-

Posts

4,405 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Everything posted by Lownslow

-

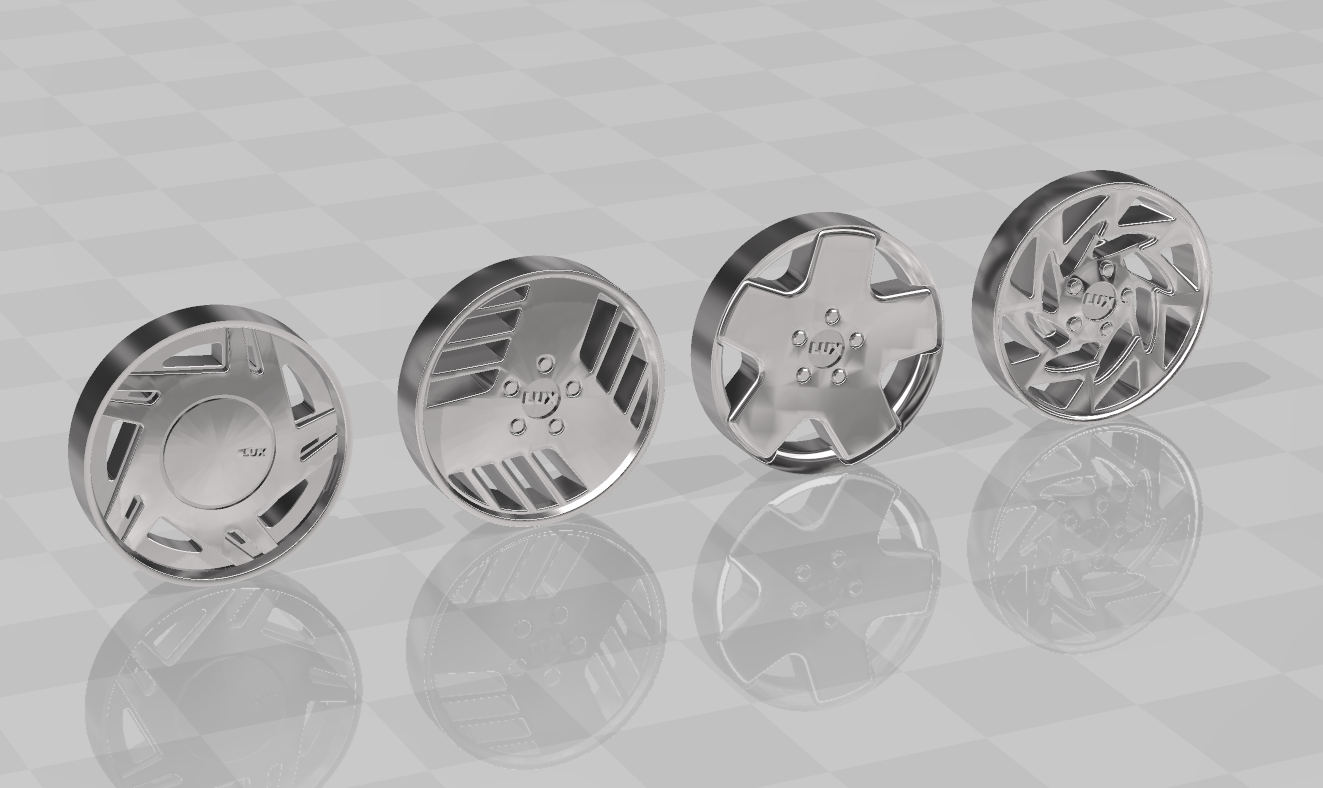

I corrected the issue by making 17" versions of the factory wheels even added the pontiac turbos for fun currently working on the tires

- 39,241 replies

-

- 2

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

- 39,241 replies

-

- 4

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

- 39,241 replies

-

- 4

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Something for the truck guys

Lownslow replied to Lownslow's topic in General Automotive Talk (Trucks and Cars)

lift kit alone will cost more than 12 and none of it looked like it was permanently attached to the base -

Something for the truck guys

Lownslow replied to Lownslow's topic in General Automotive Talk (Trucks and Cars)

around 12$ if i remembered right -

Tractor supply has these 1/32 trucks at the door the suspension, wheels and tires are 1/24. the Tires are roughly 33/34s in 1/25

-

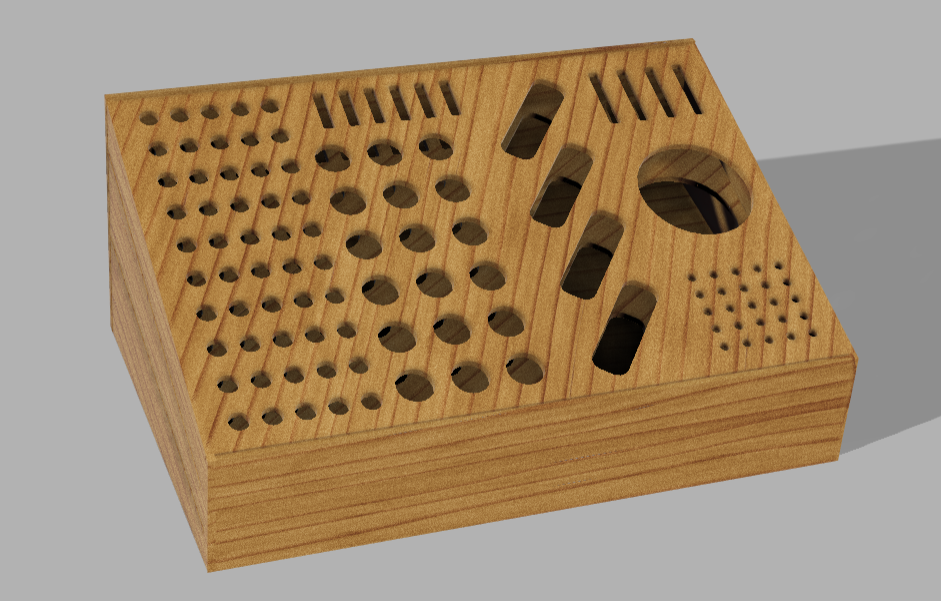

i bought a scratch bot 1000. Time is a luxury i cant afford to waste trying to scratch build things all the time

- 39,241 replies

-

- 3

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

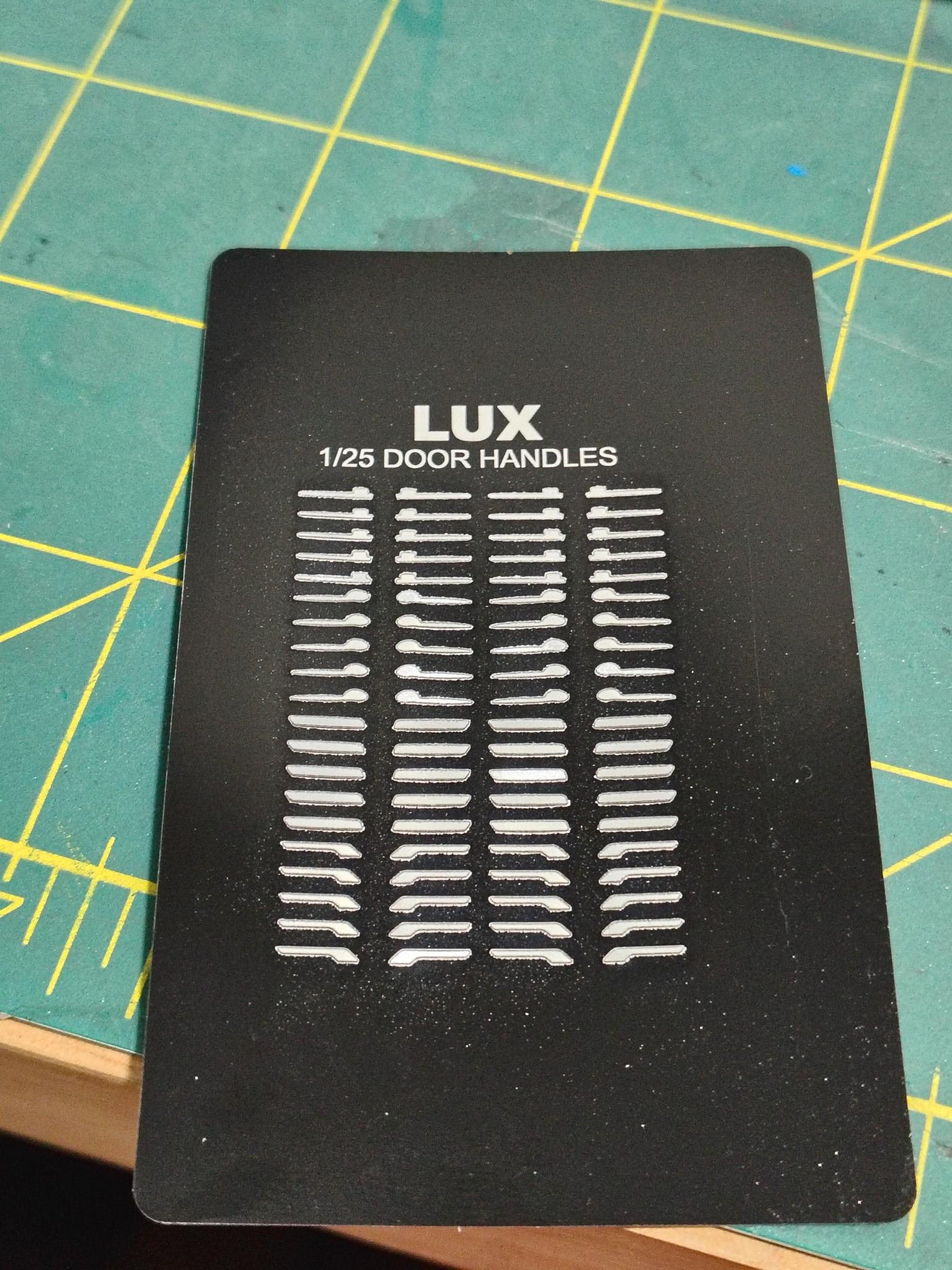

Photo etching at home

Lownslow replied to drummerdad's topic in Car Aftermarket / Resin / 3D Printed

Im pretty good about offsetting costs, especially the engraver, when im not making model parts im clearing about 200-400$ a month making slate coasters and pet headstones. The laser is pretty easy to manage its small and the software is user friendly. -

- 39,241 replies

-

- 10

-

-

- johan

- glue bombs

-

(and 1 more)

Tagged with:

-

Photo etching at home

Lownslow replied to drummerdad's topic in Car Aftermarket / Resin / 3D Printed

-

Theyre only being used for special events 3 of them already got damaged due to lack of experience by their officers

-

-

Revell of germany kit but honestly its nothing worth raving about because the pillars were virtually bent in all 3 purchases i made

-

i love seeing these built as they really are a bear to put together, nice work on the stance

-

The new Charger

Lownslow replied to Jon Haigwood's topic in General Automotive Talk (Trucks and Cars)

Theres one driving around sema its giving off Dodge Avenger with a v8 vibe -

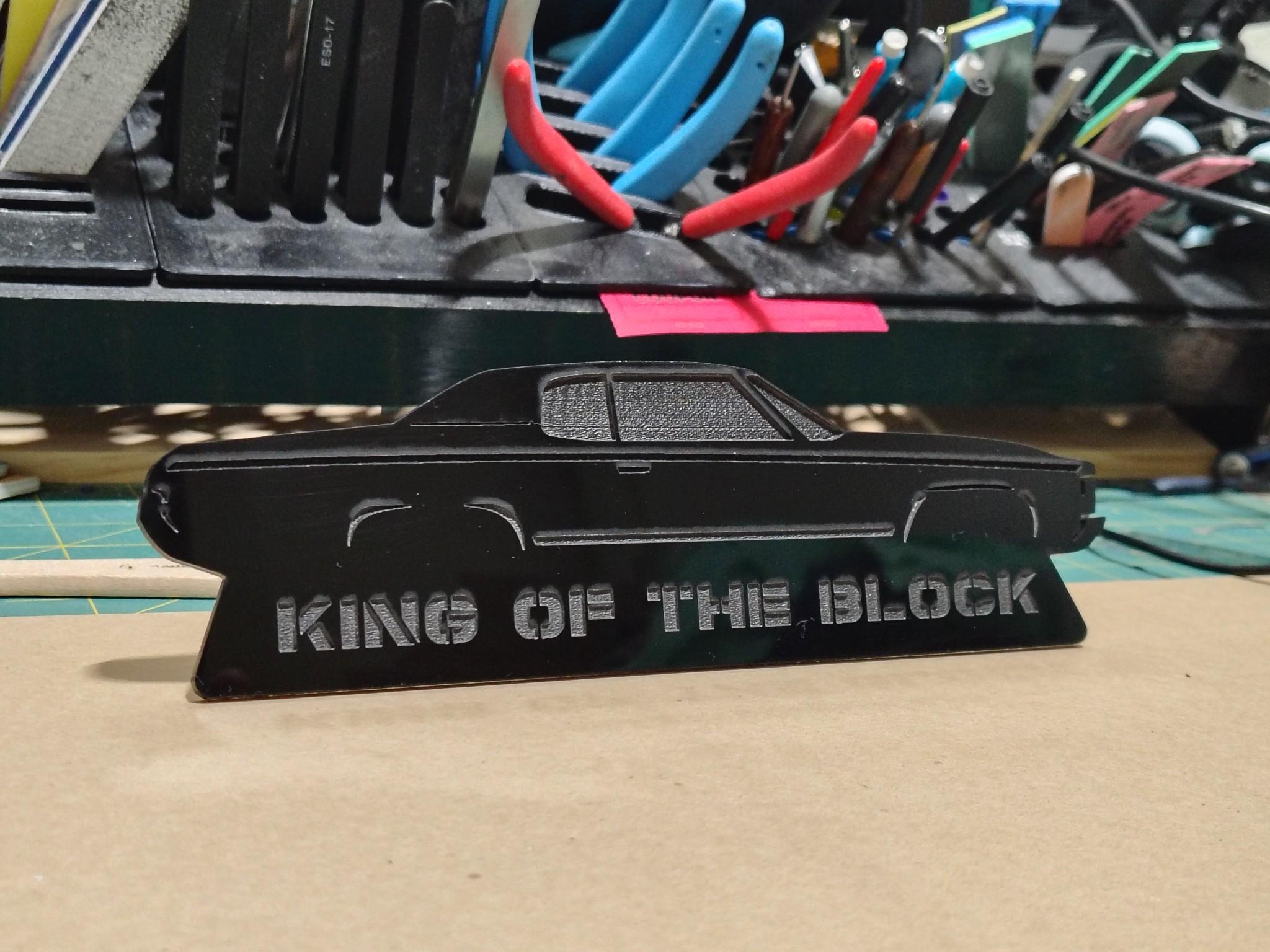

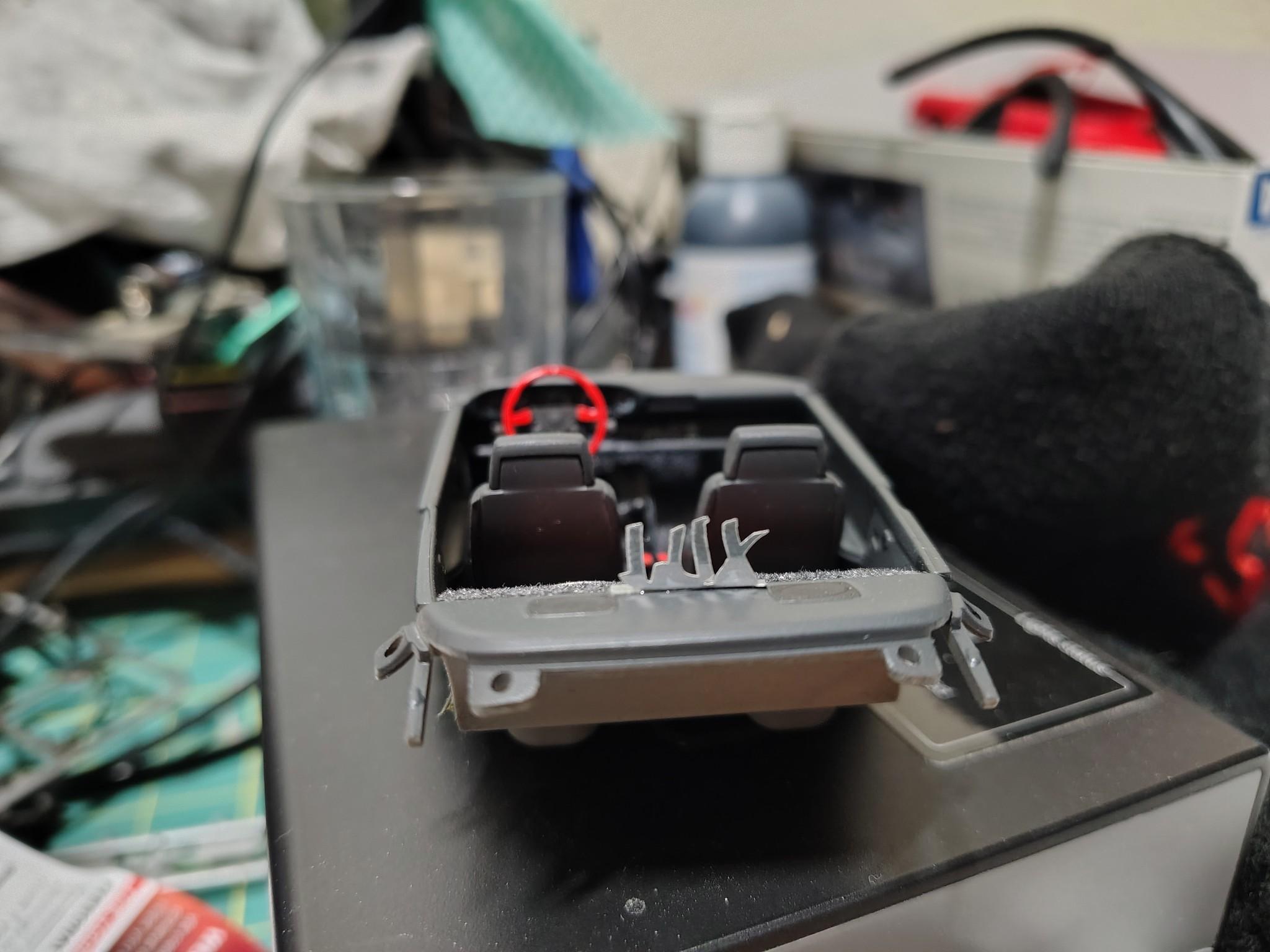

Not my best build but had the most interesting time building it. Originally for a 80s build off I lost the motivation because I just wasnt feeling the 16" wheel size and I knew 17 wasn't gonna be any better so I dropped off the build off and tried to salvage the build. Switched the wheels from 16" to 18" one offs, by then I had my laser dialed down so I made custom subwoofer covers to match the wheels theme, it was still missing something so I cut my own lowrider plaque. The kit itself? Build it really slow it's finicky with the glass at the end.

- 8 replies

-

- 11

-

.jpg.b52f92c47c700b39e0889ae38cf5923f.jpg)