-

Posts

1,678 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Jürgen M.

-

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Those seem to be even better in size! Thanks for the Info! Taking notes like Gary! -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Good luck! ?? -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

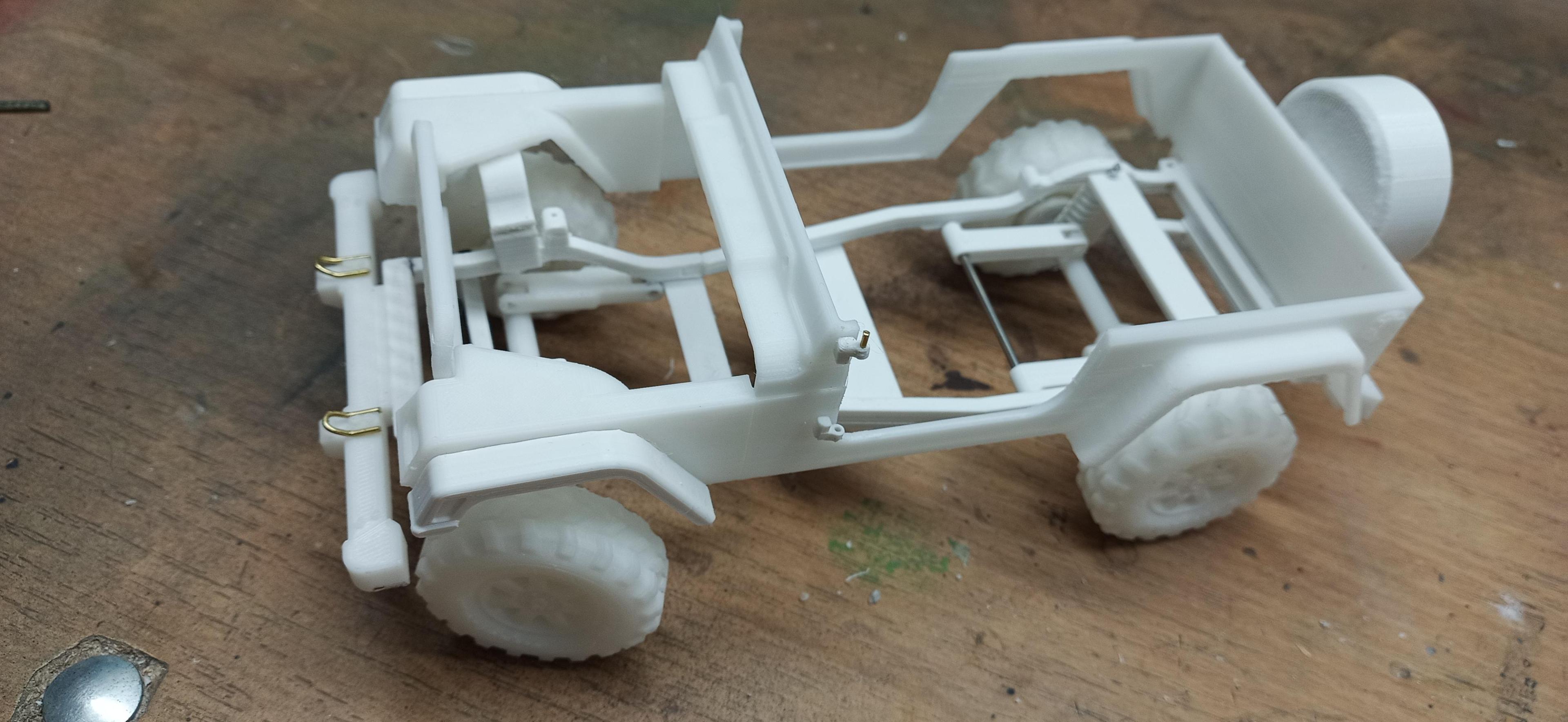

I actually printed hinges myself once when I built the TJ! Worked out pretty well but they're quite fragile too. Had to reprint them a couple of times. -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

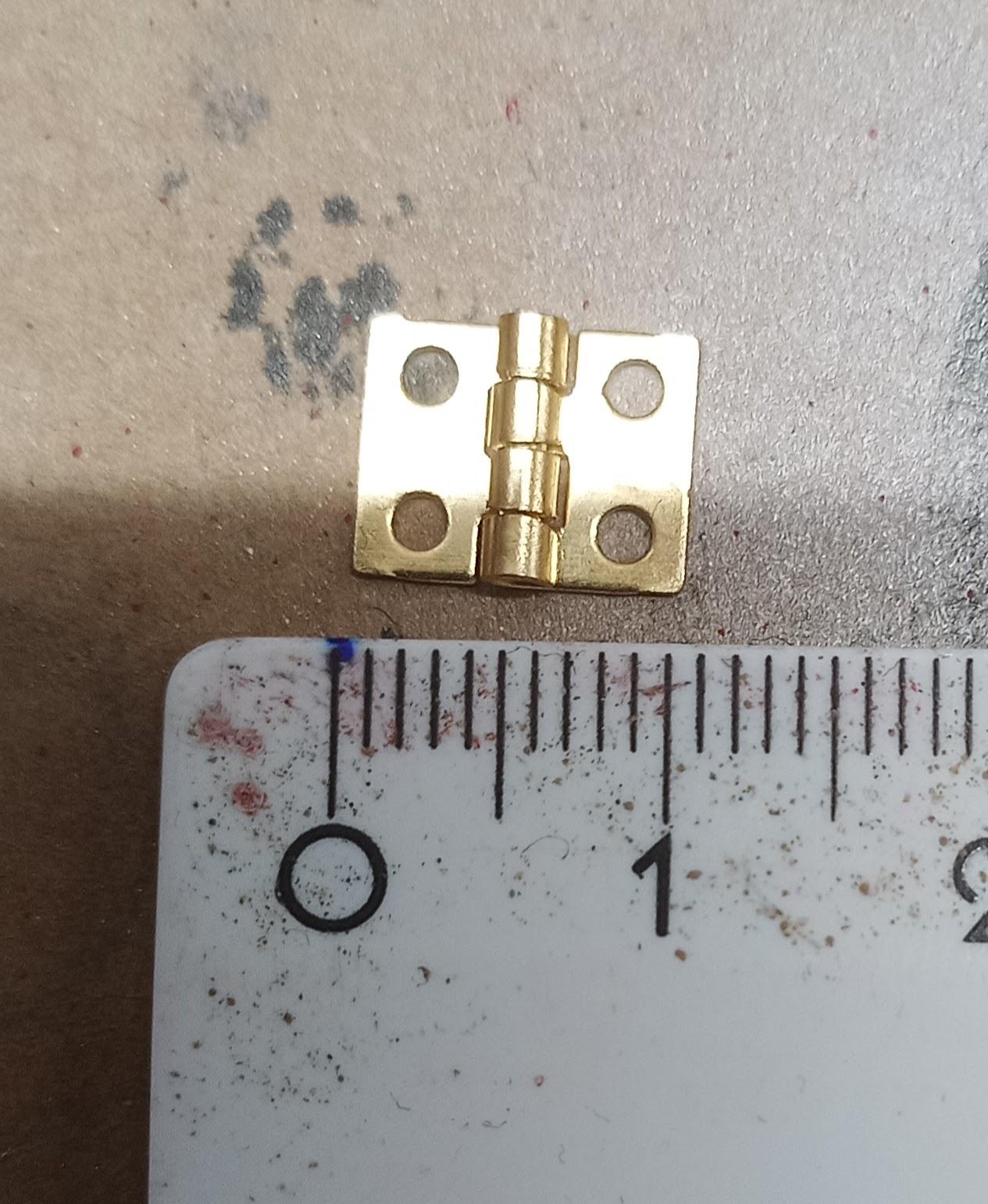

You guys are really full of good ideas! I used these hinges for the doors of my Pete: They're 8 x 10 MMS, 0.5mms thin. They work great. Available at Amazon! -

The Same but “ a little “ Different

Jürgen M. replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That is absolutely true! I can only agree! Of course it's nice when parts just fit without a lot of rework (Talk about the Ertl CO4070). A dream for anyone WHO despises extra work! But yes, it is much more satisfying when you have to search you brain for good ideas how to straighten a chassis or carefully smoothen surfaces and edges! Taking that as a measure, printing parts is modeling XXL! There's no part that goes through without rework! At least not from my printer! You guys have the true modeling spirit and I really appreciate that! -

Pete 352 day cab

Jürgen M. replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks very much Jeff! ? I really appreciate it! Keep on truckin' Pal! -

Pete 352 day cab

Jürgen M. replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you Gary! ? -

Tigercat 880E longer 1/48 scale

Jürgen M. replied to François's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

? Don't worry Steve! This is not a competition my friend! If it we're, I would never be able to compete with the knowledge all you guys have about trucks! I think it would be quite even! ? -

Tigercat 880E longer 1/48 scale

Jürgen M. replied to François's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Yes, I'm sure! Thanks very much for your advice and experiences! I think I'll give that a serious thought. I use the Cura slicer! Seems to be pretty good! I don't have any experience with others though! -

Tigercat 880E longer 1/48 scale

Jürgen M. replied to François's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks for your opinion Francois! I just had a look. It's really not that expensive! Is there anything to pay special attention to, when you switch to a resin printer? -

Pete 352 day cab

Jürgen M. replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Steve for your nice words but your work is amazing! Your ideas and skills converting a fairly detailled 1/32 snap kit into a full grown and highly detailled 18-wheeler are just unbelievable! -

Tigercat 880E longer 1/48 scale

Jürgen M. replied to François's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Francois! Yes, I agree, the orientation of a part in the slicer is very relevant for the quality of the part. Also sanding is important but not always possible! The filament gets very hard and you can hardly achieve any improvement by sanding, especially when you have small or very detailled parts. I use PLA and an Ender 3 V3 printer. It's a good combination but still needs improvement and for a hobby I'm not willing to pay a lot of money for a better printer. I'll give it a thought though! -

Pete 352 day cab

Jürgen M. replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

When I look at my printed models I do feel a bit disappointed to see all the effort and still no immaculate surface! I decided to try out a smaller nozzle next time. It slows down your print but it's supposed to improve the surface in form of less or not as visible printing lines! The primer filler is ok but still it doesn't do the job. Too many layers of primer and paint also ruin the surface. Anyone have any other ideas? -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

I think your stuff looks pretty cool! Very nice looking parts! Can't wait to see more! -

Pete 352 day cab

Jürgen M. replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

-

The Same but “ a little “ Different

Jürgen M. replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That looks really good Jeff! Seems the cab is of good quality! I remember building my Pacemaker. It had quite a few "disturbances" in the cab surface and other parts! Keep going, it's going to be a great build! -

Tigercat 880E longer 1/48 scale

Jürgen M. replied to François's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Very nice prints! Can you tell me which printer you're using? -

Pete 352 day cab

Jürgen M. replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thank you! ? I try! -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

If you're interested, my ACX is in this WIP in page 5. The cranes aren't telescopic but self designed and printed, just like the whole truck! -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Paul! Very nice of you! I'll have a look at them. Maybe I'll find a use! I'm always looking for new interesting projects! -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

That would be great, Paul! Thanks! I've never worked with TinkerCAD before. Is it easy to use? I work with Autodesk Fusion360. Quite easy to learn! -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Thanks Paul. Didn't you say you printed the crane parts? Did you get the files from the internet? I've also downloaded one or the other file but I enjoy designing too. Anyway, your build is coming along great and I'll keep watching with big interest! -

Pete 352 day cab

Jürgen M. replied to Jürgen M.'s topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

The doors fit and work! The Driver seems to be a Harley fan! ? Now my absolutely Not favorite Part comes! Cutting the window pieces to size! But it's part of the deal so I won't complain! The lower window in the passenger door is a piece of 0.5mm transparent foil put between the doors and the panel! -

Service Truck Kitbash

Jürgen M. replied to PHPaul's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

This is going to be a great build! Keep going Paul! I like the crane! Reminds me of how I printed the two cranes for my ACX! It's a great Feeling when you put it together and it works! -

The Same but “ a little “ Different

Jürgen M. replied to Biggu's topic in WIP: Model Trucks: Big Rigs and Heavy Equipment

Wow, Jeff, that's a great curriculum of Hayes! Amazing knowledge! Thanks for sharing that! I like the one with the the Mack cab! Could be an interesting build! I didn't want to build another Mack since I've got five already but that would be a nice way of going around it and still having an F700 cab!