Bren

Members-

Posts

126 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Bren

-

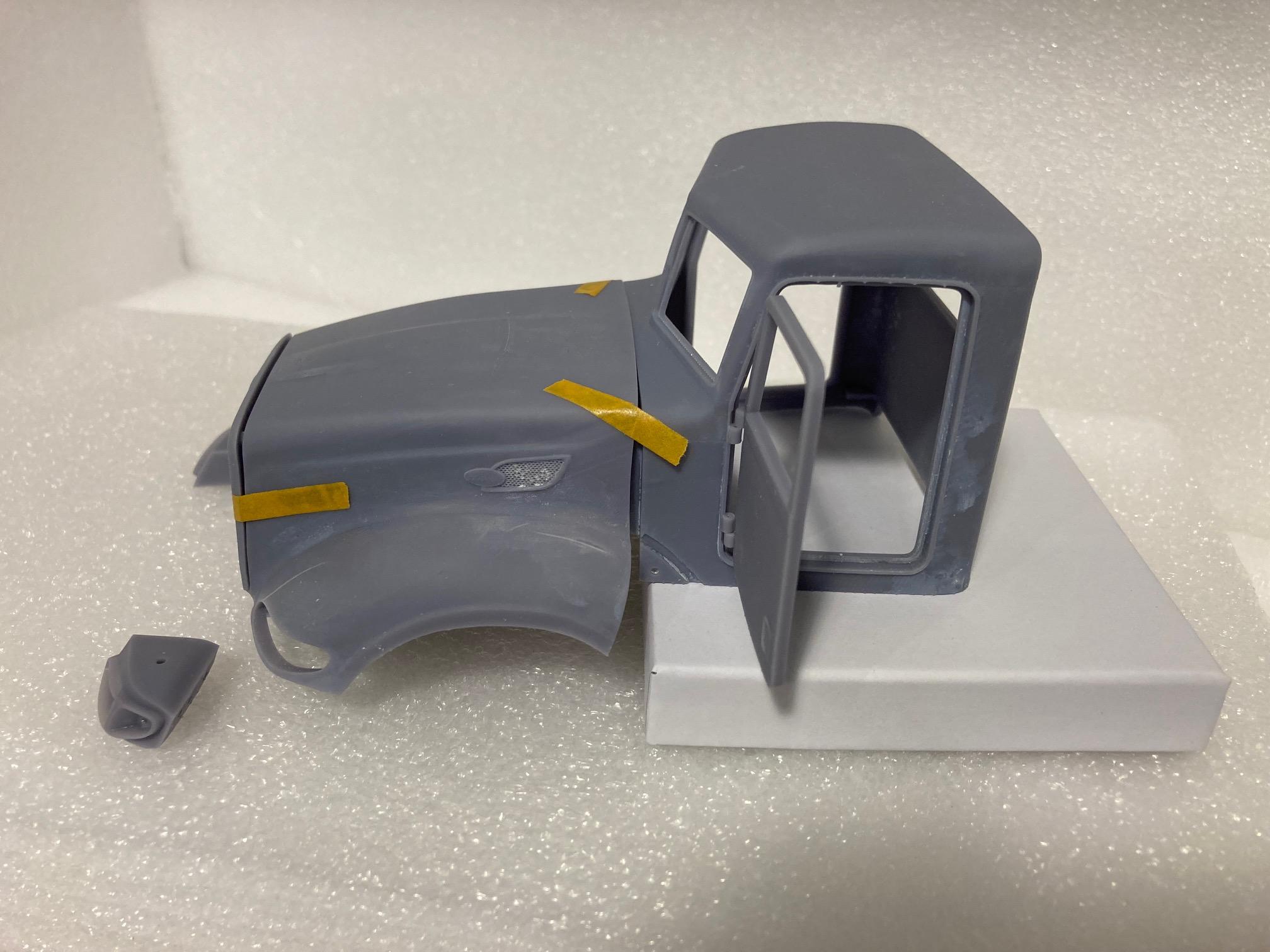

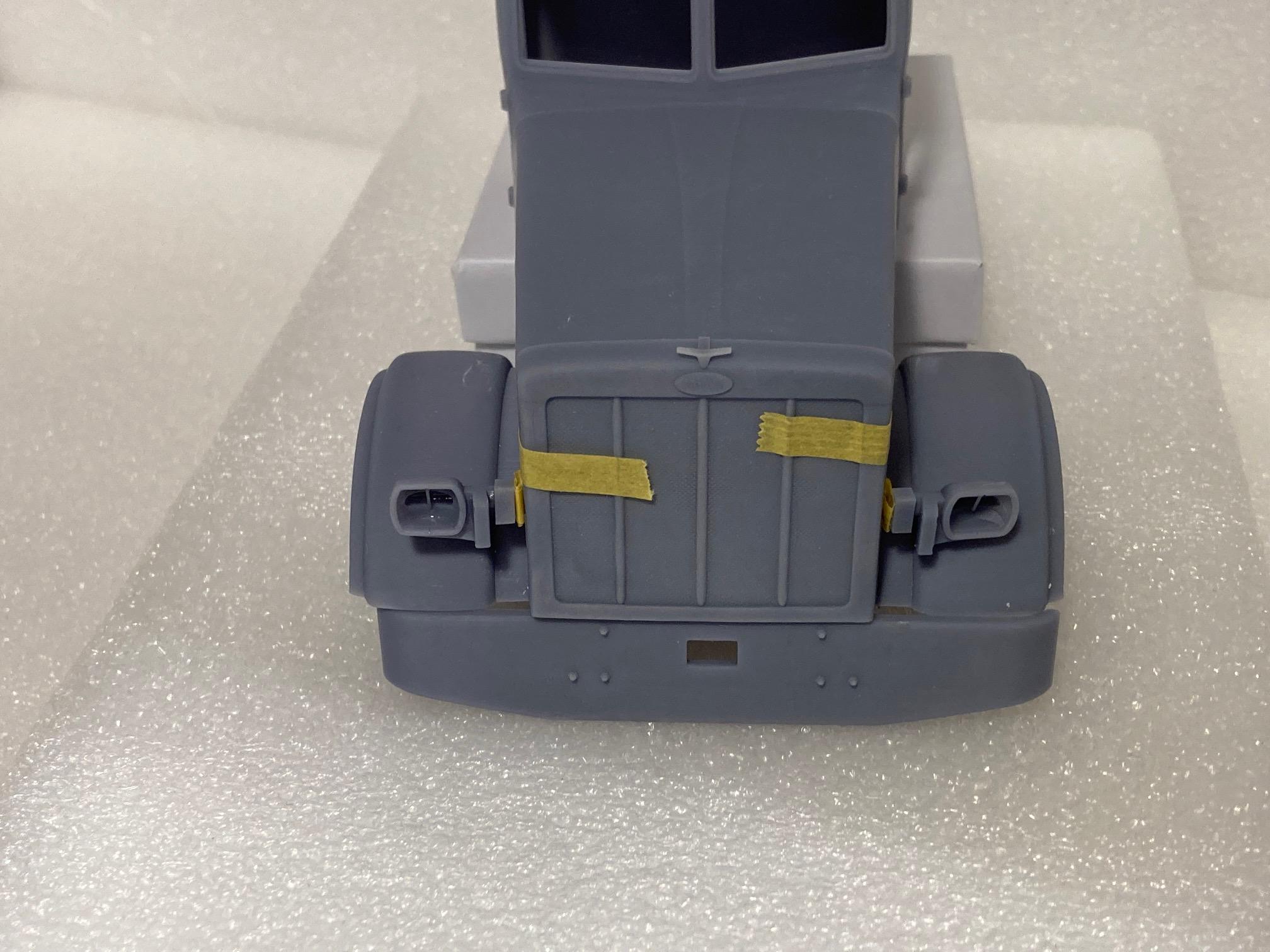

RoninUtah was interested in the Cascadia - so I printed out the files (not quite finished yet). I think there's a bit of interest in this model, so I thought I'd post the first shots of it taped together in case the rest of you guys wanted to see. This is from Alfa Centauri on Cults3D website. The file is 1/14, reduced in the slicer to 1/25 (56%).

-

Mack F700, and the woes from 3D printing.

Bren replied to Repstock's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I getcha! I’m on the other side of the retirement thing. Anyways - when I get to the bench next week I’m going to print the Mack on my larger anycubic mono printer which means I should be able to angle it and avoid some of the challenges you are having. If it works I’ll send you some pix and if you’d like me to send you a copy I can do that, no charge. -

International CO-4000, Navajo Trucking.

Bren replied to Repstock's topic in Model Trucks: Big Rigs and Heavy Equipment

This build is a workshop in understated super-realistic weathering. As has been said you rocked the underside of the cab - an area often overlooked. I totally get the fretting over the grill detail - we all do that - something nobody else even notices drives us nuts! Congratulations on a masterful execution of a great subject. -

Wow! Some great CAD skills there! Maybe you can post some hints or direction on where to go so we can learn to do some of this?

-

Mack F700, and the woes from 3D printing.

Bren replied to Repstock's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

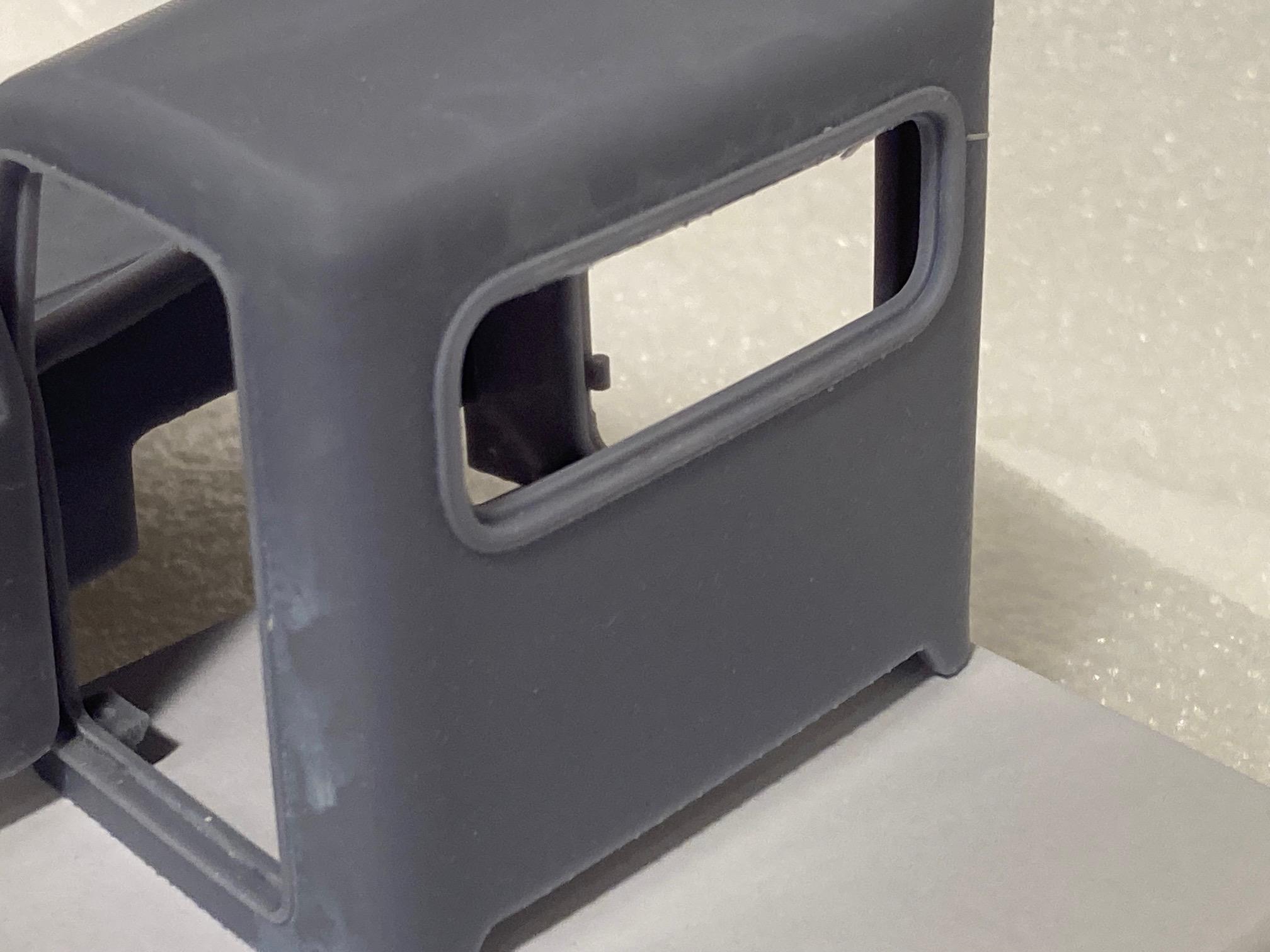

I’ve had a chance to look at your photographs in more detail - here are some additional observations. I believe your print IS Alfa-centauris’ Mack 700 file from Cults.com. Originally he published it in 1/32 - it can scale up to 1/25 no problem but that makes the walls kind of thick - like you are seeing. It appears the body was printed flat based on the layer lines of the cab roof - which makes the lines more visible and is prone to sinking. - as your copy did. Parts should usually be tilted at about 20 degrees to minimize lines like this. I also question the resolution of the printer- the dash details appear a tad fuzzy - they should be crisper - this should be printed at a resolution of .05 mm at a minimum. I’ll try printing this file and post my results to see what I can achieve. -

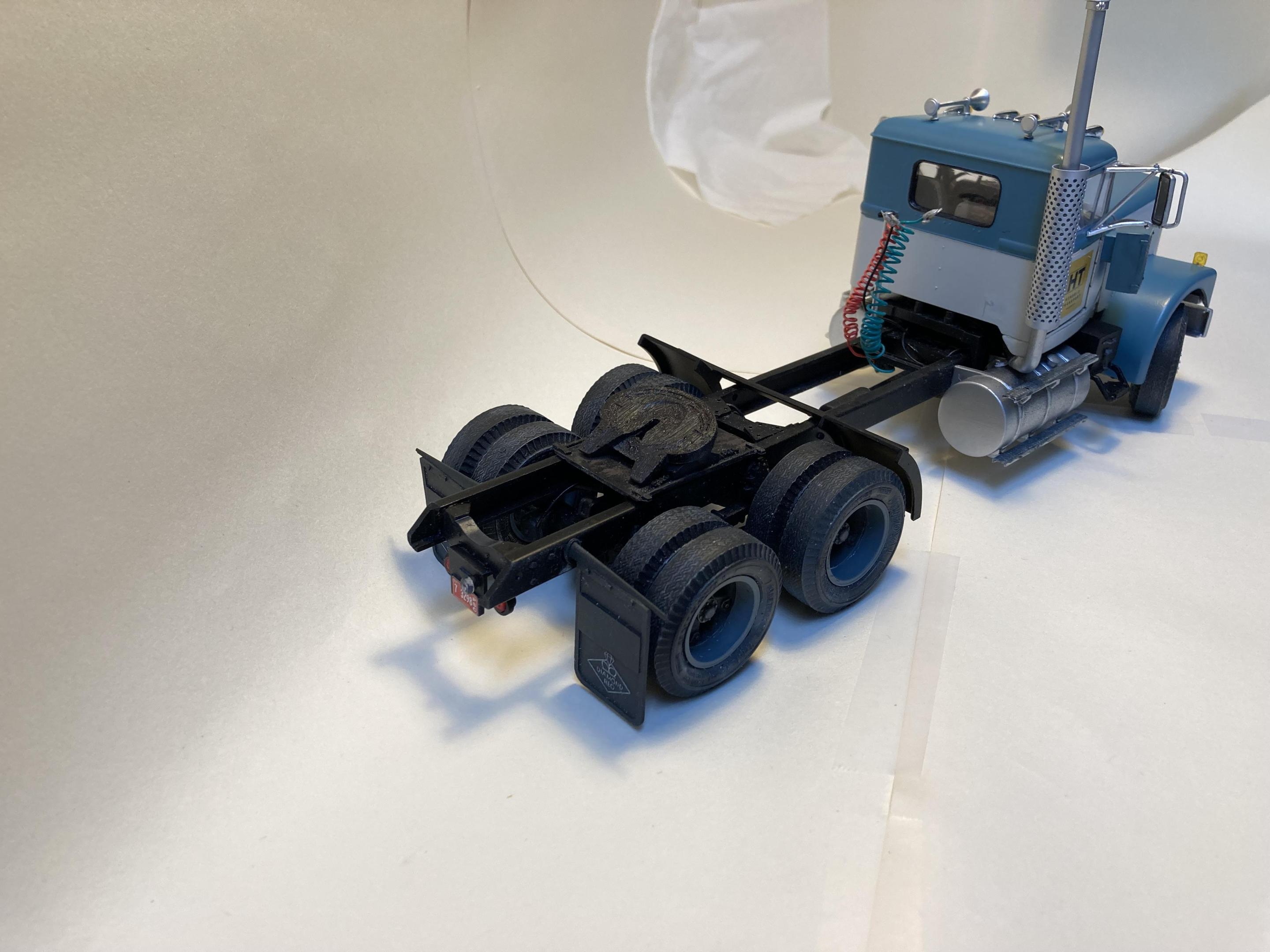

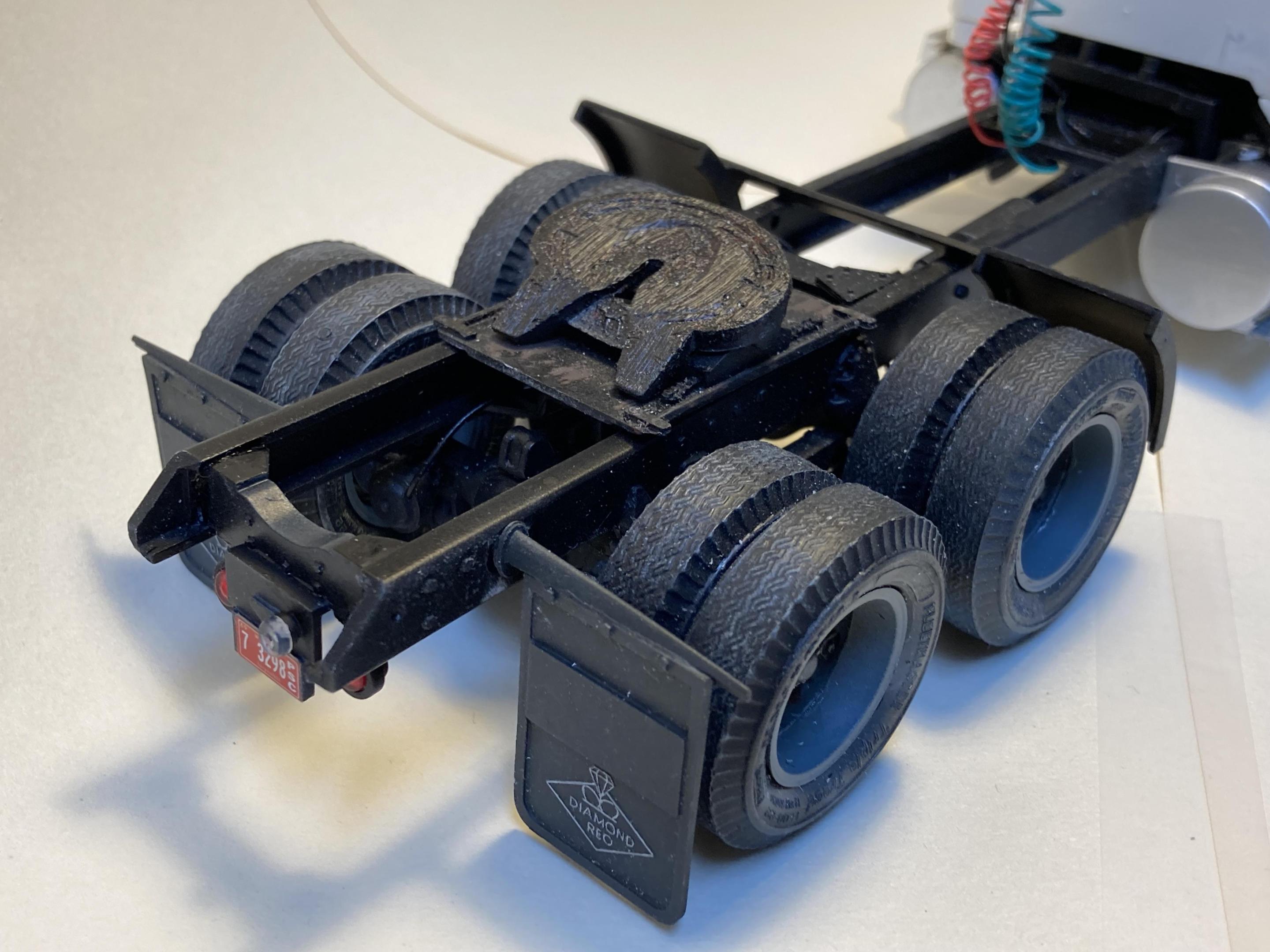

I love the look of old school Diamond Reos - you’ve done a really nice job here Randy. The small touches like your clean window gasket painting really make it pop. Well done!

-

I needed another project....T800

Bren replied to gotnitro?'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very nice build. Thanks for sharing your challenges - it gives us all great ideas. You have some impressive skills there my friend! -

Mack F700, and the woes from 3D printing.

Bren replied to Repstock's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I do a fair amount of 3D printing - but don’t hold myself out as an expert (I’ve posted my prints under the 3D aftermarket section here). Here are my suggestions. Firstly - for what aftermarket suppliers often charge for their stuff I’d consider investing in my own printer - they are much more affordable these days - then you have complete control over resin type and curing. One thing often overlooked is thick parts containing uncured resin inside - this will “split” or curl your part. Simple fix - hollow the part in your slicer software, and leave a drain hole. Next, there are a few “non-negotiables” - an ultrasonic cleaner is a must - remove ALL uncured resin. The other must is a UV curing station, 2-4 minutes works for most 1/25 scale parts. Then place any thin parts under weight to completely cure - I use 123 blocks - and leave them 1-3 days. I use Elegoo water-soluble grey resin for model parts - a bit brittle but overall a good choice. I suspect your supplier is not curing properly - and may be in a different humidity climate than yours. Last thing - if you’re a Mack fan check out Alfa-Centauri on the Cults website. He’s got a great assortment of Mack’s with interiors - l’ve printed them without problem. Most are 1/14 and scale easily to 1/25. Hope this helps. -

M-20 Prime Mover

Bren replied to Chariots of Fire's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Wow! This is scratch building at its finest. My hat is off to you. Terrific work. Following with interest… -

Both are available as .stl files for 3D printing if you're into that - or want to get them printed by someone else. Here's the Cascadia. And below it the Coronado. I've printed the Coronado in 1/25 - looks great.

-

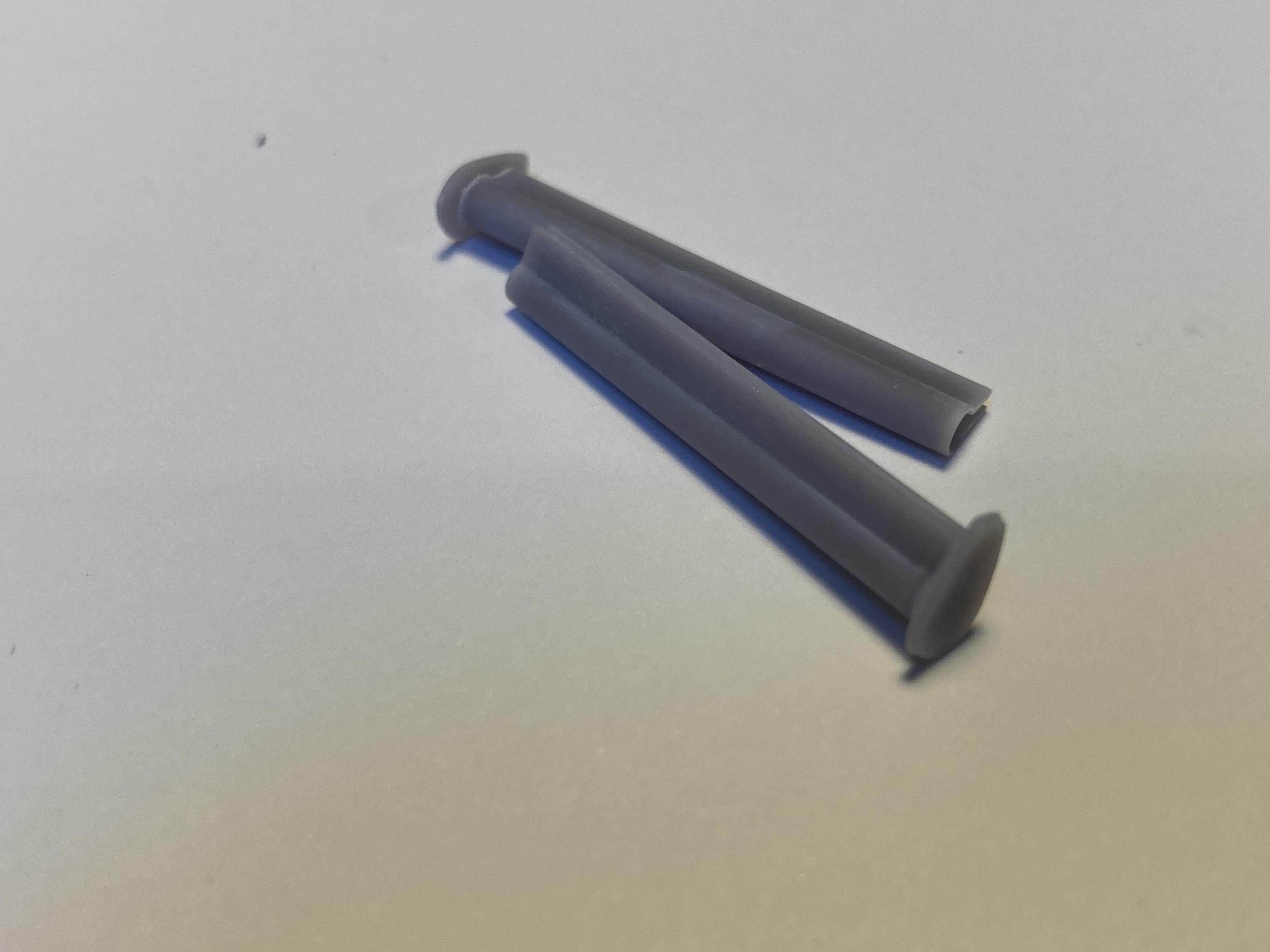

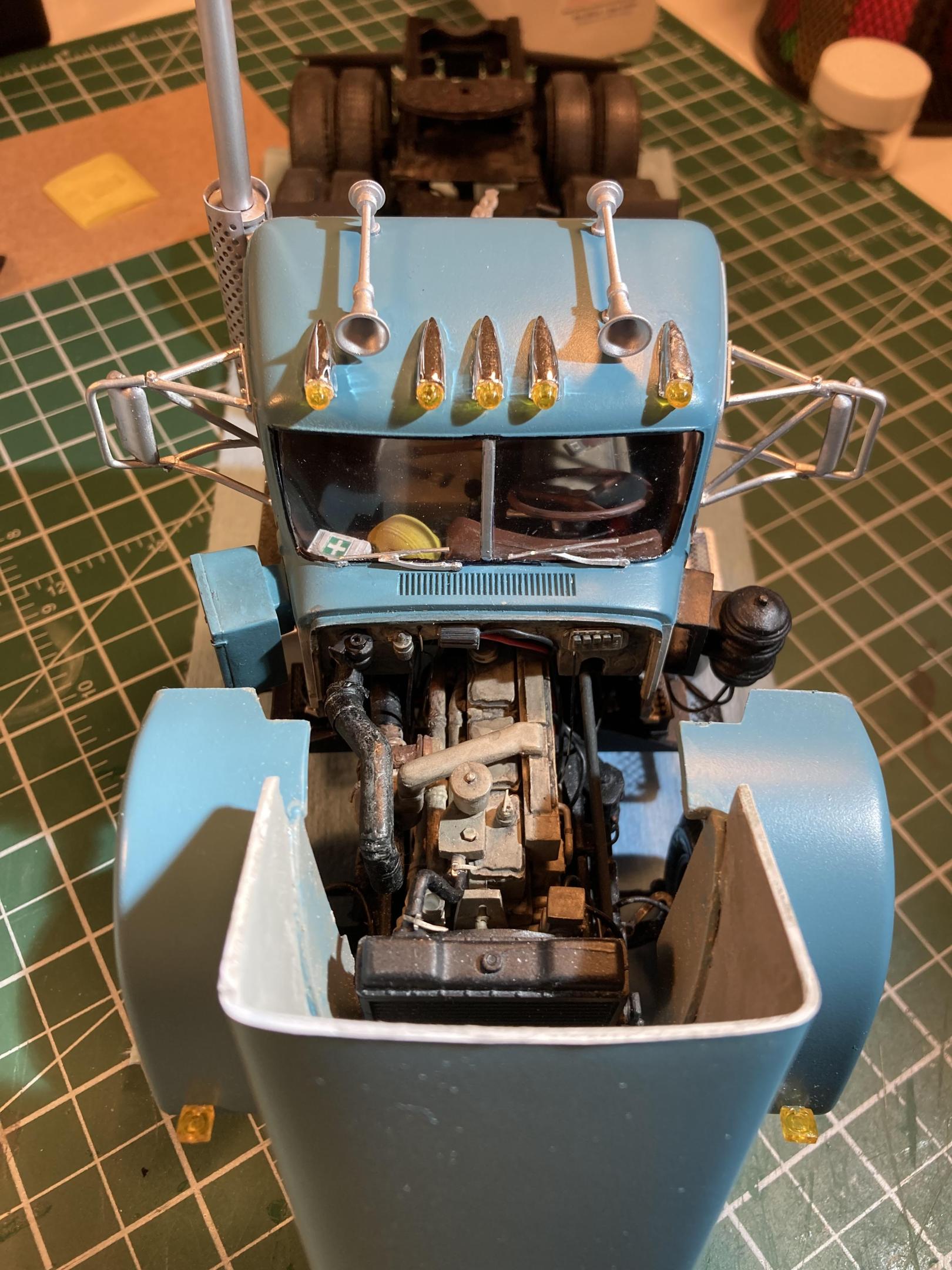

Here are some other prints I've used. Glad hands, air horns, flapper valves, pipe bends, mud flap hangers - you name it, there are files of all of them. Many are free, some are a few bucks. My Diamond Reo, in the completed build section of the forum uses a lot of these, if you want to see the "finished product" (couple of photos below). There are tons of cool things to use for cargo - pallets, tiedowns, construction equipment, pipes, cranes - you name it. Most of these I haven't even seen in the after-market. And for those of you who want to tweak the dimensions - 3D printing is super-easy - your slicer software can scale up or down by fractions of a millimeter. I adjusted all of these to the exact dimensions I needed - simple as 1 mouse click. No 'tech-geek' wizardry required. So there you have it. I'm happy to answer any questions - within my own limited skill set. I stress again - if I can do it - you can do it! I hope this gives you some ideas for your builds. And remember - even if you don't want to print, you can get files printed by any number of online printing services (though they aren't cheap). Happy building guys - thanks for looking!

-

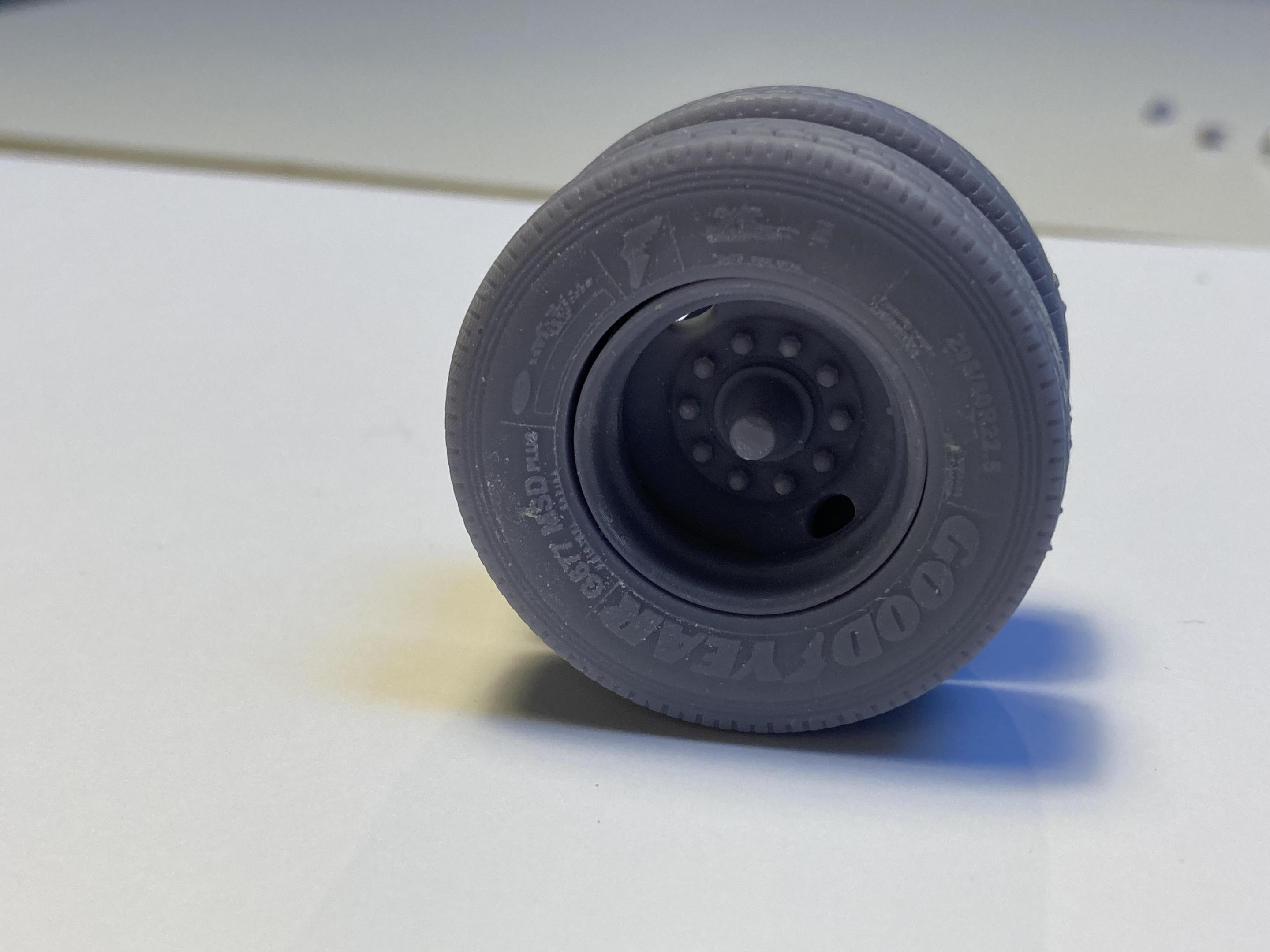

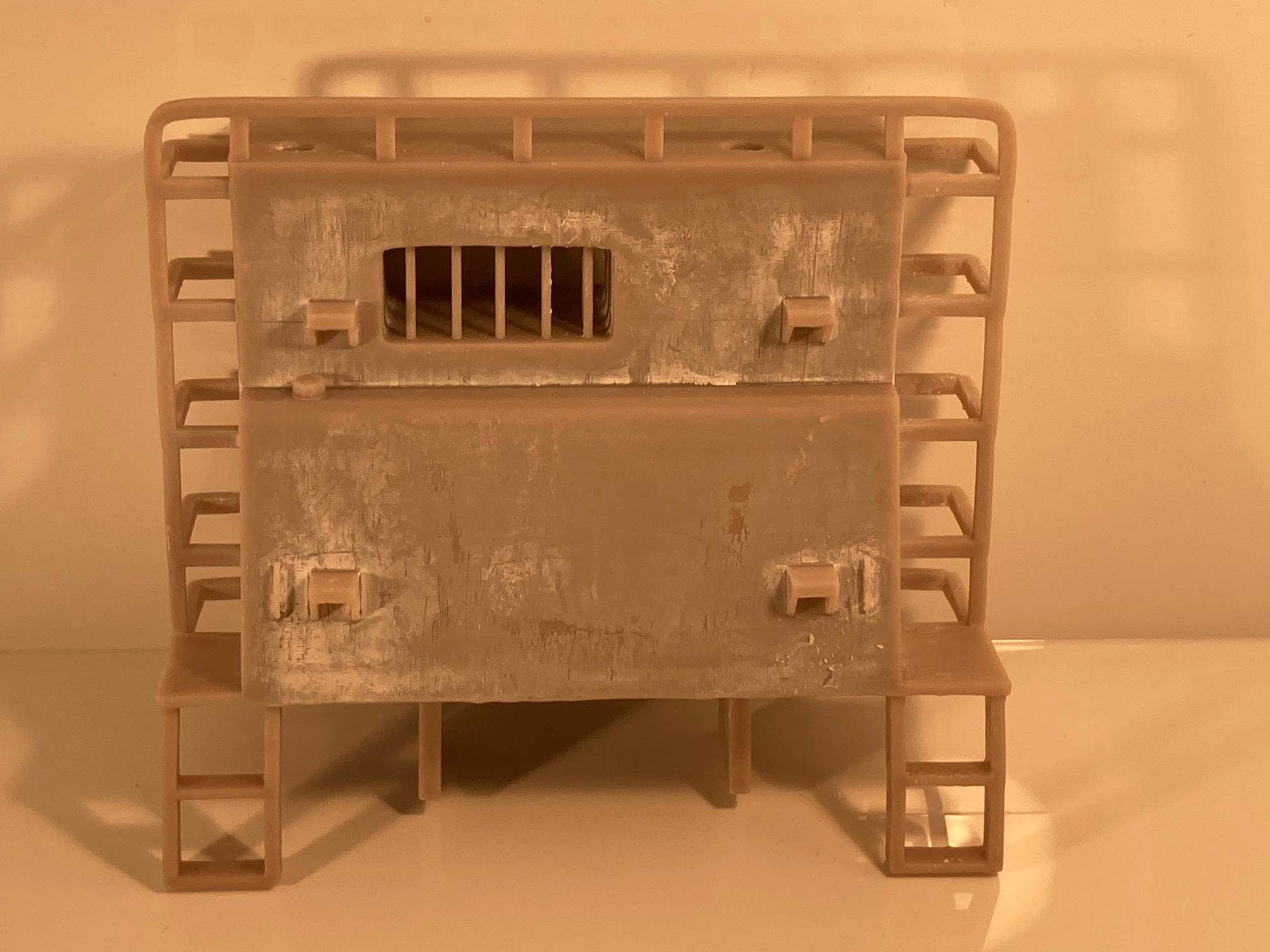

Okay - cool bodies - but how about parts? Well - this is where 3D printing comes into its own. I have collected a binder of thousands of 1/25 scale parts - an amazing resource for my scratch building. Just about anything you can think of is here. 2 hole Buds? - yup. Accurate sidewall truck tires? - yup. Now you can print footwear for dozens of Michigan trailers for pennies (well - a few bucks) - honest! This is from my trailer build I'm doing now.

-

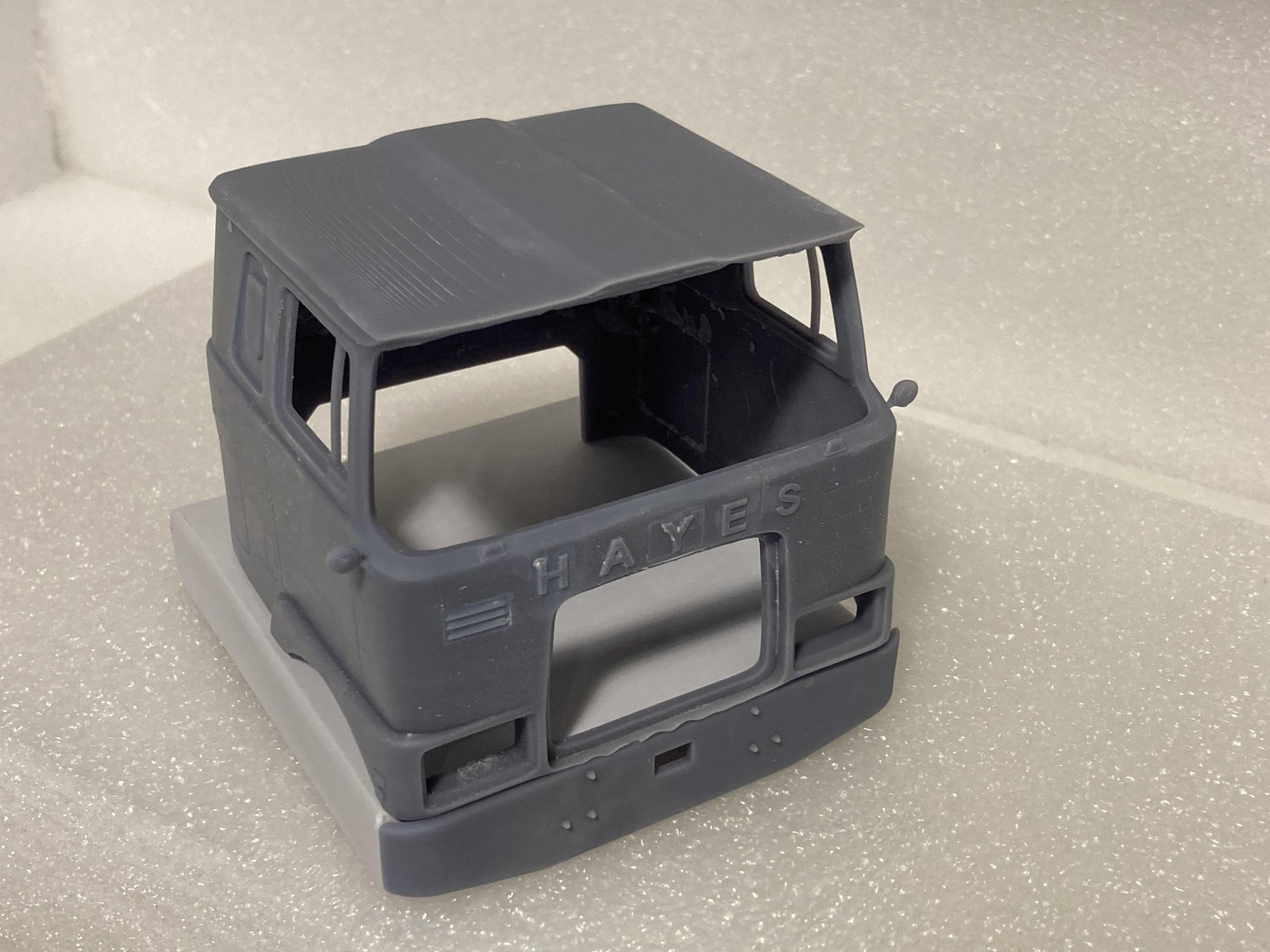

Prefer old classics? - here's two. A monster of an HDX logger, and a vintage Hayes cabover (forgive the quality of the cabover - I printed it flat as it was too big for my printer - I have a bigger printer now so I'll re-pop it.) The grey grill on the HDX shows one of the challenges of resin - it can warp while curing - I reprinted leaving the supports in place and cured it like that - problem solved. Note the headlight guard snapped off the grey one - water soluble resin is rather brittle - handle with care!

-

Below are my prints of a Peterbilt 386 in 1/25 scale. Want models of new, modern trucks? There's lots! This is only a partial print of the files - not shown are 'glass' , fuel tanks, bumpers, air filters etc. Requires engine and frame/running gear donor. Time to print about 5 hours - cost five dollars in resin.

-

I have been reading the posts for a while here (always a wise idea before opening one's big mouth and inserting foot!). I'm not sure this thread goes here or in WIP - but here seems more appropriate. I want to make clear I'm not selling anything - and this isn't an after-market pitch - just some observations about 3D printing and our hobby. It seems to me more of us should be taking advantage of this amazing technology to answer several common problems evident in the threads here. Firstly - as we know - truck modelers are largely ignored by the mainstream companies - and the aftermarket, although producing some great things - is really expensive, and often sold out. Buying the tires/wheels for that Michigan trailer will bankrupt your yearly hobby budget! I am NOT a tech guy, or young computer savvy kid (68 years old), but I bought a 3D printer and began to experiment with it to print stuff for my builds - not as a hobby in itself. I've been amazed. What you see in the next pictures are results ANYBODY can achieve - I'm no pro, I just set up the machine and hit 'PRINT'. These are my actual prints of files obtained online, I didn't write the files - I can't do CAD if my life depended on it. So I stress - if I can do it, ANY of us can do this. If there's an interest, I can share more, including equipment and settings, file sources etc.. If not - thanks for your time in reading. All comments and opinions welcome. Below is my print of a Peterbilt 367 (held together with tape) as it comes raw out of the printer with no sanding etc. in 1/25 scale. Time to print is 5 hours, cost is about 5 dollars in resin. There are a wide variety of well detailed cabs available - I'll post some more. This file comes with interior, filters, fuel tanks and "glass". No engine/frame/running gear - need donors for that.

-

Finally finished! Diamond Reo

Bren replied to Bren's topic in Model Trucks: Big Rigs and Heavy Equipment

Thank you Noah! -

Finally finished! Diamond Reo

Bren replied to Bren's topic in Model Trucks: Big Rigs and Heavy Equipment

Yup - I tried those. They do work (there is a good youtube video on how to by Showtime studios) but I found them very fiddly and difficult to control. Mine wound up bending out of true easily. But they look good for sure. Thank you for your kind words on the build! -

Finally finished! Diamond Reo

Bren replied to Bren's topic in Model Trucks: Big Rigs and Heavy Equipment

I used 22 gauge hypodermic needles (I'm a doctor so sourcing them is easy for me! :-)) with brass rod, cut into sections using a dremel cut off wheel -

Finally finished! Diamond Reo

Bren replied to Bren's topic in Model Trucks: Big Rigs and Heavy Equipment

❤️ -

Finally finished! Diamond Reo

Bren replied to Bren's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks Vincent. I added a comment explaining where the 3D files could be found for anyone interested. Appreciate your input! -

Finally finished! Diamond Reo

Bren replied to Bren's topic in Model Trucks: Big Rigs and Heavy Equipment

Thanks very much Jim. Appreciate the comment. -

Finally finished! Diamond Reo

Bren replied to Bren's topic in Model Trucks: Big Rigs and Heavy Equipment

Yeah the exhaust turned out really well - I was happy with it. The flapper 3D file is on Cults, and the perforated heat shield 3D file is scaled down from a 1/14 King Hauler file on Thingiverse. I posted makes to each of those sites if you need more details. My user name there is Heavyhaul. -

This is my AMT Diamond Reo - I stretched the frame, opened the doors and swapped out front axle for a KFS/Auslowe steering one, and used photoetch for the front grill. Lots of 3D printed detail parts (exhaust, flapper valve, air/electrical connectors, interior details etc). Otherwise stock. Now onto the trailer.......

- 25 replies

-

- 13

-

-

the 353 revell western life kit

Bren replied to graintruck's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Yup - couldn't agree more - In fact Tim has been quite helpful in answering some of my questions and providing reference material. And his 353 is a real treat - I studied these pix long and hard - I'll post my finished work but you'll see Tim's influence on it for sure. Bren -

the 353 revell western life kit

Bren replied to graintruck's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

.thumb.jpg.a8c078a469d89ad706868140c1a41a8e.jpg)

.jpg.714b32a25ec616520d39ed9ddfe5adc5.jpg)

.jpg.cdc800c774e5fcbb488fe364c3525687.jpg)