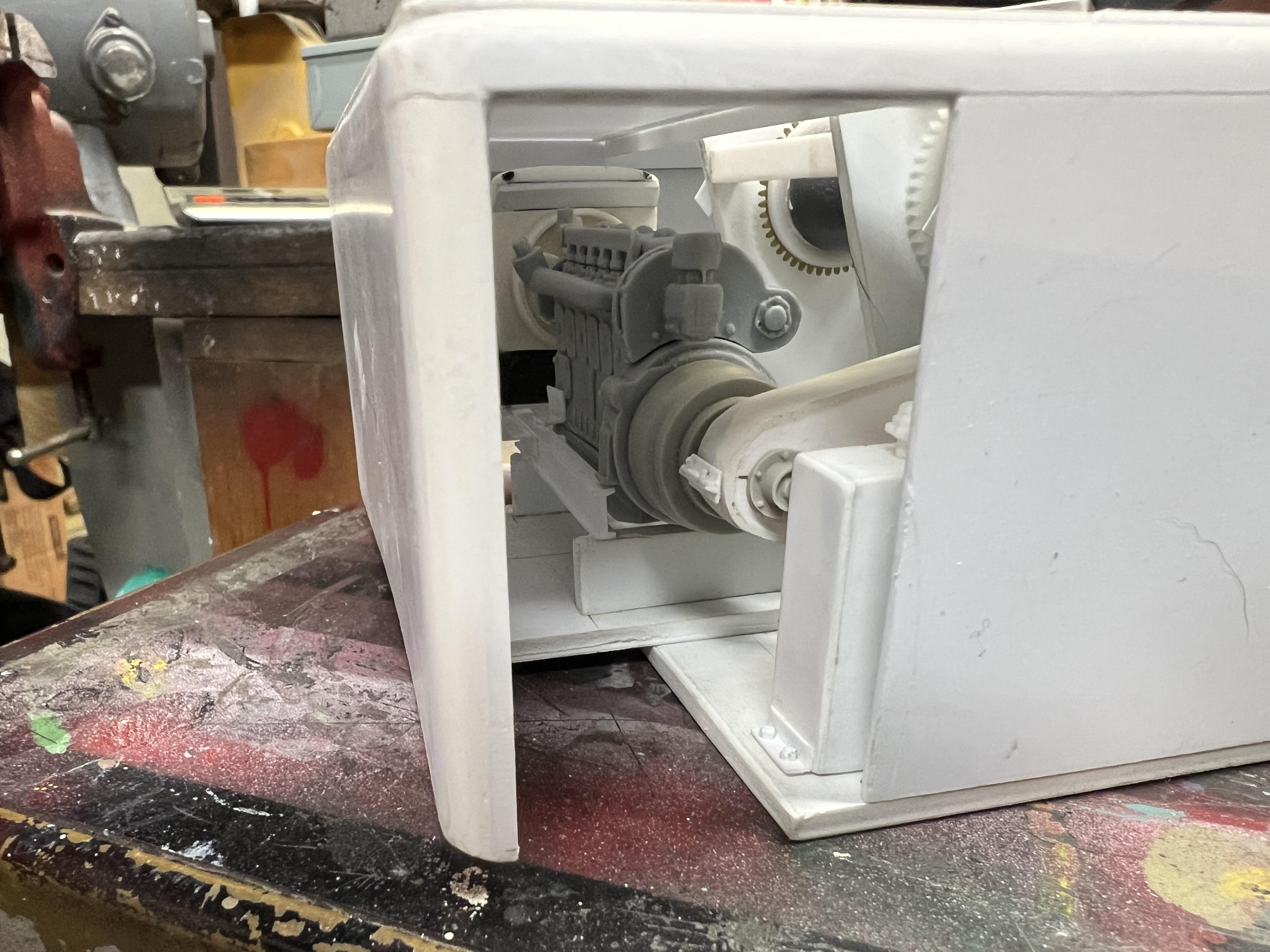

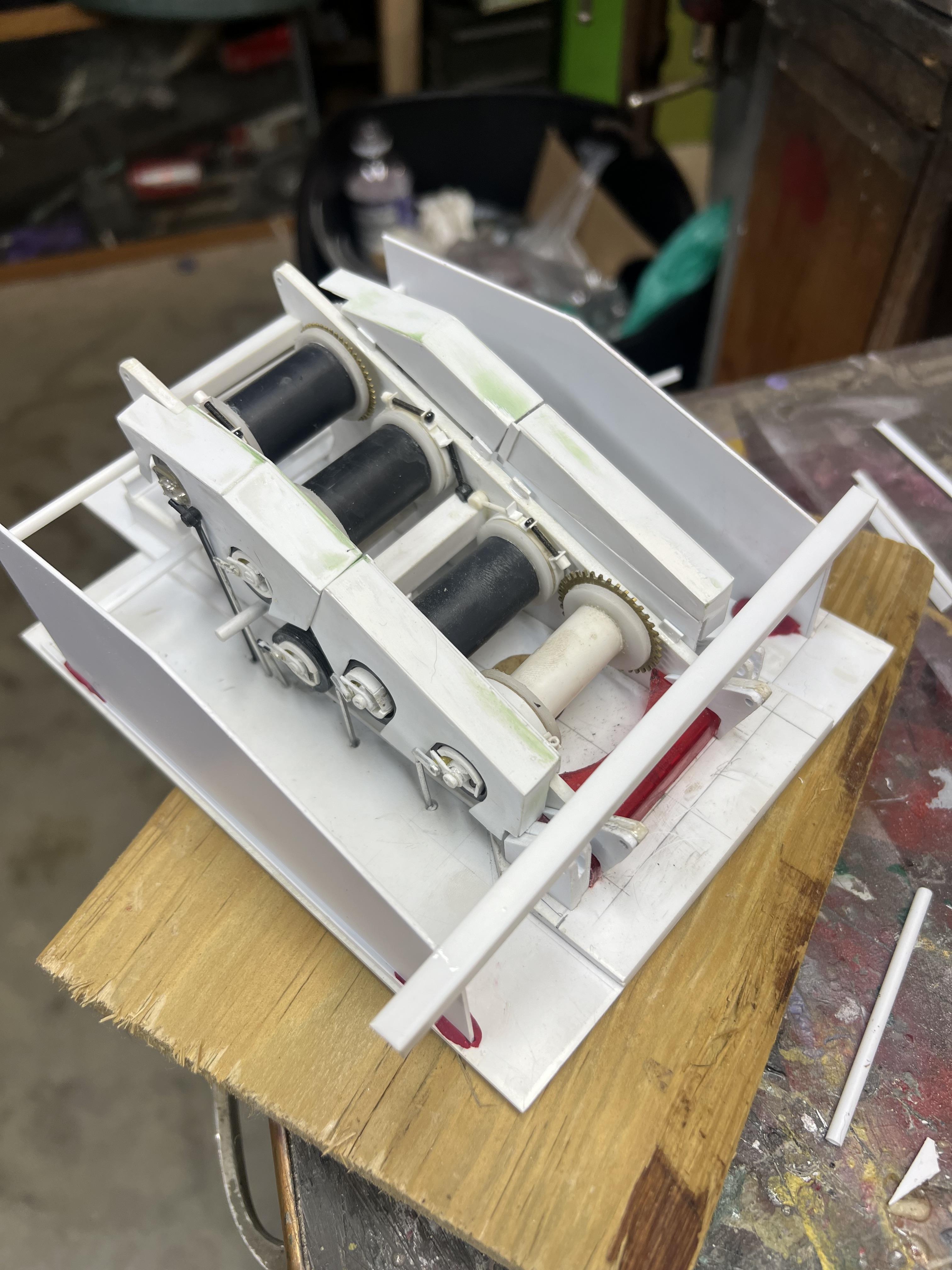

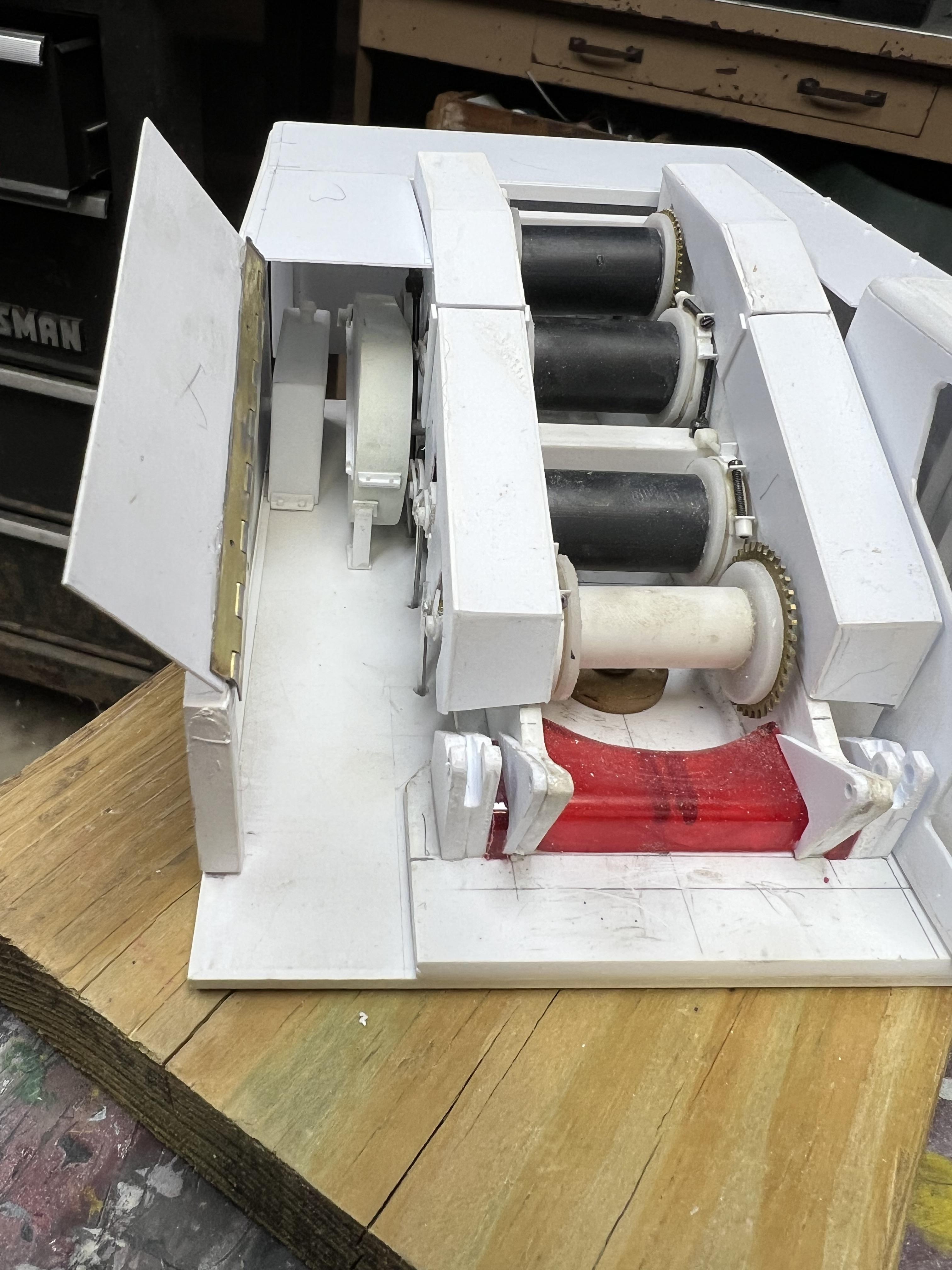

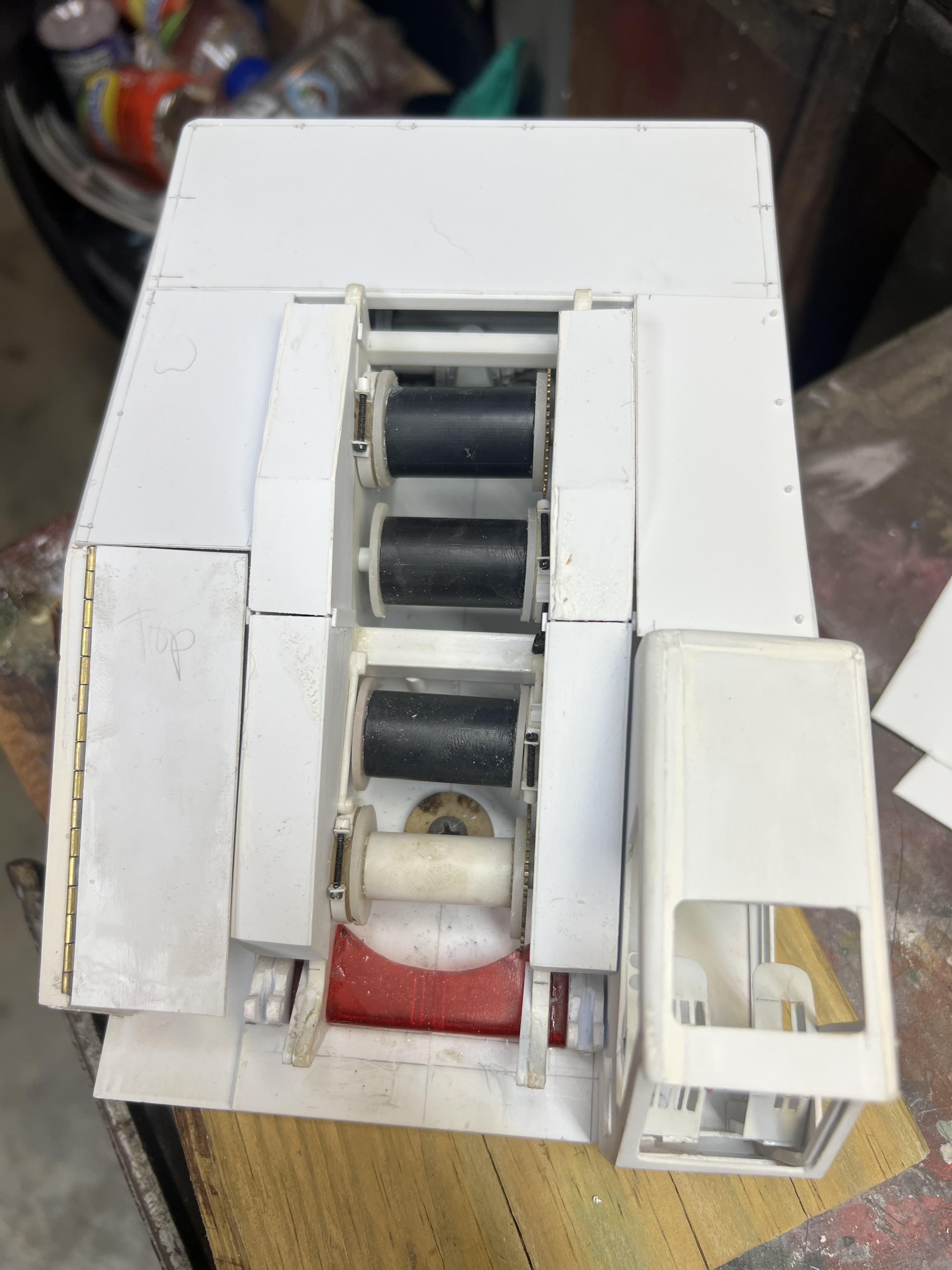

Appreciate the good words sir! It’s only cutting and gluing pieces of plastic that is assisted by having all the manuals and being intimately familiar with the real machine. And it helps to have a background of being a fabricator as one of my former jobs. Got the drive covers fine turned today so at this point this part of the build needs some final gizmos and then all of the wiring and air and hydraulic lines and the counterweights, but those will be done later. Now the next step is perhaps the most straightforward but also most likely the most difficult to get right. The boom assembly is next. I asked for guidance from the best modeler I know, Charlie Rowley, on how to work with brass. He gave some superb pointers. So I figured what the boom would weigh and decided to go with styrene instead. I plan on making a scale 100’ of boom, which will be 4 feet long. In brass it would be way too heavy, so on to cutting and fitting a LOT of Evergreen tubing!

-

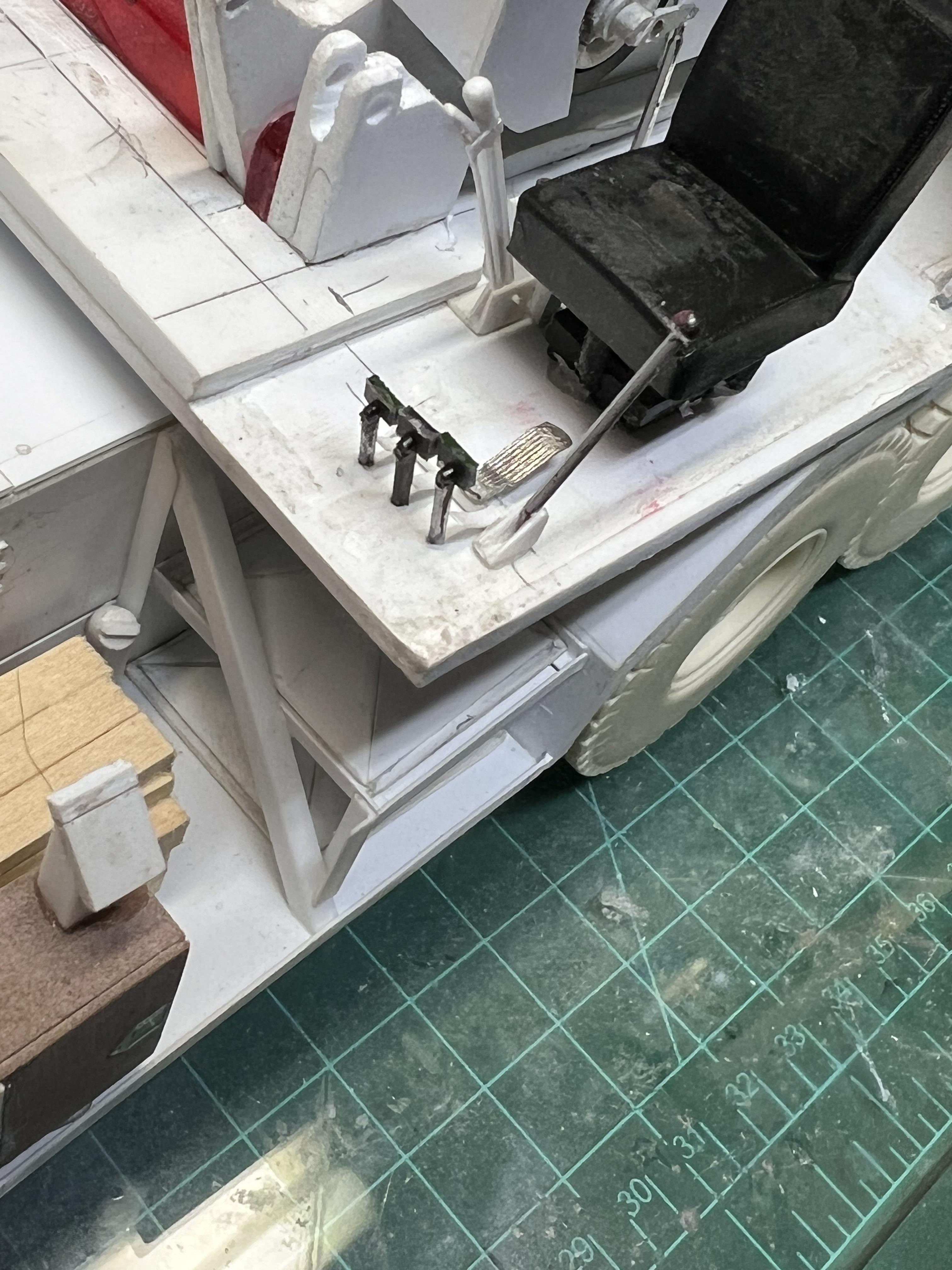

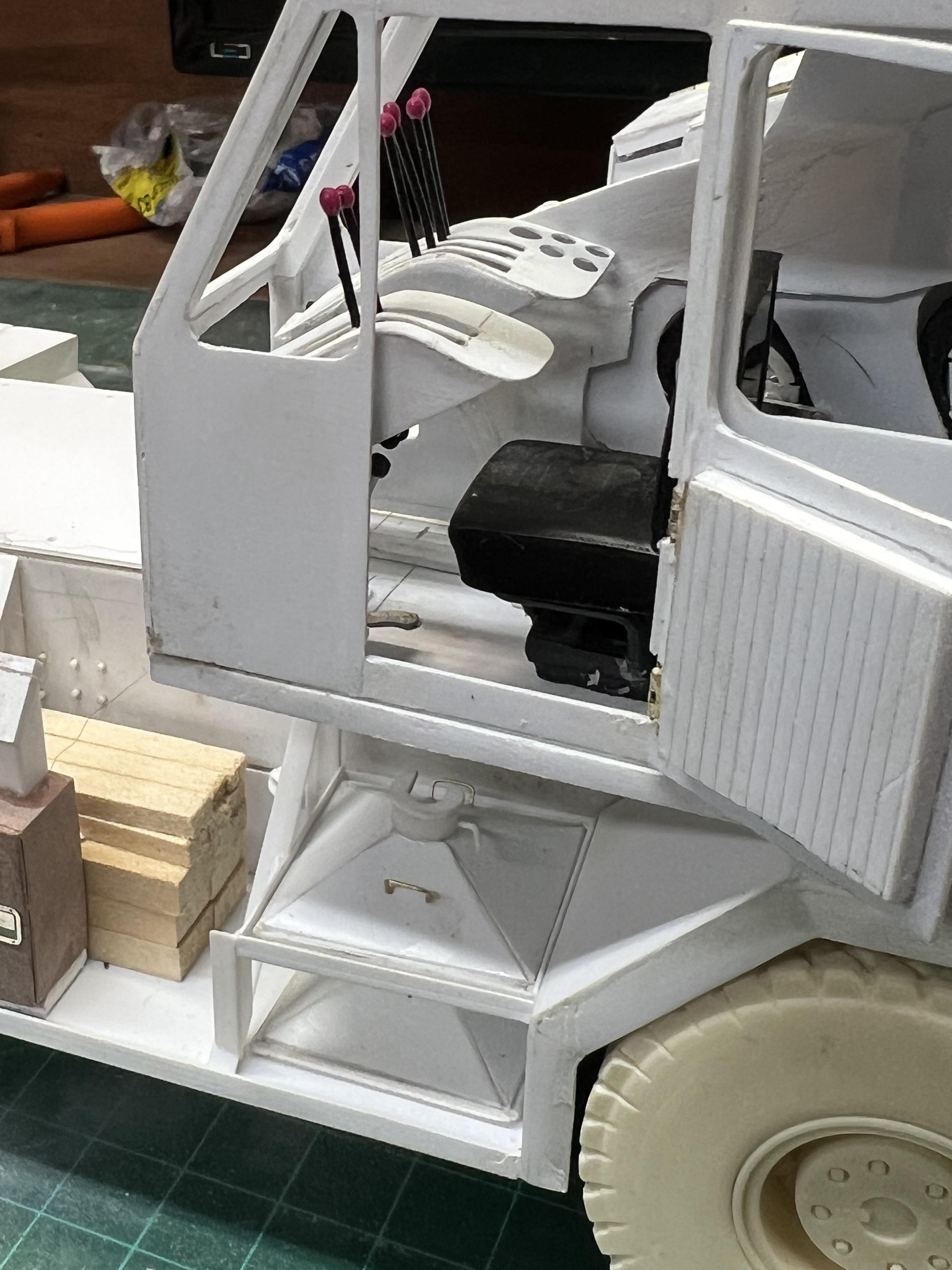

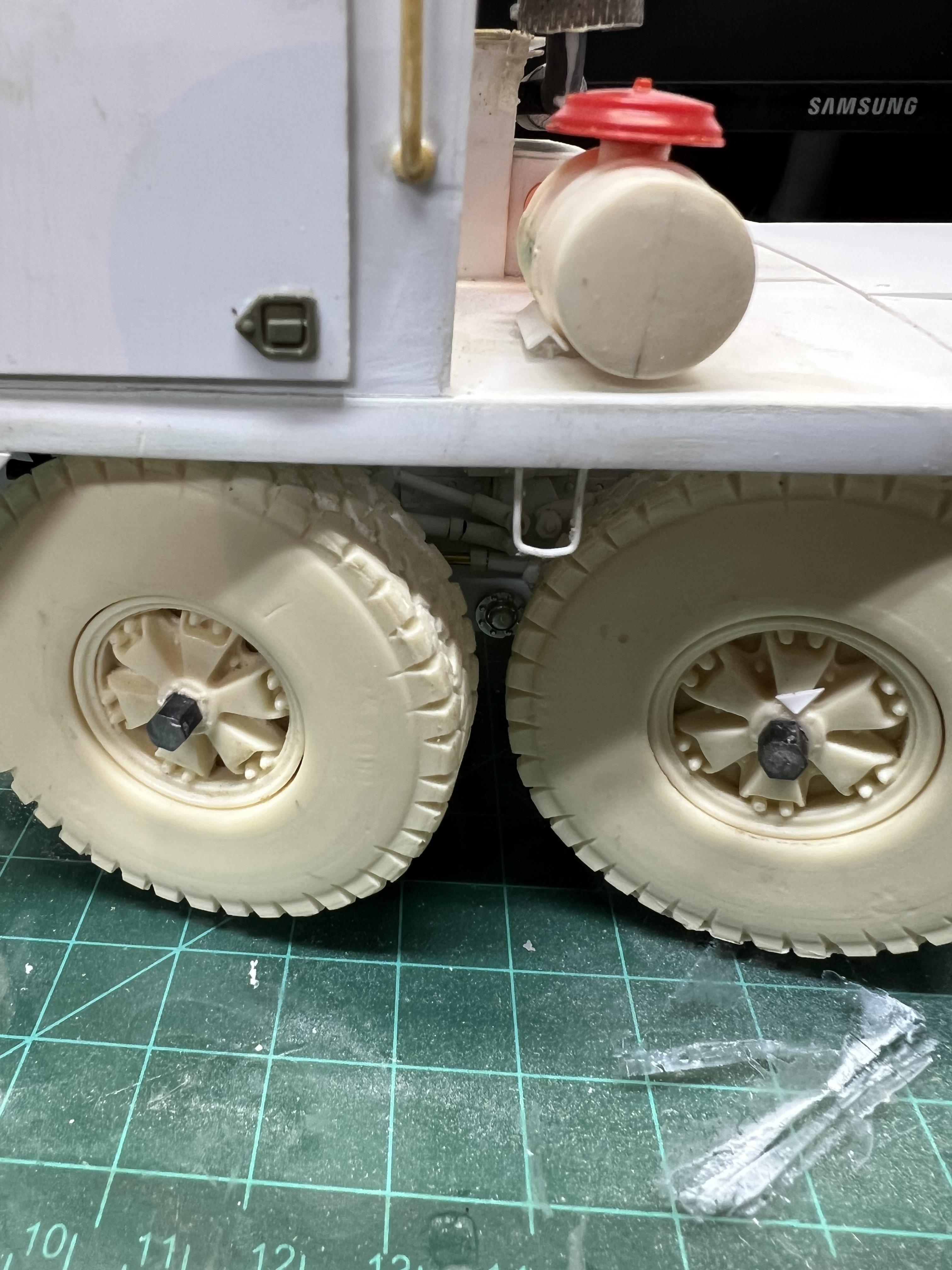

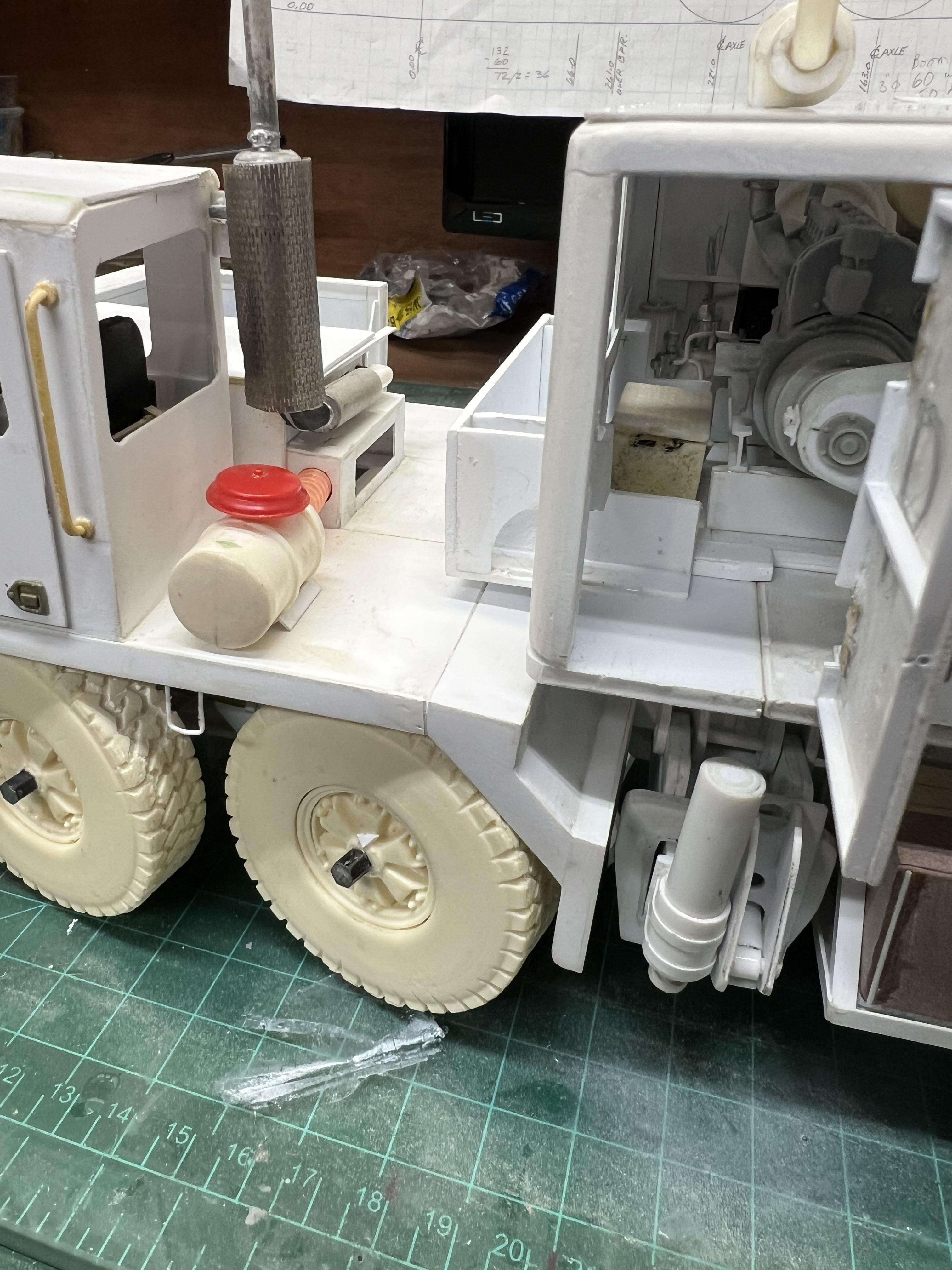

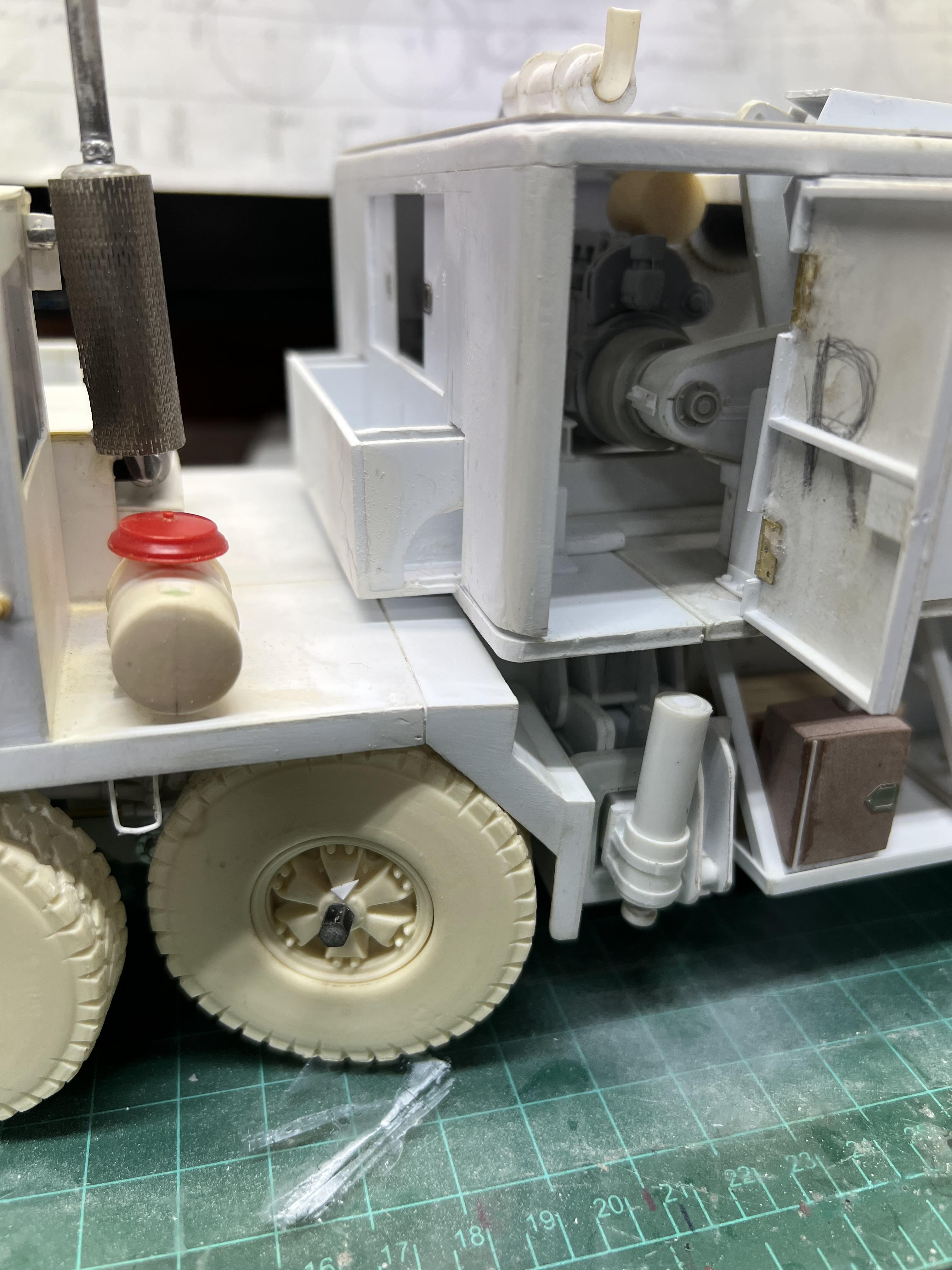

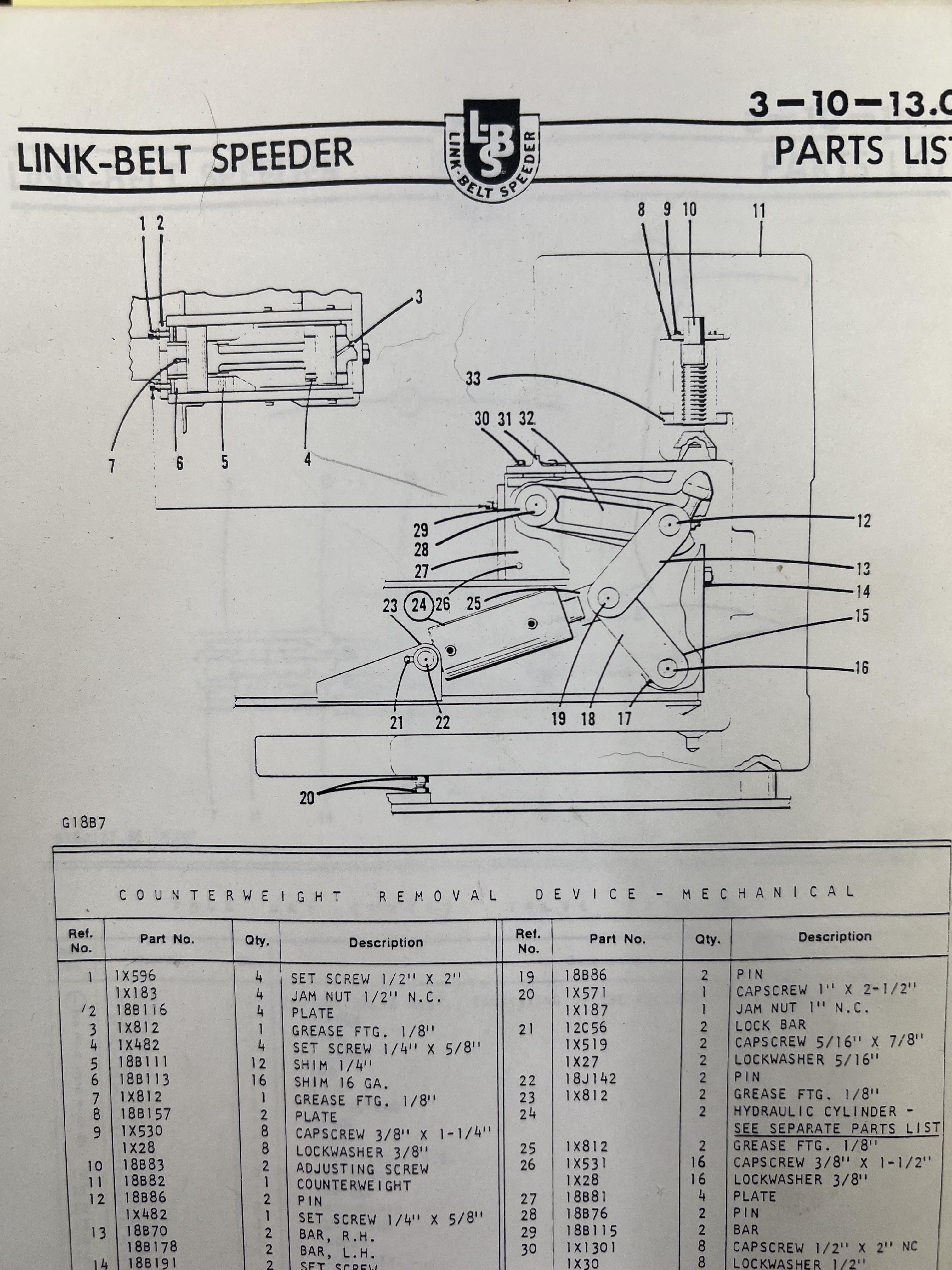

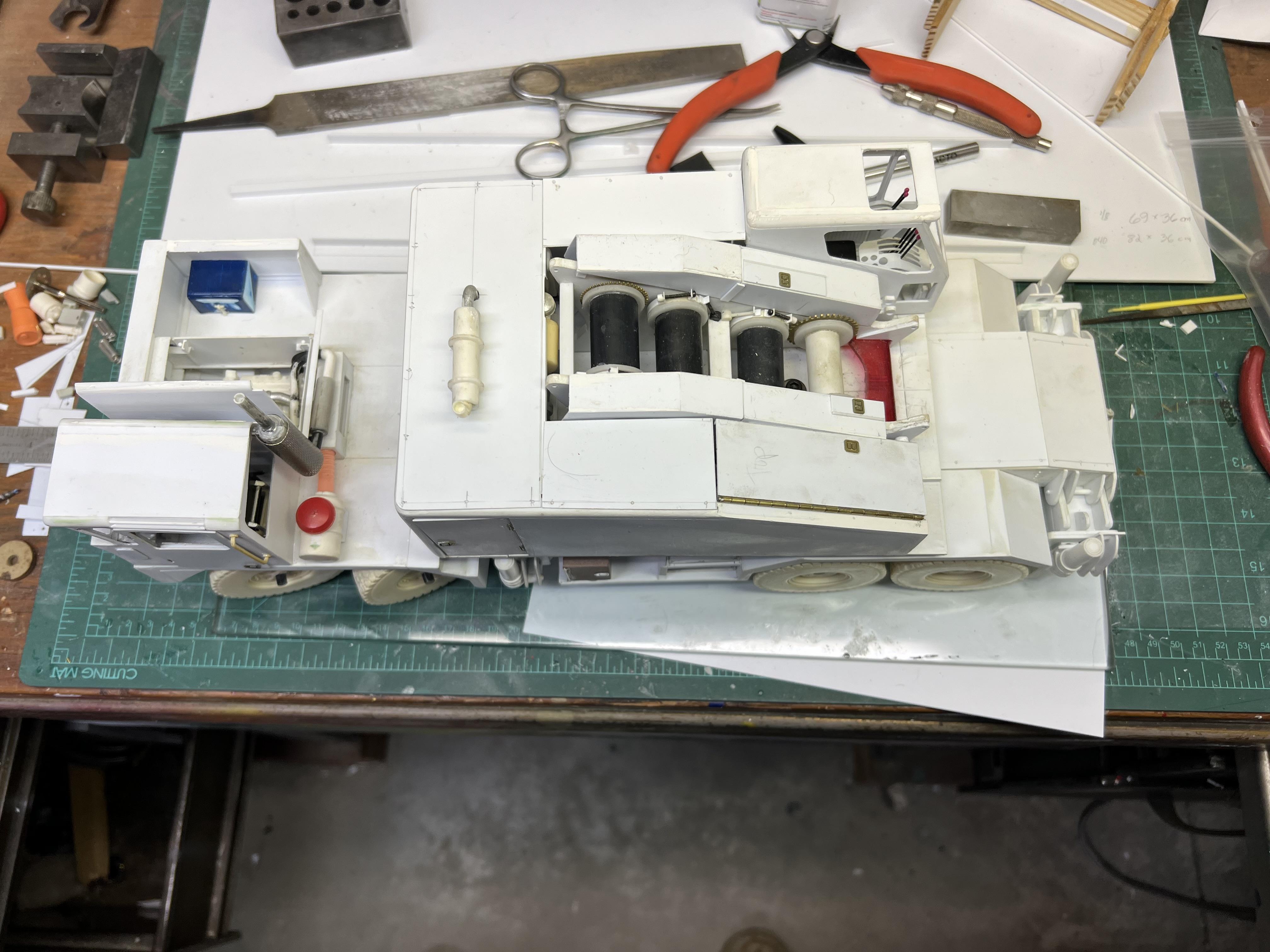

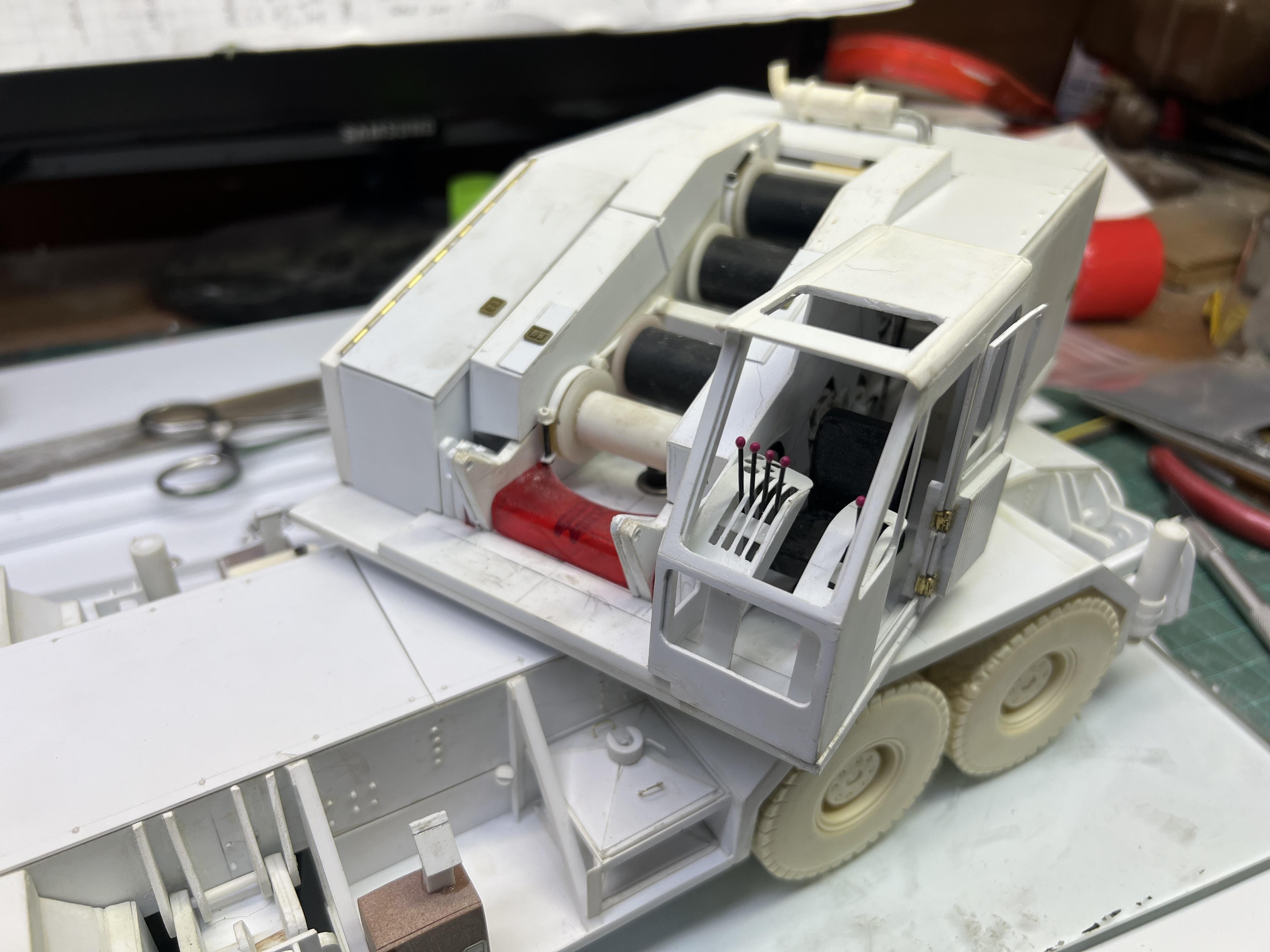

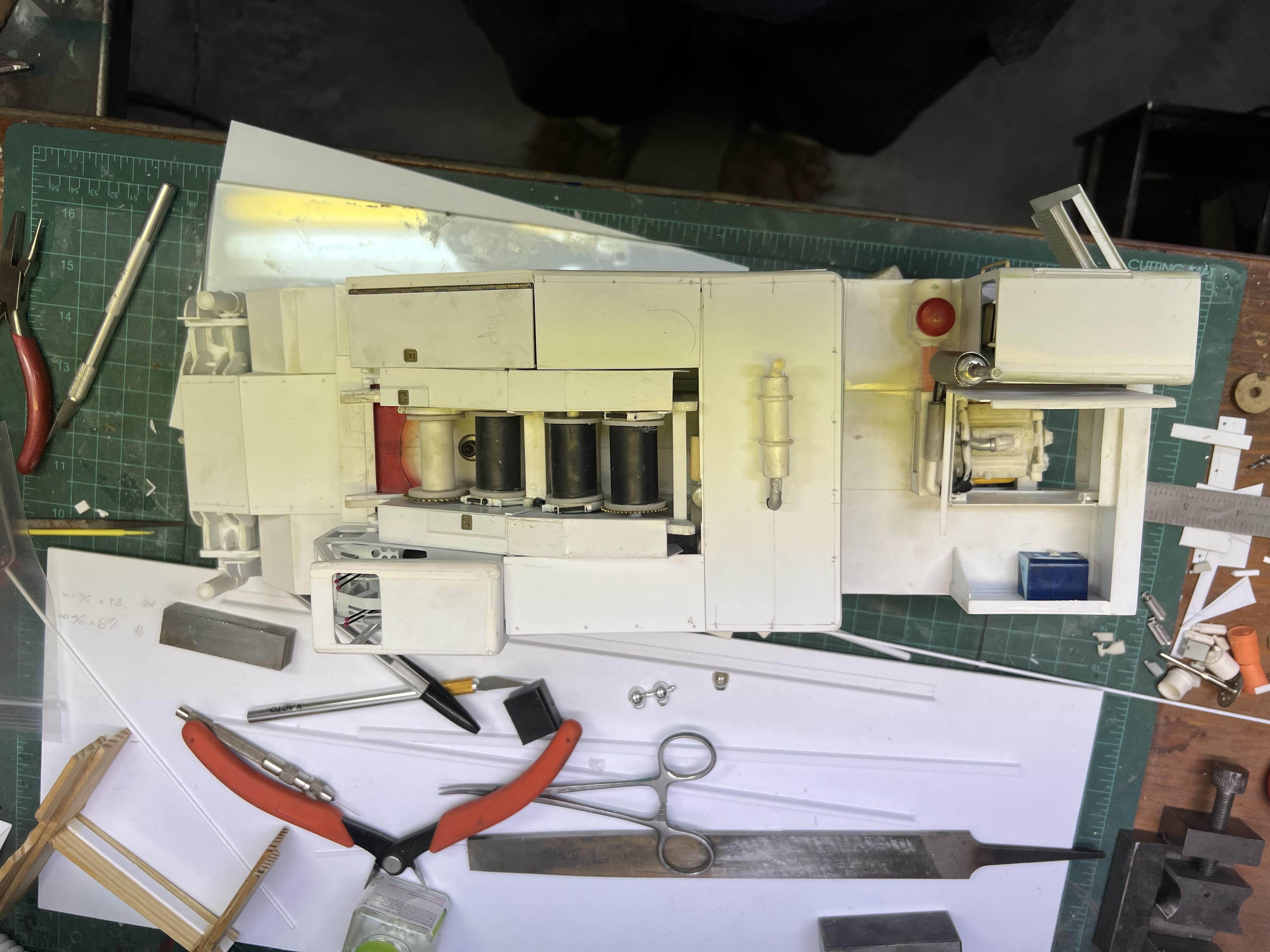

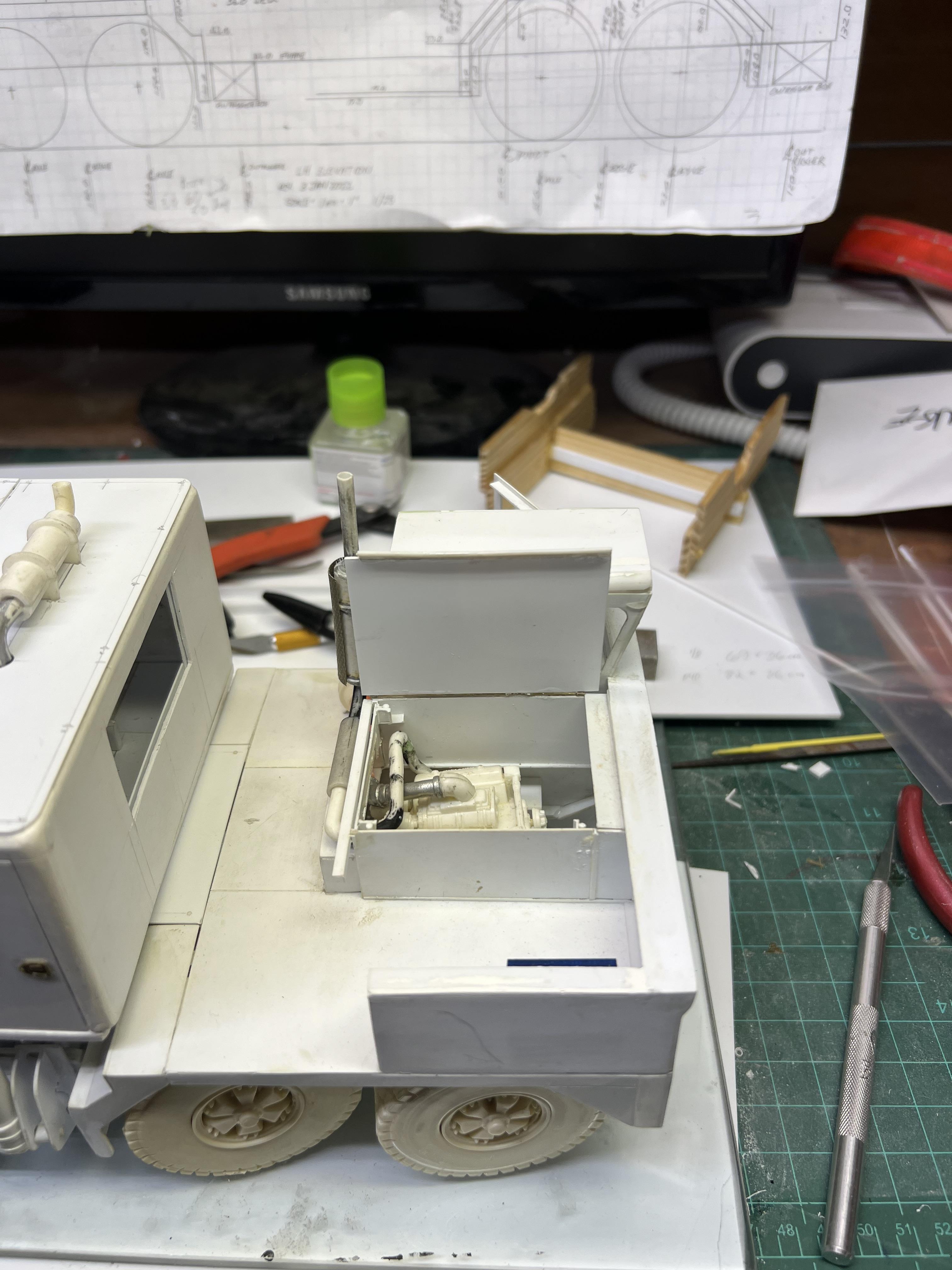

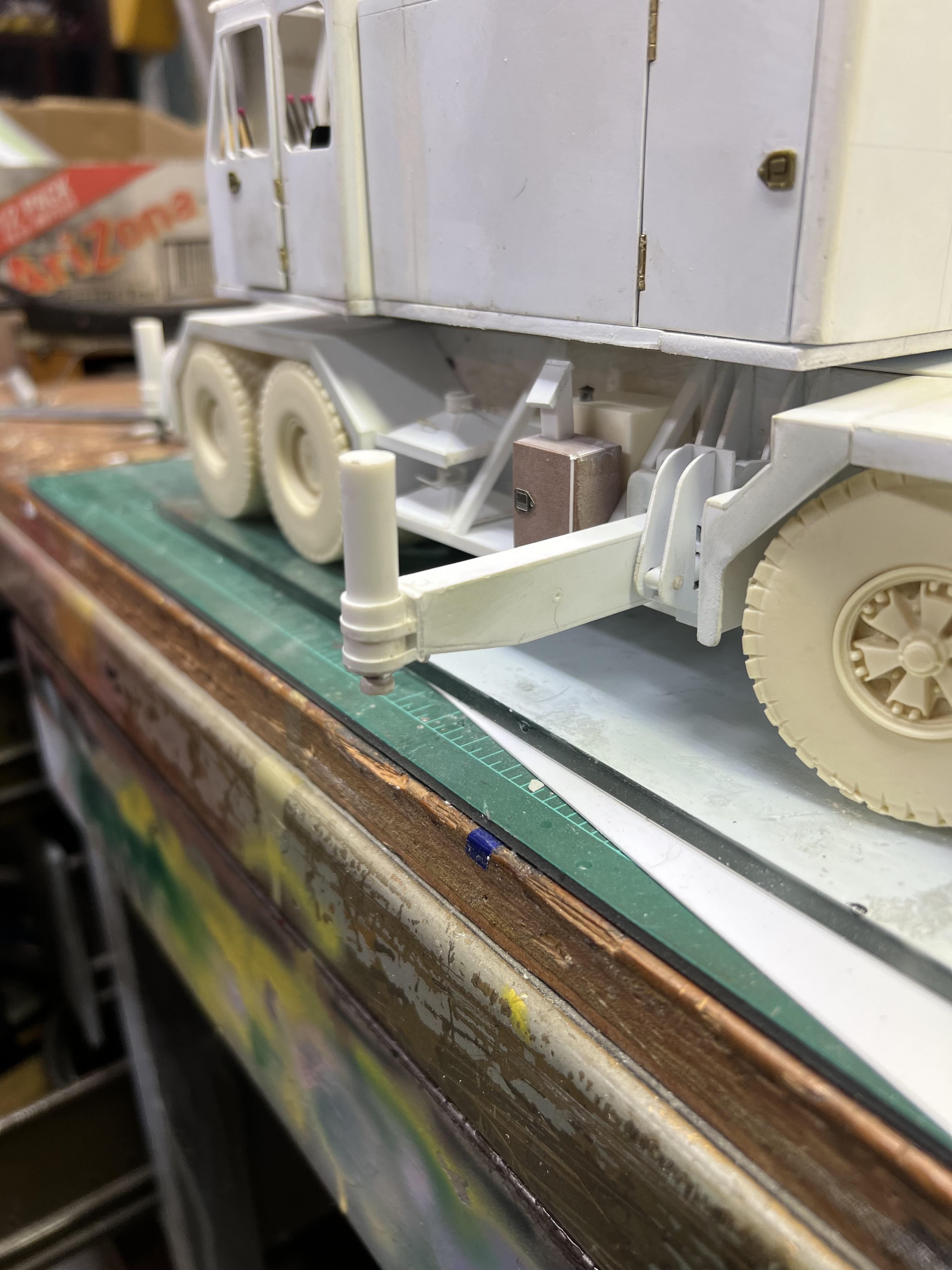

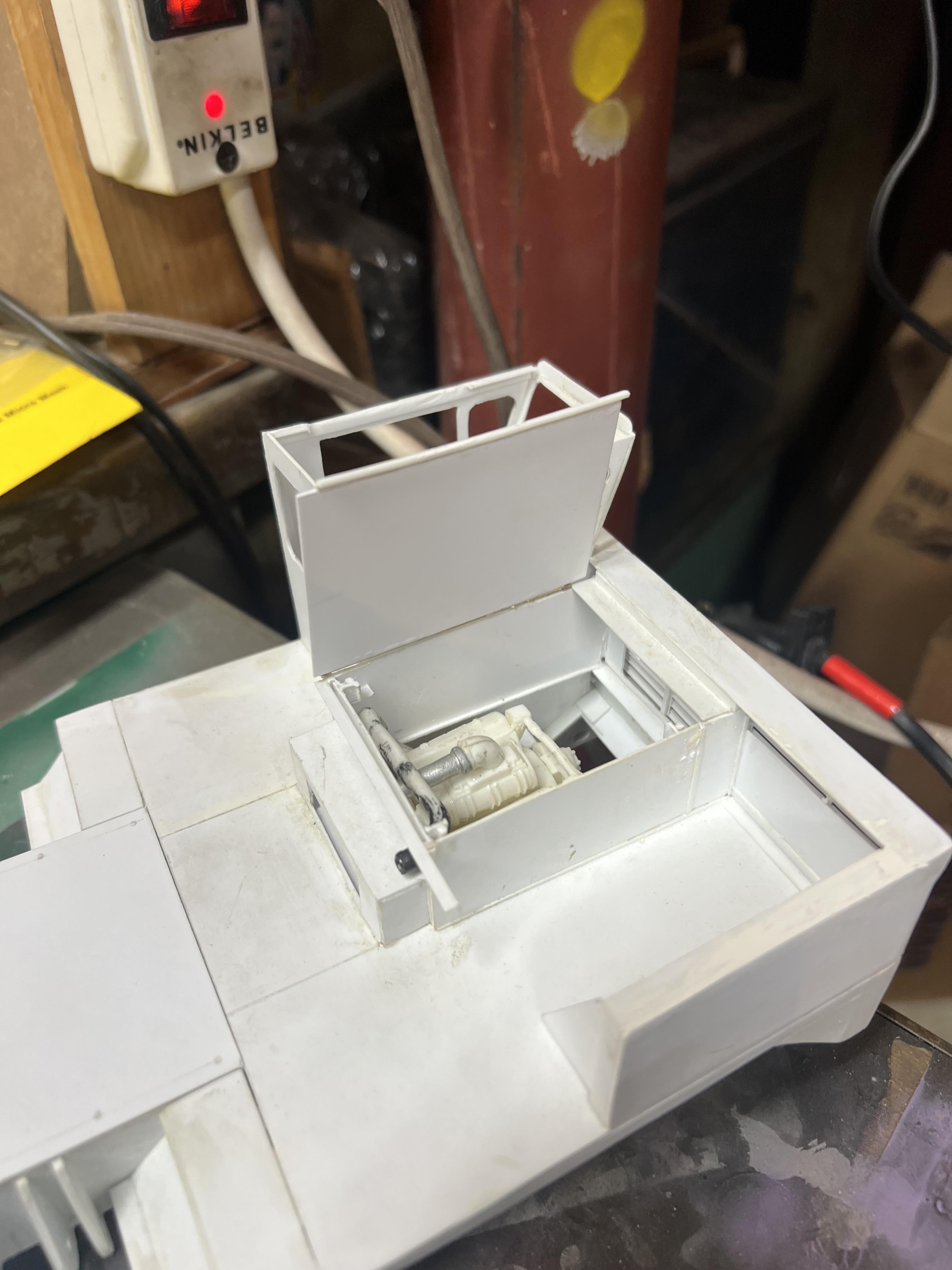

Got a few more things done. Fabricated the swing control lever. Added the rest of the controls to the upper cab. Made up the counterweight support structure and installed it to the rear of the upper house. Will make up the counterweight removal linkage next. Made the counterweight removal hydraulic power unit. Added dunnage to the carrier trays. I put a leash on the radiator so it doesn’t wander away again! Added the step to the carrier for the driver and the hexagonal hub extensions on the drivers side front axles that are used as a step to get into the cab. Still have to do some fine tuning to the drive guard covers and make the counterweight removal linkages. Have all of the recently added pieces held to the build with museum wax so the final assembly after paint will allow final alignment. Then unless my OCD finds something else to do before I get the boom under construction.

-

The big problem I always have doing a build like this from scratch is that I am never happy with some aspects of my work, whether it be from design or fit or finish. It's just a curse that adds a bunch of time to my builds as I so often go back and rework something to make it satisfy me. I am trying mightily to fight this "2 steps forward, 3 in reverse" issue, but it's hard to teach a really OLD dog new tricks! That hinge as well as about 15 other items are on my "do-over" list, that may or may not get done. I have SO much to do on this, (I hope I get it done in my lifetime), and every step I take, I find a tangent to go off on to add "just a few more details", so it's kind of a never ending spiral! But it's the most fun I've ever had when I get to building these things, as I can't remember that last out-of-the-box build I did!

-

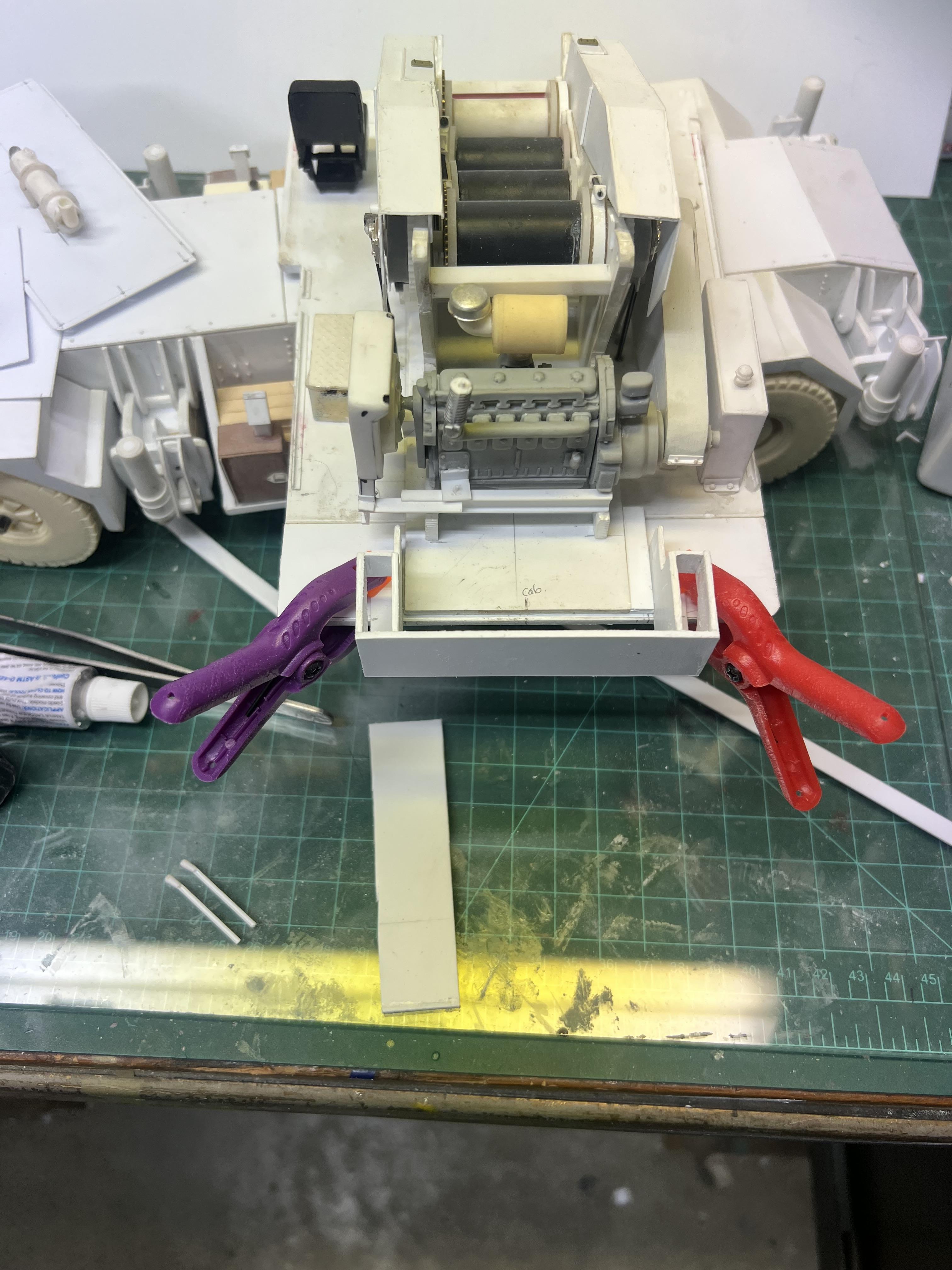

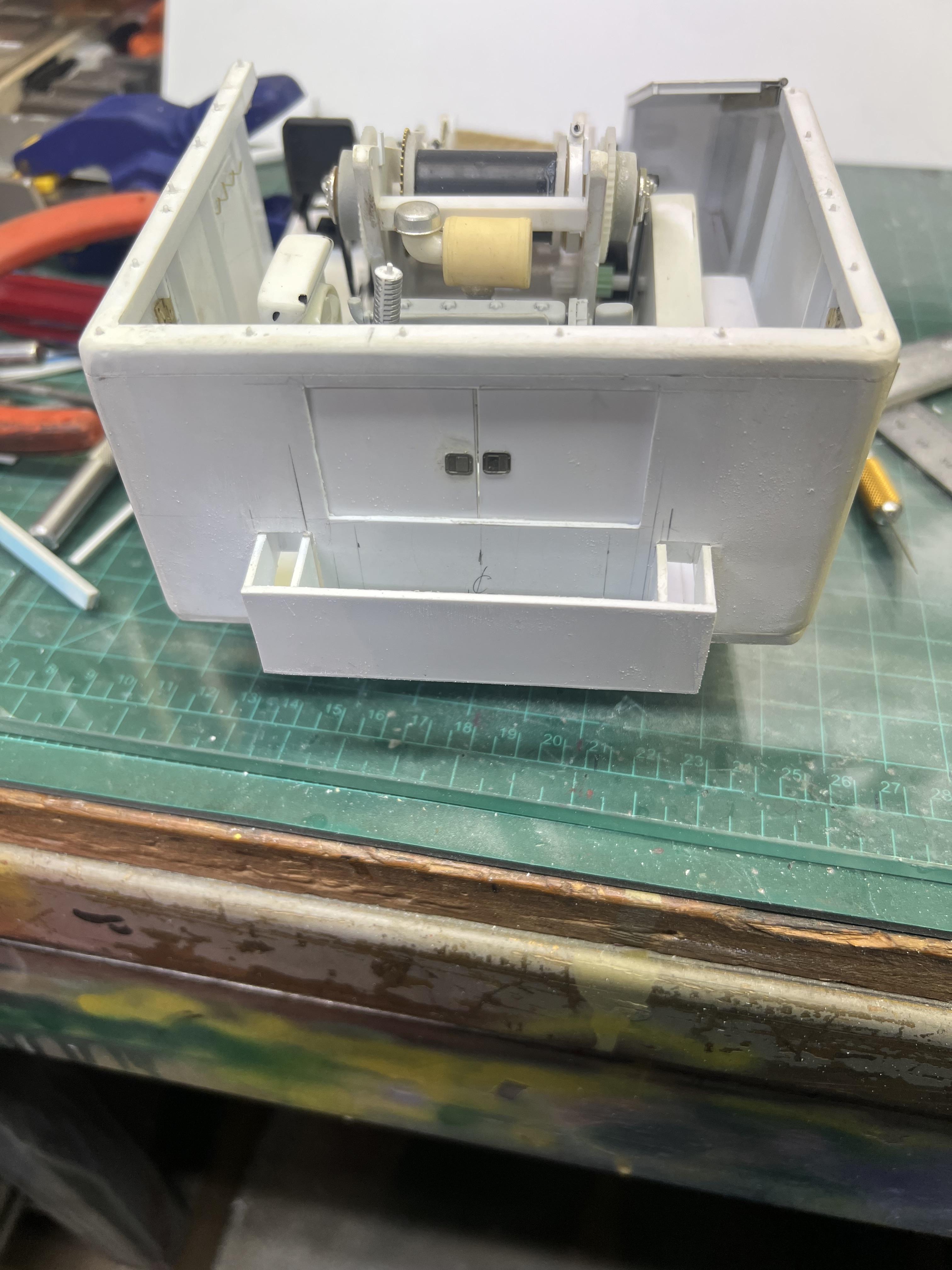

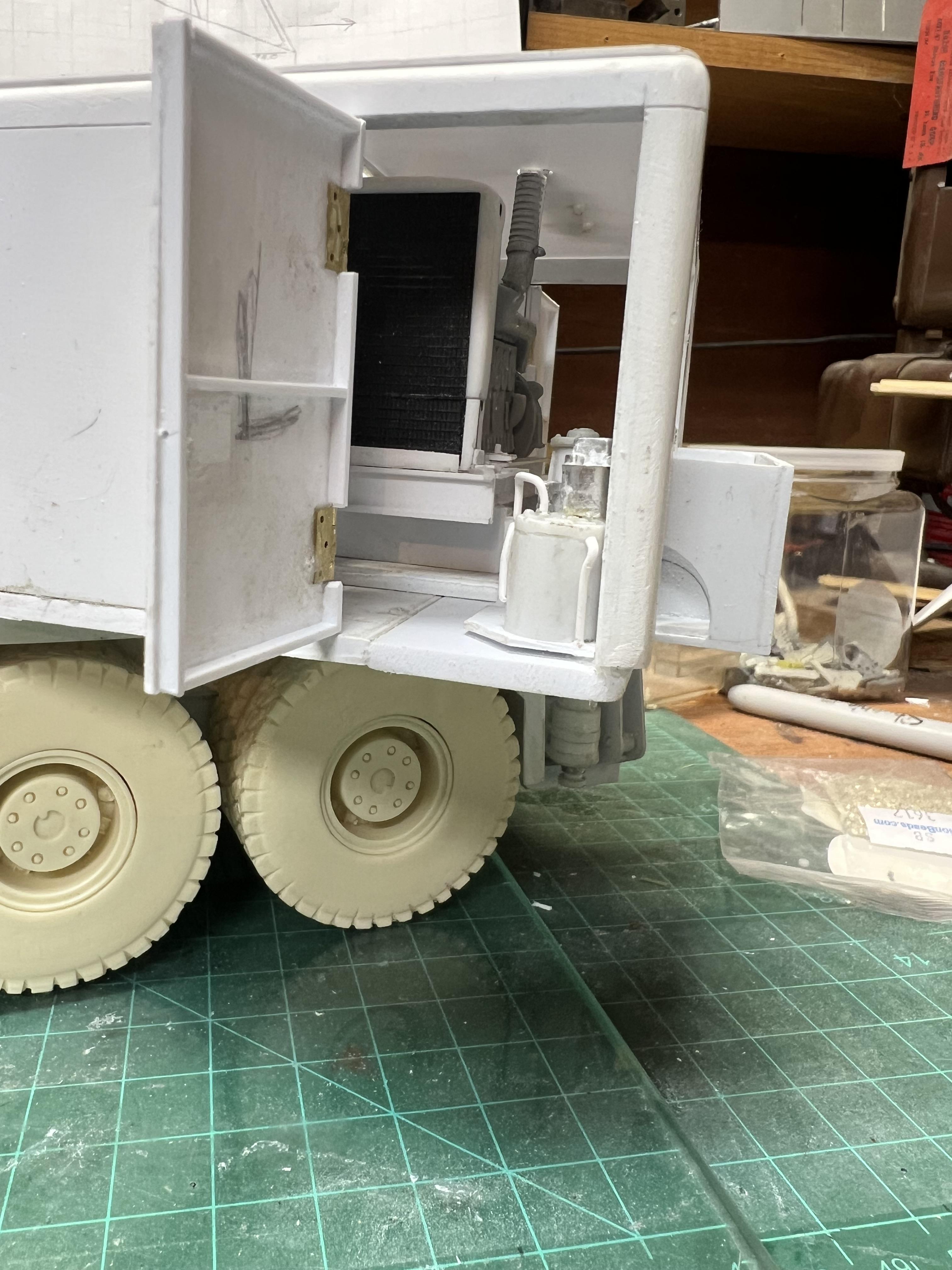

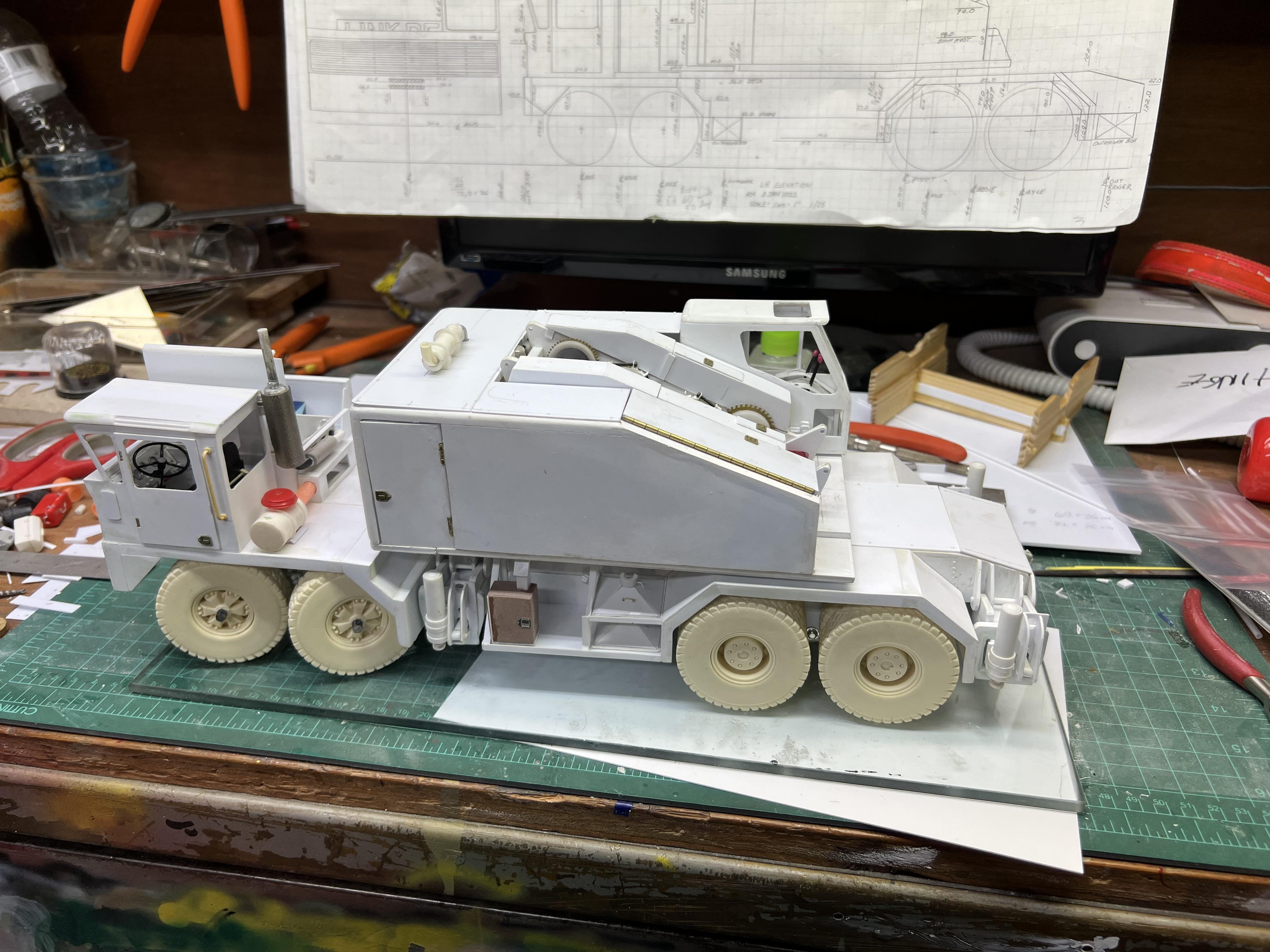

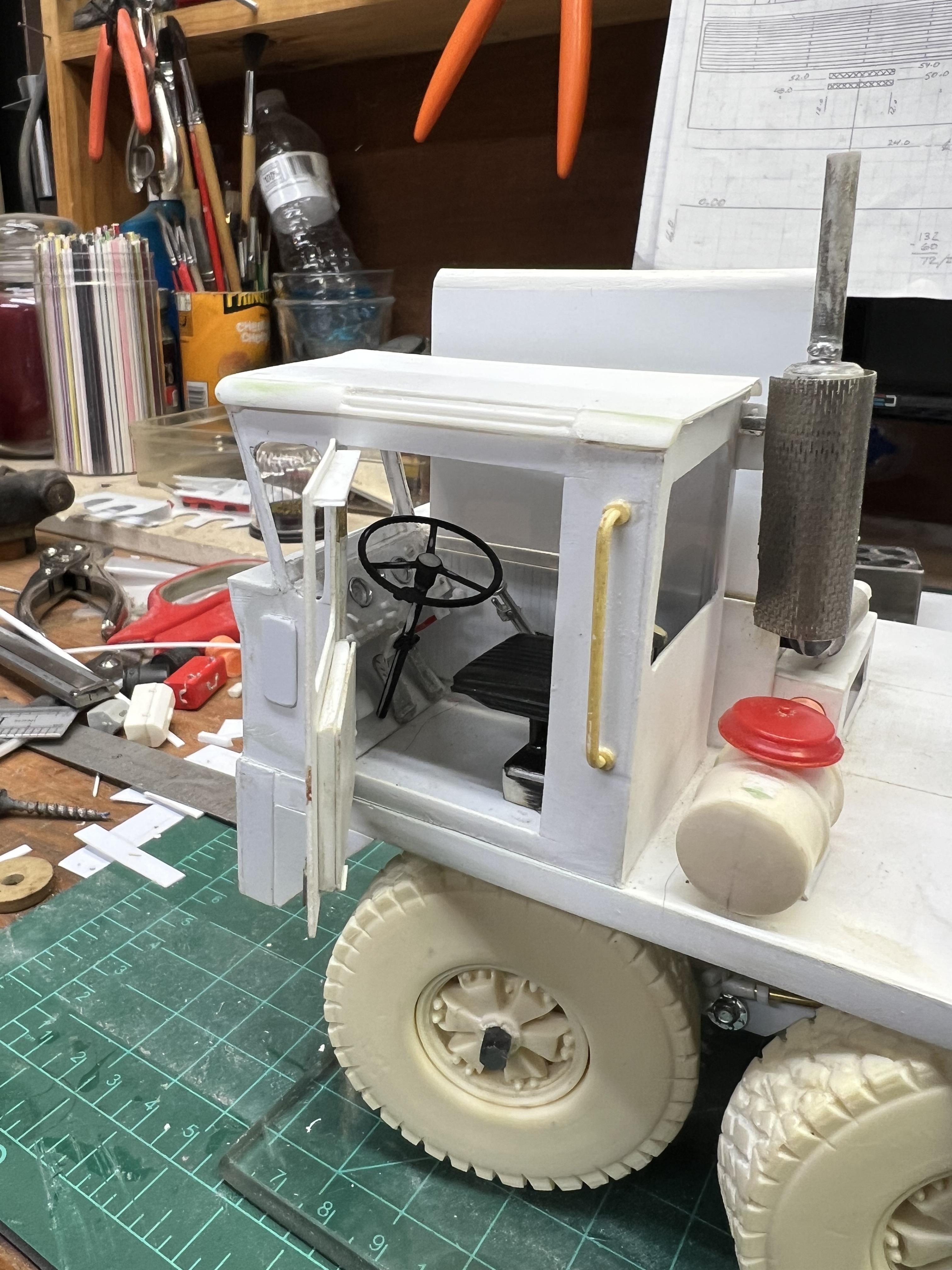

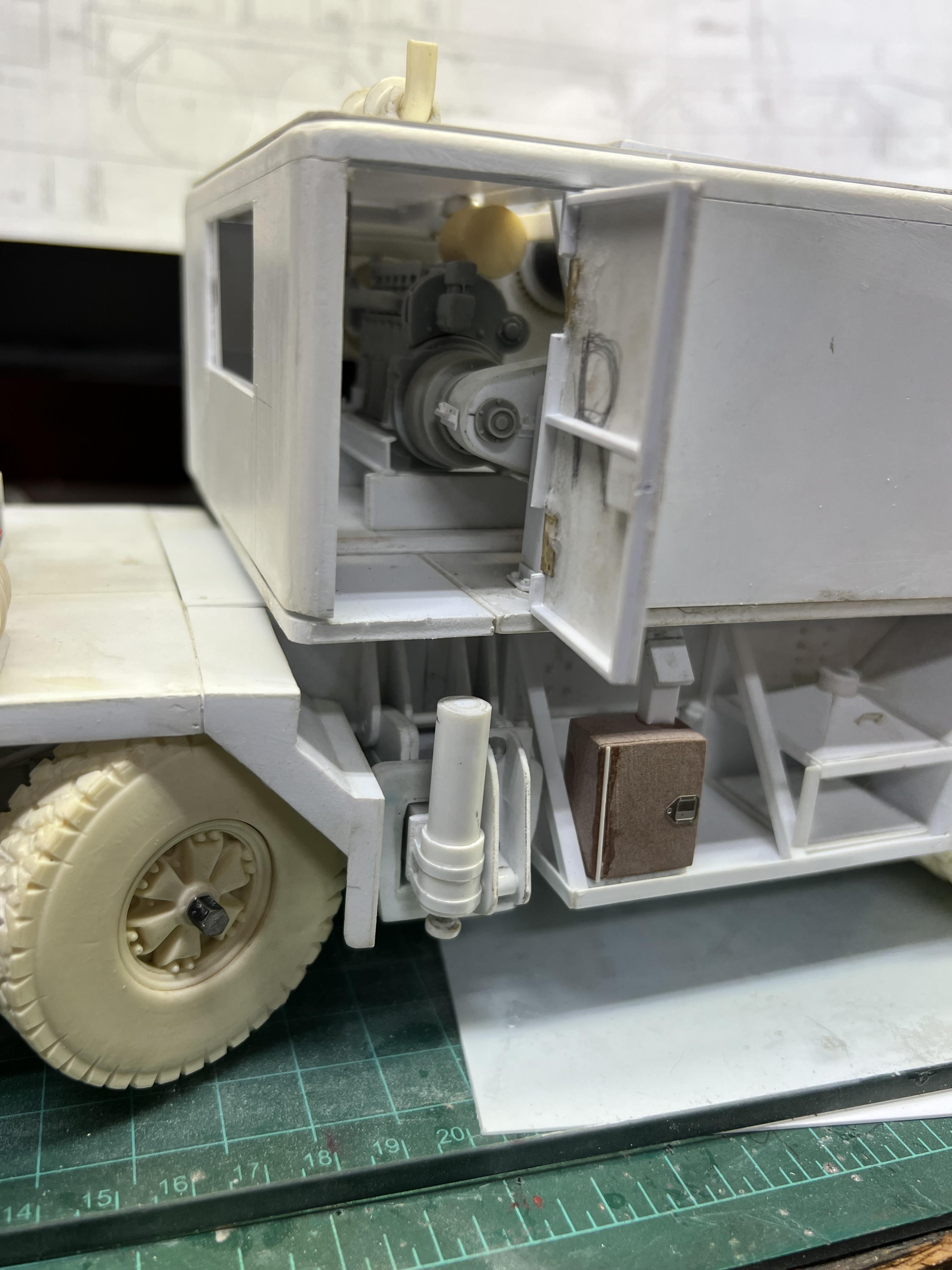

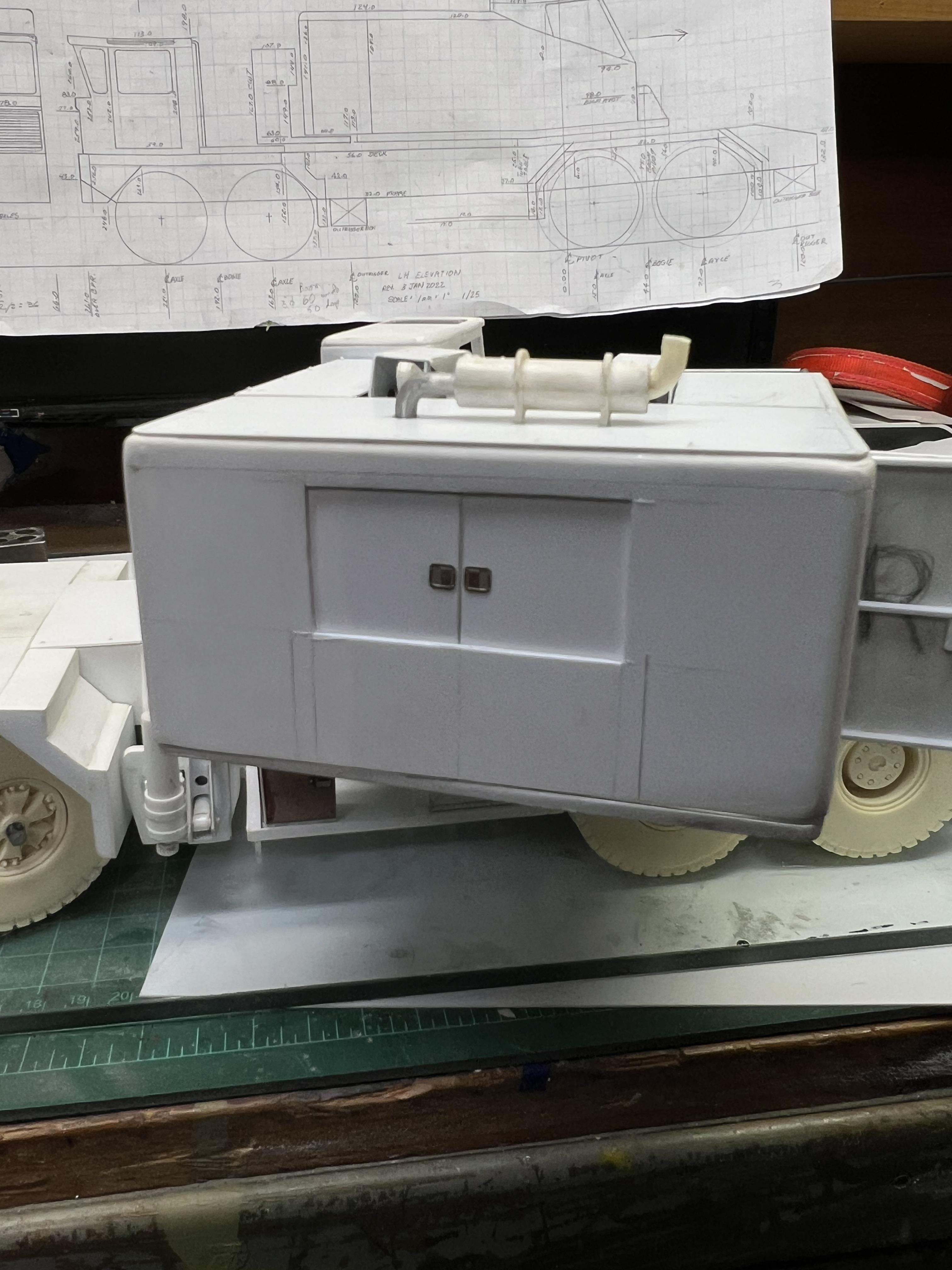

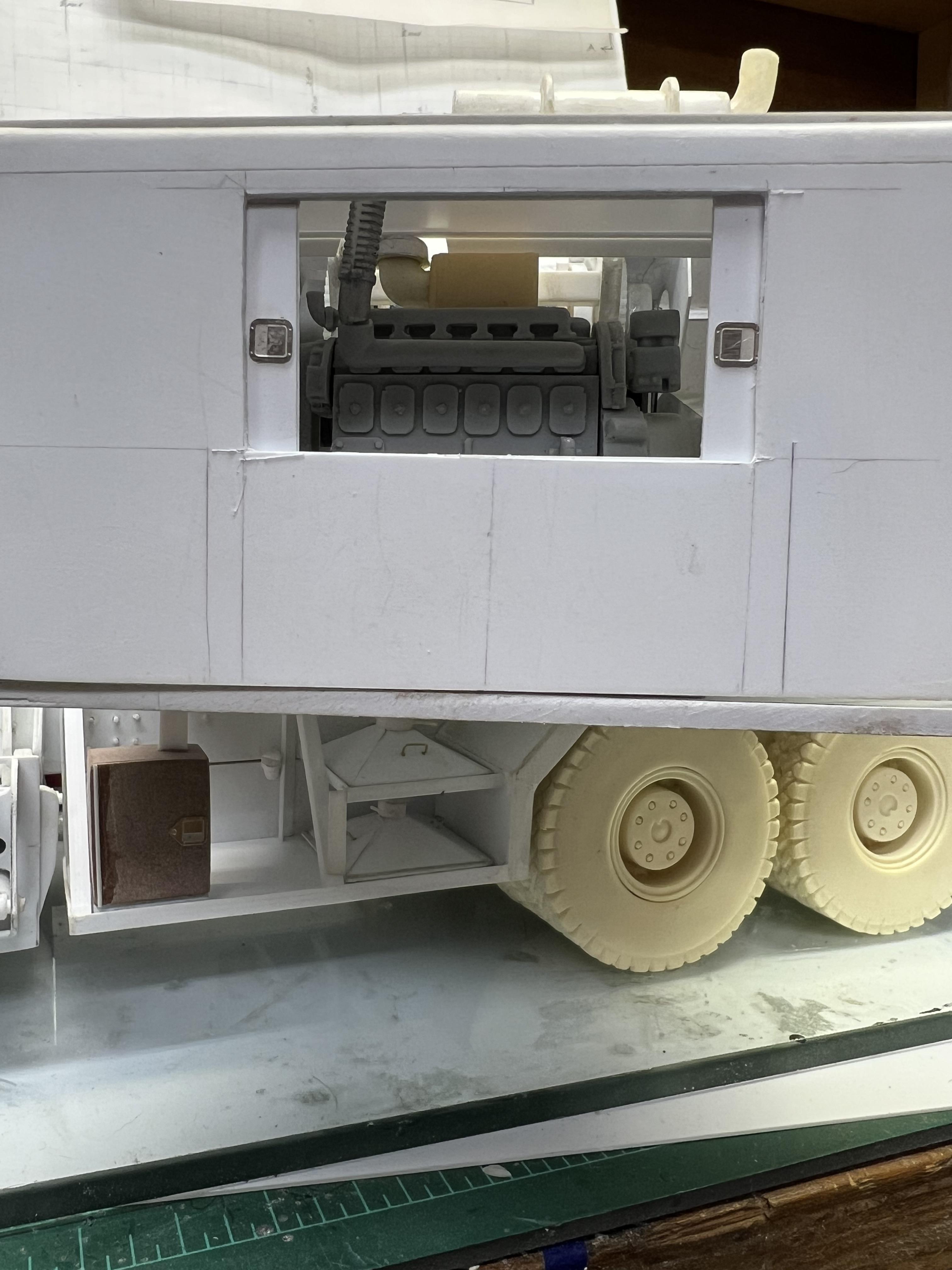

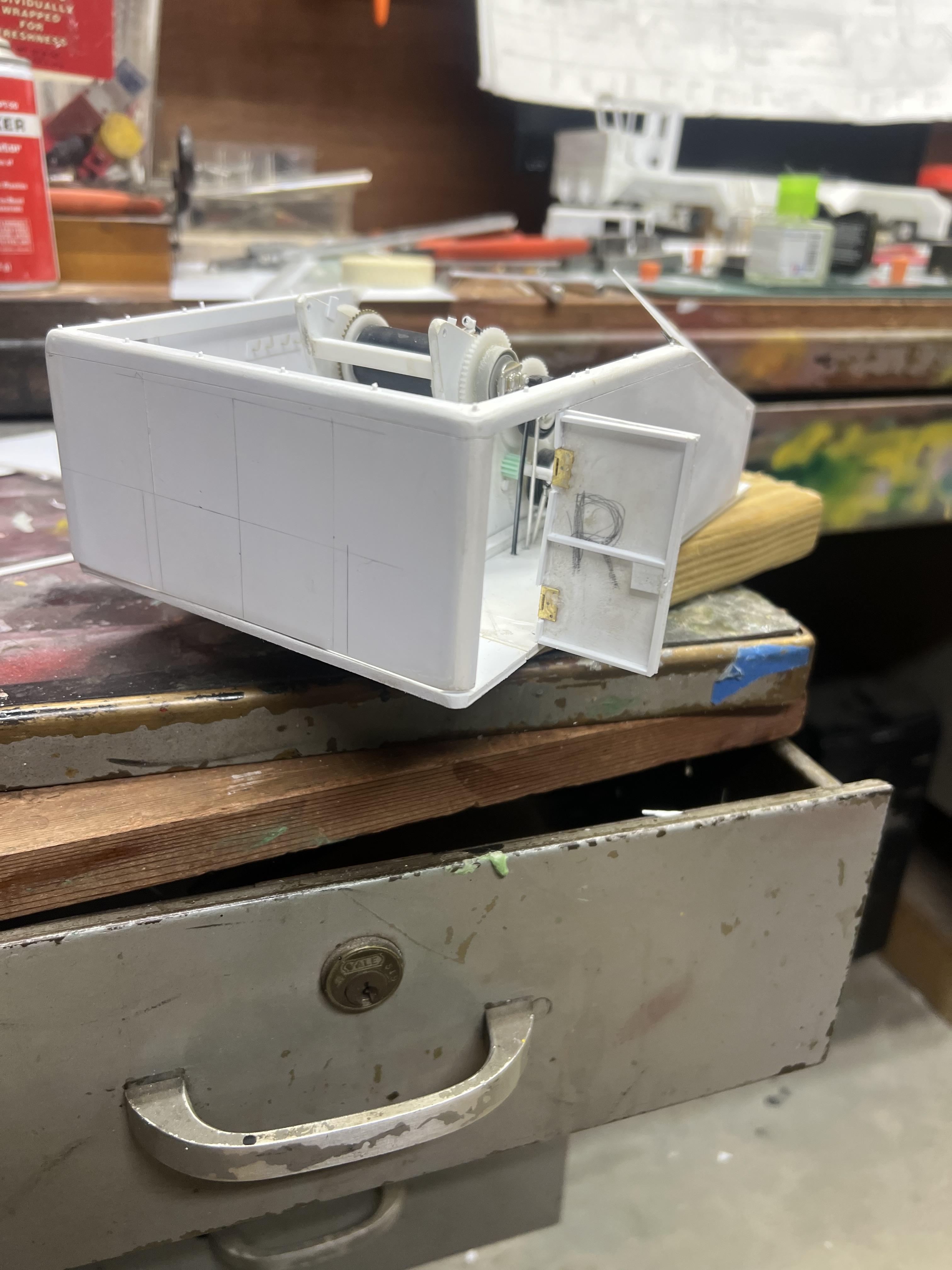

Installed the carrier and operators cab doors, both rear side doors on the upper house, the rear sliding access doors on the house and all of the top covers. Added the outrigger control cabinets on both sides along with the outrigger hydraulic tank, and the hydraulic power pack for the counterweight removal system. Added upper and carrier battery boxes. Added the upper exhaust and air cleaner. Changed the bifold carrier engine cover to a one piece side hinge. It is all mocked together in these photos to check fit. And in the process of fitting it together I discovered that I misplaced the carrier radiator and presently have zero idea where it is! Oh well! Now have to fabricate the counterweight removal mechanism. It’s coming along! Maybe the radiator will show up…….maybe not! EDIT....And ten minutes after I wrote the post……I found the radiator!

-

Just did these hinges last evening. The two side access doors on the upper house are the #15259. They come assembled. The ones on the carrier cab and the upper house operators doors are #15256, and the long one on the upper winch cover is #85816. The #15256 have to be assembled, which for an old guy with arthritic fingers can be a challenge. Do it in a box so when the parts go flying they don’t disappear!

-

.thumb.jpg.4bca3333e1da4027c381d8d56a564ec1.jpg)

Mo'luminum?

redneckrigger replied to ShakyCraftsman's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

We may not see parts from Moluminum again, but we should not bemoan that fact. What we SHOULD do is try to support Jamie in their time of need. If we see parts from him again, it will be a bonus. If Jamie gets better, THAT will be the true gain here! -

I use the Micro-Mark #15256, the #85816, the #15259, and the #15258, all dependent upon where it is being used and how big it has to be. They work wonderfully but are TINY! Be ready to chase the tiny parts all over your bench, or floor, or wherever you build. Fortunately, we rid our house of the dreaded carpet monster a few years back!

-

David, I might suggest that if anyone has ordered from Jamie in the past and they have his address, that they contribute directly, or to his PayPal account, as that way they will realize more from the donation than thru go Fund Me. Just a suggestion, Jamie is the best there is, a great guy with a great family who can use his supporter's help in his time of need. Tom

-

Well, got back home on 1 April from our winter trip south and then west to Texas, weather was nice so even got my Corvette out for a ride. The next day it snowed and almost every day since then at least enough to stifle Corvette fun. So…….got some much missed and needed bench time. Worked on the upper crane works. Made a jig with false sides to allow me to make the guards so they all lined up with the house sides when I put them on. It also lets me rotate the house to work on it without being attached to the carrier. Makes it easier to work on house and carrier. Was able to get the house and all guards, covers, and upper doors figured out. Also got the operators cab all roughed in. Lots of detailing to do now. After the last year of being so busy trying to sell my business, which fell through about 9 days from closing, we decided to get on with retirement and liquidate it in pieces instead of selling as a going business. Couple that with TRYING to retire, and didn’t get much time at the bench. But working on that now! Cleaned my bench off, for the second time in two weeks, holy cow it gets cluttered FAST! Now more details for the upper works, then boom time! Oh boy!