-

Posts

85 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by dpride

-

Thank's all for reply. Ognib, the rat rod is :http://www.modelcarsmag.com/forums/index.php?showtopic=51823 Bernard Kron, the 1/4 scale stuff is almost like parts of 1:1. The car in my avatar is the last build for street use. I drove it for many years. 454-LS7. Hope to have more work soon so I can "justify" spending on the rest on the materials like fasteners, molding and casting.

-

Ray, the first thing I would suggest is to find somewhere you can test weld some aluminum with someone who has training with tig. The grade is also important as some (machine grades) are not considered weldable. If you are using scrap, you will have to identify the material. 6061 is a common structural grade and is good to weld. The type of welder that RAT-T suggested has the features you will want. For a novice to attempt tig welding a full chassis as a first project is ambitious. Tig is a totally new ball game compared to stick or mig. How do I know.............I've been welding for 46 years. I'm not trying to put you off, just see what is involved first.

-

Highly impractical (like, no room for a human) but BEAUTIFUL

dpride replied to Ace-Garageguy's topic in Auto Art

Looks like a lakester with steampunk influences....... -

Thank you to everyone who took the time to comment. I'm getting the valve covers printed (from my 3d model) so I can mold and cast them in metal. I have had to slow spending on bits as it seems like the industry I work in is taking a long break........:-( A lot of pieces are finished and waiting to go on as soon as I get more fasteners that are the right type and scale. Also printing the front Avon cycle tire to be period correct. Will cast in black urethane. thanks again...pix soon.

-

How much $ do you put in a kit?

dpride replied to pandamonium2112's topic in General Automotive Talk (Trucks and Cars)

Exotic metals, mold and casting materials............ $5800.00 3D printing and freight costs................................ $2375.00 Plastrut, Evergreen and K&S stock.......................$1734.00 Chrome plating and freight costs..........................$892.00 Paints, coatings, glues..........................................$698.00 The look on your face when you see 58 more replies for the 25th scale glue bomb than your large scale scratch built ........PRICELESS. -

Where do they go?

dpride replied to moparmagiclives's topic in General Automotive Talk (Trucks and Cars)

I will make cabinets for them soon but now it's good to see them everyday while I work. Only problem is.... the cabinets cost as much as the models...... -

-

Harry, these are great. I also like to 'mess-up' cars with Pshop and Painter. Remember those kits that were fiberglass 1940 Ford front section for VW's.

-

pharoah: The programs I use are similar to 3D Studio Max but deal more with accurate real world dimensions. Solidworks, Autocad, Rhino are more suited for engineering models rather than models for animation or visual arts, Much of my childhood was spent in Indiana but I escaped......

-

I thought people might get a kick out of see some of the psychedelic period art that I did during the 60's and onwards...... I certainly did.....

-

CAT D8

dpride replied to Swamp Dog's topic in WIP: All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

I see you have a set of CAT pliers...... Good job so far. It will look great with some weathering. We have a real one (D6C) and I like how it makes everything that's in front of it behave. -

One of the most irksome for me, is solder, pronounced as SODDER. I think DONK, when referring to an engine, would rate a close second.

-

It's ironic that some of the posts in this thread contain eggcorns.

-

1/4 scale girls

dpride replied to dpride's topic in WIP: All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Jim B, there are a few printed 1/24 scale figures available without the set up costs (digital sculpting). Like: http://industriamechanika.com/shop/index.php?main_page=product_info&cPath=4_12&products_id=7 -

1/4 scale girls

dpride replied to dpride's topic in WIP: All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Thanks for comments. Jim B, the people who do my printing can get this quality (1/25 scale) at the higest resolution, but it's not cheap. This is a sculpt and build I did a while back. The bike is inspired from the Akira cartoon. At 1/4 scale. The bike has printed tires, wheels machined from 6061 aluim, and body from heat formed styrene sheet. The rider is sculpted from polymer clay, molded, and cast in tool grade urethane resin. -

I've finished a few more bits: magneto, spark plugs. and molded some wheels and tires. I thought it a good idea to make molds of things that I might use for other builds like all the engine parts that are common, rear end etc. The spark plugs are machined from stainless and white styrene. Boots are shrink wrap. My good camera is kapooted....the one I'm using for these pics cost less than $100.

-

Harry, the program is Solidworks.

-

1/4 scale girls

dpride replied to dpride's topic in WIP: All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Jantrix, the "Bazooka Girl" was digitaly sculpted in a program called Zbrush. I converted the file (3D) to an stl file and the body was "printed" on a 3d printer. The head, hands, and boots were printed at a higher level because I didn't want to sand or do too much work to them. Then all pieces were molded (silicone) and cast in polyurethane tool grade resin. Painting is with an air brush. Clothing and other bits scratchbuilt. The "Rocket Girl" was sculpted by hand from a polymer clay called "super sculpy" over a wire armature and molded and cast as the others. I don't build kits of these girls or kits of cars for that matter because I like having unique models. It keeps me off the streets. -

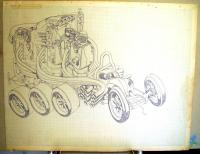

A couple of the pieces I did when I was learning new programs. It was either learn or become obsolete. The car is purely fictitious, it was not patterned from any existing vehicle.

-

Thanks guys. Scott : the frame is put together with oxy-acetylene and 45% silver solder. I am going to try laser welding the brackets on a stainless steel tube front axle in the next few weeks. More photos you might be interested in. I made some tools from old hacksaw blades to turn little heim joints for the injector linkages. The third shot shows the removable section of the frame to allow the engines to be taken out.

-

Thanks for the comments, it makes it worthwhile to post the progress. Here are photos of the body construction process I used. I could have carved it, or cnc'd the master but this way suits the style that could have happened in 1960-ish if someone had built a chopped,sectioned, and narrowed fiberglass competition coupe body. The first coat of primer is on and now to chase all the rough spots. I will mold this and make a urethane body. I found a 1/25 scale Fiat body I had cut up many years ago which is in one of the photos to show scale.