-

Posts

11,326 -

Joined

-

Last visited

About David G.

- Birthday 07/02/1964

Previous Fields

-

Are You Human?

yes

-

Scale I Build

1/25

Contact Methods

-

Website URL

http://www.daveag.com/

-

Facebook

https://www.facebook.com/Model-Cars-Mostly-110571964655216

Profile Information

-

Full Name

David A. Gudzinas

Recent Profile Visitors

25,086 profile views

David G.'s Achievements

MCM Ohana (6/6)

-

1962 Rolls Royce Silver Cloud II by Minicraft Models: Finished

David G. replied to David G.'s topic in Model Cars

Thank you Noel. His was a few years newer, a '65 limousine I think. Thank you very much Philippe. =D- -

Rolls-Royce No Chemicals, No Paint, No Harmful Glues

David G. replied to Anglia105E's topic in WIP: Model Cars

Thank you kindly David. Yours are coming along quite nicely too. I think the vanity mirrors you're adding will help give this kit's sparse interior a more complete appearance. David G. -

I believe you're correct though I don't recall seeing that one. =D-

-

Rolls-Royce No Chemicals, No Paint, No Harmful Glues

David G. replied to Anglia105E's topic in WIP: Model Cars

Yeah, having one of the tables opened would be great but I just took the easy way out for mine. I just glued some styrene shapes to the seatbacks and painted them. Cheers! =D- -

I'm glad to know that your surgery went well Chris. It must be nice being back at the bench. Driveshafts I usually paint for a steel or black rusty iron color. But that depends on what you want your build to look like. Didn't some of the cars of that era use some kind of leather torque tube as a driveshaft? David G.

-

Rolls-Royce No Chemicals, No Paint, No Harmful Glues

David G. replied to Anglia105E's topic in WIP: Model Cars

Great progress on this David! When I built mine, I did make a set of snack trays but I missed the mirrors. I don't recall seeing them in any of the photos I saw during my research. Were they an optional item? David G. -

1957 Ford Del Rio "Shooting Brake" Ranch Wagon

David G. replied to LennyB's topic in WIP: Model Cars

Great work getting the engine and transmission sorted Len. David G. -

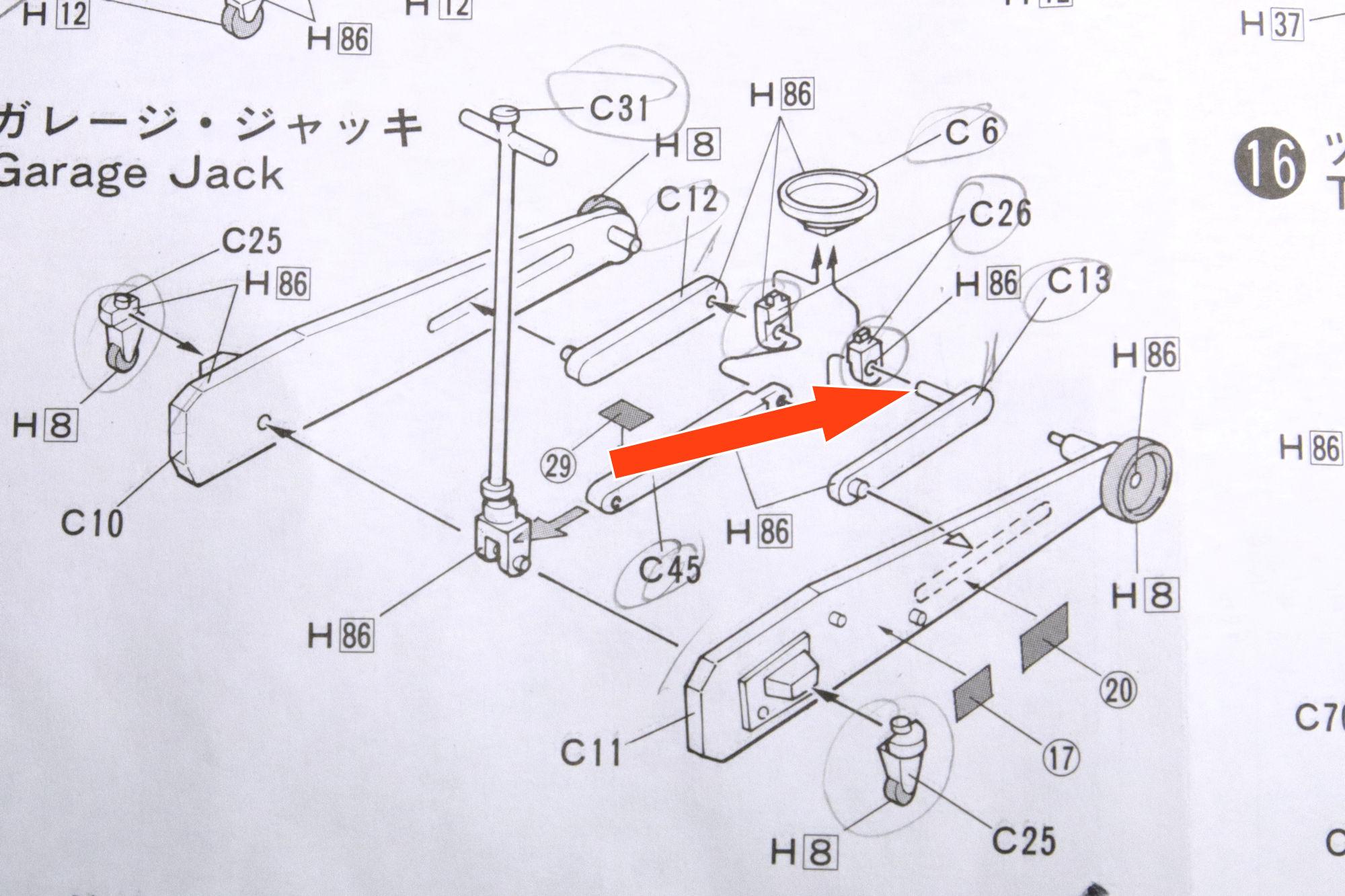

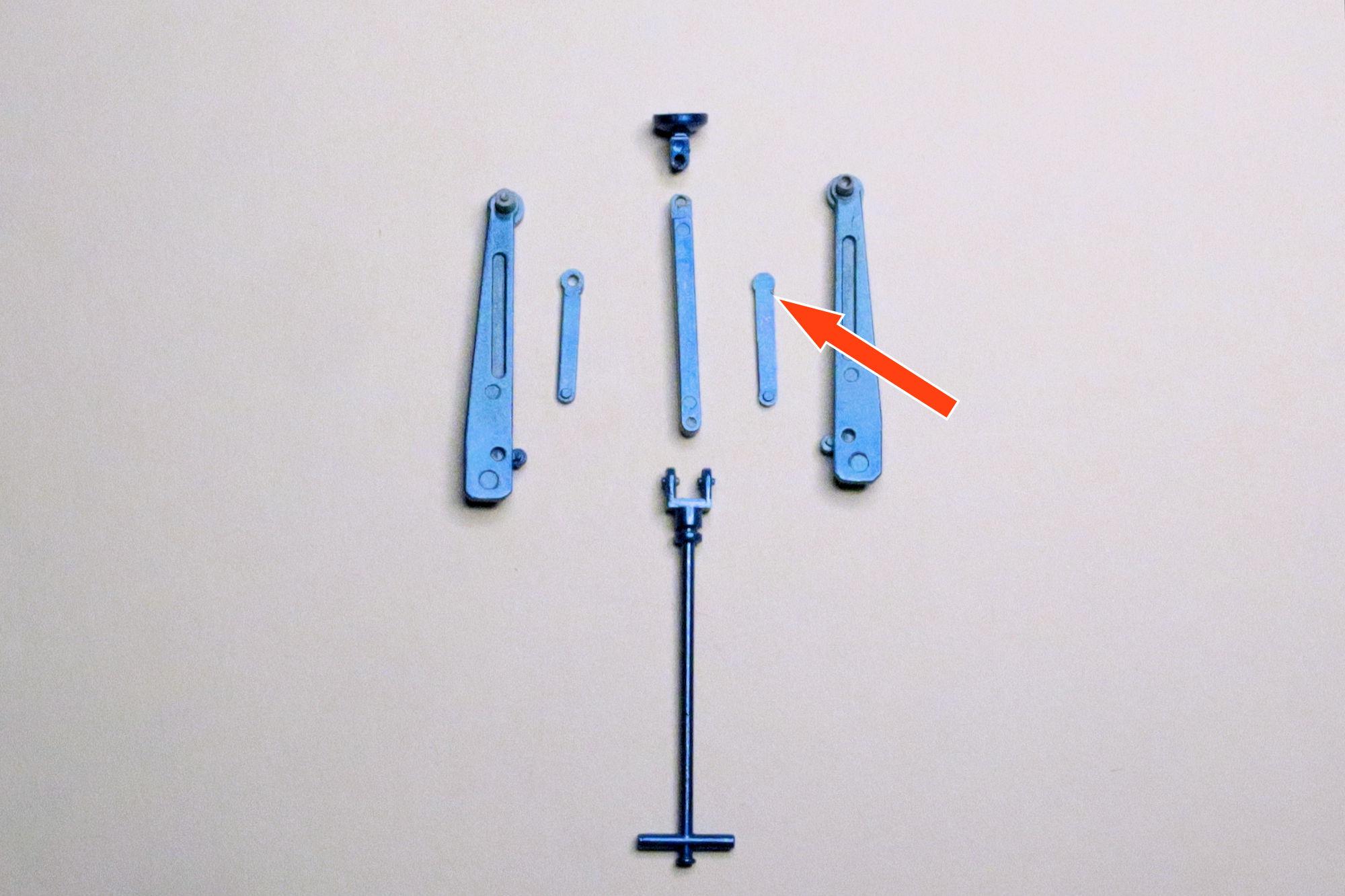

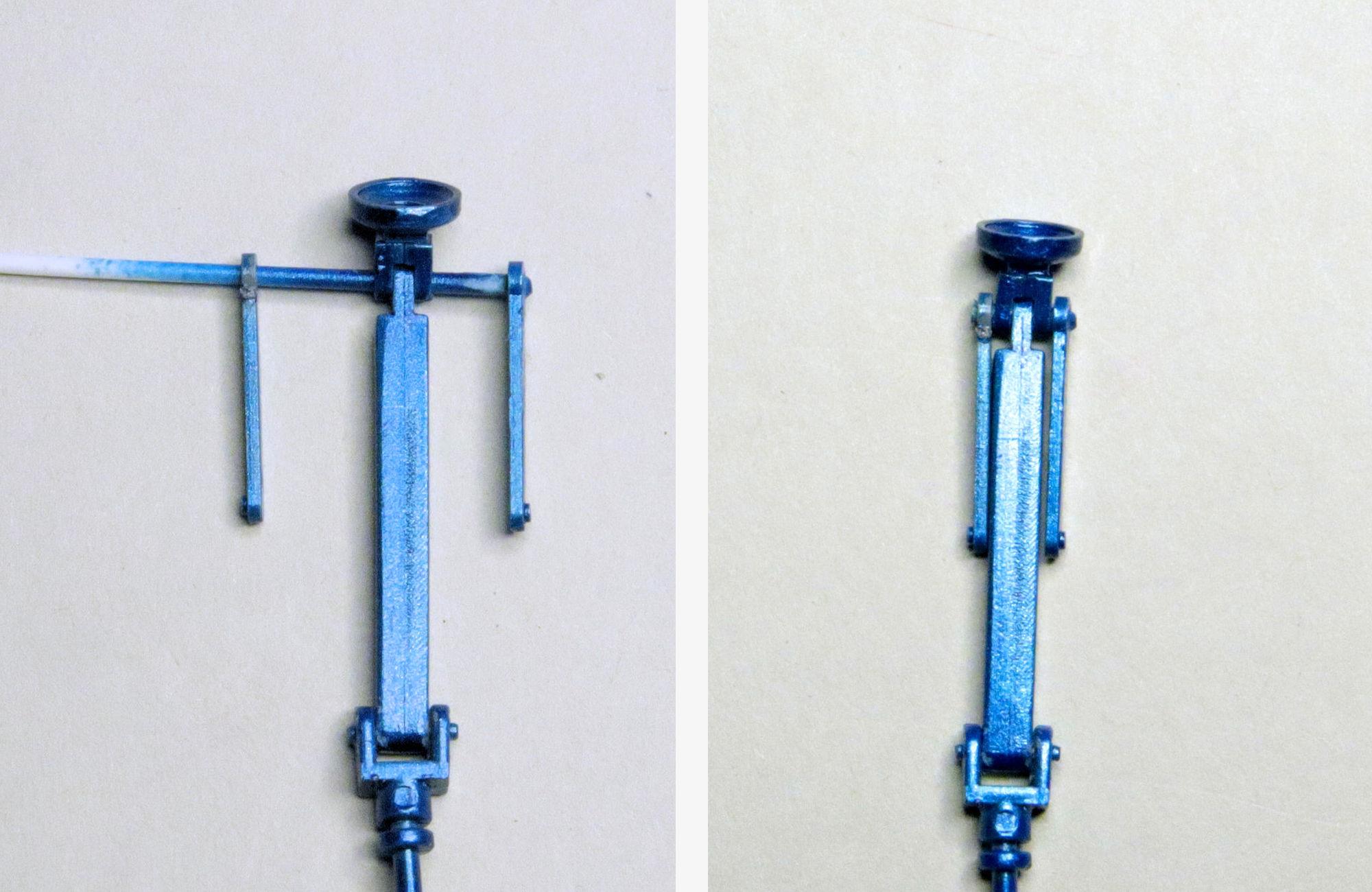

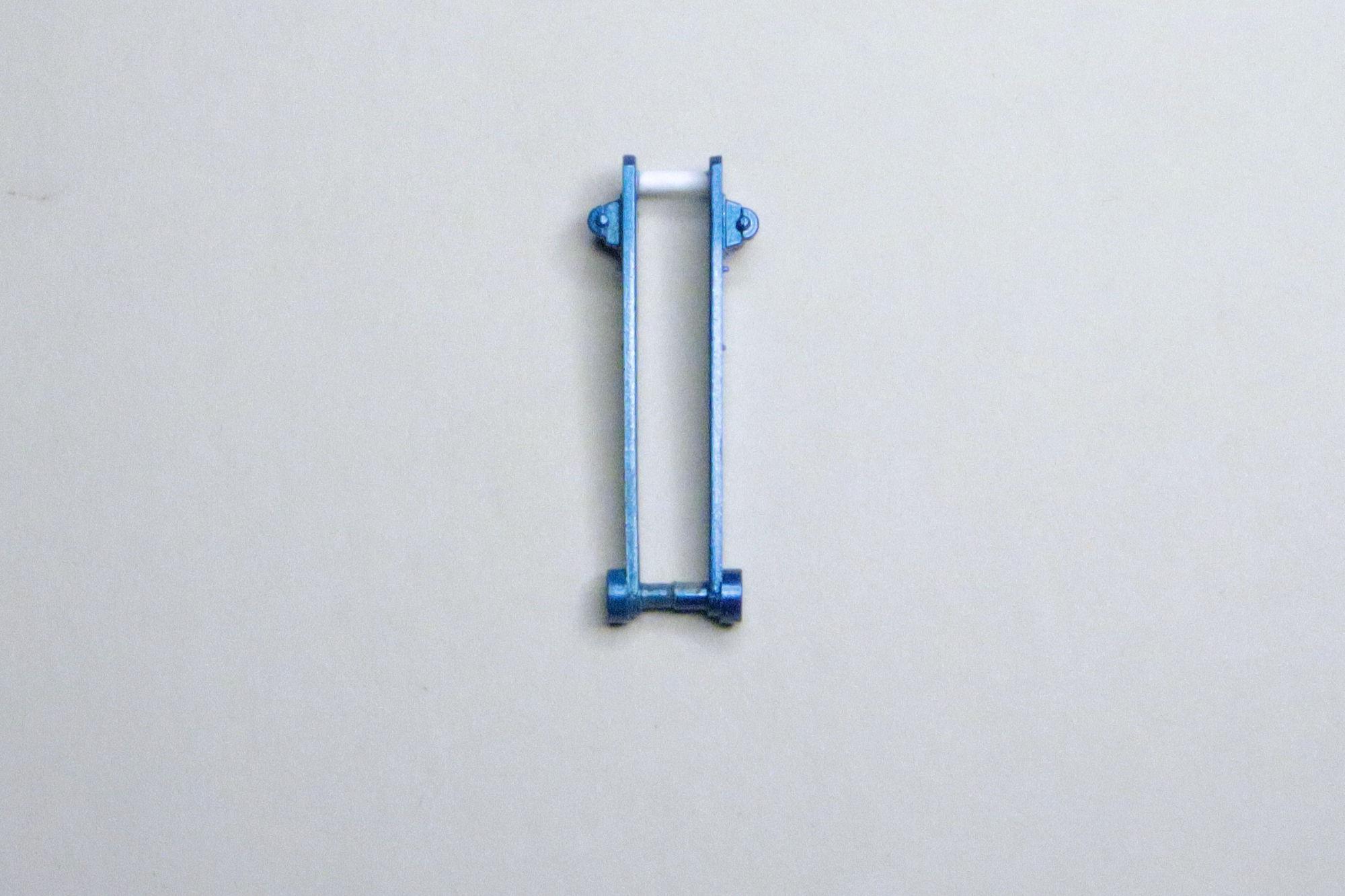

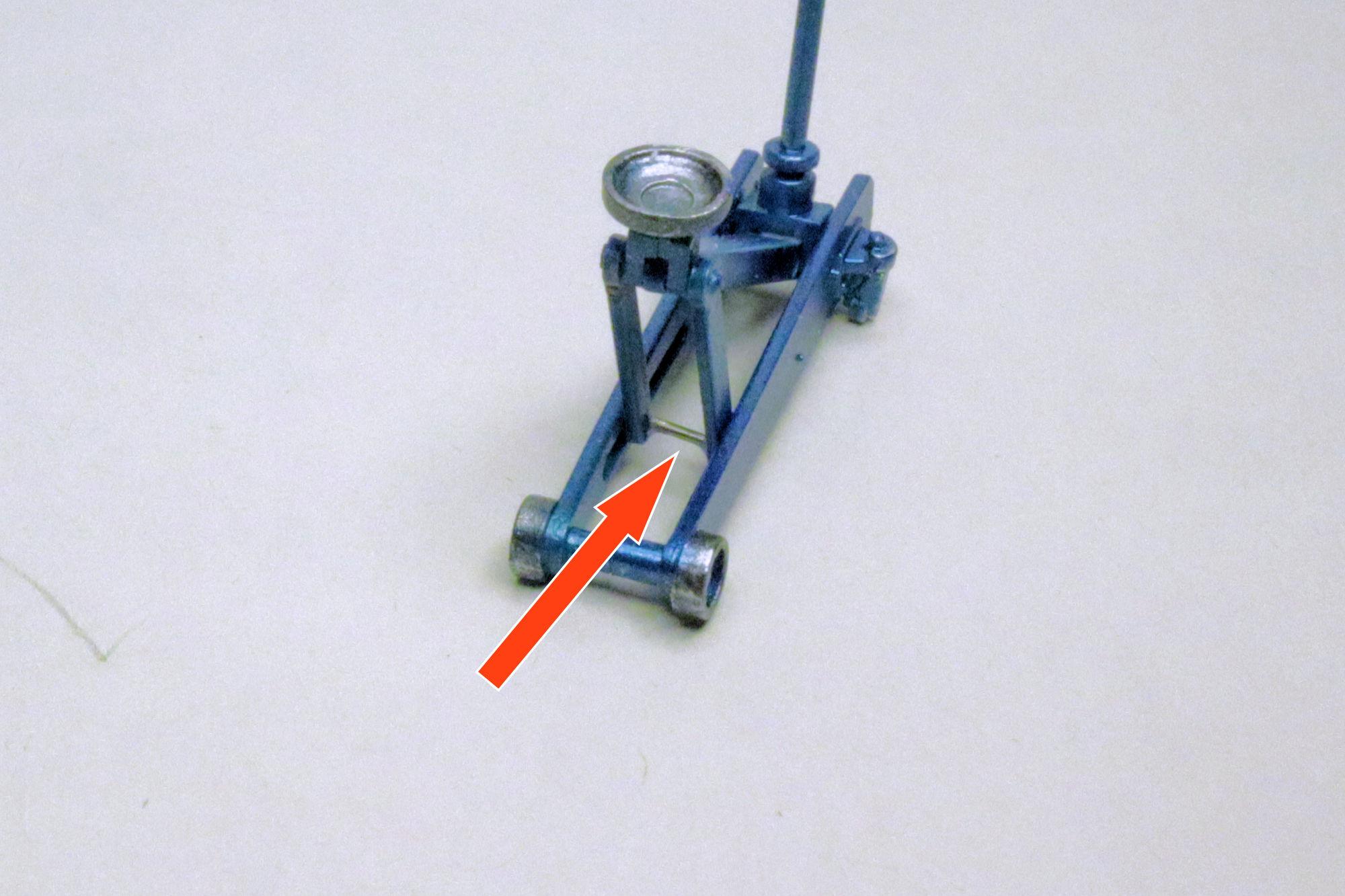

Hello Everybody! Thank you all for following along. As always, I do appreciate your comments, questions, pointers and suggestions. Moving on to the floor jack, Fujimi has left me with another error to correct. On part C-13 there is supposed to me a shaft that during assembly, passes through the cup support brackets and central lifting arm before anchoring in part C-12, pretty much holding the entire lifting mechanism together. As cast, part C-13 has no shaft to pass through the other assemblies. (first panel) I've drilled out part C-13 (on the right) to accept a piece of styrene rod that I pre painted. The rod is glued in place with some Tamiya cement. Part C-12 is on the left waiting in place for C-13 to cure before I cinch the whole thing up for final assembly. (second panel) The central mechanism with everything cinched together, glued, trimmed and touched up. Now on to the frame. One end of the jack's frame is held together by the connectors at the bottom, the other end by the lifting mechanism and handle. The jack frame seems to be designed to both capture the lifting mechanism and be held together by it. 😕 The implication of this design seems to be to make the jack poseable. I don't see this working out very well as it is, so I've added a reinforcing brace of styrene rod. I'm hoping this will allow it to be poseable once it's assembled. I've added another support piece to brace the arms and keep them engaged with the slots in the side frames of the jack. The jack is completed and I managed to retain the poseability feature! And of course, the floor jack at home in the shop. Thanks for taking the time to look and please feel free to share your thoughts. David G.

-

1962 Rolls Royce Silver Cloud II by Minicraft Models: Finished

David G. replied to David G.'s topic in Model Cars

I agree. I just didn't have access to one at the time. Thanks, David G. -

1962 Rolls Royce Silver Cloud II by Minicraft Models: Finished

David G. replied to David G.'s topic in Model Cars

Thank you most kindly Scott! It's nice seeing this one float up to the surface again.. David G. -

Thank you most kindly Scott. I'm pretty pleased with how it turned out. =D-

-

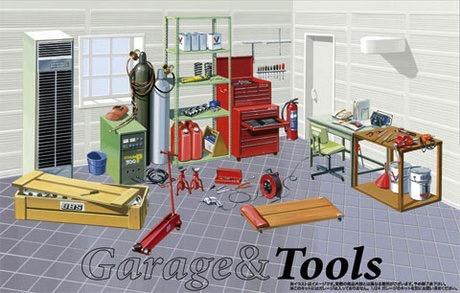

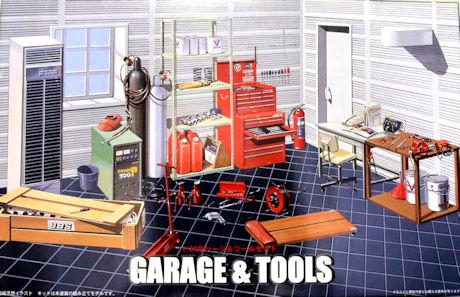

Thanks, I'll keep that in mind. Thank you Devin. Yes, everything you've seen in this post is included in the kit and a little more. I'm currently working on a floor jack. I'll be posting photos of that soon. But when you go to buy, be aware that there are two versions of this kit. One is "Garage Tools" which has just the tools and the other is "Garage and Tools" which has both. I hope this helps. David G.