Oldmopars

Members-

Posts

2,058 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Oldmopars

-

First, I am not saying these will be offered, more of an question to address the viability of such a thing. For Semi trucks, if someone were to offer frames, would basic C channel be desired? Frames with drop fronts, specific truck style frames, etc? Next question, what would be MAX length? These would be printed with no holes, just straight frames with possible front details, but just long C-Channel cab back. I know someone offered brass at one point, but those were just long bent channel. I was just wondering if frames made to a max length that you could cut down would be of any interest. Any thoughts?

-

BTW, that is the very bumper that is on my 1965 Chevy C-10. That is what that one was modeled after.

-

Yes, the front with winch and rear with drop are what he has right now. I don't like to waste time on things that won't sell. If nobody buys them, it is time I could have spent on other projects that someone else wants. So, if these first bumpers sell and do well, I will be on board for making several more designs.

-

Grill design requests

Oldmopars replied to Texas_3D_Customs's topic in Truck Aftermarket / Resin / 3D Printed

Got a picture of what it looks like? -

So, I have been so busy on other projects, I kind of lost track of this one. However, I may have a new plan. I have been using a SLA (resin) printer to do these parts, but I recently got a FDM (filament) printer and have been playing with it. While there will not be the crispness that the SLA gives, the frame printed with FDM should be stronger, not warp and be an easy print. A little sanding and some primer should remove any layer lines. It will be a near future print for sure.

-

I will also be following. I have I have the Camaro, Firebird, 85, 82 and 65 Corvettes, 32 Ford and 2 Lindberg T Buckets all 1/8th scale. I'd like to add as much details as possible.

-

Check out Texas 3D customs, he has some nice stuff and does 1/8. He can get you an 1/8th 350/305 and a T5

-

Texas 3D Customs have the file and is ready to print them. You may have to ask for them.

-

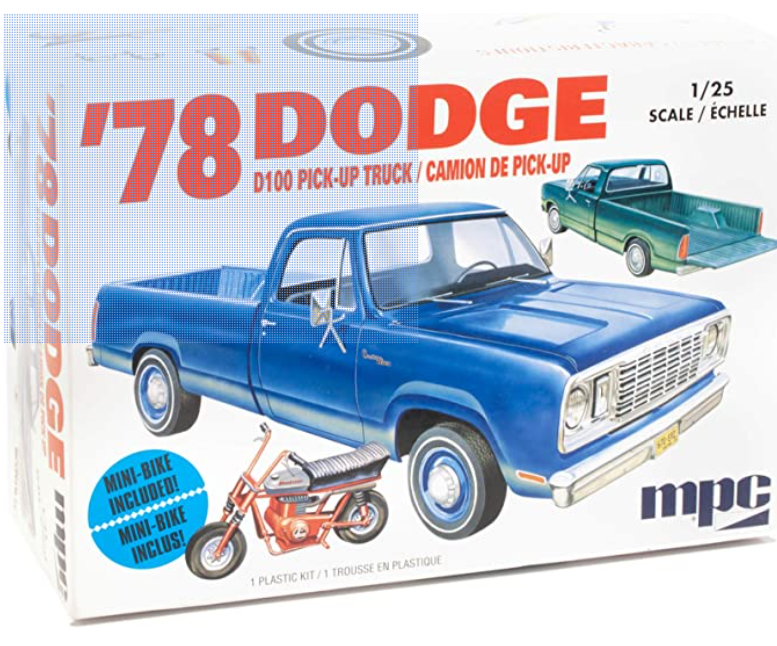

Well, to be clear, yes I have been messing around with them. Texas3D has one set now. However, these were set for Pick-ups and will be too wide for a Jeep. Making parts for an out of production kit is lower on the priority list that things we know will sell.

-

Building more than one kit at a time.

Oldmopars replied to ctruss53's topic in Model Building Questions and Answers

Having a really bad case of ADD helps, I have projects that I started over a year ago and not finished. I have some projects that I get an idea for, will add parts to the box and write the main theme on the outside of the box on painters tape. I go back and forth between projects depending on my mood or interest at the time. Putting all the parts back in the original box is one of the best ways to keep everything organized. However, some times 2 or more kits will be on the bench at a time. For me, my winters are very cold and I don't have an indoor paint booth. So, I build during the winter, paint and finish in the spring/summer. Other interests, hobbies, time, etc. all play a factor. I can be done, and I bet most here have at least 2 or more going at a time. Its just the nature of the hobby. Oh, and I was thinking my stash was getting big at 150+ kits, then I browsed a thread where guys here have 1000-5000+ kits. I don't feel to bad now. -

Yes, people are finicky. You build/Design what people ask for, then they complain. Price, its not made to fit this rare out of production kit, etc. I have also had, myself, been very interested in a resin body, had the money. But then it took longer than expected to get it done, and by that time my financial situation had changed and I could not longer afford it. It happens. I wish I could do 3d Design of model parts full time. My health is such that I will not be able to do what I do for another 10 years. I just can't see me being able to do design full time, there is just not enough money in it. So, for now it is a part time hobby that adds a little bit to my model budget each month.

-

Dodge Magnum V8 (318/360)

Oldmopars replied to olschoolkid's topic in Model Building Questions and Answers

You are right, I had forgotten that. I started mine, but got frustrated and put it back in the box. -

Dodge Magnum V8 (318/360)

Oldmopars replied to olschoolkid's topic in Model Building Questions and Answers

-

Yes, I get that. I was responding to someone saying that "Yes, 3D printing (either at home or someone selling printed parts) is the way of the future, but the quality is still not there." As for Resin casters, I am looking for a quality caster to do some casting of parts. I have some parts planned that I think would be better done cast than printed due to issues we are facing with printing certain parts. Currently the Ukraine seems to be leading the way in that area, even with all the current events in the area.

-

I agree with Bill. The quality is there if you know who to buy from. I can attest to this as I do design work for a top quality 3D printer. For example, when I design an engine, I use 50+ photos, gaskets scaled to size, measurements from real engines, scans, etc. The latest engine I just finished is as close as you will ever find to the real thing. I know this as I used the real thing to design it. I have the real engine, I measured it, took pictures of it, used scans of gaskets, etc. to get it as perfect as possible. 50+ hours of design went into that one engine alone. Then, Charles prints these engines to the highest level of quality. He knows some VooDoo magic that I can't recreate at home. As an example, look at the Slant 6 below. Try to find that detail in either a kit or resin. Check out Texas 3D Customs, you will see very high quality products are available, and at a reasonable price.

-

I agree. As a matter of fact, I am looking in to the possibility of using both in the near future. There are limitations to 3D printing. Somethings are difficult to get all sides to look right every time. I thinking about making one good master print, then seeing about having the rest cast. However as you pointed out, many of the great casters are closing up shop, so finding someone to cast my prints is not easy.

-

I can see both sides of things. I have a 3D printer, I do my own designs, I even sell some. It's not a cheap hobby to get into. A printer can be $300+. Resin is $25-75 per 1000mg. The act of designing can be daunting to many. However, getting into resin casting, to do it well, is not cheap either. Good pressure pots, silicon casting molds, the resin, is all costly too. Molds wear out. You have to master one in ever size you plan to sell. A casting is only as good as the master, making good masters is a real skill. In 3d printing, we often design a part or engine, or whatever in full scale. I do all my engine designs in 1:1. That way if someone wants a 1:32 or a 1:8, it is just resized in the slicer. Evolution of the hobby, well yes. People aging out, possibly. Some are attempting to run a business and a full time job and finding that life has gotten in the way. I do think 10 years from now, the resin cast parts will be few, and overshadowed by 3D printed parts. When it comes to details, you just can't beat a 3D print, if the designer put them there. 3D printing not for everyone, nor is resin casting. I hope the aftermarket continues for many more years.

-

I will have to think about these. Super easy to draw, like 3 minutes. The issue will be printing them. If done with normal resin, they will print, but I fear they will warp due to the small size. I also am worried about them just breaking due to the size. I have 2 possible thoughts on this. 1. print them as part of a panel. Like in the picture, they would be attached to a flat sheet, you would then either cut it off, or graft the panel into the model. Option 2. There is a tough rubber resin. It is black (or clear) and the parts would not break, very very strong. The down side is price. This resin would be 2 times the cost of normal. So, these parts, while printed in a very durable black rubber like material, would be a little more cost. Now, I don't do the printing, so this would be up to Charles if he even wanted to bother, but just know these come with a bit of a challenge just due to the size and shape.

-

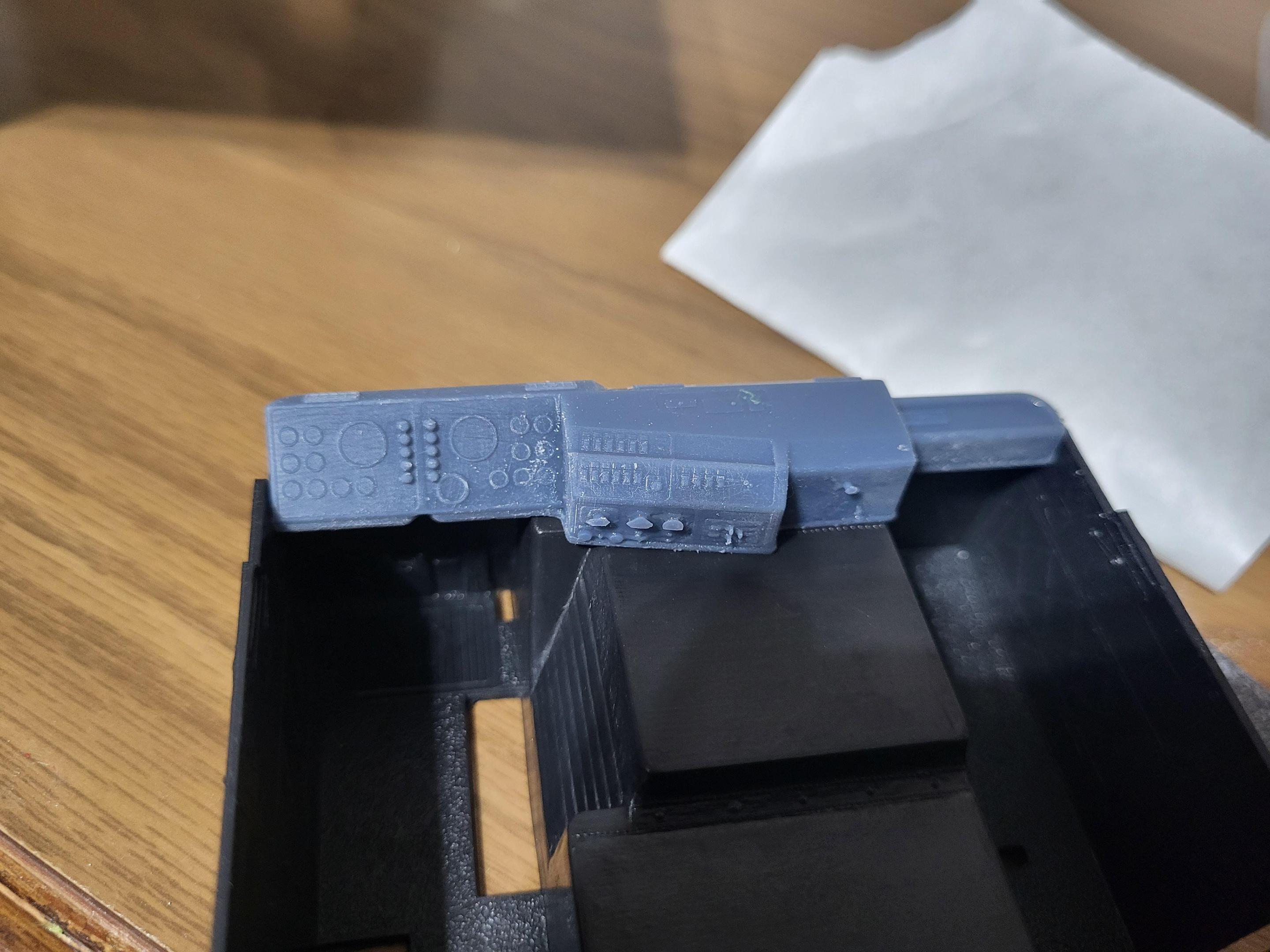

Ok, I got a good dash to print out. I should have cleaned it a little better, so ignore the shiny spots and fuzzy areas, that was me. I'm going to go back and increase the size and depth of a few things. While they are the right size in scale, once printed it would be very difficult to detail as the features are just too small. They printed, they are there, but good luck painting them. I discovered this on things like panel gaps. You have to exaggerate them a bit in scale, so that once printed they show up well enough to clearly detail.

-

3d White Freightliner cab sorely needed

Oldmopars replied to leafsprings's topic in Truck Aftermarket / Resin / 3D Printed

I will look into it. Right now we are still working on getting the W1000 Ford cab to print in a way we are happy with. Once we get past this little hurtle, many more cab options will be possible. -

Well, I ordered the new/repop Blazer pull dozer. Maybe there will be more demand now and that will help me get it figured out.