-

Posts

2,362 -

Joined

-

Last visited

About johnyrotten

- Birthday August 31

Previous Fields

-

Are You Human?

Yes

-

Scale I Build

1:24

Profile Information

-

Full Name

John Rourke

Recent Profile Visitors

5,492 profile views

johnyrotten's Achievements

MCM Ohana (6/6)

-

Welcome to the forum Don.

-

Great looking Cuda, William.

-

Keyboard warriors are often found in their natural habitat, their mother's basement.

-

That doesn't look bad at all Don. Personally I'd clear it and polish it out. I bet that would polish as it sits.

-

I built one in back when I was a kid, cool subject and a nice kit. That one always stuck out to me on how good it looked. Years later I actually learned about johan models and it makes sense now. I was, and still am, blissfully ignorant of a lot of model history. Good luck with that build when you get it.

- 39,238 replies

-

- 1

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

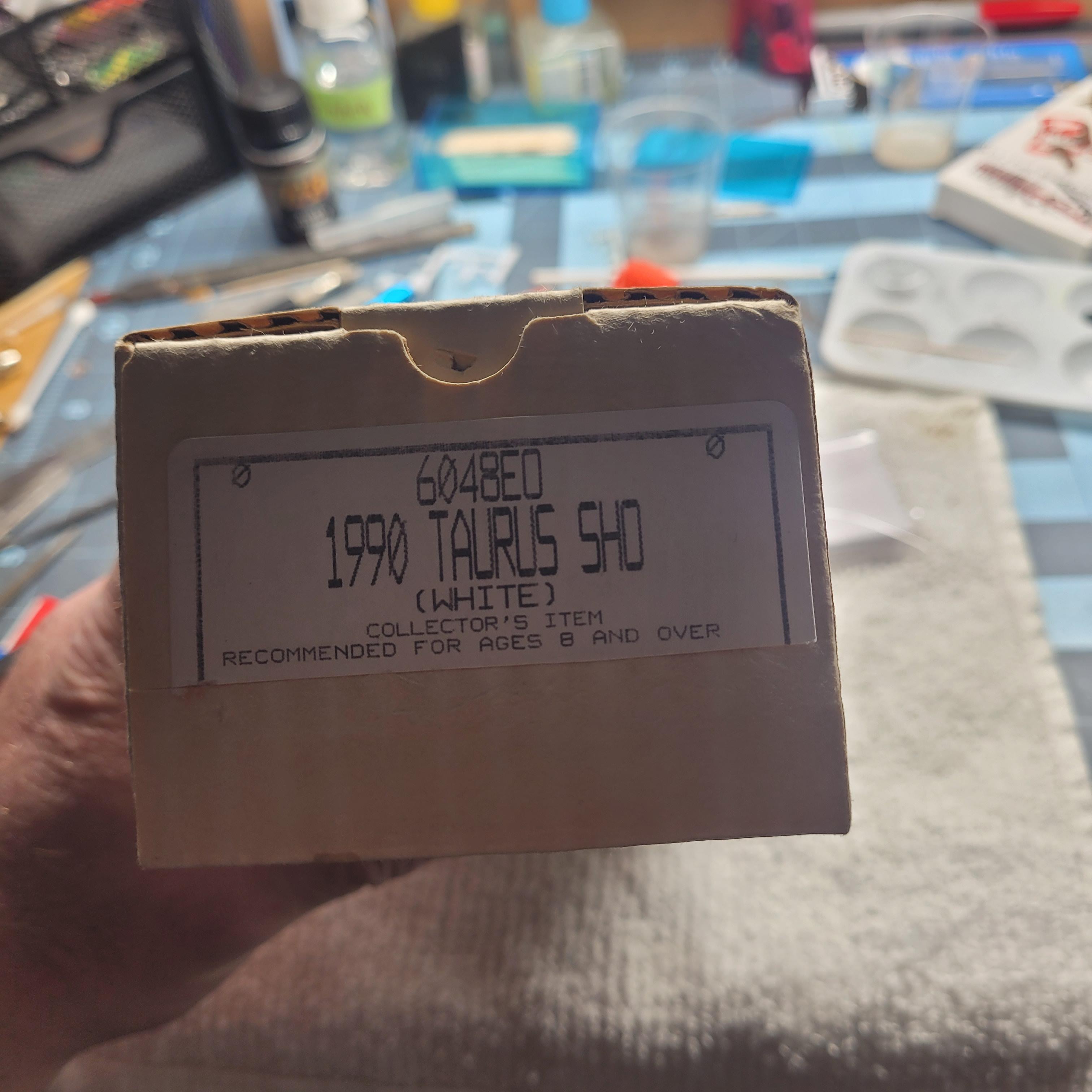

I like to hunt for deals, especially with with my model hobby. Any hobby can get get expensive, believe me I know, my other one is motorcycles. I've managed to find some killer deals on kits and supplies. It's safe to say half my stash and most of my paint was acquired at well below retail. I recently got over 100 various tamiya, humbrol and model master paints for free. Just time invested in sorting them out. This promo is one I don't see often, and for 2 bucks, not gonna pass it by. Especially since its a subject i like. I'm probably the guy that reaps the rewards from people that think like the person you are talking about when their plan doesn't work out.

- 39,238 replies

-

- 1

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Here's a costly model

johnyrotten replied to johnyrotten's topic in General Automotive Talk (Trucks and Cars)

Ninety grand. You could probably(?) replicate the full size body for that price. ouch -

- 39,238 replies

-

- 5

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Great work Michelle. I really like that blue you used, and you have that car sitting perfectly. Gives off a real sleeper vibe. I like it.

-

Not my typical subject, I'd be on board to build the race version. That's one beautiful looking ride.

-

Pets also doomed to be replaced by AI and bots...

johnyrotten replied to Ace-Garageguy's topic in The Off-Topic Lounge

Right there with you on that. Like any "system", it's abused and loopholes exploited.