-

Posts

364 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by John Clutch

-

I'm very new here. I haven't built a model in thirty years, so I thought I would give tube frame fabrications a trial run to see what it's like working with styrene. It's definitely a great material to work with. I started bending the rods with a pair of needle nose pliers and taped the sections to a block of birch plywood to get a feel of it and see the working time of the glue. My direction for jigs and templates has changed a bit, and I'm glad I decided to "wing" it for this first small project. I went to my LHS to order my Foose Camaro and to pick up some supplies. Drill set, glue, some styrene rods and decided to get a 1/25 Corvette. My father had a 1969 Chevelle, and always wanted to turn it into a pro touring car with vette drivetrain and suspension. He sold the car before he had a chance of building it, so I thought I would surprised him with a model of one. That's not going to happen now because I made a rookie mistake and picked up the AMT 2009 vette "showroom replica" with no drivetrain in it lol.......so on to what I learned so far...... 1. READ the box! Don't assume it's a full kit lol. 2. Styrene rods when cut with a hobby knife will fly into the abyss, so watch what you're doing. 3. Styrene rods have memory. 4. Keep a wire in the glue syringe to unclog it, the cap is false security. 5. Protect all clear components like the windshield. I threw it back in the box and scratched it up. Thanks for looking. Feedback is always appreciated. 6. I can't load pics from my phone lol

-

That paint is gorgeous!!!!

-

Looks awesome. The stance is perfect, with the chassis rake.

-

Looks cool! And from.here, the color looks great

-

Yes, Im only getting one now also, but it says it full lol

-

I would like to suggest a "Pizza" button, where I can order pizza while Im building stuff

-

When I get a notification for the chat room, I click on "CHAT" and anywhere from 3 to 5 identical windows pop up, saying if I accept the terms and conditions, etc. I commented on the chat earlier today for the first time, and assuming there was a comment made in the chat room, but there wasnt. Clutch

-

Turned some parts on the Lathe today

John Clutch replied to Brent's topic in General Automotive Talk (Trucks and Cars)

Nice job! I have a microlux 7x16 lathe myself, best $800 I ever spent. It has a brushless motor and belt drive. VERY quiet (but the autofeed is plastic gears and is a bit noisy, but nothing like an other mini lathe Ive had) and plenty of power. I used a 3/4" drill on aluminum 1-1/2" deep and not even the slightest bog. Very tough little "toy". Ive made combustion chambers and modified pistons for 46cc two stroke engines, and the unit is very accurate. I highly recommend it. -

I wish you and yours the best, Mark.

-

Ive been drag racing remote control cars since the late 90s. At the time, there wasnt many companies catering to drag cars, so 99% of the cars are scratch built. The only company at the time that offered drag chassis was New Era, but they are too heavy to be competitive. They made a great lexan body for their dragsters, and refused to sell them to anyone that didnt have their chassis with their serial number on it. So if you wanted a body, you needed to own a chassis. One guy had the car, and would order the bodies for us. After ordering 6 or 7 bodies from them, they come him off...... Now they dont exist anymore.

-

Thank you Phil. I did a little research on it, and a chopped sedan resin from Jimmy Flinstone exists, which would probably be my best bet because I not planning on using much other components. http://www.hobbylinc.com/jimmyflintstone-1932-ford-sedan-chopped-rat-rod-body-for-revell-resin-model-vehicle-accessory-1:25-nb152?source=froogle&gclid=CMbk2rHQ3cYCFQ8YHwodoqgFjQ

-

Im impressed with the build and VERY happy to see a two door sedan. Im very new to this (havent built a model in over 30 years) and a hot rod sedan is definitely on my list to build.

-

Very cool. The camaro grill sounded odd when I read it, but when I saw it, it was a completely different story. Awesome !

-

Awesome ! Im looking forward to the progress !

-

70 Chevy Nova Outlaw..updates (11/08/15)

John Clutch replied to tyrone's topic in WIP: Drag Racing Models

very nice ! -

Thanks Fabrizio! Shaun, Tim..... The plan is to build a single 88mm turbo (pro mod) small block with stock bore spacings on alcohol (non intercooler). Powerglide and fab9 rear. 25.3 spec cage. I chose this class because you need to retain the original firewall (somewhat) the floor pans from the firewall to the rear door jams and the stock chassis from the motor plate to the rear of the rear wheelwells. I always wanted to build a real car under these conditions, so Im building it exactly the way I would do it. (hopefully) So since the kit requires a good amount of the original kit to be used, Im hoping to be able to make the chassis with styrene. If this was any other chassis, it would be made from brass. Im a metal fabricator by trade and worked with brass my whole life, but I dont have alot of experience with plastics and wanted to use the medium as much as possible.

-

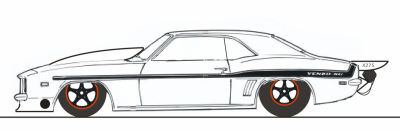

I cant build anything without at least some sort of drawing that give an idea what the finished piece would look like. I just took a camaro pic and did some adjustments on coreldraw. I should have an actual kit soon.

-

WD40 (and like products) and cigarette smoke can cause fisheyes. That much I know from experience lol

-

'81 Camaro Batmobile?

John Clutch replied to Snake45's topic in General Automotive Talk (Trucks and Cars)

Sometimes, ideas should never leave someone's head. This is a prime example.