-

Posts

2,651 -

Joined

-

Last visited

Previous Fields

-

Scale I Build

1/25

Profile Information

-

Full Name

Tim Hoagland

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Codi's Achievements

MCM Ohana (6/6)

-

Been a while but rest assured I've been active trying to figure something out since my last post......that and my daughter had significant knee surgery this week so I'm playing "Mr. Jeeves" the butler. Thanks to the guys that posted above and the wonderful comments. I'm trying to wrap up a few things on the car this summer before building the chassis finally. I did want to share with Andrew what I use for the tweezer "grips" that he mentinoned. It's a product called Tool Magic, available on Amazon for about $16.00. You just dip the end of the tweezers in it and hang em' upside down while drying. Done in about 2 hours. After the stuff gets "gnarly" or dirty you just peel em' off and dip again. I've been using one jar for 3 or 4 years now. Still good. I hope everyone else is enjoying their summer and hopefully your weather has been better than Pennsylvania's. Cheers, Tim

-

Grumman F6F-5 Hellcat

Codi replied to Brizio's topic in WIP: All The Rest: Motorcycles, Aviation, Military, Sci-Fi, Figures

Certainly not for the faint of heart Fabrizio........but with the first pic and post of your progress, I'm confident this will turn out fantastic. You have my attention and will certainly follow along. Have you done these before btw? Cheers, tim -

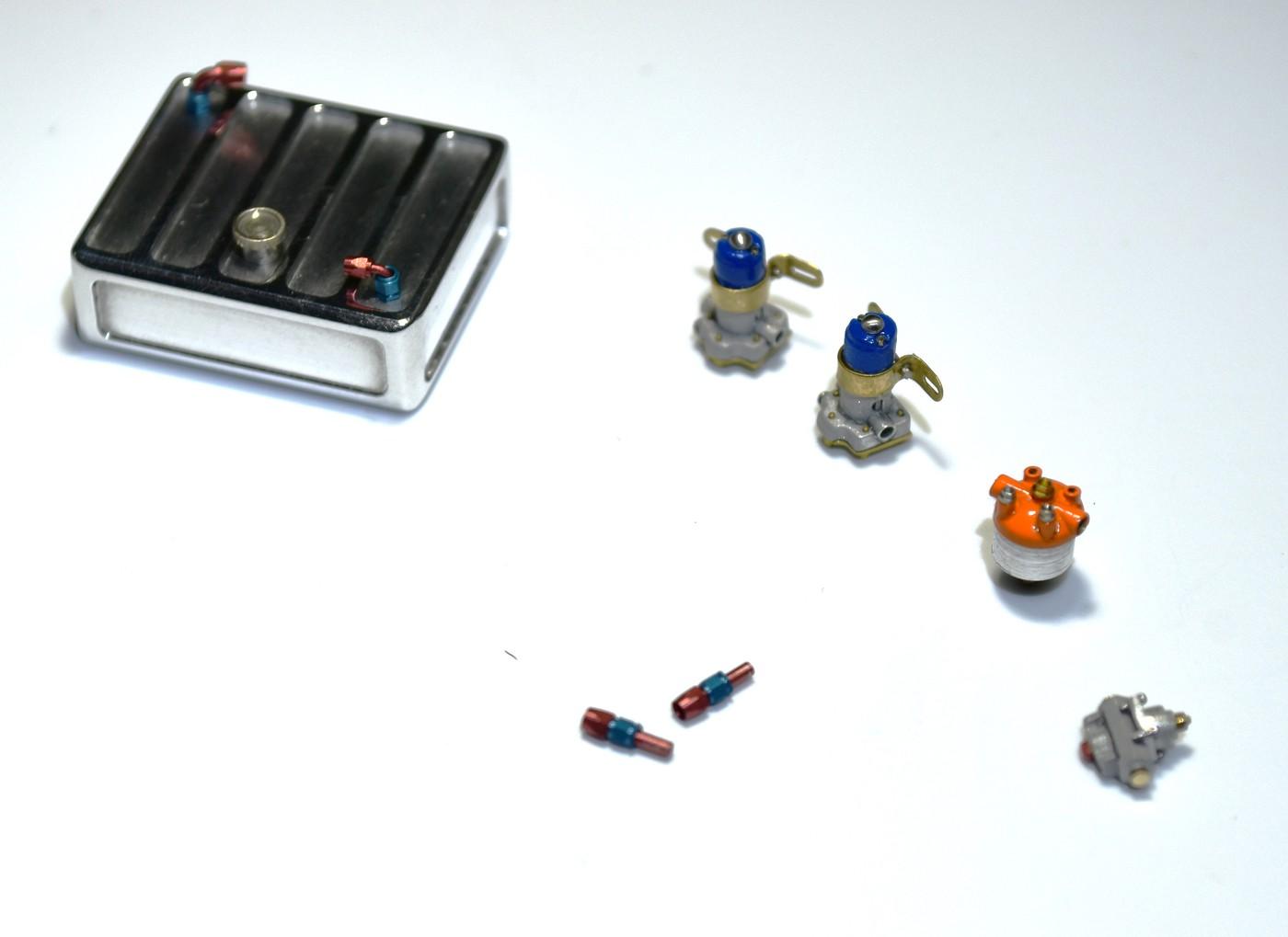

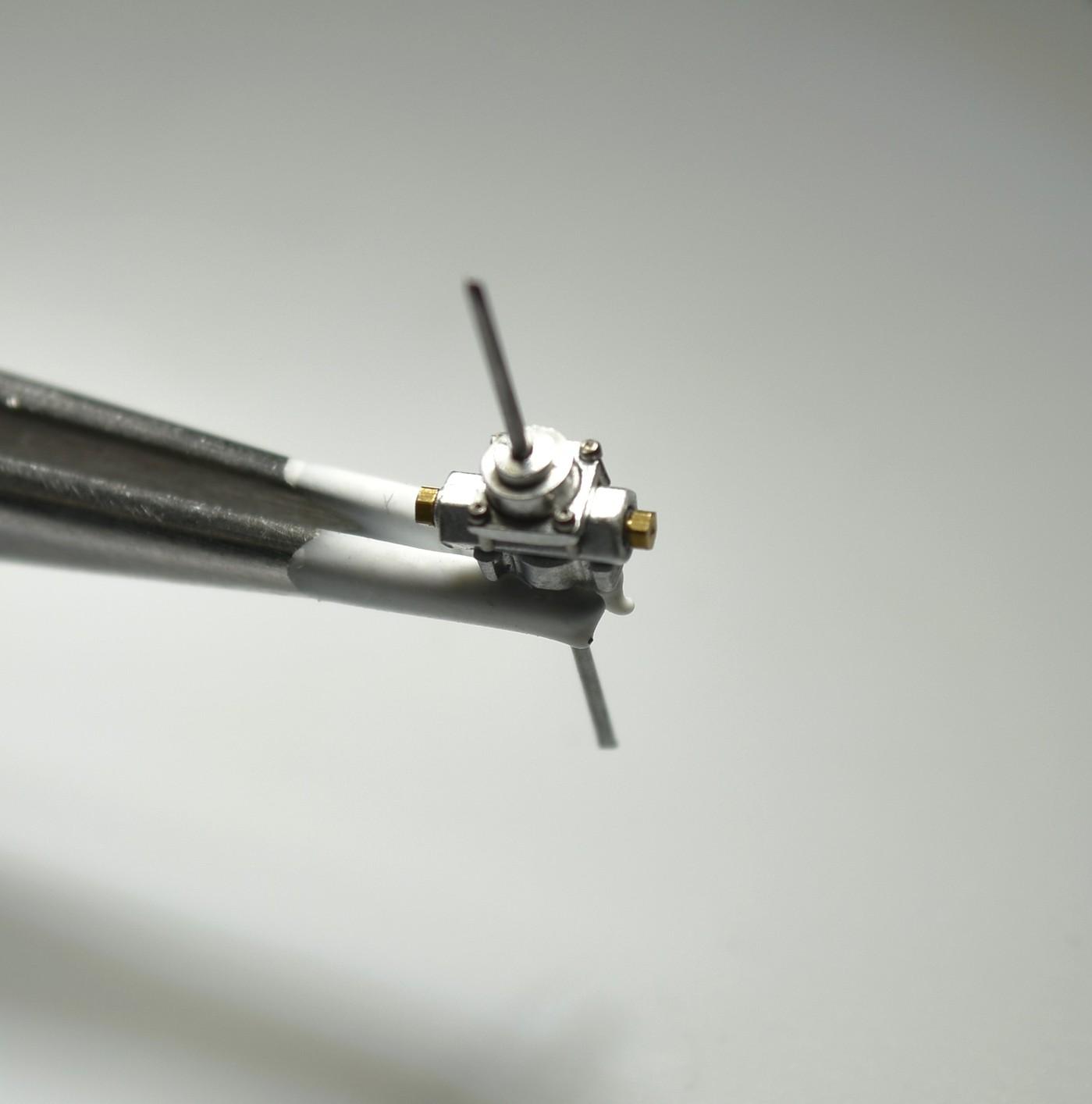

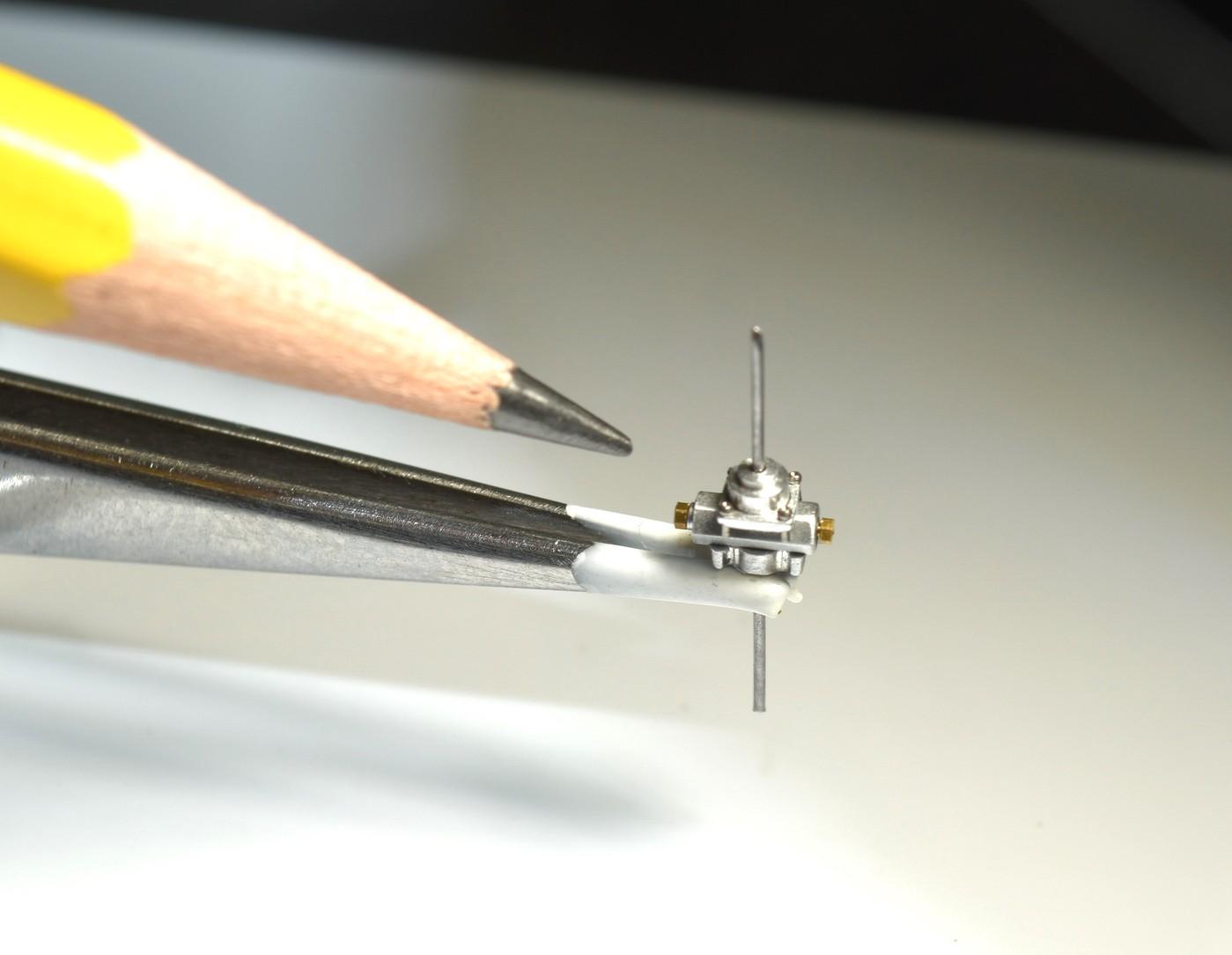

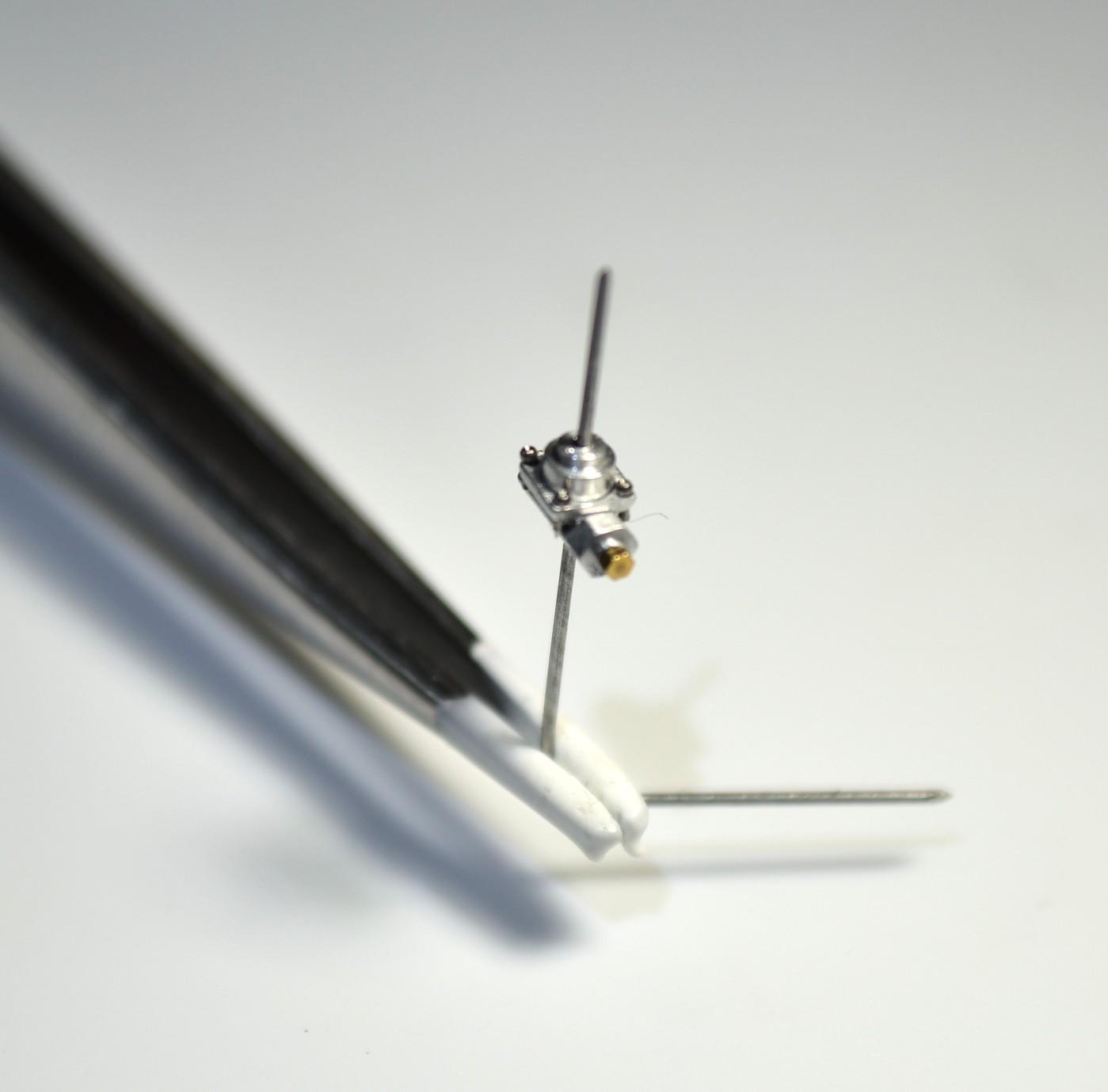

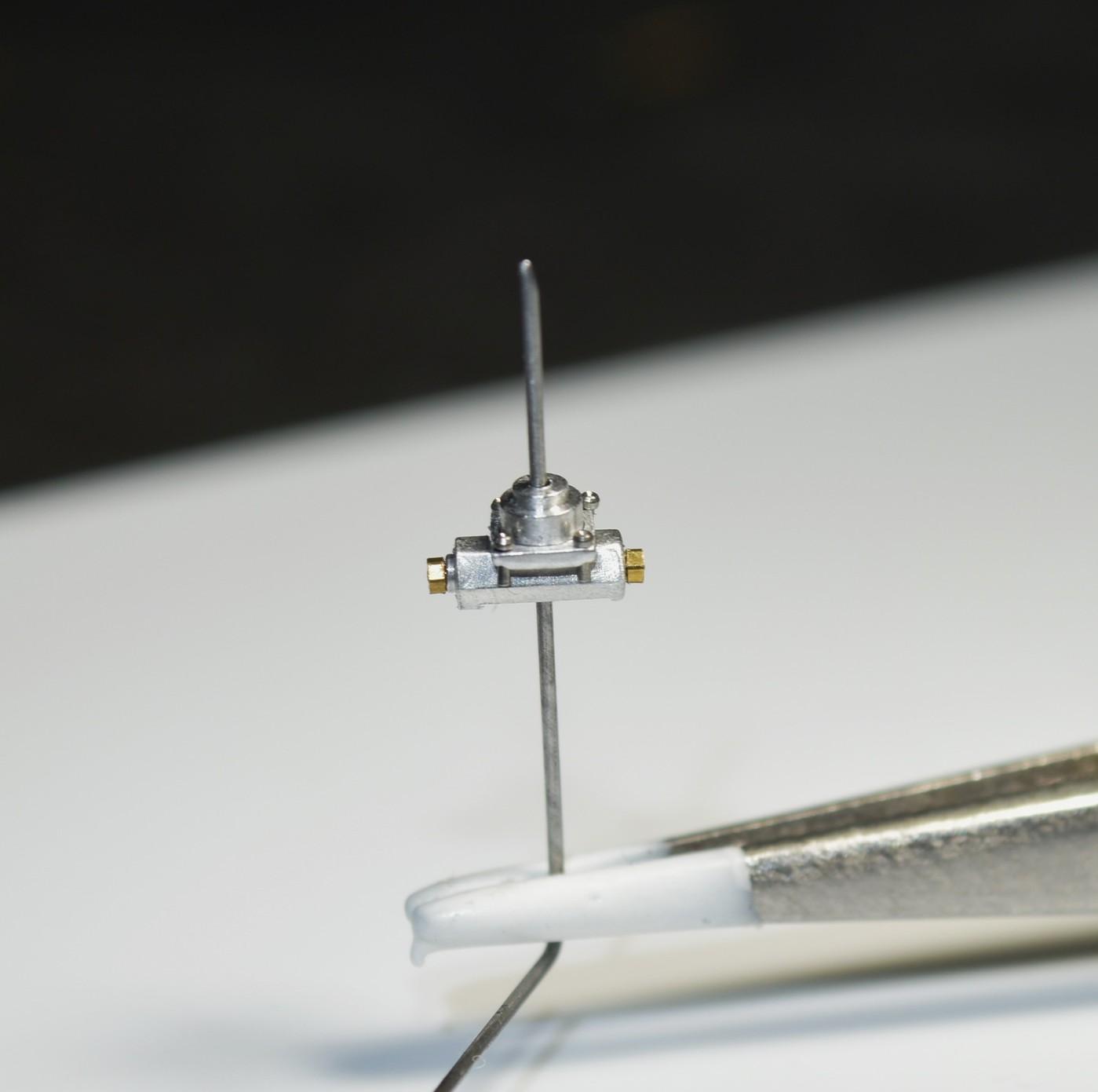

Today pics of the entire fuel system I've been working on the last month+.......tank, pumps, regulator & filter.....cheers everyone, tim

-

My tribute to the Jim Keeler “Dodge Fever” 1968 Coronet

Codi replied to LDO's topic in WIP: Drag Racing Models

Any pics of the real thing? I've never seen this before. cheers, tim -

Nice looking and your choice of a pro-charger makes it all the better. Your paint & roof texturing really stand out. cheers, tim

-

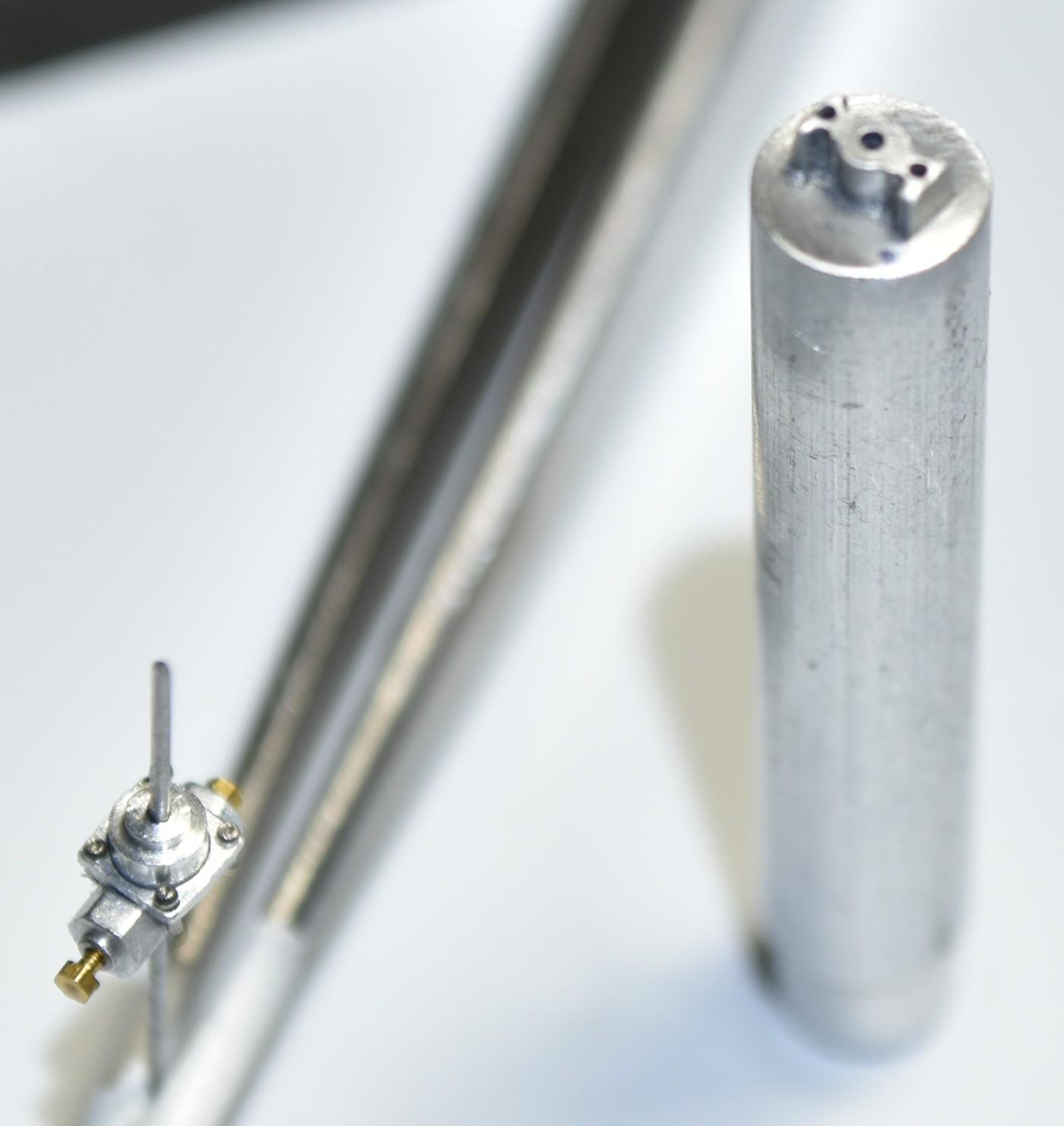

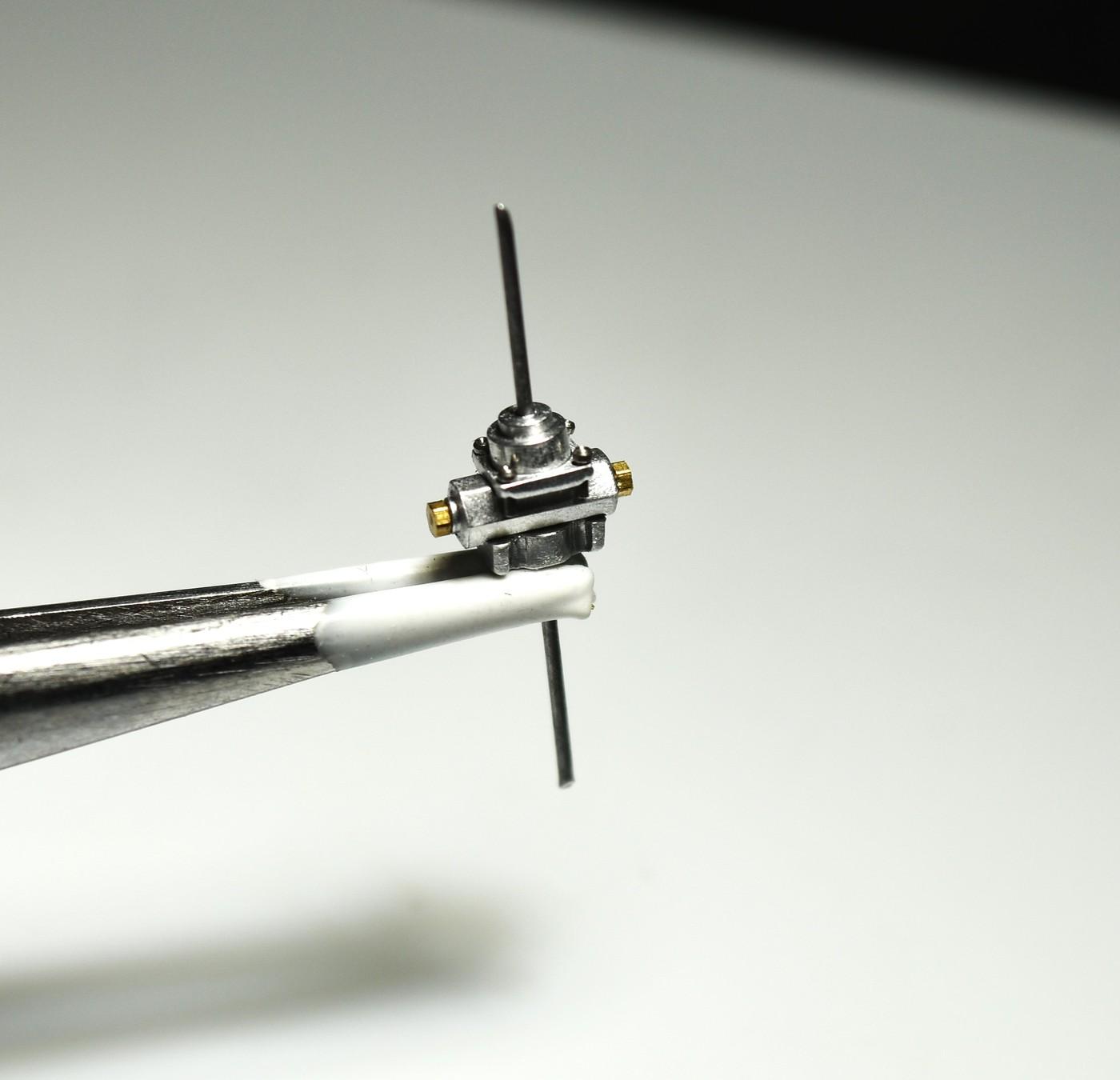

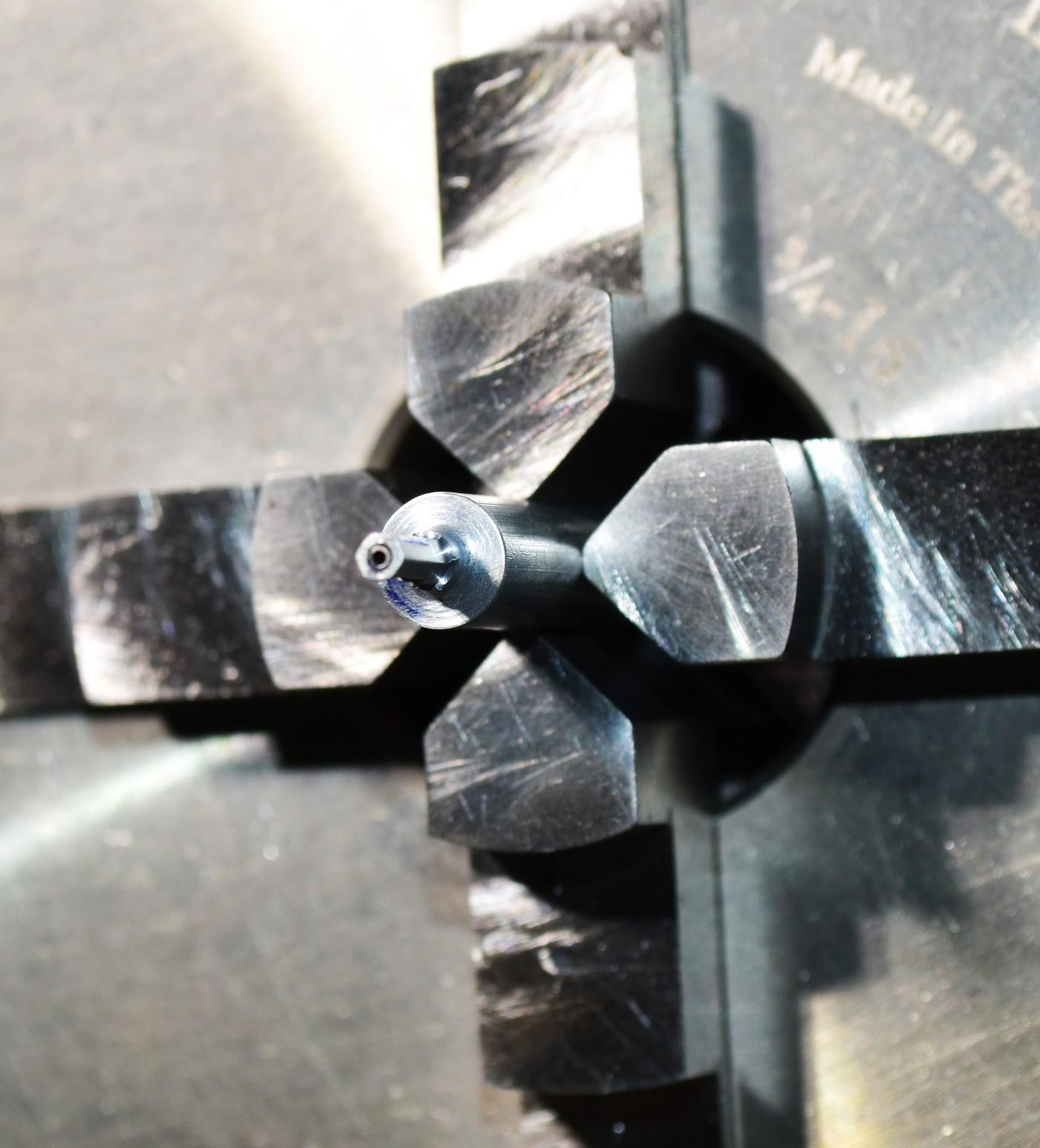

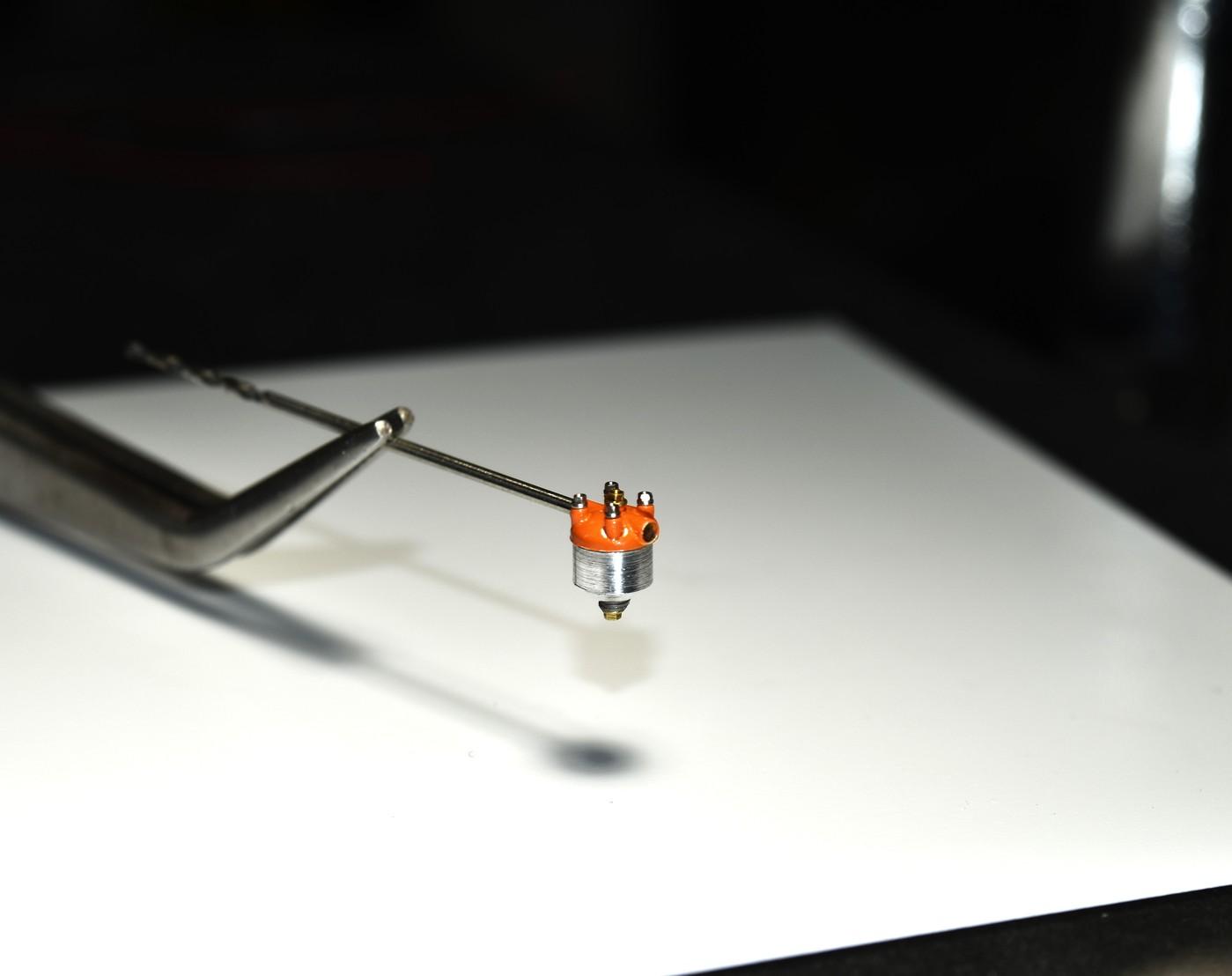

This part is done except I'll shave down the bottom portion (the lower half of the "body") as it's about .3 or .4 to tall.....not sure how I missed that. Not looking forward to the final assembly as this thing is so darn small. cheers everyone, tim I will media blast it before final assembly too btw........

-

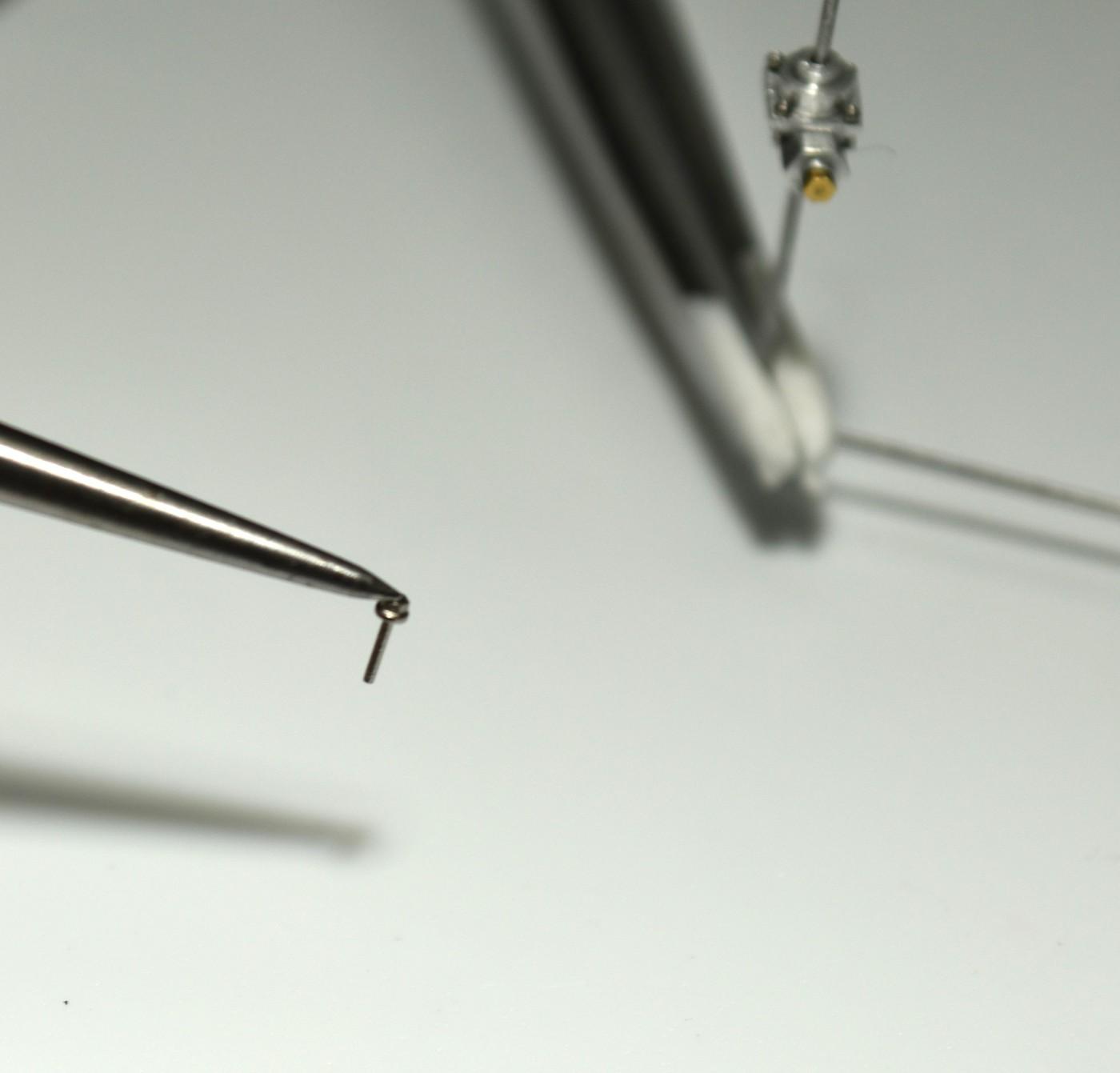

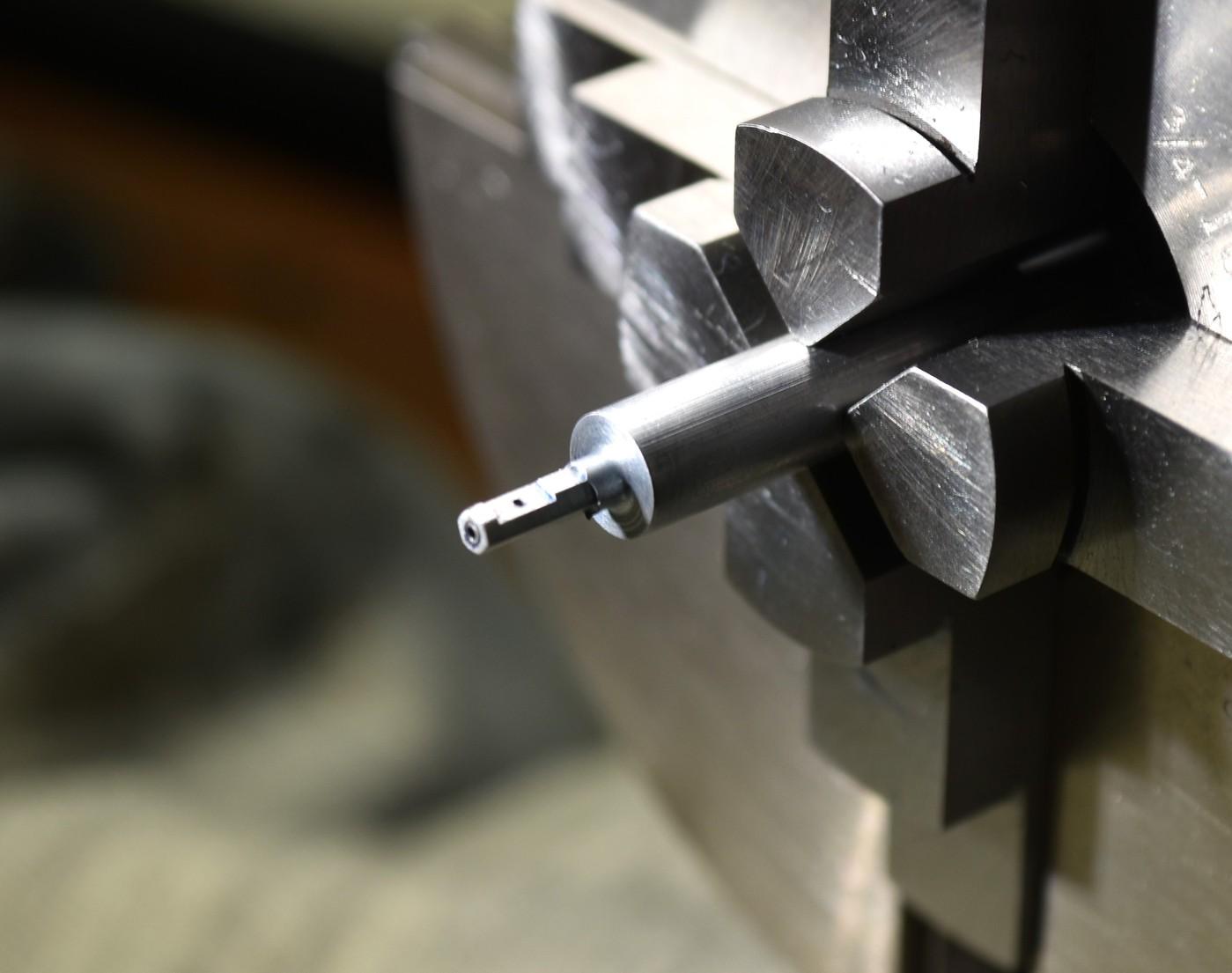

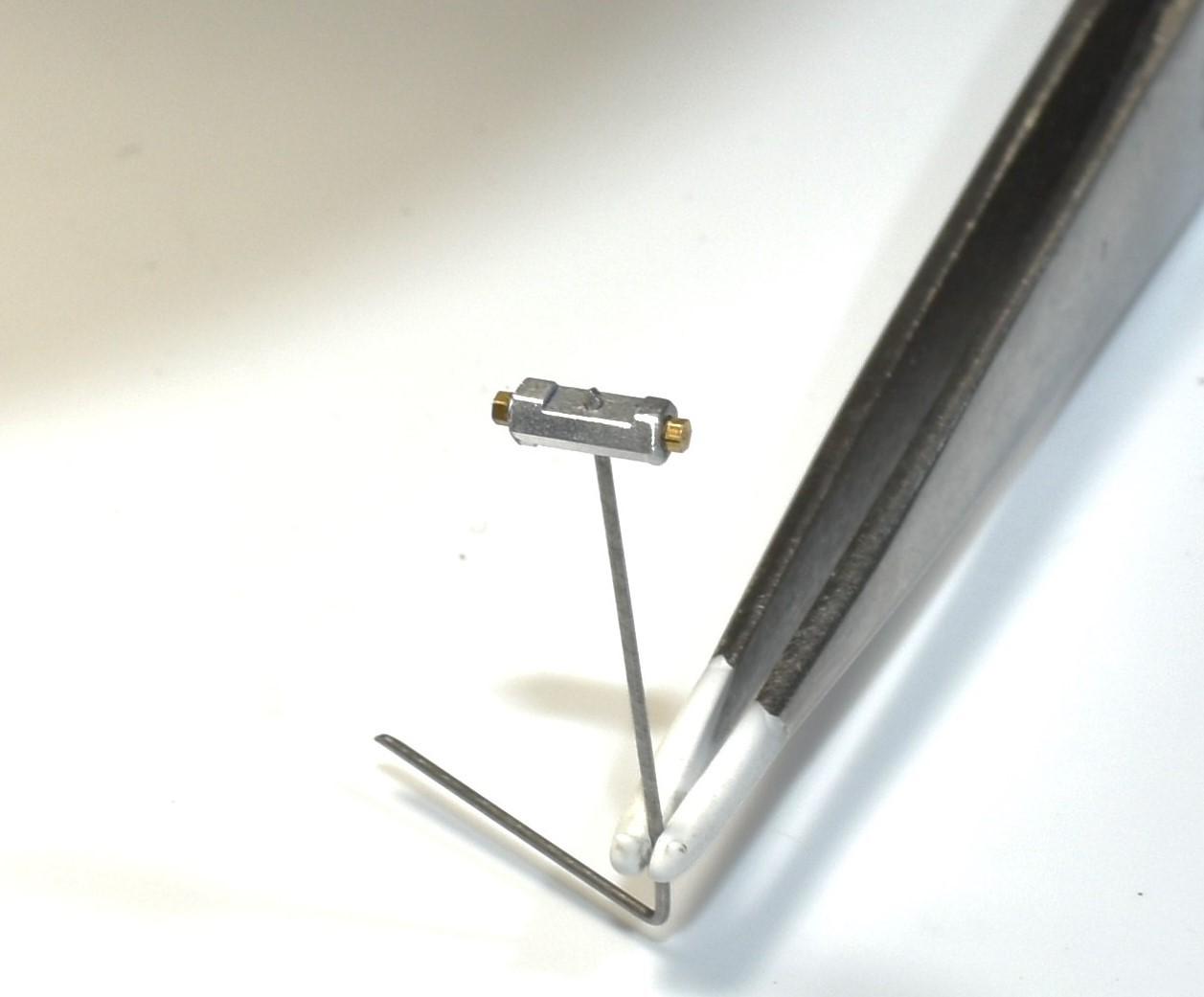

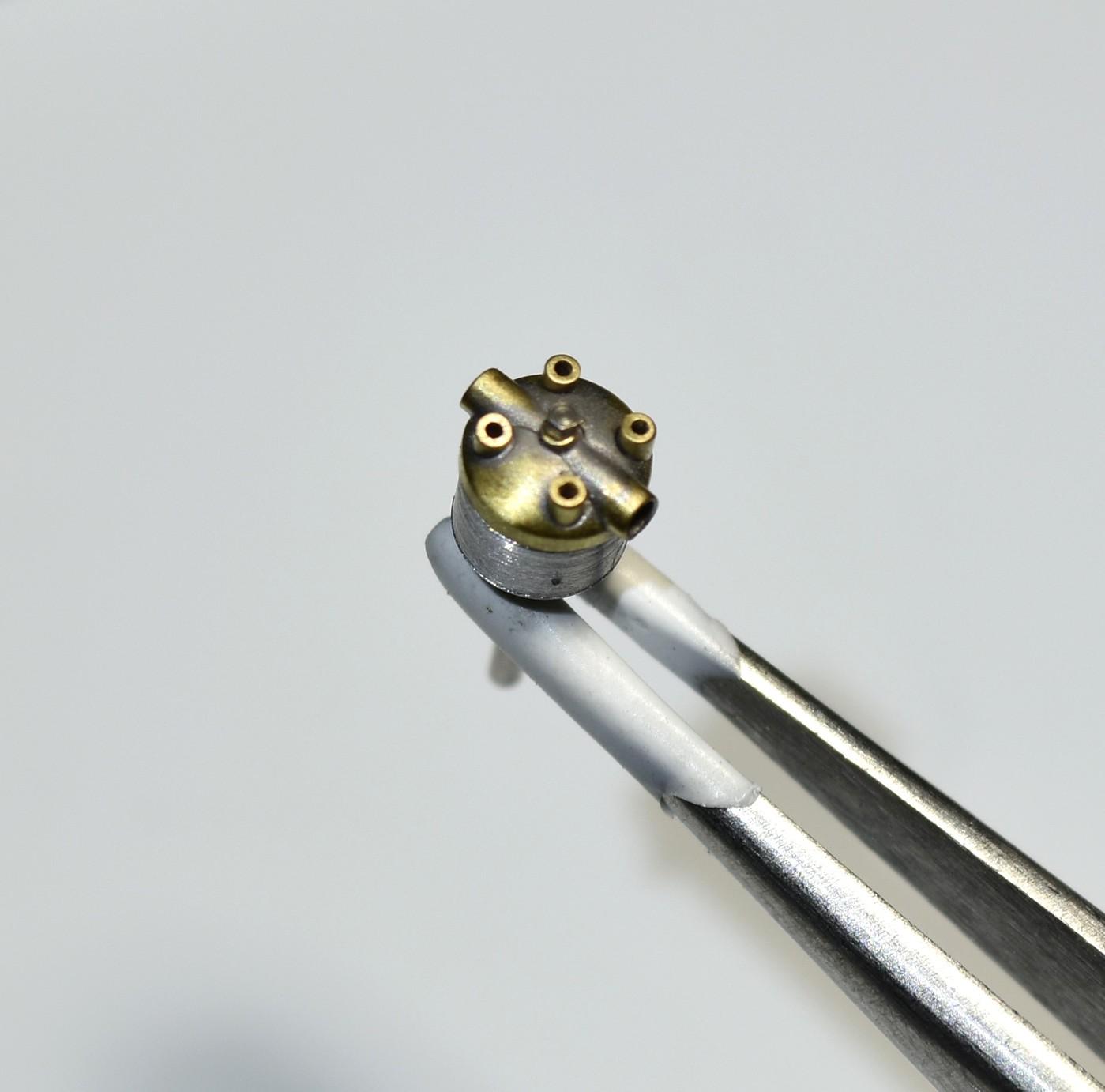

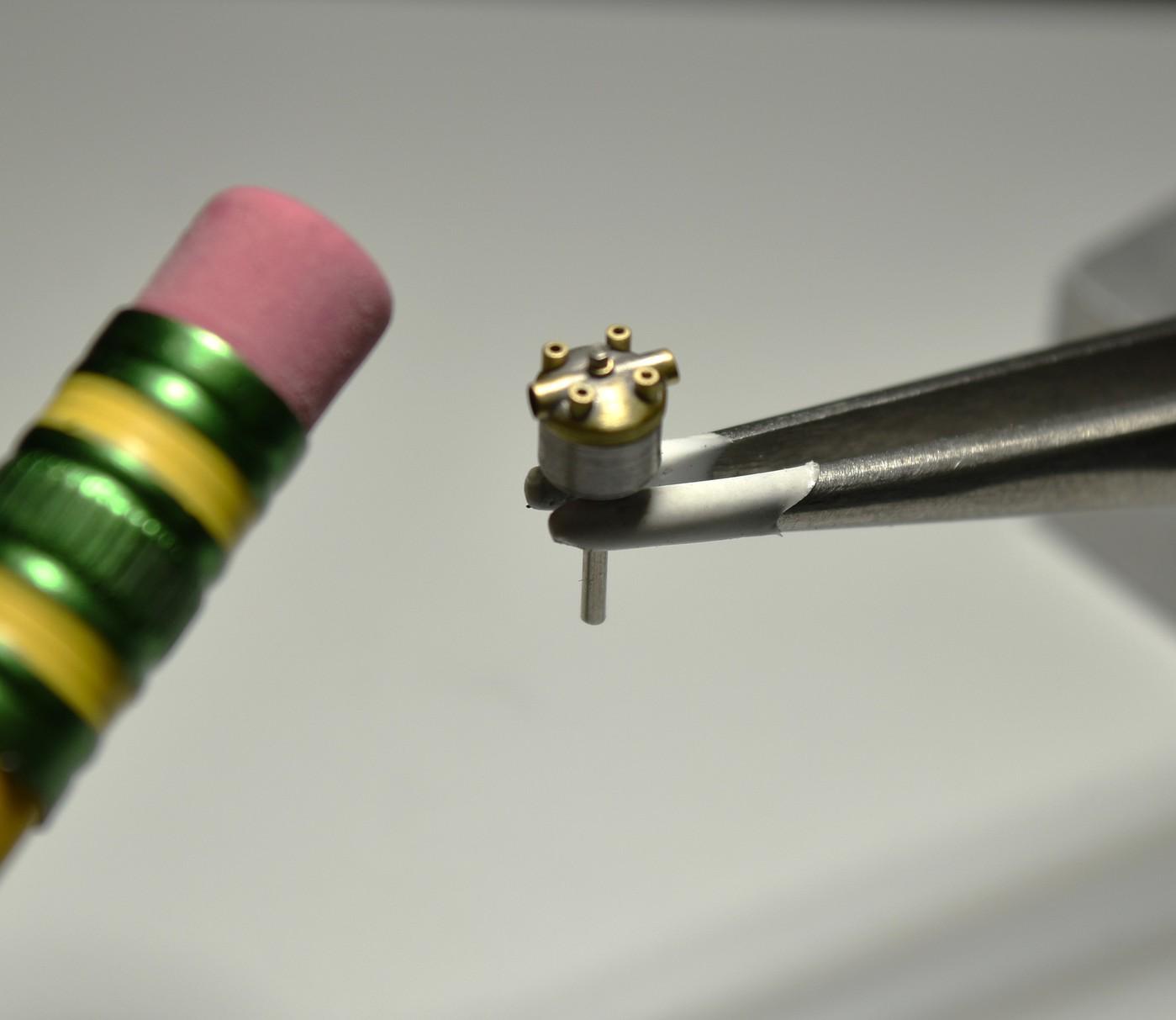

Thank you Ian & Robert.....this piece tested me too.....I admit that it took me so long on the first part of this piece as it wasn't centered when I removed it from the mill, so a re-do. This upper body part is 2 pieces actually and the "base as I call it turned out perfect (super tight tolerances) and while cleaning it up....BING......off to never never land and not to be seen again, so, another re-do.......here's 2 pics showing it right now and I'm tickled with it and the last pic is showing a magnetized steel scrawl that I use to pick up teeny bolts with to place them in their holes. No tweezers have ever been created to do this task. IF the bolts aren't steel but alum. or brass I simply take a small glue applicator, remove the end, apply some spit (yuck right?) and use that to pick them up. Works amazingly well! cheers, tim

-

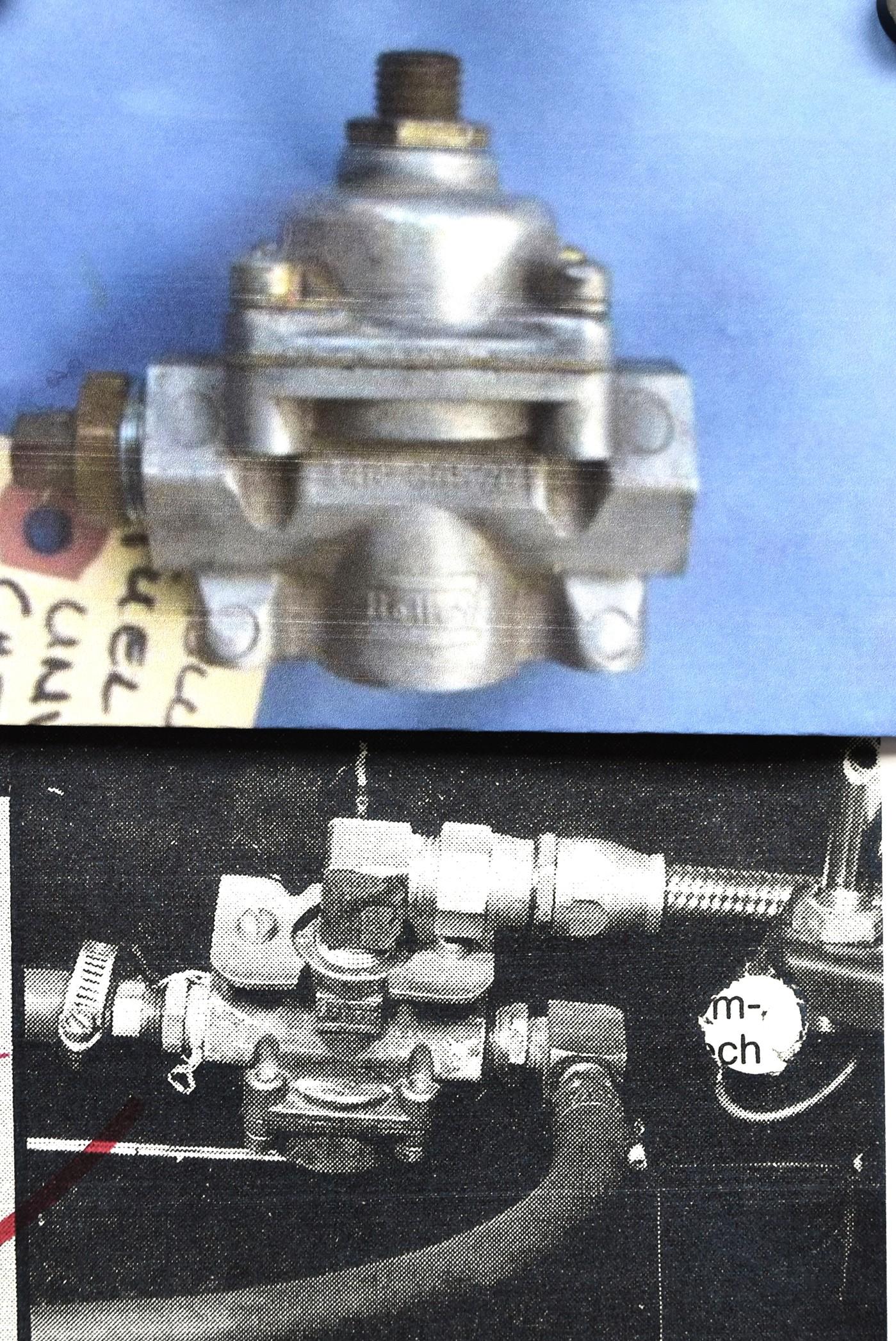

Thanks Brian, I airbrushed it of course as a can would have covered up the detail. I just wish I had a tiny Fram decal to go on it. I have tons of decals, many by Slixx too and none of them have a decal sized to fit......... Anton, now you've done it, your wife will certainly declare me certifiably "insane"......one of the things that I've come to enjoy about making the majority of the parts in metal is of course nothing looks like it, but it also let's me strive to be more accurate on such tiny parts. Thanks for checking it out. cheers, tim Thanks Francis.......this part I'm sharing today is even smaller and more detailed than the filter. Today, I finally got the body done of the Holley fuel regulator. There are 3 more parts to make, upper, lower parts and the bracket to hold it. This started out as round stock but the body is hexagonal in shape....this piece has about 6 or so hours in it not including the drawings I had to make. A pic of the real thing with the bottom pic showing it attached to a 76' Pro Stock Mustang II. They had to mount it backwards and upside down as space was at a premium. More pics to follow once I get the next 3 parts made. cheers!!

-

Peugeot 905 evo bis

Codi replied to Chris Smith's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Hi there Chris, You're off to a good start on the engine and the time spent on the valve cover was WELL worth it. They're sharp. Having seen pics of the real engine, this one is going to be challenging but boy will it be something else when completed. Cheers, tim- 23 replies

-

- 24hr le mans

- mfh

-

(and 1 more)

Tagged with:

-

’72 Dodge Demon Drag Racer 1/25 scale

Codi replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

I like "different" Francis....and those fit the bill exactly. I admit I'm not familiar with that particular head per se but you sure made them look fantastic. The machinist in me makes me pause and smile at the things you incorporated and they're just the ticket to go with your block. Can't wait to see the valve covers (hint-hint) Cheers, Tim Hope you don't mind Francis but I love the back-story on these and I believe this is the head or a VERY close relative/version of it and I thought I'd share it.........Hot Rod mag article.....it is quite interesting. https://www.hotrod.com/features/the-b-1-attack-phase-2-april-1991-982-1472-111-1 -

Hi Chris.....well, here's what I worked on this week, it's the in-line spin on Fram fuel filter. There were a lot of little steps to go thru to make this itty bitty one. It's actually prep for the this weeks project, the Holley fuel regulator..... here's the pics. cheers, tim

-

T41 Bugatti sport coupe

Codi replied to charlie libby's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Spectacular Charlie. I'm more than impressed to say the least. cheers, tim -

1/16th 55 Thunderbird BB/FC Funnycar "GIRL TROUBLE"

Codi replied to Ian McLaren's topic in WIP: Drag Racing Models

Showing off with 2 brass frames in one pic........sheesh. Cheers, Ian- 33 replies

-

- 3d printed

- scratch built

-

(and 2 more)

Tagged with:

-

’72 Dodge Demon Drag Racer 1/25 scale

Codi replied to AmericanMuscleFan's topic in WIP: Drag Racing Models

Good morning too Francis, I just checked and it seems there is a cold front headed your way and the forecast is for 2 more weeks of snow and sleet. I'll expect your post with pics by weeks end. lol......tim -

Brian & Jerry, thanks fellas, hope you like the rest that I'm working on! Francois, not a "perfectionist" per se but I do try to stretch myself....lately I find myself each time walking away from the bench muttering on the days progress with the thought that "well, it didn't come with instructions" or "I've never done that before" to help keep things in perspective. cheers, tim