-

Posts

128 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Chris B

-

That would be great I do buy a lot already from the states and accept that shipping is gona cosr

-

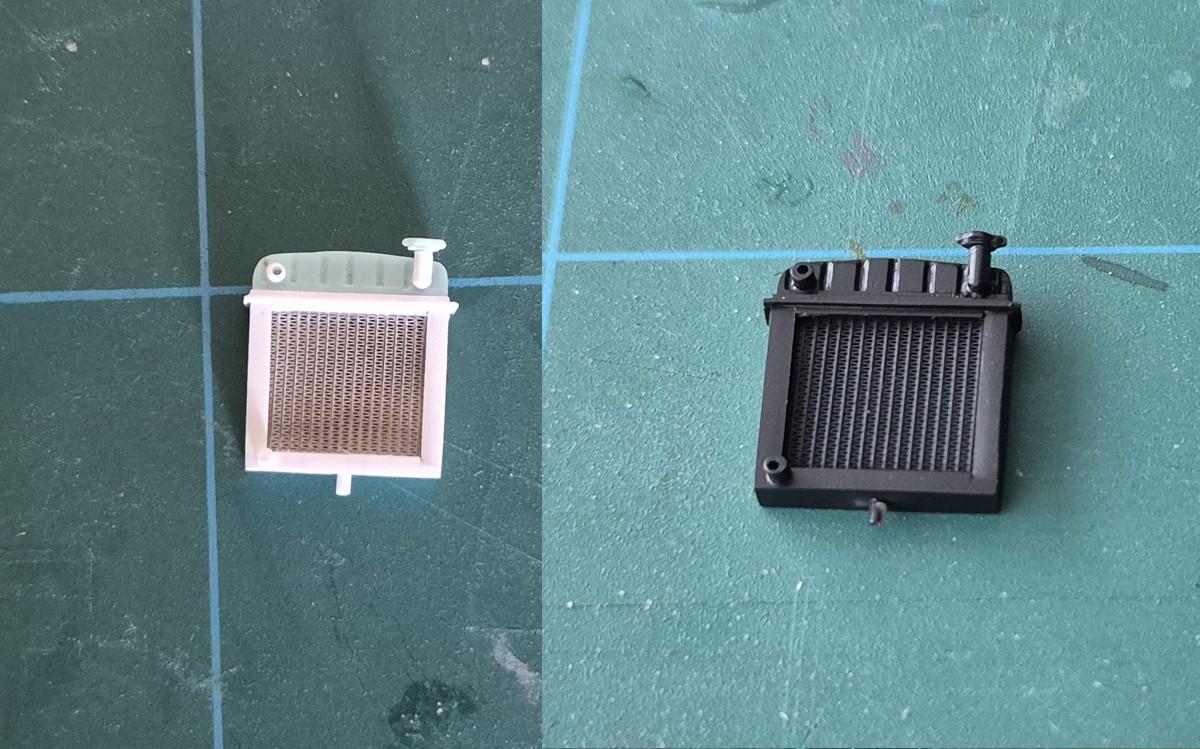

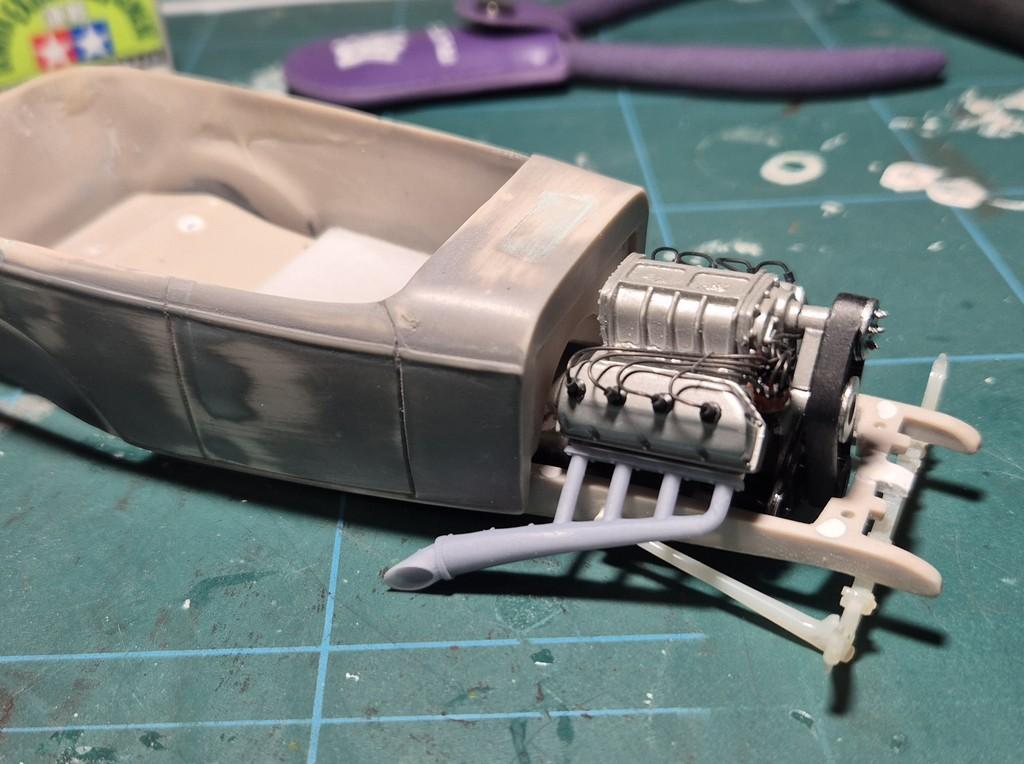

Pretty happy with how the radiator came out, what a difference a bit of paint makes Just to change the subject a bit 52 years ago I built what has always been my favorite model Tom Daniels Quicksilver. At some stage in that 52 years the model disappeared off the face of the earth, I have parts of it in my parts stash and I have always hoped that someday I would stumble across it packed away in a box that I haven't opened in a long time. I recently found a built Monogram 32 Ford roaster that I built as a teenager packed away in a box that I hadn't opened since I moved into this house 25 years ago. I have been searching the internet for at least 20 years in the hope I would find one for sale and when recently putting the question out there on a Facebook model forum I belong to some had a slightly tired built up model that they were willing to part with I have big plans to restore this model in the near future with a little bit of a modern twist but staying true to the original model

-

I have been thinking about it there is not enough room behind the radiator although after this photo was taken i trial fitted the grille suround and found that I need to move the radiator forward as it is too far away from the surround I haven't yet found a suitable electric fan I did think that I could fit a blow through fan in front of the radiator behind the grille if I can find something to fit

-

Radiator a lot closer now Just the filler neck and radiator cap to fit now. If glued a pin to the bottom of the radiator to locate it in the correct place. That big Hemi is a bit of a squeeze between the cowl and radiator but it fits

-

Thanks David

-

I found a suitable radiator in my parts box originally from an old release Monogram 53 Chev. It was mounded complete with Rad core support and horns, I cut the core support and horns away from the radiator and through them back in the parts box as those horns could come in handy at a latter date. It was too wide so i cut the width down a little and made a frame from styrene so that I could slide two pieces of the photo etch radiator face into it spaced apart with a suitable wide strips of styrene. A little more detailing, adding the inlet and outlets to the top and bottom tanks and as well as the filler neck and radiator cap. I will also add some thin strips of styrene around the bottom of the top tank and top of the bottom tank to mimic the flanges that the tanks are soldered into. I may also reshape the top tank a little to get ride of the bump where the original top rad hose fitting would attach. The grille surround is now the correct dimensions for the grille to fit neatly I will add the crank tube to the apron and some styrene tubes glued to the rear of the apron that will correspond with some wire pins glue to the front of the chassis cross member so as to mount the grille and surround to the chassis I'm going to do something similar with pins glued into the bottom of the radiator bottom tank that will slide into holes drilled into the top of the same cross member.

-

Back to work next week Unfortunately I didn't get to do much modeling It was a little hard to sit at the bench

-

Love this car Those wheels really set it off I've been looking for wheels like that for one of my projects

-

Awesome build Dan I have been off work for a while now Dan recovering from a hip replacement and got pretty bored with watching TV so I started watching YouTube model building channels and discovered yours and I have to say I love it I have watched every video more than once Your models are all exceptional you are clearly a talented builder.

-

Managing to get a little bench time this morning between Dr and Physio appointments. After cleaning the grille surround up I noted that the photo etched grille I have is for the Revell 32 and the early Monogram grilles are a little different dimension wise. I pulled out a Revell model I have and confirmed that the grille fits nicely. rather than use the Revell grille surround I decided to widen the Monogram one to suit. First of I cut the grille shell in half perfectly in the middle at the top and inserted a piece of styrene sheet in the split making sure that the surround was flat on the mat and that the styrene also sat flat on the mat. This way the surround remained square, I glued this in with Tamyia thin cement. Once it was dry I trimmed back the styrene to a closer shape and checked the Grille fit, it looked good so I continued on and cut the bottom of the surround and inserted and glued a a piece of styrene sheet into the bottom of the surround

-

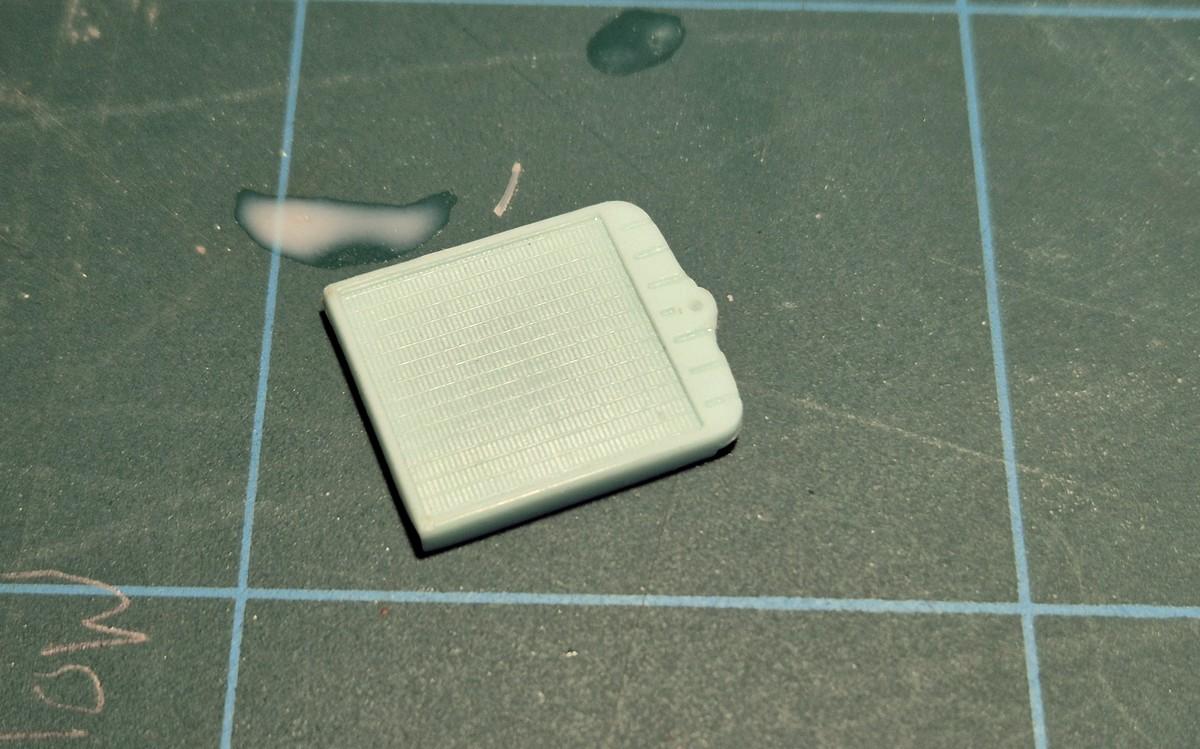

Well while I've been of work recovering I ordered a few goodies for this and another model namely a photo etched radiator face and I already had a grille put aside. The radiator is molded as part of the grille surround on this kit so I got out the scriber and scribed around the inside of the grille shell. And sanded down the back until I reached the scribe With a little bit of smoothing and some more material removed from the top back to more simulate a better surround thickness this should be good

-

And they wear out with time

-

My dehydrator is a good size, I did think of that and checked before I got too far to check that it would fit

-

-

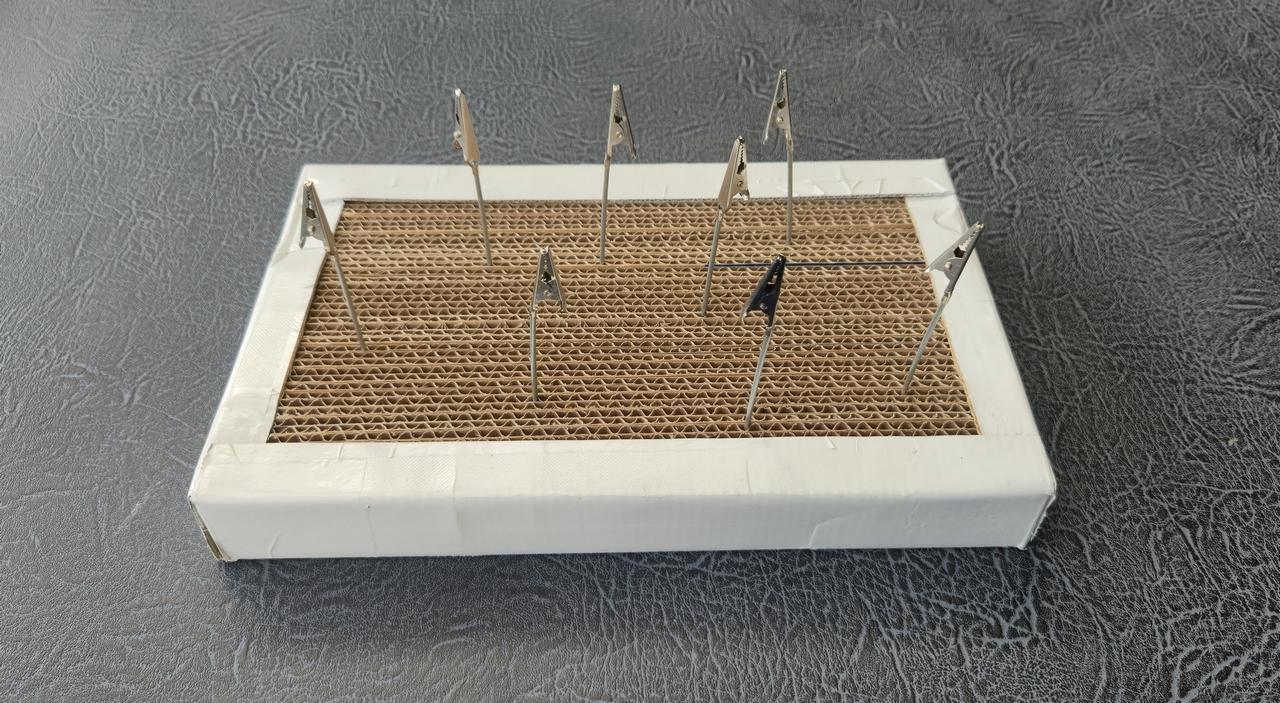

I saw something like this on a YouTube clip the other day and it got me thinking. I rummaged through the local supermarket cardboard box pile looking for a suitable corrugated cardboard box with suitable sized coronations (With there permission of coarse) I cut strips using the width of a steel ruler to get all of the strips the same with an hobby knife cut them all the same length to fit into an old shoe box that a model kit came packaged in that I had brought online. Once I had enough of them I glued them all together with PVA glue. I cut the shoe box down to the desired height and then glued the stack of cardboard into the box and folded the top of the box down to form a frame. The lid still fits the box to protect the coronations when not in use I think I have got a pretty good useful clip holder for next to nothing the only thing that cost me anything was the PVA glue and I brought that over 20 years ago

-

Thanks David Yes some early vehicle did have leather boots on the driveshaft. I originally planed on painting the driveshaft tube (Bear in mind it is only a tube not the driveshaft as the driveshaft runs inside the external tube which acts as a locating device and is attached to the end of the gearbox with a ball and socket arrangement) aluminum color and then I saw a full sized vehicle with a similar diff arrangement and the nugget was the only aluminum part, Now I'm not sure how I want it to look.

-

Well it's been 3 weeks today since I had surgery to replace my right hip joint, all has gone well and today I felt like I could sit at the bench long enough to do something. it's not much but I got a bit of color on the rear axle and shocks. I'm contemplating whether I should paint he driveshaft tube aluminum also, what do you think?

-

Thank you all for your wishes, much appreciated

-

Looks nice. Should be a sweet build when finished

-

Well it looks like I may not be getting too much done on this build in the very near future. I have finally got my appointment for my total hip replacement and it is only a couple of weeks away baring any issues. About a month ago I had to have a CT scan with contrast die added and the next day I broke out in a total body rash that has mostly healed up because of the cream they gave me to smother myself in but unfortunately there are two spots where it has not completely heal one being on the hip right on the site that the incision will be. When I had my pre-opp appointment yesterday they were not happy with this and have insisted that I see a GP Nurse at my Dr surgery everyday for the next week to monitor the rash, photograph and measure it and do everything possible to get it to heal in one week so that at the end of that week they can decide if they are going to proceed with the opp I have also purchased a new PC that I am currently transferring everything from my old PC to the new one so I will not have too much time spare to work on the model between now and surgery. I am hoping to finish painting the rear diff and shock absorbers however. I will then pack it away until I am sufficiently healed enough to sit back at the building bench

-

Thanks David I really appreciate it

-

With the rear end finished I threw some color on it and while waiting for it to dry I moved on to tackling the exhaust starting with the Lakester style headers. I had to make a wedged shape piece of styrene to glue between the head and header flange to raise the angle of the primaries up so that they would not interfere with the chassis rail/ I took this opportunity to drill some holes and super glue styrene locating pins to the header flanges. It is my intention to run an exhaust pipe out of the back of the headers under the vehicle some how.

-

Beautiful model. What do you use to paint the exhaust/trans etc?

-