foghorn62

Members-

Posts

376 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by foghorn62

-

No no no Ricky, this forum is not about giving up! It’s about displaying individual creativity, and encouraging others to take a step out of their own comfort zones, and try new ideas that they had previously thought to be too difficult or impractical. This kind of work is not that difficult. If you see something you like, don’t hesitate to ask questions, and then try it yourself. You may surprise yourself at how nice it comes out.

-

Thanks Carl! TS Thanks Kurt! When soldering like this, the important thing is to control the heat. You don’t need a torch like you would for plumbing. I use a small soldering iron, and flux.

-

Thanks Danny! TS

-

LOL!! Exactly WWWEEEEEEE!!! TS

-

Thanks Trevor! That is an interesting observation. I have not seen that configuration. What is that based on?

-

Thanks for your suggestion Daniel! I agree, louvers would look good, except the 12 velocity stacks will poke slightly through the hood, so there won’t be any room for louvers.

-

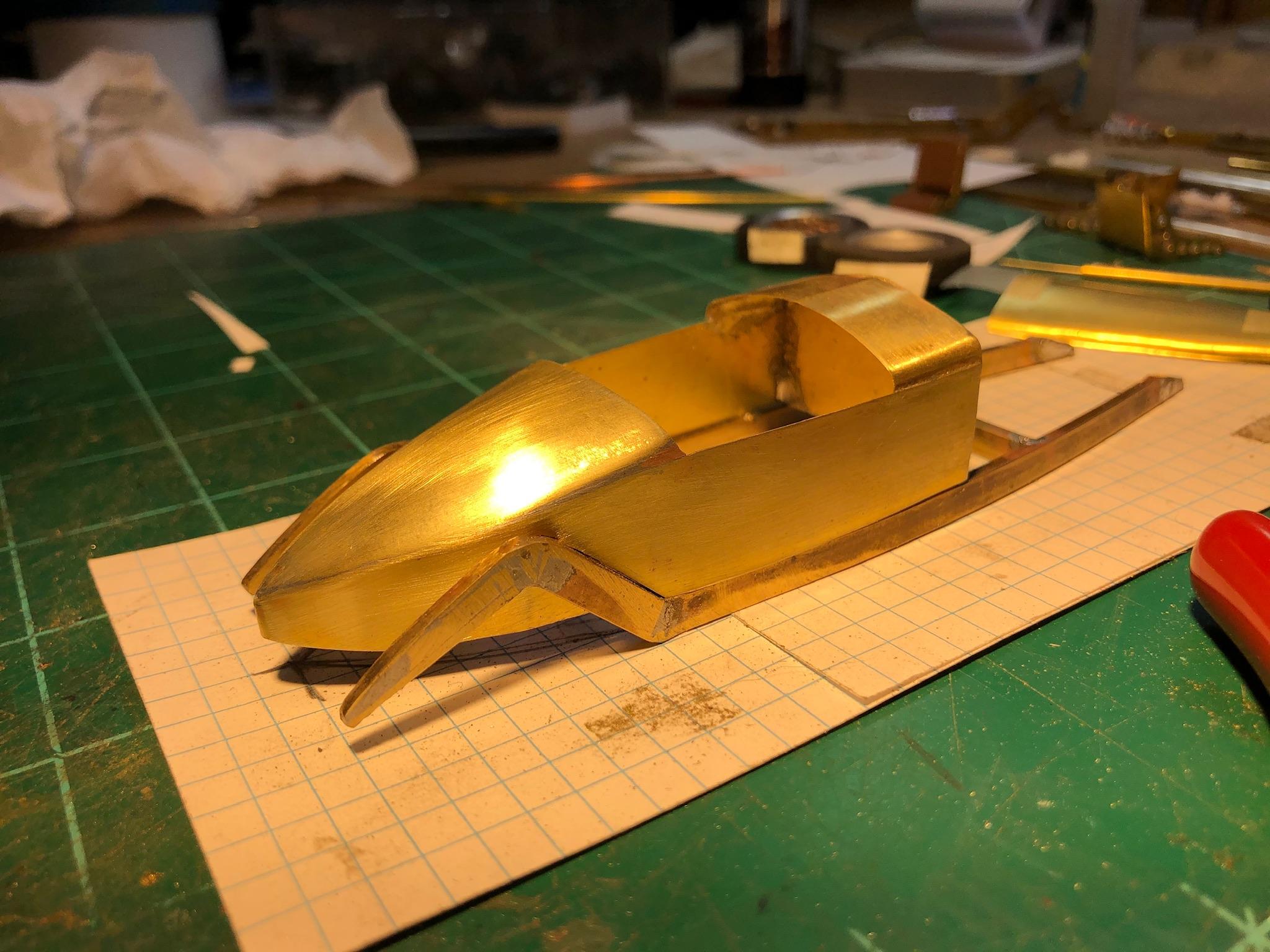

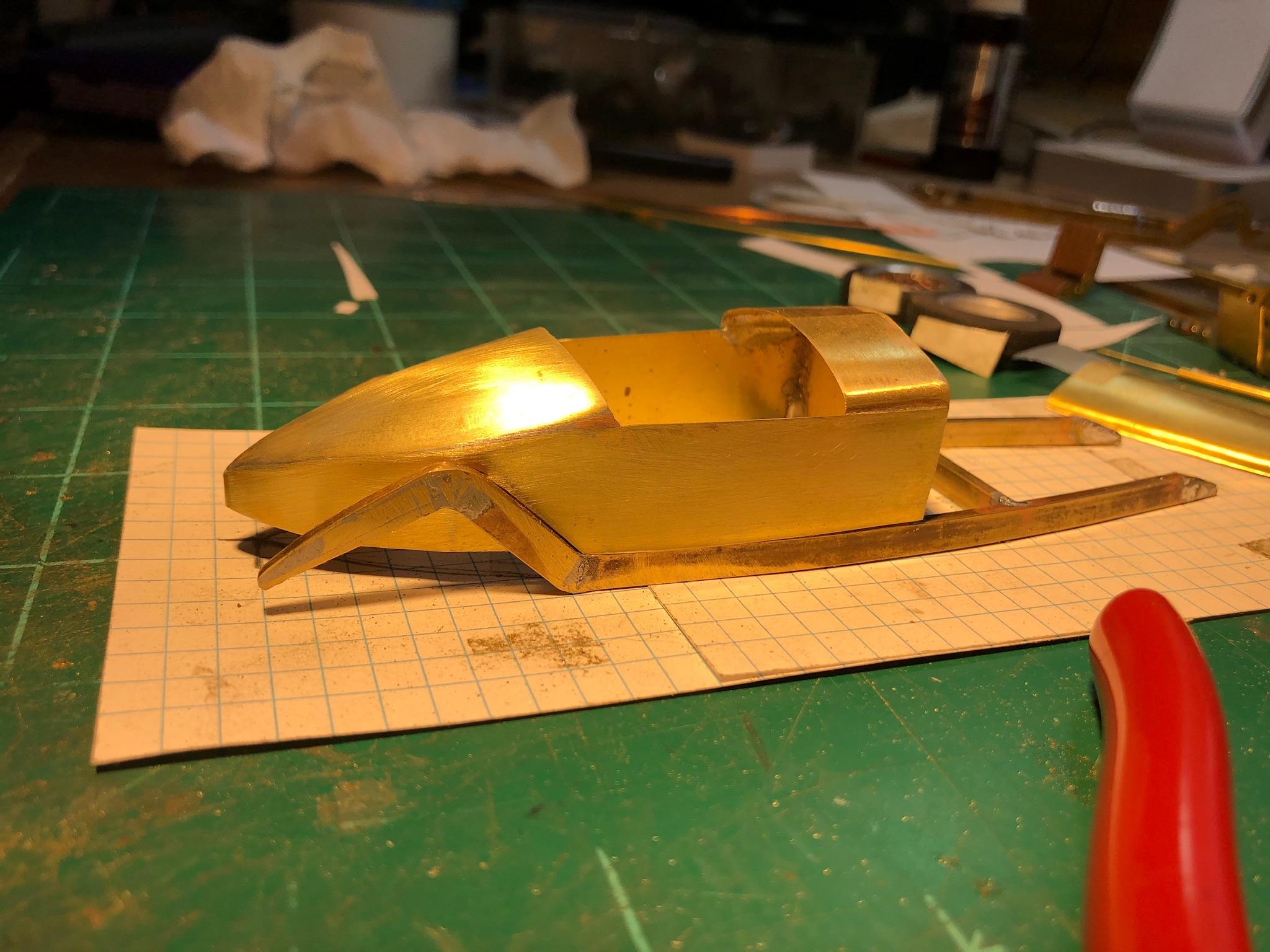

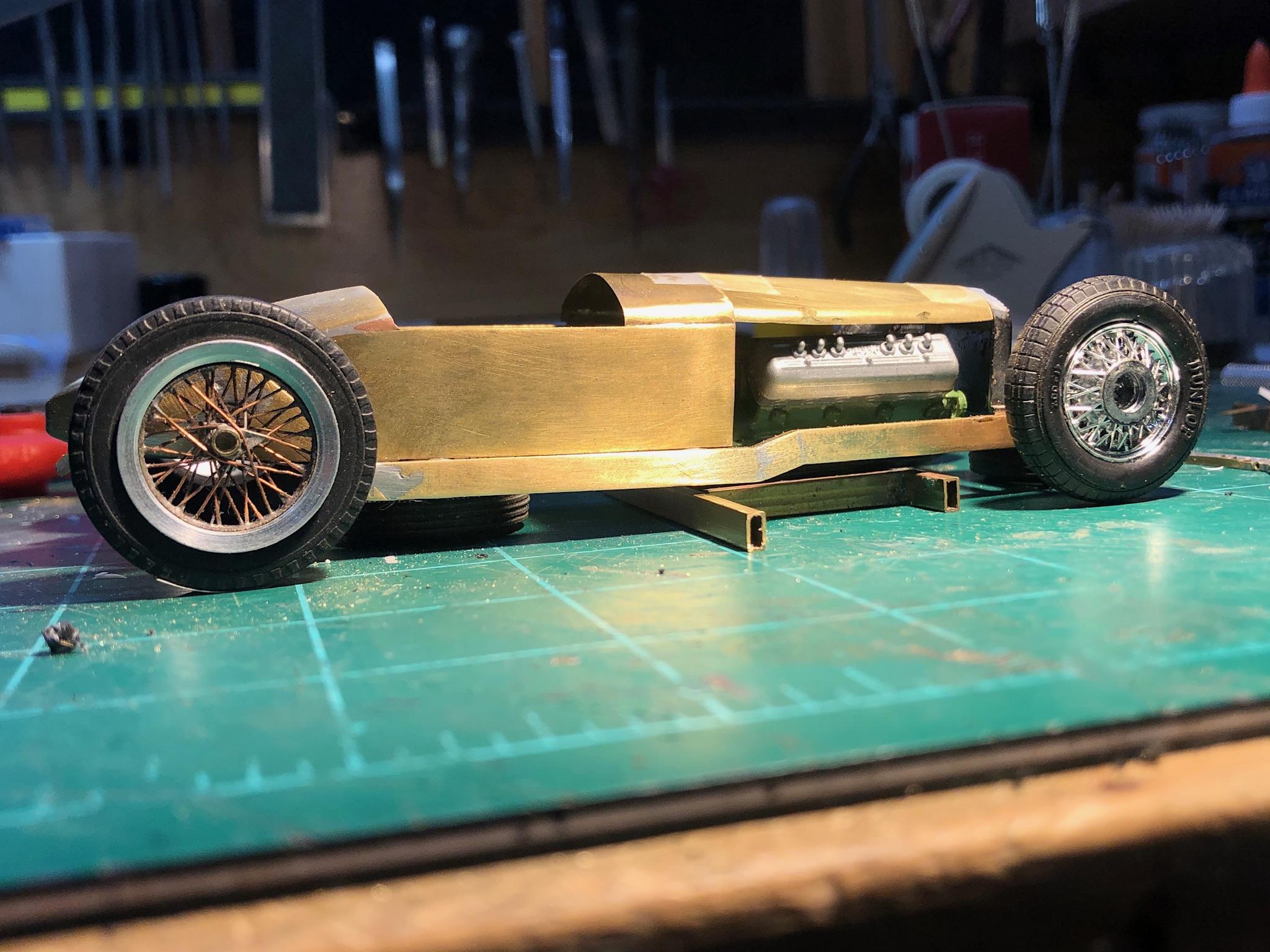

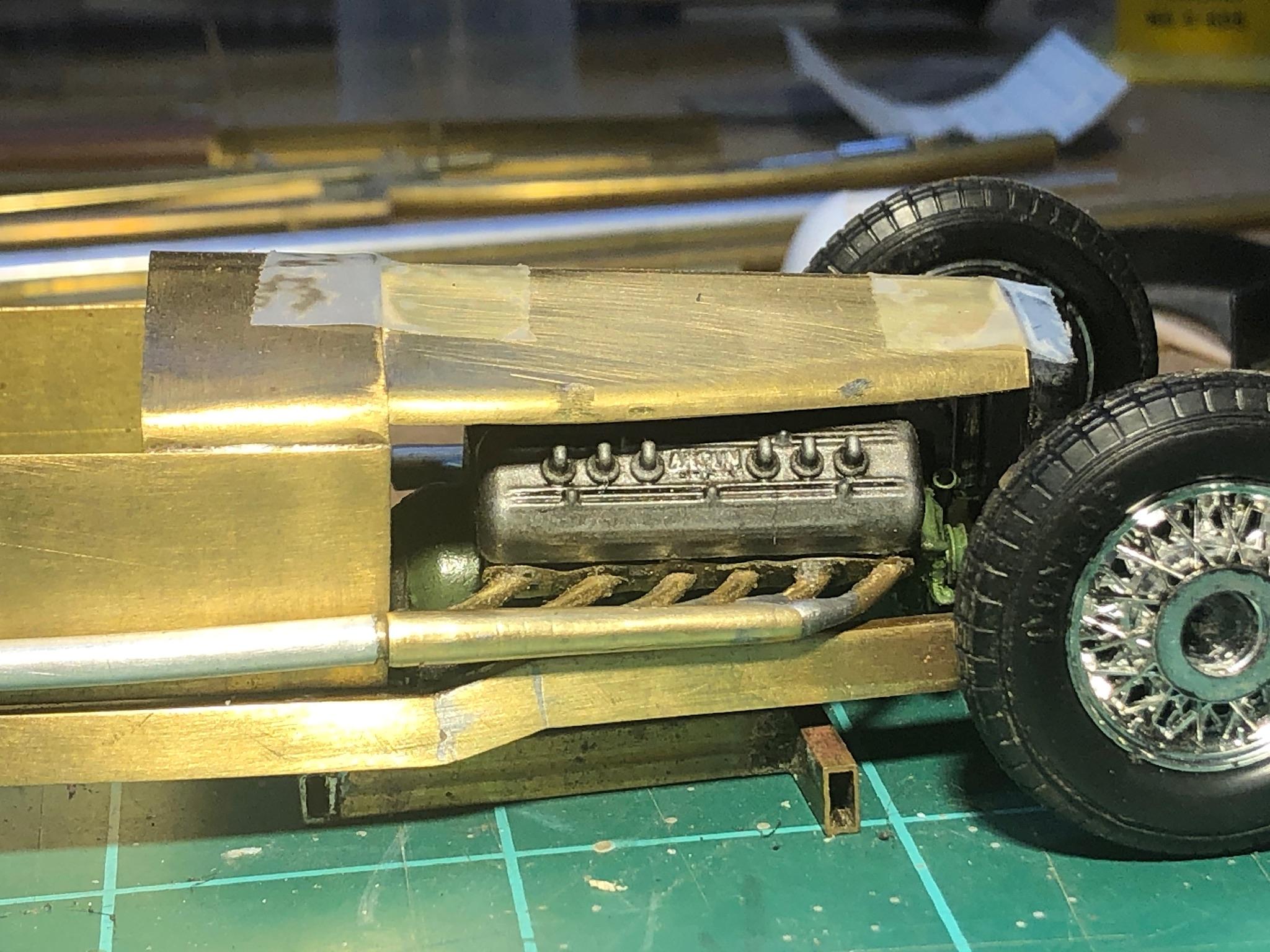

So I had this cool 3D printed Lincoln Zephyr V12 Flathead, with Arden heads by Ron Olsen through Shapeways, and I wasn’t sure what I wanted to do with it. I knew it needed to be some kind of hot rod that would show off the motor, and I had in my head that I wanted to do a build using as many brass and aluminum scratch made parts as possible. I’ve been intrigued by the Speedster style hot rods for a while, and I thought a boat tail might be kind of cool, but I also wanted it to be low. I built up the motor to the point where I could use it for mock ups, and started to mock up some frame rails, using 3/32’ X 3/16” rectangular brass tubing. Then I picked out some wheels and tires, and using sheet brass, started to shape a body on top of the frame. The sides are pretty straight, but the compound curves in the top of the boat tail had to be hammered and stretched freehand and soldered on top of the sides. I soldered a piece of 1/16” solid brass rod along the seams inside the boat tail. The seams were rounded and the top of the boat tail was smoothed by grinding and hammering.. Basic body shape on frame rails. The frame had to be slightly Zd just in front of the cockpit to help achieve the desired stance. Using a 23T grill shell, I shaped a hood by bending a crease into the center of a sheet of brass, and hammering the edges over a solid bar in a vice . The sides of the hood are slightly curved from front to back, to match to shape that I bent into the frame earlier. Also in this pic is one of the two headers that were made for the V12. Two pieces of aluminum tubing were bent to hug along the sides of the body, and rise over the frame step ups, for the exhaust. At this point I decided to choose a lower profile and skinnier set of front tires which were mocked up onto the dropped front axle, to help further lower the front of the car, All of the wheels in these pics are temporary. I will be stringing a complete set of wire wheels similar to the one in back for the final assembly. Also seen in this pic is a flair that was hammered into the cowl on the driver’s side, and a head rest fairing behind the driver. A new grill shell was scratch built from brass to take the place of the plastic one I had been using for mock ups. The sides of the body were reshaped at the cockpit. Also visible here is the dropped front axle. Time to take a step back and see how the overall shape and stance is coming along. Up to this point, the frame consisted only of two rails, and a couple of temporary cross members. It was time to add some structure. 1/16” brass tubing was bent to shape and soldered in. Coming long. Time to start working on some suspension parts. Stainless steel leaf springs, with quick change rear end and solid axle, and friction shocks. Louvers were punched into the filler pieces between the rear frame rails and the boat tail. That gets us pretty well up to date. Rear suspension is complete. Front suspension will be next when I get back to this build, which I hope will be pretty soon. Thanks for stopping in. I really hope you have enjoyed the project so far, and will join me for the completion of this build. Thanks! Tim Slesak.

-

Thank you Danno! Have a Happy New Year! TS Thank you Chris! Have a Happy New Year! TS

-

Thank you very much Tim! I strive to make my builds believable. Your comments mean a lot to me! Have a Happy New Year! Thank you very much Scott! Having my work appreciated by someone that doesn’t otherwise follow my passion is a high compliment.. Have a Happy New year.! Thank you very much Steve! Have a Happy New Year! Thank you very much Jay! I’m glad you like it! Have a Happy New Year!

-

Thank you Dave! Your kind words are very encouraging! Have a Happy New Year! Thank you for commenting Bill! Have a Happy New Year! Thank you Bruce! Ed Roth is one of my idols, so comparing my work to his is high praise indeed! Have a Happy New Year! Thank you very much Jim! I appreciate your comments very much! Have a Happy New year!

-

Yes, but Francis, your reproductions are perfect miniatures in every way and can be measured against actual full size parts to prove it. My creations are the product of artistic license. They have nothing to measure them against, so I have a lot more leeway to apply a fudge factor. If we had a full size shop building full size cars, I could be concept, and you could be execution. Keep your hat Francis. It’s getting cold outside.

-

I grew up in Livonia, and Seger was a regular at high school dances and ice rink youth concerts. I saw him many times as The Lost Herd, and the Bob Seger System, but the most memorable concert was in the Spring of 76, when the Silver Bullet Band played at the Omaha Civic Auditorium the night before the World Of Wheels was scheduled to move in. Jr. Laravee knew the arena manager, who arranged to let a few of us in. Jr. and Mark Laravee, Ryan Milkee (aka Shadow) and I had no seats, so we stood in front of the stage and jammed out! I can still hear Alto Reed’s wailing sax as they played Turn the Page. We were all on the road again in Omaha.

-

Thank you Kurt! You are correct. I have a real problem with stock.

-

Thank you very much Oli! I took a look at a few of your builds, and I am blown away! The 41 Lincoln is just amazing! I have noticed several first class builders these days living in Germany. It’s good to have you guys chiming in and showing us your talent!

-

Thank you David! Your observations are very encouraging!

-

Thank you Larry! Thank you Rob! Thank you Steve! Thank you David! I am happy that I am able to share many of the build details on this forum. Thank you Oliver! Thank you Ed! Thank you very much Alan! I am happy that you are able to recognize the “Elky” in my build! It is important to not completely cut away the original. Your observations gave me chills, because that is exactly what I was trying to accomplish. A race bred radical custom show car. Thank you Craig! Thank you Claud! It is amazing to me how many truly world class model car builders like yourself live north of the border. When I moved here from Texas, my friends could not understand what I was thinking. I tried to explain that there is another whole country north of here, full of fine people. Your words and encouragement mean a lot to me Claud!! TS BTW, it was at the encouragement of another mutual friend of ours, also north of the border, that I decided to post this thread.

-

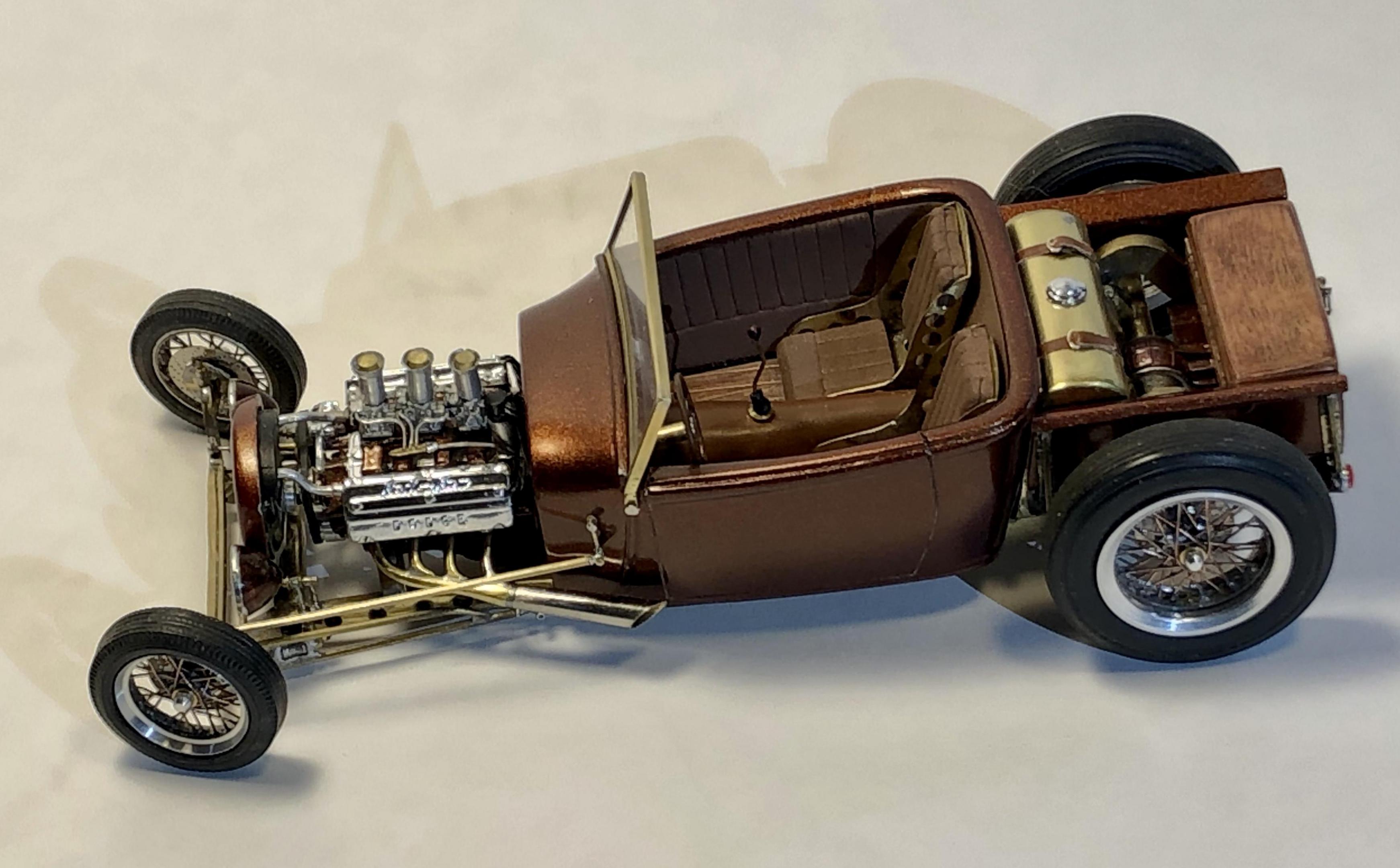

The only two that I finished this year. The 29 Model A Roadster Pickup features an all brass scratch built frame, and suspensions as well as windshield frame, gas tank, bed supports, and bomber seat frames, with wooden trunk and floors. Engine is a Chrysler 354 Hemi out of the Moebius 56 Chrysler 300B. Wire wheels are also scratch build using copper wire, and turned aluminum rims. My Gremlin XPress is based on an AMT 75 Gremlin, chopped, pie cut, and channeled over a MPC 72 Corvette chassis, with scratch built brass working front suspension and steering, and 3D printed Jag IRS from Ron Olsen. Headers and side pipes are scratch built using polished aluminum tubing. Engine is an AMC 401.

-

Both super clean and awesome builds! I had to look several times at the pic of the Cutlas with the hood off to be sure that it is really a model, and I’m still not totally convinced. Your work under the hood is superb on both!