-

Posts

3,981 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Pete J.

-

All you need is some 6" platform shoes, bell bottoms in gold lama, a leopard jacket, and a wide brimmed fedora and "You be Fly, man".

-

A Drill for General Model Work Recommendation

Pete J. replied to Miatatom's topic in Tips, Tricks, and Tutorials

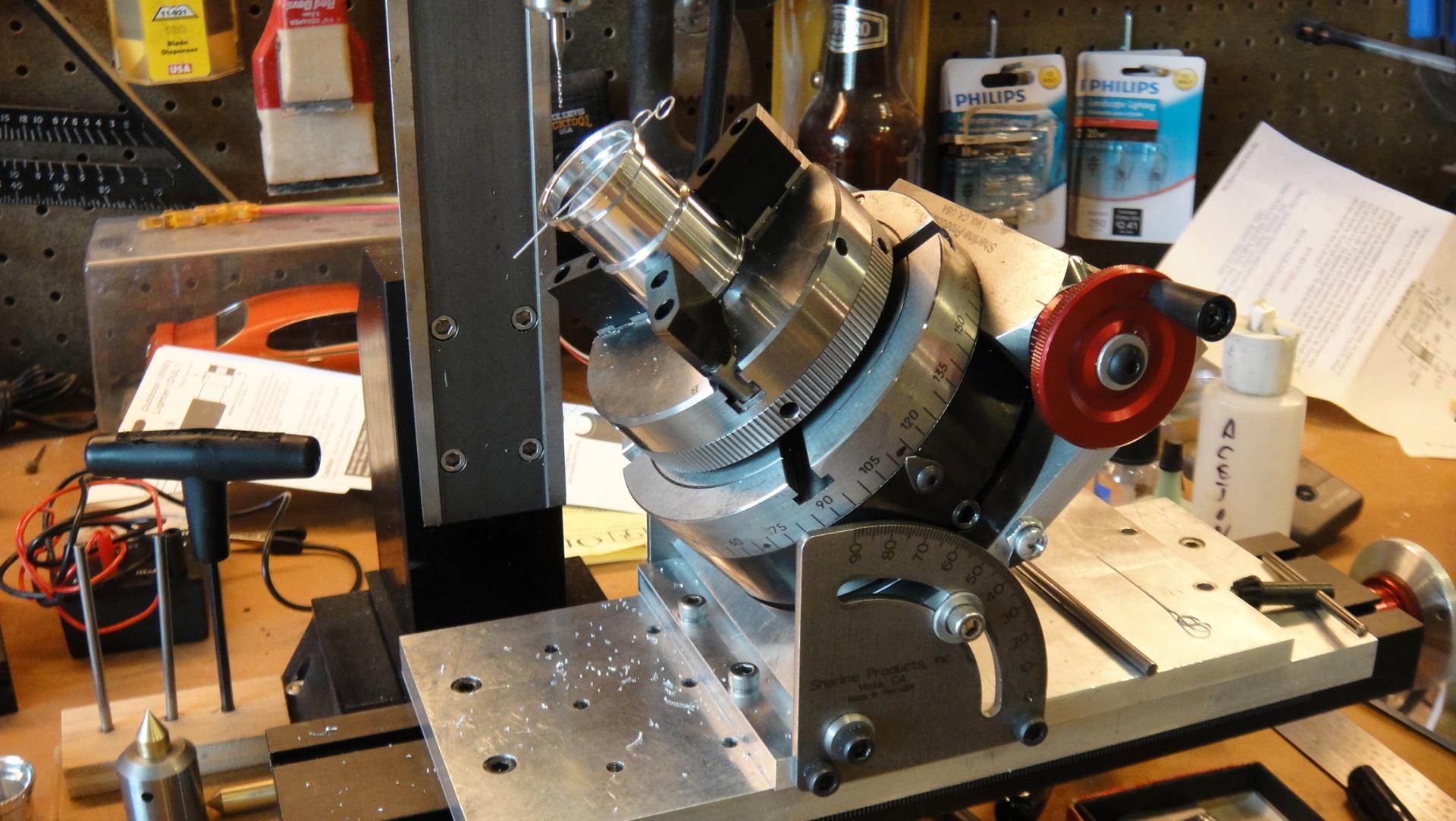

Peter, no, they are the "replaceable" jaws. You can get them in Delrin(which these are), nylon, aluminum, soft steel and brass. Here is the page. http://sherline.com/product/chuck-top-jaws/ I contacted Sherline after I bought a set and got the dimensions for the soft parts and now make my own to suit my job. Quite handy! -

A Drill for General Model Work Recommendation

Pete J. replied to Miatatom's topic in Tips, Tricks, and Tutorials

Why something other than a pin vise? Because sometimes you just need something a little more precise! -

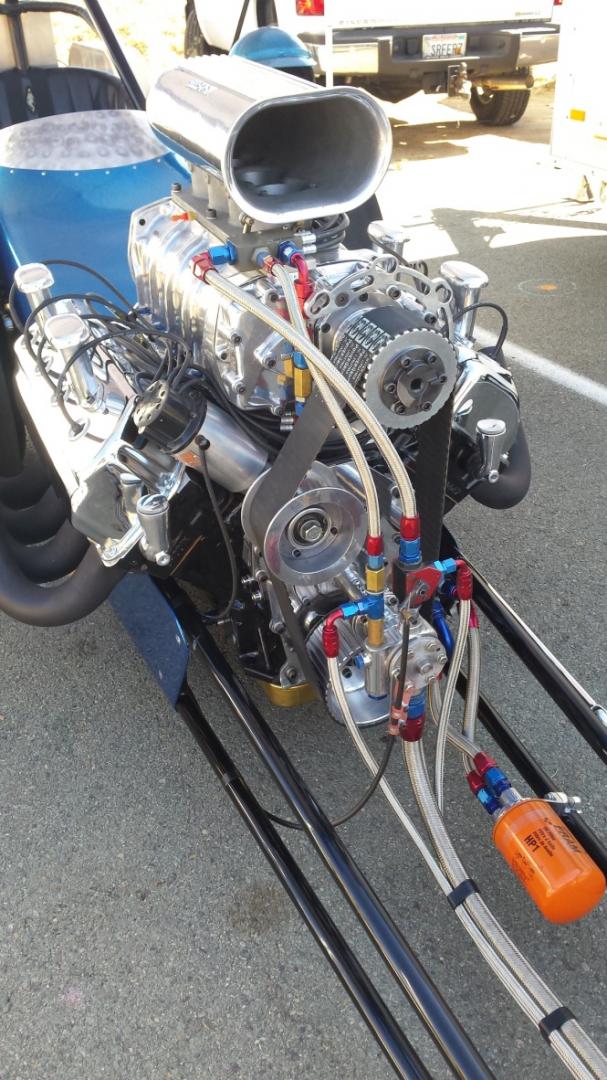

Ok Tim, these photos are now getting into the "Holy s///" category!!! I hope your final plan include a simple coat of clear lacquer over the whole thing. This is just to pretty to paint any other way!

-

I would not normally post a photo on someone else's thread, but this time I couldn't resist. A friend of mine took this as Escondido's Crusin Grand. This is a heck of a comparison to the work you are doing Tim. Put your work side by side with this and I think most people would have trouble deciding which is the model and which is the real deal! Makes your work look all the better!

-

Ok, Tim now that is a cool idea! I have used photoetched for this before and it is really not that easy. I like the idea of using tubing and soldering to it. Much sturdier than my way. Thanks againj!

-

Most people aren't aware that there was a CJ-2A civilian version from 1945 to 1950. The "A" stood for agriculture as it was intended for farm and ranch use. I had a three speed two range gear box with two or four wheel drive and an optional power take off. It also had a manual throttle on the dash so you could run it at a constant speed. There were a plethora of plows, blades, scoops and other attachment for agricultural use. This was the first vehicle I drove. My dad had one and we ran the wheels off of it. It is still running on the farm to this day.

-

Boom! Mike hits the floor! You've done it again Tim. If you show this model at a show, you must put an album together to place next to it. Otherwise people are likely to not understand the level of craftsmanship and work that has gone into this.

-

Absolutely agree about the 'acrylic" term. Not long ago, I had a paint chemist correct me on this and actually "acrylic" is a long chain polymer that is added to paints to increase the durability of the paint. I remember way back in the day that Earl Shibe(Any car, any color $39.99) use to charge you an extra $5 to add it to your paint. He took a small vial of the additive and dumped it in the gallons of paint he used to paint your care. Unfortunately, we misapplied the term and are kind of stuck with it. By the way, Tamiya is absolutely correct in labeling their paint as acrylic lacquer. The old lacquers were nitrocellulose lacquers.

-

This is my stock answer. The strength of the solvent generally determines what goes over and under. Stronger solvent goes on the bottom. Acrylic solvent- Alcohol(weakest)(though most will try to convince you that it is water), then enamel- naphtha, then Lacquer - lacquer thinner(strongest). Now this is an absolute generality and no guarantee that it will work because different companies use different concentrations of chemicals to make their paint. The other problem you can have is a difference in shrinkage rates between paints. That is when you get the wrinkling and that is an entirely different problem.

-

Humm, very interesting way of doing that! Never thought of that. Another tool in the back of my mind. Thanks for the tip!

-

Tim, it looks stunning! It will match the work on the engine perfectly. One piece of advise though. Never measure the success of a week in the number of parts you produce. Measure it in the pleasure you got from what you produced. You can have a very successful week and only make one part. It is not about how much you make, but the quality of what comes out of the shop. I would gladly have a single Rolls Royce as opposed to 100 Kia's.

-

Thank you both very much for looking in. I intent to be done with this project by August of next year, but like anything I tend to take a few of life's detours from time to time. This build has been no exception. Enjoy the ride but be ready for a bump or two along the way.

-

Thanks Tim! I will do that. The four jaw is really taking some thinking time to make it work the way I want too. A lot of time roaming the internet and YouTube. I am getting closer, but it is going to take some work.

-

Chris, thanks for the complement but frankly, I use Tim and Randy as a resource. They are way ahead of me, but they are really great at sharing and giving solid advise. It is just great to even be mentioned in the same sentence with them. Thanks.

-

Started work on the superchargers. This is the second crack at it. Not good enough yet and I have to make two of them. Still learning a lot about using a four jaw chuck and rotary table to make the piece and get the grooves evenly spaced. Back to the bench!

-

Ok, just dropped a buck and a quarter on a set of micro tap and dies! Got to keep up with the Jones's. Or would that be the Tim and Randy's?

-

Just to see if you could! Great reason to do something like that! Very nice piece. What size tap?

-

I'll be darned. Who knew?

Pete J. replied to smhardesty's topic in General Automotive Talk (Trucks and Cars)

1972 240Z, 1974 Porsche 911. Yup I had a couple of cars I regret leaving behind while in the military but then the fact that we left them is what makes them rare and desirable. -

It really depends upon the paint, but here is something to consider. Have you ever used acetone to clean your hands and after a couple of seconds that that weird taste in your mouth? Well that the the chemical going through your skin and through your blood stream to your mouth. Same thing with paint. Your skin is a semipermeable membrane and some very bad things can get through it and mess up your liver, brain and kidneys over time. If you are young now and don't protect those organs, you may be lucky to live long enough to regret it. In that respect it is a little like tobacco. No noticeable effect from this exposure today or maybe the next, but 20 or 30 years down the road you may wish you hadn't take a little bit of care now.

-

Tim, Thank you. It is good to be back on the bench. You and Randy's posts kept me interested though the wood project. It is quite a stretch for me to see what you do. Thanks for being here and showing the way! I have two more strips to do so I will shoot the "in progress" part tonight or tomorrow. As to the desk, it is exactly the same challenges as model building. You are just working in a different material. The mental gymnastics are the same. Oh, and bigger tools. Much bigger tools.

-

Thank you Randy. It is great to be back at the bench again. It took a little time to blow the cobwebs out of the brain to get it thinking in terms of machining again. The one thing I am not fond of with Shereline is that it is .050 per turn and I have to keep track of the turns. It would be far easier if it was .100 per turn but then it wouldn't be as precise. Two models you are doing. They keep me motivated to stretch my limits.

-

Tim, this stuff in legendary! Seriously nice work. I have been following for the last couple of months but not posted for fear of being chastised for not being at the bench. Now that I am back, I can be a bit more vocal. Great work. I look forward to each installment. Pete

-

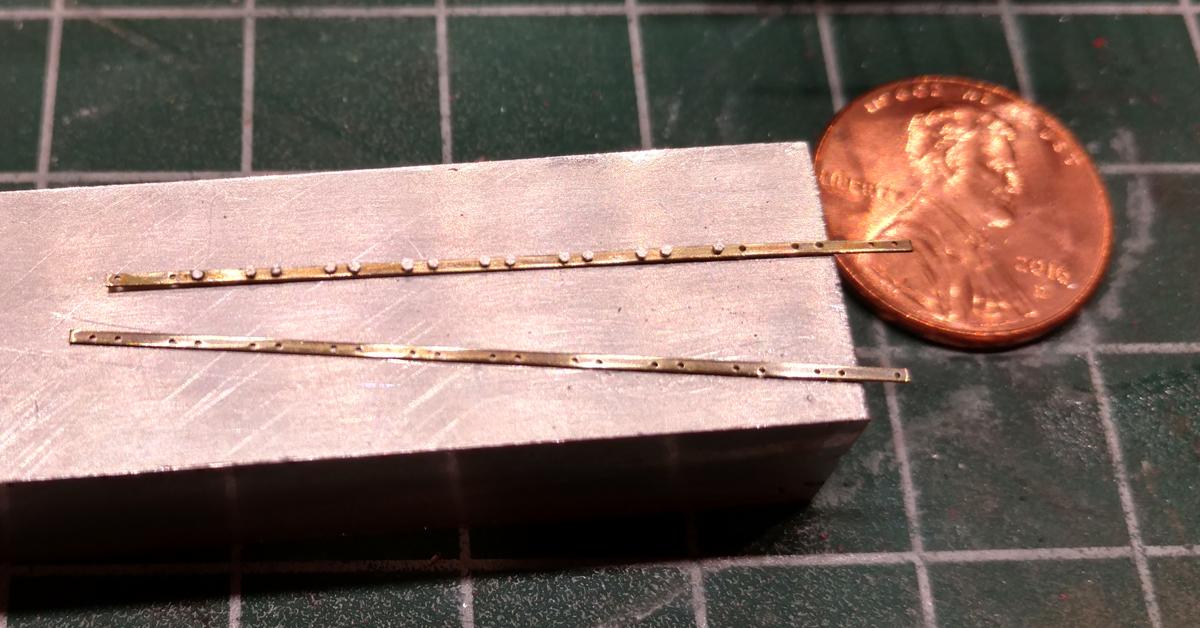

Ok, back on the bench again making little bitty parts. These are the seals that run the length of the valve covers. They are used where two pieces of sheet metal join on the real car. The brass strips are .030" wide and the holes are made with #79 wire gauge bits. The bolts are from RB Motion, and yes, I could make them but as Robert makes such wonderful parts at a reasonable price(well that is a mater of perspective) why would I spend my time making them. For those who were wondering where i have been for months, here is a photo of my other project. I have been working with wood for 40 years and still tackle large projects like this built in desk. Thanks for looking.