-

Posts

33,709 -

Joined

-

Last visited

Previous Fields

-

Are You Human?

yes

-

Scale I Build

1/25

Contact Methods

-

Website URL

http://www.ace-garage.com

Profile Information

-

Full Name

Bill Engwer

Recent Profile Visitors

76,680 profile views

Ace-Garageguy's Achievements

MCM Ohana (6/6)

-

Today will be yesterday by tomorrow.

-

You just have no idea, no idea at all.

-

Kid gloves can be made of leftovers from baby goat curry.

-

Culture some bread-mold and make your own penicillin.

-

Monkees...3 of 'em anyway...took the last train to Clarksville a while back.

-

"Macaroons" sounds like a cross between macaroni and baboons...and what could be more fun than a pot full of cheesy monkeys?

-

Google's "AI Overview" is really, really stupid.

Ace-Garageguy replied to Ace-Garageguy's topic in The Off-Topic Lounge

Thing is, it has no common sense or critical-thinking skills...which is no surprise, all things considered, is it? It apparently weighs everything it gets from the web equally, just like a lot of dumb people do. IBM's "Watson" introduced in 2011, that competed on and won a million bucks on Jeopardy, was WAY smarter than Google's hot mess. https://en.wikipedia.org/wiki/IBM_Watson IBM once stated that Watson uses "more than 100 different techniques to analyze natural language, identify sources, find and generate hypotheses, find and score evidence, and merge and rank hypotheses." In other words, it's capable of critical thinking in a way poor little Googlie can't even come close to. Google hasn't unleashed artificial intelligence. They've delivered artificial stupidity, and I'm sure they're very proud. -

Forum website has been sluggish for the last few days

Ace-Garageguy replied to peteski's topic in How To Use This Board

Yup, that's the frustrating nature of whateveritis. Sometimes it works great for some while it hangs interminably for others. Right now it's hanging very randomly for me. -

Google's AI Overview is comically bad, kinda like a Dunning-Kruger know-it-all who actually knows very little, has no common sense, gets everything scrambled, and believes he's a genius. https://www.technologyreview.com/2024/05/31/1093019/why-are-googles-ai-overviews-results-so-bad/ In short, Google has electronically cloned the typical internet "expert". This is what AI Overview has to say about itself: Google's AI Overviews feature, which summarizes information from websites and answers search questions, has been criticized for producing incorrect, misleading, and even dangerous responses. For example, when asked "How many rocks should I eat?", the AI responded that eating rocks could be good for your health because they contain minerals. Other examples include: Suggesting using non-toxic glue to make pizza sauce stickier Saying that Barack Obama was a Muslim president, which he is not Advising drinking urine to pass kidney stones quickly Responding to an Associated Press reporter's query about cats on the moon with "Yes, astronauts have met cats on the moon, played with them, and provided care"

-

Songs about luuuuuv seem to me to be, more often than not, whining about how awful it is.

-

What non-auto model did you get today?

Ace-Garageguy replied to chunkypeanutbutter's topic in The Off-Topic Lounge

Great story. -

Thanks for giving this one a bump, gennelmen. There's actually a chance I might work on it this coming weekend. I'd really like to at least get it in paint soon, and it's close to ready at this point. A little fine bodywork, and a coat of white primer... I need to use up the leaking cans of Testors Fiery Orange metallic (or is it Flaming Orange?) pretty soon too.

-

What non-auto model did you get today?

Ace-Garageguy replied to chunkypeanutbutter's topic in The Off-Topic Lounge

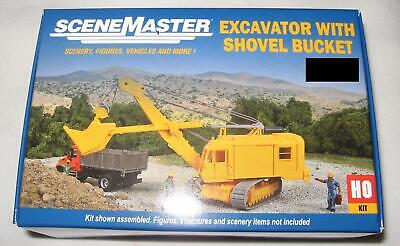

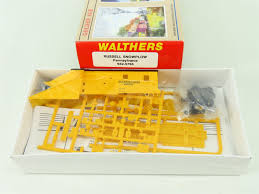

I rarely buy "new" model train stuff, other than NOS kits from decades past. However, what I want isn't always available as vintage NOS. After finishing my emergency roof repairs on the back shop-room of the house I'll be leaving soon, I decided to give myself a reward for getting something really unpleasant done, and went to HobbyTown for a kit I'd seen earlier in the year. The price at HT was considerably better than what I could get anywhere online with shipping, and buying current-issue kits and supplies like paint and Plastruct stock from them is all I can do in the name of "support your LHS". This Walthers SceneMaster tracked excavator is a nicely detailed little kit that will easily backdate to the period I'll be modeling. And even though it represents a diesel unit, converting it to steam won't be hard. It'll be working at a coal mine, supplying both fuel for steam locomotives and the coke ovens at a steel mill. Speaking of NOS, I also snagged this Russell snowplow kit for a fraction of the going price for the currently available RTR version. It's in Conrail livery, and Conrail didn't happen until much later (1976) than my intended layout represents (mid '50s) but color and livery changes are easy, and the price was definitely right. It's not a car that gets run frequently, if ever, but plows, flangers, etc., look great sitting on work-train sidings, rusting quietly and patiently until they're needed.