Kingslug

Members-

Posts

109 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Kingslug

-

Your having aa better time with it than me...takes so long to do a few things. Oh..and it looks like the directions for the rear suspension are wrong about a few things..The tension shocks are upside down..the 3 spring goes on the bottom...not worth removing as no one..but us will know. Found that in another build diary. Apparently Italeri issued corrections in a later run of the model.

-

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

OY..further research shows the suspension directions are wrong. The rear suspension tension shocks are supposed to have the 3 springs on the bottom and the 2 on the top...I'm leaving it..too much to risk taking it apart. Italeri did not do all their homework..oh well -

This...is cool!

-

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

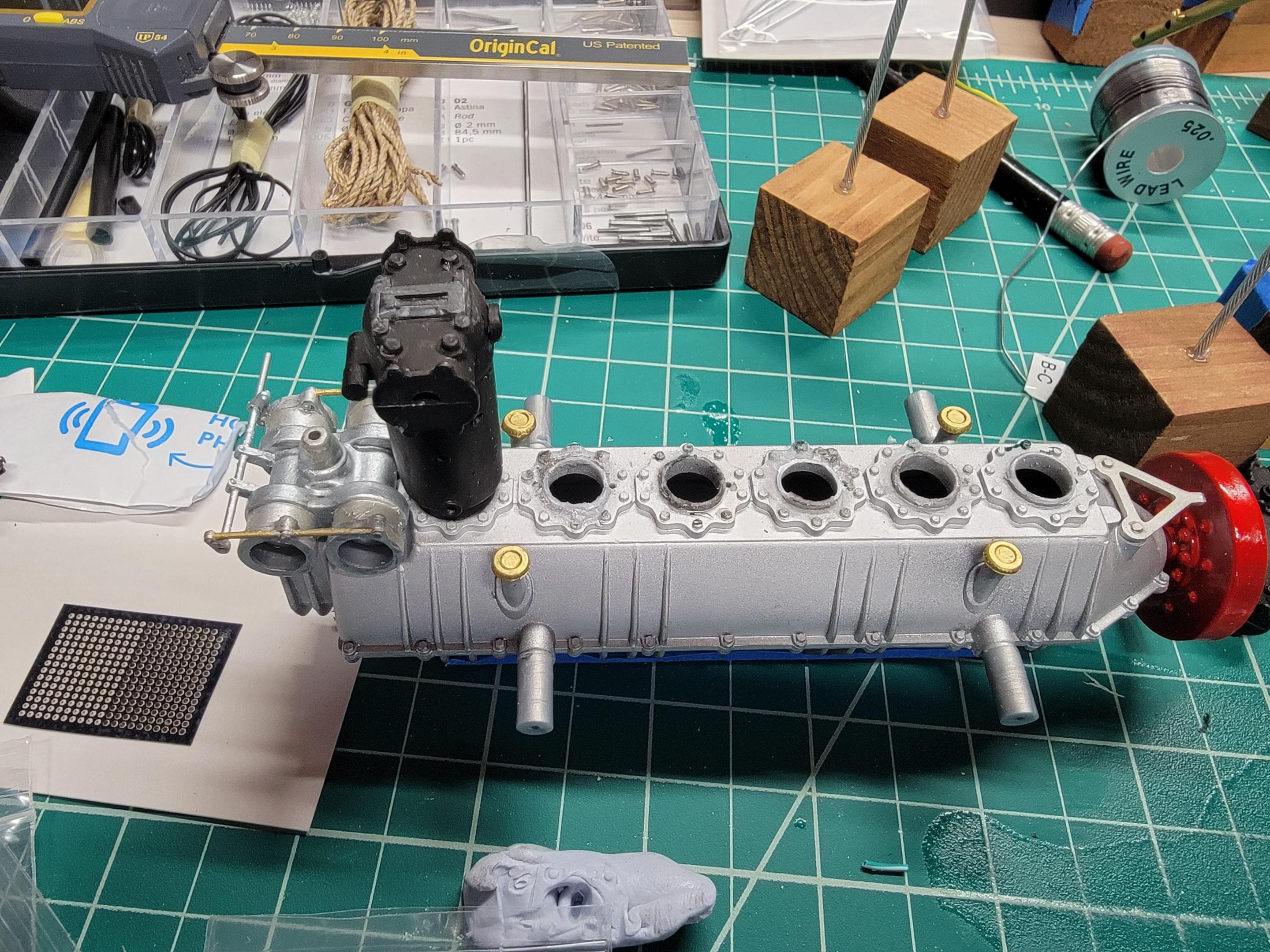

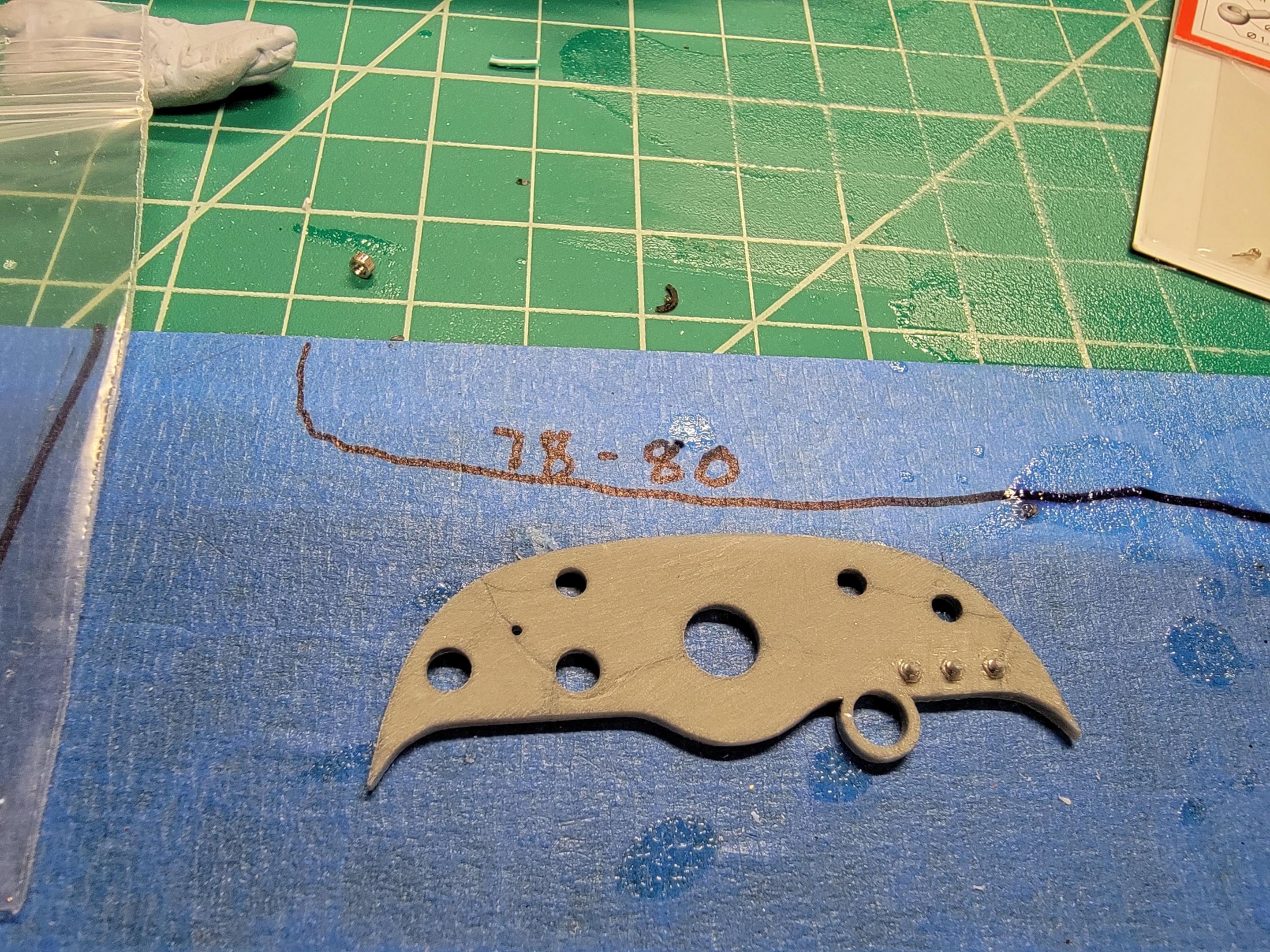

Decided to finish painting some motor parts with the AK paste..comes out pretty good. Started on the dash by sanding all the marks off it..now trying to come up with toggle switches to replace the nubs. I could buy them but they cost a fortune when shipping is added. Going to try brass tube and some small nuts. My new phone takes better pics than my camera! -

Mclaren M8B...

Kingslug replied to 4mula1fan's topic in WIP: Other Racing: Road Racing, Land Speed Racers

The definition of...fiddly bits -

Leon CVSTOS AMG GT3

Kingslug replied to harti20's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Looks good..how do you take pics..they look great. -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

True..you dont see much of the cylinders buried behind all the stuff though...maybe ill work on the wood parts -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Wow..just spent an hour trying to find tubing in these sizes..ended up with 14mm tube from an aquarium store and some 11mm from Amazon. -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

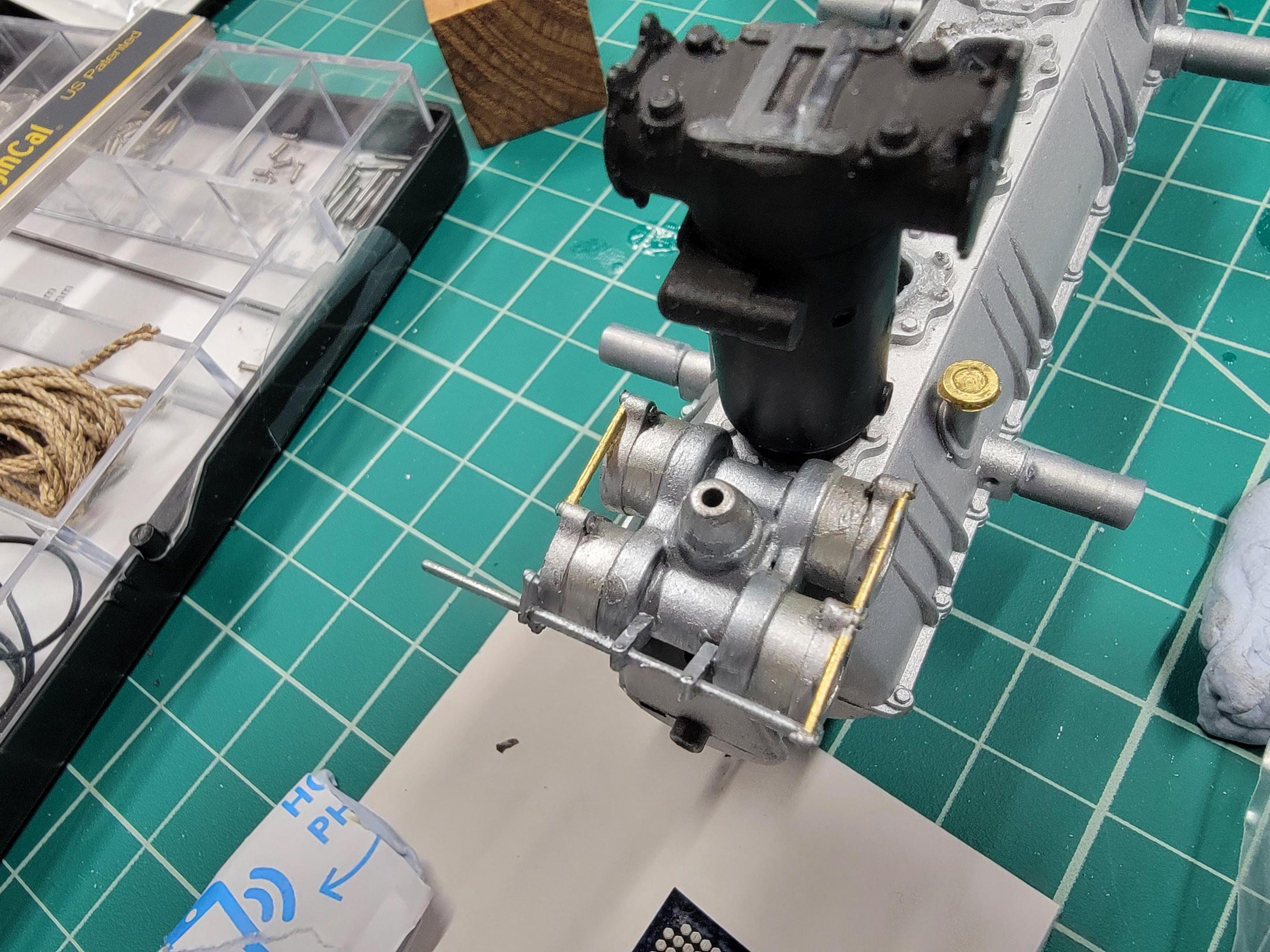

Well..big screwup..when the glue spilled all over the place i was trying to cement the barrels to the block..and last night saw i had 5 of them upside down..had to tear them apart to get the valve bodies off..so now i have to figure out how to make them..i guess styrene tube or rod..wish i had a lathe..going to add a lot more time..and i was already to start attaching things.. -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Each piston is the size of a whole 8cylinder 350 cubic inch motor. All that to make 300 hp. -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

This is a great pic of the motor -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

I'll check it out! -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

This is a nice build -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

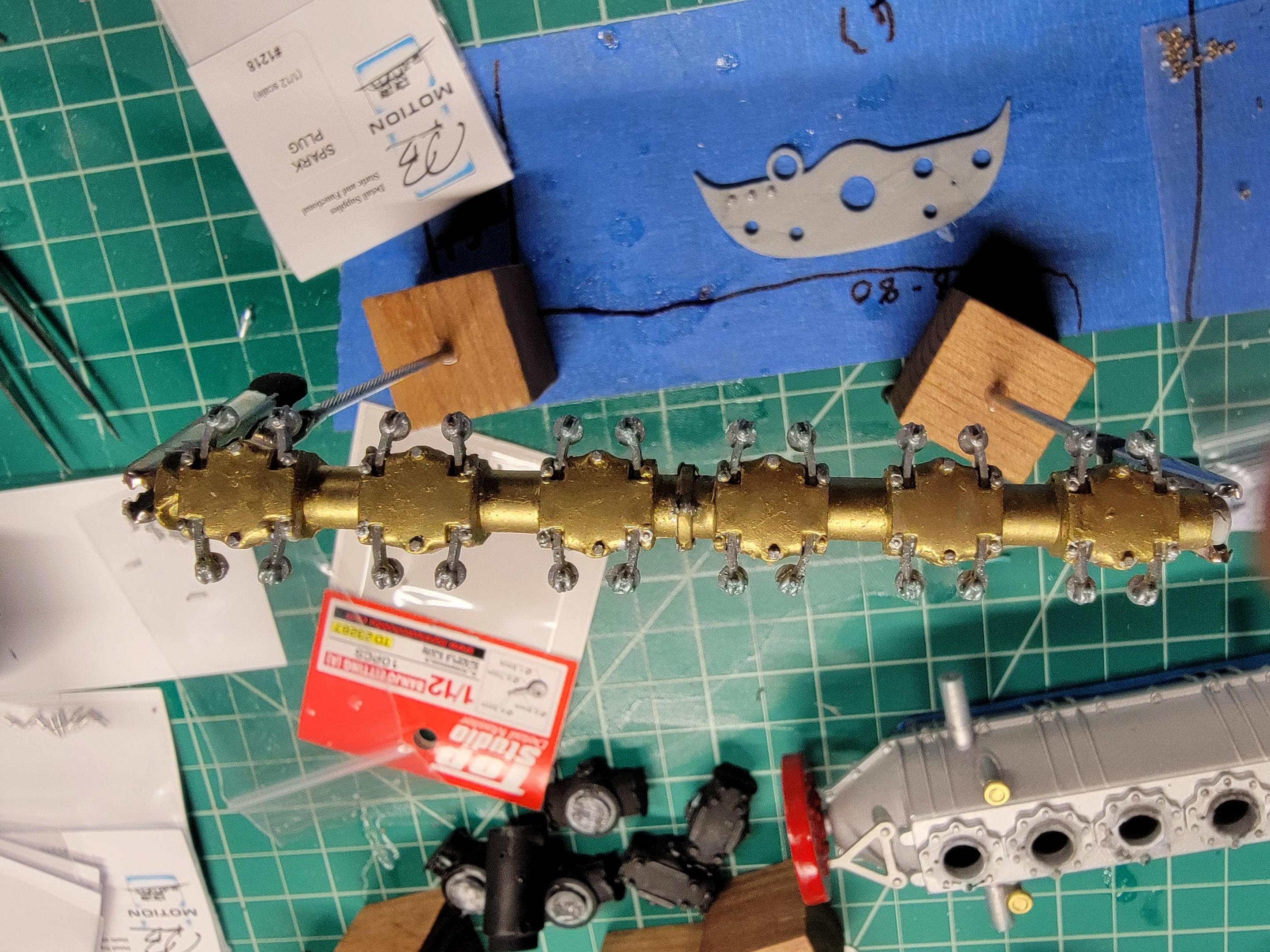

I saw a build diary about that. He simulated the soldering with putty I believe then used copper foil..I've been using the AK metal paste and i like the way it looks..its just not very durable if you handle it too much. So far I've been adding all the little bolt heads to the rocker heads and some other parts..but my internet cables got ripped down and are all over my driveway..so no pics. The hardest thing will be the springs. I'm going to use lead wire and wrap it around a tube cut exactly to size..then cement it to the valves..then cement the rocker cover and camshaft on top of them..going to use JB weld so I have lots of time to line it all up. Theres a whole build diary on that..i'll see if i can find it..I printed it up. -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Not much but it took an hour to get these tiny PE bolts in place..makes a big difference..color is by AK True Metal..a wash will come later to dirty them up Good thing I have a lot of good pics of the real thing -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Finally got all the suspension on the frame..now I either keep working on the motor or start the body -

Italeri Alfa 8c- WIP

Kingslug replied to jaymcminn's topic in WIP: Other Racing: Road Racing, Land Speed Racers

This is great!!...maybe..my next build? and I can cheat and copy some stuff you did..as I certainly could do no better... -

This is great..really moving along..sadly my time is limited but I can see what your doing to check im moving in the right direction. I messed up and wrapped the springs fully..now I can find the locating hole..guess once I try to put it on it will align right.. I'm going to try to make my own stencil and just...copy what you did!

-

Model factory hiro Porsche 935/78

Kingslug replied to Brudda's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Amazing stuff...really need patience and time for these. I watched the video on his factory..very cool how they make all the parts..and its whatever he comes up with. -

Restoration of a Porsche 934

Kingslug replied to kpnuts's topic in WIP: Other Racing: Road Racing, Land Speed Racers

Looking good... -

Fiat Mfistofele

Kingslug replied to Kingslug's topic in WIP: Other Racing: Road Racing, Land Speed Racers

I'm using the AK interactive glop for brass, aluminum and steel...interesting stuff..not paint but a pigmented wax..goes on very smooth and a little goes a long way. Only thing is you can't use regular panel line accent on it..it will eat it..so "im going to make some from oil paints I have..the stuff also can be mixed with oil paints..I'll use that to dirty up the motor as this motor spews as much oil as it burns.