-

Posts

267 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by mikevillena

-

Just a little bit of bench time tonight. Putty work trying to blend things. Quick and dirty mock-up of the wheelbase and stance using the kit supplied wheels and tires: I'm going to have to use a deeper radiator core to handle the cooling requirements of the Cosworth. The Cosworth is rather compact length-wise but I might shift it further back slightly past the stock firewall. It will have a bell-housing but the transmission will be part of the rear axle so that the engine shouldn't intrude too much into the cockpit. I will also incorporate teardrop shaped bulges on both of the engine side covers to accommodate the "bundle of snakes" exhaust headers. I will have to use the non-louvered covers to make it work.

-

Not satisfied with it, I built another one that was closer to the original shape using the same technique: Additionally, thank you for sharing your project insight. You have shown some nice solutions. I had originally planned on scratchbuilding a Ford Cosworth DFV that has a dry sump. I also planned to saw off the belly pan as a complete assembly so that I can shape and blend the inside surfaces and build a complete space frame. I will also incorporate removable access panels for the engine and transaxle on the belly pan. Ultimately, the belly pan will be re-attached using tiny screws in the final assembly. Carl, thank you so much for sharing your superb projects.

-

Thank you Carl. Hi Bernard. And thank you very much for sharing that magnificent project. Absolutely beautiful work. As to the approach, I simply adapted an old technique that I had previously used on a larger project from 2005/2006. It was my 1/10th scale Super Seven R/C car: http://www.scale4x4rc.org/forums/showthread.php?t=4443 I ended up building two complete noses, the first one having a lot of compound curves:

-

Thank you for the overly generous compliment Stan. I think it's more problem solving than skill as my building techniques are still rather crude at this point. Thanks G!

-

Beautiful work Dan. Incorporating a virtual "box" with the model increases the appeal to modellers even more. Again, really beautiful stuff!

-

I didn't have 300+ dollars for an entry-level Foredom so I bought this cheapo knock-off for around 50 bucks : It has been absolutely reliable throughout the years. It has tremendous amount of torque even at crawling speeds and gives me far better control than a Dremel mototool. The chuck isn't the best and I have to be careful in setting up the bit otherwise it wobbles.

-

Got a little bit of bench time tonight after work. I was somewhat undecided regarding the wheel well. Some of the traditional rods had them filled in while others did not. I opted to use them unfilled and incorporate their shape into the belly pan. I also shaped the tail section to get a true "rolled" pan. I really like the front end view. It is reminiscent of the bow on a boat or a Bugatti. I will have to engineer the front suspension so as to maintain a clean appearance.

-

Thanks guys. Still feeling my way through the project.

-

A lot of shaving and sanding. I had to constantly fire up the vacuum cleaner to keep the bench clean. Pre-curved a piece of .040 thk sheet roughly cut to cover the bottom opening and glued it on. Started roughing out the passenger side: Whittling and shaping by dragging the knife blade perpendicular to the surface gave me a little more control and less plastic dust. I also switch to a single edge blade for the larger areas. "Boat hull" starting to take shape: This reminds of the Testors Boyd's Alumacoupe model I built many years ago. The slightly curved bottom almost begs for some louvers around the engine compartment. I might try to scratchbuild them using quarter round styrene. I also used the non-louvered hood panels as sacrificial components so as to leave the louvered panels intact for the finished product. BTW, here's just one example of Bernard Kron's beautiful work: http://www.modelcarsmag.com/forums/?showtopic=66573 I hope he doesn't mind my linking to it.

-

1955 Nomad Drag Wagon AKA The 9 Second Grocery Getter FINISHED

mikevillena replied to DynoMight's topic in WIP: Model Cars

Great work so far. One small suggestion is to not be in a hurry to slap some color on. Take the time to finish off the bodywork. Just my 2 cents. -

I was really eager to try and tackle the challenge of building the slick belly pan so I give it a go. I was inspired by the way boat modellers construct the hull on wooden sailing ships so I adapted the technique. Plank on plank to build up the rough shape. After some quick and rough sanding (proof of concept) I'm pretty confident that the technique will work. I now need to build up the other side and joint the middle with several sheets. Then it's a lot of shaping, sanding and blending. Once the entire belly pan has been shaped externally, I will saw it off just like the lower hull of a scale warship waterline model. Then I will shape the internals.

-

Thanks Jim. I'm sure someone has already thought of it before.

-

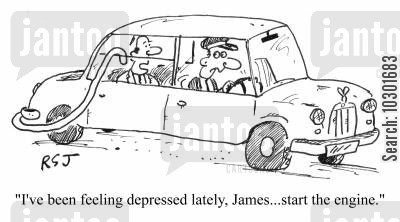

This is just ridiculous!

mikevillena replied to Harry P.'s topic in General Automotive Talk (Trucks and Cars)

-

Thank you for all of the kind words of encouragement. This is the first time that I've done major "hot rod" style modifications so I'm somewhat shaky with the techniques. Although I'm very happy with how the chop turned out. I thought about sacrificing my very expensive Italian painting knives to make specialized sanding pads but I went to Michaels and got a cheapo one to experiment with. I give the blade a shot of 3M adhesive and stuck on some 600 grit wet and dry sandpaper and trimmed off the excess: This shape allows me to sand small surfaces absolutely flat. While working on the shell I forgot to use my grippy pad of kitchen drawer liner and (you guessed it) the shell slipped off the glass surface and fell off the workbench. I grabbed it out of reflex but cracked the glue joints on the "A" and "B" pillars. I had to re-glue the joints and blend everything again. I decided to tack on the rest of the panels to plan what I was going to do with the project. I tried various set ups and I think I might stick with this stance and track width: The front of the grill shell will almost be dragging on the ground. I will also do a full length fully contoured belly pan very similar to this: There are other forum members that have done belly pans too so I'm not exactly breaking new ground here. My plan is to build up and shape the belly pan's external contours while it is glued onto the shell and then sawing it off so that I can shape and finish the inside contours. This also allows me to build the space frame. Meanwhile more blending on the windows to hide the chop:

-

Thanks for the link. I am so stoked with the possibility of an Audi, Toyota, Porsche battle! BTW, you guys know that we are having an "Endurance Racing Group Build" right? Here's the link for sign-ups: http://www.modelcarsmag.com/forums/index.php?showtopic=89848 Here's the official thread: http://www.modelcarsmag.com/forums/index.php?showtopic=90008 It's currently locked until the official start. It's open to ALL SKILL LEVELS AND SCALES. Hope to see all of you on the grid.

-

Thanks Glenn. Your " 9 Second Grocery Getter" project is looking great!

-

Thank you all for the very kind words I haven't had much time on the bench as I've been busy sharpening my Creo skills for my new job on Monday. In the meanwhile, I finished mating the chopped top to the rest of the shell. It's fill, sand, prime, sand, rinse and repeat time: The contours around the top perimeter will ultimately be restored as well as the rain gutters. After I'm satisfied with the chop, I will build out the door jambs and start the door surgery.

-

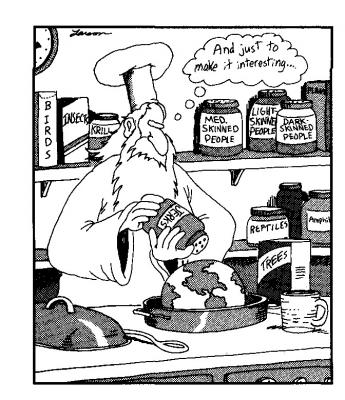

Yes, that Duesnberg is a knock out! There's also this guy: Note that the flat 12 cylinder works. There's also this build (as posted on an Italian forum): http://amgmodels.mastertopforum.com/alfa-romeo-33-2-1-8-by-stephane-dufrene-vt5855.html Note that it's in the Masterpiece sub-forum There was a german modeler who fabricated a 1/8th scale Porsche 908 out of styrene. There are a so many variables that it is foolish to compare one model to another. Some folks work entirely in metal and have a complete tool room at their disposal. Others choose to spend a lot of money on aftermarket goodies. There are others who simply enjoy building stuff from whatever material they have on hand or can afford while there are others who choose to build the model strictly out of the box but strive to do it masterfully. Another variable is time. Some folks only have a few hours a week while others have the luxury of spending thousands of hours on a single project. But all have these two things in common: the drive for perfection and attention to detail.

-

Meh, there will always be blowhard, know-it-all, self-appointed, god's gift to: (insert life aspect or activity here) jerks. What are you gonna do?

-

Since the top is not yet glued on, I can easily fill in the ejector marks and transitions with Tamiya putty and wet sand once it is fully cured: I'll give it a skim coat of Bondo red putty and set it aside for a while. Back to the Alfa project.

-

Thanks Glenn. I'll try to do a decent job. Hi Michael. To cut the doors, I used the back tip of a sharp x-acto knife blade (mounted on the handle) and lightly followed the molded door opening. The phrase " death by a thousand cuts" applies here as I kept lightly scribing and removing tiny bits of plastic with each cut. I had to constantly scrub the cut line with an old toothbrush and soapy water to remove debris as even a tiny fragment will cause the knife blade to pop out and gouge the surrounding plastic or cause the cut line to go wonky. The material loss is about the same as the thickness of the knife blade tip if one is careful. I also try to keep the knife tip perpendicular to the surface to avoid a bevel cut. I wait until it is time to fit the door before dressing the cuts. I made my own sanding pad by sticking various grades of wet and dry sandpaper onto an old machinist's 6 in. steel rule using 3M spray adhesive. This sanding pad is flexible while yielding a flat sanding surface. To cut the top, I used my old Zona razor saw: For the horizontal cuts, I started on one of the round corners and used my finger tips to help guide the saw blade. I took my time and kept adjusting the saw blade angle to make sure that the cut is straight and is perpendicular to the surface. Once I've cut through the corner, the actual cut edge acts as a guide for the blade to rest on. I also used soapy water to constantly lubricate the knife as I make the cut. Because I'm still learning and experimenting there might be a better or easier way to do this. Oh and the machinist's square is a cheap Harbor Freight version:

-

I'm sure someone else has done it this way or have found a better way. I have never done custom bodywork before so I was merely trying to replicate how they do things on the real cars. I tried to follow the steps on this site: http://www.rodandcustommagazine.com/techarticles/custom_top_cutting_techniques/ Another cool site: http://www.jalopyjournal.com/forum/forums/traditional-hot-rods.57/

-

Ah, I did miss it! And I too have on occasion been tempted to throw everything away and take up knitting or basket weaving (no offense intended to the master knitters or weavers) but I would probably be terrible at that too! But on a serious note, I would be extremely disappointed if anyone laughs at another member's work as would all of the decent folks here. The point of the forum is to share ideas, mistakes and solutions. In truth, we are all problem solvers. I too know very little and am also learning. Whether to post or share your build/project is entirely a personal choice.

-

I hope you are not offended but that is a really poor attitude to take. First of all, build for yourself and for your own enjoyment. Period. Modelling is just another aspect of life, i.e. a "personal journey". Some folks started their journey earlier than you did or have had the luxury of being able to spend more time with their hobby. Others have had to divert from it due to life circumstances. Others have taken a really convoluted path. Etc, etc, etc. This applies to everything in life. The choice is yours, either run away because you have chosen a negative mindset or open your mind and realize that there is a lot to learn. Again, it is a journey. My final thought is that it is and will always be a mistake to solely focus on being competitive and trying to out do everyone else. The fact is, there will ALWAYS be someone who can do it better. If you don't believe me just look at a leaf, or a tree or your own hands. You didn't build that.....someone else did.